J. Cent. South Univ. (2012) 19: 477-481

DOI: 10.1007/s11771-012-1028-z![]()

Safety diagnosis on coal mine production system based on fuzzy logic inference

WANG Shuang-ying(王爽英)1, 2, ZUO Hong-yan(左红艳)1

1. School of Resource and Safety Engineering, Central South University, Changsha 410083, China;

2. Business School, Hunan Normal University, Changsha 410081, China

? Central South University Press and Springer-Verlag Berlin Heidelberg 2012

Abstract:

According to the randomness and uncertainty of information in the safety diagnosis of coal mine production system (CMPS), a novel safety diagnosis method was proposed by applying fuzzy logic inference method, which consists of safety diagnosis fuzzifier, defuzzifier, fuzzy rules base and inference engine. Through the safety diagnosis on coal mine roadway rail transportation system, the result shows that the unsafe probability is about 0.5 influenced by no speed reduction and over quick turnout on roadway, which is the most possible reason leading to the accident of roadway rail transportation system.

Key words:

coal mine production system; safety diagnosis; fuzzy logic inference;

1 Introduction

Due to the extreme complexity of operation units and spatial distribution in the coal mine operation system (CMPS), there exists gas and coal dust explosion, water burst, mine fire, roof accident, gas prominent, mechanical and electrical accidents as well as other hazards and risks [1-3], which is of a three-dimensional distribution in space and dynamic development at the time. An accident in CMPS is dynamic, stochastic and fuzzy correlated with different hazards in time and space [4-5]. Therefore, the CMPS safety is influenced by the geological condition, mining control, man-machine environment and other factors [6-7]. It is urgent to implement effective safety diagnosis and evaluation of CMPS.

According to the characteristics of CMPS, generally, the safety evaluation method includes process safety review, safety checklist analysis, fault tree analysis (FTA) and Bayesian network (BN) method [8-9].

Fault tree analysis can deal with the safety indicators of CMPS effectively. However, because of the rigorous assumption, FTA cannot handle the related issues between different nodes, and results in complex computation, which limits its promotion and application. Bayesian network method is dependent on the relationship of local conditions to execute a two-way uncertain reasoning, which can be applied to prediction, classification, causal analysis and diagnostic analysis [10-11]. But BN method needs to know the exact distribution probability of the samples, which in fact cannot be given exactly.

In recent years, fuzzy logic inference (FLI) is a prevalent approximating reasoning method based on fuzzy knowledge (fuzzy rules) in the field of artificial intelligence [10-11], which is able to handle human language information and knowledge naturally. Fuzzy logic inference, aiming at the imprecise and incomplete information, can deal with the security exceptions caused by uncertain factors in complex system [12-13]. In this work, FLI is applied to the safety diagnosis of CMPS, combined with the safety management analysis and other experimental results.

2 Overall plan of FLI on CMPS

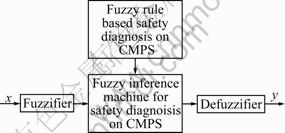

For the CMPS, FLI system is the basic premise of safety diagnosis on CMPS. Safety diagnosis based on FLI was established by fuzzy concept, fuzzy logic and was able to handle fuzzy information, whose general structure is shown in Fig. 1.

In the above system, assume that the input signal x is the point of domain U and the output signal y is the point of domain V; x and y are determined by non-fuzzy information. Object of diagnosis is fuzzy information, so the signal x needs to transform into a fuzzy set of the domain U by a fuzzifier. And the final output of diagnosis should be a clear information. It is necessary to transform the fuzzy set of U into the determinated y of the domain V.

Fig. 1 General structure of safety diagnosis on CMPS based on FLI

In fact, the system is a nonlinear mapping from the domain U to V. Based on appropriate choice of membership function, fuzzification and defuzzification algorithms, and fuzzy reasoning algorithms, safety diagnosis on CMPS based on FLI can approximate to a given nonlinear function in any precision level. Its uniqueness can make full and effective use of language and knowledge information.

Fuzzy rule base is the core of safety diagnosis on CMPS based on FLI. The basic format of fuzzy rule base of the safety diagnosis is “IF … THEN”. Web form of fuzzy rules in safety diagnose on CMPS can be described in Fig. 2. For one of rules of all the M rules in fuzzy diagnosis rule base, named R(k), according to the connection way in Fig. 2, a complete fuzzy rule network on safety diagnostic can be further provided. As shown in Fig. 2, {x1, …, xn} are n running realities, {F1, …, Fm} are m independent safety abnormities, and they have been transformed into a fuzzy value. Parameter wk,i (i=1, …, n) is the weight, standing for the importance of the running reality xi to this rule R(k). Parameter Cj,k (j=1, …, m) is also the weight coefficient, reflecting the importance of this rule R(k) to the various safety abnormity Fj. The ranges of weights wk,i and Cj,k are

![]() (1)

(1)

![]() (2)

(2)

Fig. 2 Fuzzy rules network of safety diagnosis on CMPS

In the fuzzy diagnostic rule base, a safety abnormity Fj may also be associated with several rules, and one running reality xi may also be the fuzzy condition of several rules at the same time. The complexity between running realities and safety abnormity is shown in a complete specific networks formed by a great number of rules.

After the fuzzy rule base is established, safety diagnosis system on FLI can be built by adopting the method of fuzzy inference. Fuzzy inference in safety diagnosis is to match the relevant rules in fuzzy rule base according to the current running realities in CMPS, and give corresponding safety abnormity. Its output is represented by the credibility of the various safety abnormity. Therefore, the steps of safety diagnosis on CMPS based on FLI can usually be divided into following steps.

Step 1: According to the running reality xi (i=1, …, n), the activation degree Ak of each rule R(k) can be calculated, based on weight coefficient wk,i (i=1, …, n) of R(k).

Step 2: Calculate the credibility degree Tj (j=1, …, m) of the each safety abnormity Fj in the current reality. Tj is determined by the activation degree of relevant rules Ak and the weight coefficient Cj,k (j=1, …, m) of the rule R(k). If a safety abnormity Fj is supported by only one rule, then the credibility of the safety abnormity is Tj=Cj,kAk. If it is supported by several rules, then the credibility will be synthesized by the credibility of all the supporting rules. This synthesis can be achieved by a fuzzy operator, such as fuzzy mean operator and sub-mixed joint operator.

3 Safety diagnosis methods of CMPS based on FLI

3.1 Design of fuzzifier

Take single value subordinate function, Gaussian membership function and a triangular membership function as a part of fuzzifier of safety diagnosis on CMPS to establish single value fuzzifier, Gaussian fuzzifier and the triangular fuzzifier, respectively. For any membership function type with “IF…THEN” rule, the single value subordinate function can greatly simplify the calculation of fuzzy inference. For instance, if the fuzzy “IF…THEN” rule is a Gaussian membership function or a triangular membership function, Gaussian fuzzifier or triangular fuzzifier can also simplify the calculation of fuzzy inference and furthermore, overcome the noise of input variables.

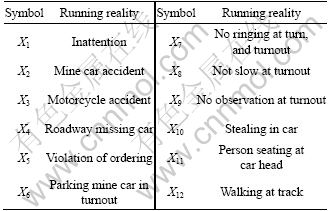

According to the running realities of CMPS listed in Table 1, input fuzzy adopted a type of continuous input fuzzification sets.

Table 1 Running realities of CMPS

3.2 Design of defuzzifier

Defuzzifier has the function of making the output signal defuzzification, transforming the fuzzy variable into a precise value, that is, the specific accident cause. For example, take ![]() as the considered fuzzy set of the domain V,

as the considered fuzzy set of the domain V, ![]() as the precise value and DF as the defuzzification operator, then the process of defuzzification of defuzzifier can be expressed as

as the precise value and DF as the defuzzification operator, then the process of defuzzification of defuzzifier can be expressed as

![]() (3)

(3)

So, DF should meet the following properties:

1) when y∈(-∞, a), if μB(y)=0, then DF(μB(y))≥a;

2) when y∈(-∞, a], if μB(y)=0, then DF(μB(y))>a;

3) when y∈(a, ∞), if μB(y)=0, then DF(μB(y))≤a;

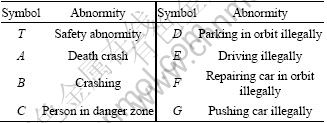

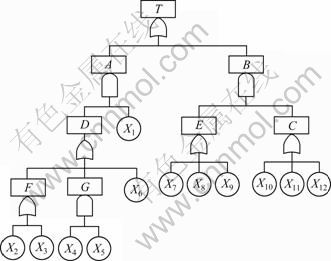

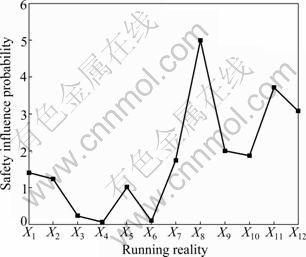

4) when y∈[a, ∞), if μB(y)=0, then DF(μB(y)) According to the running realities of CMPS, execute the defuzzification of the safety diagnosis output, as listed in Table 2. Table 2 Abnormity of CMPS Select membership function composed of two S-shaped function: f{x, [a1, b1; a2, b2]}=1/{1+exp[-a1(x- b1)]}/{1+exp[-a2(x-b2)]}, then determine the membership function of the output fuzzy variables. For example, in the membership function of illegal driving F5, under the condition of “not possible A” and “likely B”, a1 and a2 both are 5.5; while b1 is -0.5 or 0.5, and b2 is 0.5 or 1.5. Similarly, other output variable membership functions can also be determined through the above method. 3.3 Design of fuzzy rule During the safety diagnosis on CMPS multiple input and multiple output, if fuzzy rule set does not exist a rule with the same “IF” part, partially has difference from “THEN” part, the set is often treated as consistency. This consistency is important, because if there is a conflict rule (that is inconsistence), it is hard to match. The acquisition of fuzzy rule is essential for establishing the safety diagnosis system. Generally, the fuzzy rules are gradually obtained by the knowledge and experience from experts or through self-learning fuzzy logic system. The latter needs to determine the size of fuzzy rule base, fuzzy set A and the membership function form of 3.4 Fuzzy inference machine The function of fuzzy inference machine is to do the logic reasoning through reasoning algorithm and output the final result according to the original data and relative conditions of fuzzy rule base. On the basis of computation rules of fuzzy logic, inference machine transforms the fuzzy rule, like “IF … THEN” of the mapping relationship, that is, from the fuzzy set of U1 × … × Un to V. In other words, the relative fuzzy output variable y is produced by the received fuzzy input x=(x1, …, xn) and fuzzy rules. Its core is the fuzzy condition inference method. The basic forms of fuzzy condition inference include generally affirmative reasoning (fuzzy inference of affirming antecedent) and generally negative reasoning (fuzzy inference of denying the latter). For M rules of the fuzzy rule base, given a fuzzy input x=(x1, …, xn), then there are corresponding results yk (k=1, …, m) by each rule of fuzzy inference. Fuzzy inference machine can take m where “ In the safety diagnosis system on CMPS based on FLI, the combined methods of general affirmative reasoning and the general negative reasoning were adopted. 4 Safety diagnosis examples Coal mine roadway rail transportation system is an important part of coal mine production. Accident analysis shows that fatalities in roadway rail transportation account for more than 60% of the total transportation accidents and 55% people died. Thus, the safety of the roadway rail transportation is crucial to the operation of the coal transport system. 4.1 System implementaion As shown in Fig. 3, the safety abnormity tree of CMPS mainly considers two main abnormities, crash and death crash leading to roadway transportation accidents. According to Fig. 3, by learning of coal mine accident statistics and consulting the experts, the membership value of running reality can be calculated, as listed in Table 3, which can be as the membership value of the safety diagnosis on CMPS based on FLI. Fig. 3 Safety fault tree for roadway rail transport system of coal mine Table 3 Membership values of running realities of CMPS According to the membership value of running realities X1-X12 in coal mine roadway rail transportation system, by the safety diagnosis on CMPS based on FLI, probability of safety abnormity is DF(T)=0.000 559 89. However, by Bayesian networks, the obtained prior probability of ceiling events is DF(T)=0.000 5607 7. By fault tree analysis, DF(T)=0.000 5681 5. From the above results, the result by FLI is consistent with the principle that the minimum cut set is a little larger than the actual value [14]. 4.2 Analysis of safety influencing factors If there happens a safety accident in a coal mine roadway rail transportation, the fuzzy inference machine of safety diagnosis on CMPS can be used to obtain the possibility distribution that running realities affect on roadway rail transportation security and find out the most influential running realities to call for the special attention. Assume that the reliability of roadway rail transportation accidents is DF(T)=0.90, and then make use of the fuzzy inference machine of safety diagnosis on CMPS to obtain the possibility distribution that running realities X1-X12 affect on roadway rail transportation security, as shown in Fig. 4. It can be seen that the safety influential possibility of coal mine roadway rail transportation can be taken as the credibility of safety incidents in the roadway rail transportation. The possibility that the running reality X8 causes accident in coal mine roadway rail transportation system is about 0.5. However, the possibility that the running reality X4 causes accident in coal mine roadway rail transportation system is 0.005. Obviously, the running reality X8 is the most possible influencing factor leading to a roadway rail transportation accident. Consequently, reducing the membership value of running reality X8 can reduce the possibility of accident. Except for X8, running realities X11 and X12 are two factors which can cause risk and wounding events. The possibilities of X7, X9 and X10 are in the range from 0.18 to 0.20 which also need to be lowered. Fig.4 Safety influence probability distribution of coal mine roadway rail transportation system 4.3 Comparison analysis For the comparison of diagnosis of FLI, Bayesian network methods and fault tree analysis [15], the range of credibility of roadway transport accidents DF(T) from 0.4 to 1.0 was set, and 150 values chosen from them randomly to backward-inference of the credibility distrubution data by the methods of FLI and Bayesian network method were taken and simulated. Therefore, fault tree analysis (I) refers to the simulation whose data come from the backward-inference of FLI, and fault tree analysis (II) means the simulation whose data come from the backward-inference of Bayesian network. All the three methods set two-thirds of the credibility distrubution data as the training set, and the remaining as the testing set. The results are listed in Table 4. Table 4 Comparison result of safety diagnosis methods Simulation data show that fault-judging rate of FLI is the lowest, followed by Bayesian network, and the fault tree analysis method is the highest. For the fault tree analysis, the fault-judging rate of fault tree analysis (I) is smaller than that of fault tree analysis (II), where the credibility distrubution data from these two methods are different and the credibility distrubution data based on FLI are more accurate. 5 Conclusions 1) Analysis of safety factors in coal mine roadway rail transportation system shows that the possibility of running reality X8 (over quick turnout on the roadway) is about 0.5, which is the most possible factor to cause roadway rail transport accidents, followed by X11 and X12. In addition, the possibilities of X7, X9 and X10 are in the range from 0.18 to 0.20. 2) Three safety diagnosis methods show that fault- judging rate of FLI is the lowest, followed by Bayesian network method, and the fault tree analysis method is the highest. The credibility distrubution data based on FLI are more accurate. References [1] LIU Wen-sheng, ZENG Feng-zhang. Application of Bayesian networks in safety assessment of CMPS [J]. Industry and Mine Automation, 2008(1): 1-4. (in Chinese) [2] LAURENCE D. Safety rules and regulations on mine sites-The problem and a solution [J]. Journal of Safety Research, 2005, 36(1): 39-50. [3] WANG Shuang-ying, WU Chao. Construction and level analysis of enterprise’s safety capability system [J]. Journal of Safety Science and Technology, 2009, 5(3): 181-184. [4] SETH A G. Causal attributions of Ghanaian industrial workers for accident occurrence: miners and non-miners perspective [J]. Journal of Safety Research, 2003, 34(5): 533-538. [5] TONG Lei, DING Ri-jia. Efficiency assessment of coal mine safety input by data envelopment analysis [J]. Journal of China University of Mining and Technology, 2008, 18(1): 88-92. (in Chinese) [6] HEBBLE W B. Mine safety–through appropriate combination of technology and management practice [J]. Procedia Earth and Proadwaytary Science, 2009, 11(1): 13-19. [7] HOU Yun-bing, PAN Ren-fei, WU Ji-yan, WANG Bao-ping. Coal mine safety evaluation based on the reliability of expert decision [J]. Procedia Earth and Planetary Science, 2009, 12(1): 661-667. [8] DORNER S, JIE S, SWAYNE D. multi-objective modeling and decision support using a bayesian network approximation to a non-point source pollution model [J]. Environmental Modeling and Software, 2007, 22(2): 211-222. [9] SIGURDSSON J H, WALLS L A, QUIGLEY J L. Bayesian belief nets for managing expert judgement and modeling reliability [J]. Quality and Reliability Engineering International, 2001, 17(3): 181- 190. [10] CARVALHO M T, DURAO F. Control of a flotation column using fuzzy logic inference [J]. Fuzzy Sets and Systems, 2002, 125(1): 121-133 [11] WU Jian-Da, WANG Yu-Hsuan. Development of an expert system for fault diagnosis in scooter engine platform using fuzzy-logic inference [J]. Expert Systems with Applications, 2007, 33(4): 1063-1075. [12] WU Jian-Da. Fault gear identification using vibration signal with discrete wavelet transform technique and fuzzy–logic inference [J]. Expert Systems with Applications, 2009, 36(2): 3785-3794. [13] ELSEBAKHY E A. Data mining in forecasting PVT correlations of crude oil systems based on Type1 fuzzy logic inference systems [J]. Computers & Geosciences, 2009, 35(9): 1817-1826. [14] WU Chao, MENG Ting-rang. Engineering basic of mine safety system [M]. Changsha: Central South University Press, 1992: 54-56. (in Chinese) [15] E Jia-qiang. Intelligent fault diagnosis and its application [M]. Changsha: Hunan University Press, 2006: 10-23. (in Chinese) (Edited by DENG Lü-xiang) Foundation item: Project(2006BAK04B0302) supported by the National Science and Technology Pillar Program during the 11th Five-year Plan of China Received date: 2011-04-12; Accepted date: 2011-11-28 Corresponding author: WANG Shuang-ying, PhD Candidate; Tel: +86-18907315129; E-mail: hnwangshy@126.com

![]() estimate the parameters in membership function, and then, complete the process of learning and base construction.

estimate the parameters in membership function, and then, complete the process of learning and base construction.![]() as the output at the same time, or deal with the result

as the output at the same time, or deal with the result ![]() further to produce a final result as

further to produce a final result as![]() (4)

(4)![]() ” refers to a certain fuzzy operator.

” refers to a certain fuzzy operator.

Abstract: According to the randomness and uncertainty of information in the safety diagnosis of coal mine production system (CMPS), a novel safety diagnosis method was proposed by applying fuzzy logic inference method, which consists of safety diagnosis fuzzifier, defuzzifier, fuzzy rules base and inference engine. Through the safety diagnosis on coal mine roadway rail transportation system, the result shows that the unsafe probability is about 0.5 influenced by no speed reduction and over quick turnout on roadway, which is the most possible reason leading to the accident of roadway rail transportation system.