High temperature oxidation resistance of plasma sprayed NiCrAl+(ZrO2+Y2O3) gradated coating on stainless steel surface

CHEN Fei(陈 飞)1, 2, ZHOU Hai(周 海)1, L? Tao(吕 涛)1

1. College of Mechanical Engineering, Beijing Institute of Petrochemical Technology, Beijing 102617, China;

2. School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China

Received 15 July 2007; accepted 10 September 2007

Abstract:

The plasma sprayed gradated coating with the bottom layer of NiCrAl and the top layer of (ZrO2+Y2O3) was prepared by the plasma spraying technique. The phase structure and morphology of the gradated coating were analyzed by means of X-ray diffractometry (XRD) and scanning electron microscopy (SEM). The high temperature oxidation resistance of the plasma sprayed samples at 800 ℃ was investigated. The oxidation kinetics curve was obtained. The results show that the thickness of gradated coating is about 410 μm. The plasma sprayed gradated coating on stainless steel surface can improve the high temperature oxidation resistance of stainless steel. The oxidation rate of stainless steel is less than that of plasma sprayed gradated coating. The oxidation film of plasma sprayed sample is very dense and is not easily exfoliated. The dense oxidation film prevents the stainless steel from more oxidation.

Key words:

plasma spraying; stainless steel; NiCrAl+ (ZrO2+Y2O3) coating; high temperature oxidation resistance;

1 Introduction

The ustenitic stainless steel was developed to overcome the poor corrosion resistance of martensitic stainless steel and large brittleness of ferritic stainless steel, and its representative alloy is 18-8 stainless steel. The steels of this series have better corrosion resistance, plasticity, processability, welding property and low temperature property than martensitic and ferritic stainless steels, and no magnetism, so they are widely applied and take up about 70% of total stainless steels. However, under complicated working environment, merely its own performance is still not enough to meet various requirements, while spray coating is just a convenient route to obtain better application performance[1-5].

Research on Thermal Barrier Coatings (TBCs) was initiated by American NASA Lewis Research Center at the beginning of the 1950s. By the middle of the 1970s, the emergence of double-layer coating system made its application become realizable. The outer ZrO2 layer of double-layer TBCs mainly plays a thermal insulating role; while the function of the intermediate NiCrAl alloy layer mainly is to prevent high temperature oxidation and corrosion of the substrate, and increase the bonding force between the intermediate layer and the substrate[6-9]. A gradated coating composed of top (ZrO2+Y2O3) layer and bottom NiCrAl layer was sprayed on the surface of 18-8 stainless steel by the means of plasma spraying, and subjected to high temperature oxidation test at 800 ℃ to give oxidation kinetic curve.

2 Experimental2.1 Experimental materials

A 1Cr18Ni9Ti stainless steel bar was cut into sample of 10 mm×10 mm×1 mm with wire cutting machine, polished by abrasive paper for degreasing and derusting, treated by sand blasting to reach certain roughness, sequentially cleaned by ultrasonic cleaner and acetone, dried by blowing, fixed on a rotary working bench, and rotated at speed of 180 r/min and distance from a spray gun of 110 mm.

NiCrAl alloy powders were added into a powder feeder, a plasma spray coater was started, proper amount of argon and hydrogen were charged, and current of power supply increased from 450 A to 530 A to generate plasma jet. NiCrAl alloy powders were melted at the opening of the spray gun, sprayed out from the opening in colloidal state, and sprayed on the sample surface to form coating gradually. The simultaneously charged argon and hydrogen mainly serve as protective atmosphere to reduce oxidation to the full extent during coating formation, and guarantee coating density.

Spray coating procedure of (ZrO2+Y2O3) layer was the same as that of NiCrAl alloy layer, but the distance between the sample and the spray gun was 65 mm.

2.2 Checking methods

Microhardness of the gradated coating was measured with HTV-1 microhardness tester. Cross-sectional morphology of the gradated coating was observed with Hitachi S-4700 SEM. Phase structure of the gradated coating was analyzed with Rigaku D/MAX-RC automatic diffractometer adopting Cu Kα radiation source at energy of 15.0 keV.

2.3 High temperature oxidation test

To simulate application environment of stainless steel workpiece, in compliance with the standard YB48-64 issued by the Ministry of Metallurgical Industry, the sample was weighed with electric balance (precision of 0.1 mg), placed in a ceramic crucible, put on a nichrome wire rack, and subjected to cyclic oxidation for 60 h in relative static air at 800 ℃ in a SX-1200 box-type resistance furnace. To guarantee the precision of test data, the ceramic crucible was burnt at 900 ℃ to remove water and impurities, and cooled in a desiccator; the nichrome wire rack was degreased with ethanol, dried in 200 ℃ oven to remove moisture, and cooled in a desiccator; and the sample was cleaned with ethanol, dried, and cooled in a desiccator. After certain time of oxidation, the sample rack was taken out immediately, covered with dried crucible cover, cooled to room temperature in a desciccator, and weighed. In order to study the rule of oxidation, 75 h of oxidation was performed. The oxidation sample included original stainless steel sample and spray-coated stainless steel sample.

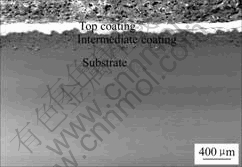

3 Results and analysis3.1 Cross-sectional morphology of gradated coating

Fig.1 shows the cross-sectional SEM micrograph of sample after plasma spray coating. It shows that the entire coating is composed of an outer (ZrO2+Y2O3) thermal barrier coating (top coating) and an intermediate NiCrAl coating (bottom layer). Thickness of the white top layer is 160 mm, and thickness of the intermediate coating is 250 mm. A ragged interface exists between the NiCrAl layer and (ZrO2+Y2O3) layer. Because the certain roughness on the surface of the intermediate layer forms by sand blasting before spraying of the outer coating, good bonding between the intermediate layer and the outer layer can be guaranteed. While the interface between the NiCrAl coating and the substrate is straight and has certain width[10, 11]. The thermal barrier coating is in strip shape, which is one of the basic characteristics of plasma sprayed coating. Many netlike micro-crack zones exist in the bottom layer, and the formation of the micro-cracks is relevant to the volumetric shrinkage of molten particles and cooling process of coating.

Fig.1 Cross-sectional SEM micrograph of coating

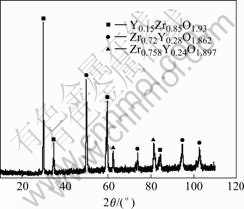

3.2 Phase composition of the graduated coating

Fig.2 shows XRD pattern of the plasma spray-coated sample after oxidation at 800 ℃. The surface phase composition of the plasma sprayed gradated coating after high temperature oxidation mainly comprises Y0.15Zr0.85O1.99 phase, Zr0.72Y0.28O1.862 phase, and Zr0.758Y0.24O1.897 phase.

Fig.2 XRD patterns of coating after high temperature oxidation

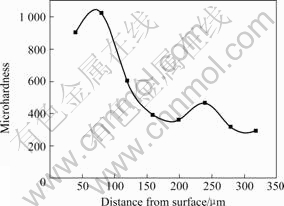

3.3 Microhardness of gradated coating

Fig.3 shows the microhardness distribution curves on different distances from the gradated coating cross section to the surface. The surface microhardness(HV) of the gradated coating reaches 1 000, which is over 3 times more than that of the substrate(280). This indicates the hardness of the stainless steel surface increases obviously after the plasma spray. This also shows that the microhardness value doesn’t drop abruptly against the increase of the distance, but decreases gradually.

Fig.3 Microhardness distribution of coating

3.4 High temperature oxidation resistance of graduated coating

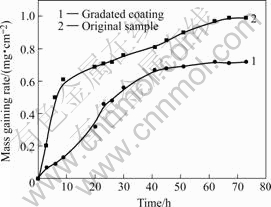

Fig.4 shows the oxidation kinetics curves of the gradated coating and original sample at 800 ℃. After high temperature oxidation has started, mass gaining speed of the untreated original sample is very fast, and reaches 0.6 mg/cm2 after oxidation at 800 ℃ for 10 h; keeps on increasing with oxidation time, finally reaches 0.97 mg/cm2 after oxidation for 75 h, and maintains a rising trend. While for the spray-coated sample, in comparison with the untreated original sample, mass gaining speed is obviously slowed down. After oxidation for 75 h, gaining speed of the gradated coating is only 0.63 mg/cm2, and basically keeps unchanged during the period of 50-75 h. This indicates that high temperature oxidation resistance of the spray-coated sample is substantially improved. At earlier stage of the oxidation, the gradated coating is relative loose, and easy for oxygen molecules to enter. However, after certain time of oxidation, a uniform and dense oxidation film is formed on the surface of the coated sample to prevent it from being further oxidized.

From Fig.4, it can be found that the oxidation kinetics curves of coated sample and original sample both approximately fit parabolic rule, that is, accord with the equation: (Δw/S)2=Kpt+C. Where Δw/S represents mass gain per unit area; Kp represents parabolic oxidation rate constant (mg2/(cm4?h)); and t represents oxidation time. Oxidation rate constants of the original sample and coated sample at 800 ℃ calculated according to the equation are 0.013 1 and 0.006 7 mg2/(cm4?h), respectively. It can be seen that Kp of the coated sample is smaller than that of the original sample by one order. Oxidation rate can be characterized with Kp, and smaller Kp represents slower mass gain and stronger oxidation resistance.

Fig.4 Oxidation kinetics curves of gradated coating and original sample at 800 ℃

References

[1] LUTHRA K L, BRAINT C L. Mechanism of adhesion of alumina on MCrAlY alloys[J]. Oxid Met, 1986, 26: 397-403.

[2] CHEN Bing-yi. Thermal barrier coatings of speed development[J]. Engineering of Aviation Manufacture, 1994, (6): 25-26.(in Chinese)

[3] HU Chuan-shun, WANG Fu-hui. Review of progress in thermal barrier coatings[J]. Corrosion Science and Protection Technology, 2000, 12(3): 160-163.(in Chinese)

[4] EVANS A G, HUTCHISON J W. On the mechanics of delamination and spalling in compressed films[J]. Int J Solids Structures, 1993, 74(2): 1321-1326.

[5] MENDELSON M L. Graded thermal barrier coatings: Evaluation[J]. Ceramic Enginerring and Science Processing, 1994, 15(14): 555-562.

[6] BRINDLY W J, MILLER R A. Thermal barrier coating lige and thermal oxidation of low plasma-sprayed bond coat alloys[J]. Sur Coat Technol, 1990, 43: 446-457.

[7] LELAIT L, ALPERIEN S, MEVREL R. Alumina scale growth at zirconia-McrAlY interface: A microstructural study[J]. J Mater Sci, 1992, 27: 5-12.

[8] MARTIN F, CHRISTER P. Influence of particle in-flight characteristics on the microstructure of atmospheric plasma sprayed yttria stablized ZrO2[J]. Sur Coat Technol, 2001, 4: 115-127.

[9] KHOR K A, Dong Z L. Plasma sprayed functionally graded thermal barrier coatings[J]. Materials Letters, 1999, 38(6): 437-444.

[10] KAWASAKI A, WATANABE R. Thermal fracture behavior of metal/ceramic functionally graded materials[J]. Engineering Fracture Mechanics, 2002, 69: 1713-1728.

[11] WANG Ning, LU Chun-yan. Effect of NiCrAlY coatings on oxidation resistance of Ni-base superalloy K17[J]. Corrosion Science and Protection Technology, 2002, 14(1): 7-11.(in Chinese)

Foundation item: Project(20061D0500500151) supported by Beijing Excellent Talent Nurture and Sponsor program; Project supported by Academic Human Resources Development in Institutions of Higher Learning under the Jurisdiction of Beijing Municipality

Corresponding author: CHEN Fei; Tel: +86-010-81292141; E-mail: chenfei@bipt.edu.cn