![]()

Trans. Nonferrous Met. Soc. China 22(2012) 1947-1953

Long-period stacking ordered structures in Mg-3Cu-1Mn-2Zn-1Y damping alloy

HUANG Xue-fei1, ZHANG Wen-zheng1, WANG Jing-feng2, WEI Wen-wen2

1. Laboratory of Advanced Materials, Department of Materials Science and Engineering, Tsinghua University, Beijing 100084, China;

2. College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China

Received 9 September 2011; accepted 17 December 2011

Abstract:

14H, 18R and 24R long-period stacking ordered (LPSO) structures were observed in the as-cast Mg-3Cu-1Mn-2Zn-1Y damping alloy using transmission electron microscopy (TEM). These LPSO structures contained Mg, Y, Cu and Zn and thus they were quaternary phases. Sharp diffraction pattern of the 24R structure was obtained and the angle between ![]() and g10024R was measured to be 5.03°. During high resolution TEM observations, lattice fringes with two characteristic spacings were observed within the 24R structure. Based on the experimental results, 6H, 7H and three 8H are suggested as the building blocks of 18R, 14H and 24R structures, respectively. The 24R unit cell can be interpreted as the stacking of 8H building blocks in the same shear direction with a shear angle of about 5.03°. The imperfect 24R structures are in order or disorder arrangements of principal 8H and minor 6H blocks. This double-block structure model is also applicable to other reported defects in LPSO structures.

and g10024R was measured to be 5.03°. During high resolution TEM observations, lattice fringes with two characteristic spacings were observed within the 24R structure. Based on the experimental results, 6H, 7H and three 8H are suggested as the building blocks of 18R, 14H and 24R structures, respectively. The 24R unit cell can be interpreted as the stacking of 8H building blocks in the same shear direction with a shear angle of about 5.03°. The imperfect 24R structures are in order or disorder arrangements of principal 8H and minor 6H blocks. This double-block structure model is also applicable to other reported defects in LPSO structures.

Key words:

magnesium alloys; long-period stacking ordered structure; TEM; building block;

1 Introduction

Long-period stacking ordered (LPSO) structures have received considerable attentions recently due to their significant strengthening effect in the Mg alloys [1-3]. LPSO Mg97Y2Zn1 alloy with a yield strength of 610 MPa and elongation of 5% at room temperature has been developed using rapidly solidified powder metallurgy process [1]. The prominent strengthening behavior has been considered to be derived from both the refinement of Mg grains and the presence of LPSO structure [2]. It has also been reported that the critical resolved shear stress of the basal plane increases due to the formation of the LPSO structure and the non-basal slip is activated by preventing the basal slip, indicating that the LPSO structure is beneficial to both the strength and ductility of the Mg alloy [4-6]. Therefore, one potential approach to strengthen and toughen Mg alloys is to promote the LPSO structure through the addition of proper elements.

The X-Mg12ZnY phase in the Mg-Zn-Y-Zr alloy was first characterized by LUO et al [7,8] as a 18R LPSO structure. KAWAMURA et al [9] further noted that high-strength Mg-RE-Zn (RE=rare earth metals) ternary alloys usually contain LPSO structures. These alloys have a typical RE/Zn atomic ratio of 2 [9]. In addition, LPSO structures have also been observed in the Mg97Y2Cu1 [10] and Mg90.5Ni3.25Y6.25 [11] ternary alloys. In Mg-Y-Zn alloys, a series of LPSO structures have been reported, including 18R,14H, 24R and 10H [12]. Among these LPSO structures, the frequently observed 18R and 14H structures have been studied in more detail. The unit cell of the 18R structure has three ABCA-type building blocks arranged in the same shear direction with a shear angle of 6.75°, while the 14H unit cell has two ABCA-type building blocks arranged in opposite shear directions [3]. These LPSO structures contain Mg, Zn and Y, and hence they are ternary phases [3]. However, most high resolution transmission electron microscopy (HRTEM) images of the LPSO structure are obtained at the scale of several or dozens of (0002)Mg atom layers [2,3,5]. So far, most study is focused on the stacking order of the closely-packed planes within the unit cells of the LPSO structures. Arrangements of the LPSO building blocks at a greater scale have not been reported.

In this study, the LPSO structures found in a novel damping Mg-3Cu-1Mn-2Zn-1Y alloy were reported, where Zn and Y were added as modified elements to optimize the damping capacity of the alloy [13]. The LPSO structures are different from those previously reported that they are unstable upon annealing at elevated temperatures. The RE/Cu (and Zn) atomic ratio of this alloy is smaller than 1, which is also different from that in Mg-RE-Zn (Cu or Ni) systems. Most important, based on the experimental observations, different periods often coexist in the 24R structure. A structure model for the LPSO structures in terms of building blocks was proposed, which is also applicable to other reported LPSO structures. The LPSO structures found in this system are useful to guide the design of composition and process for the control of LPSO structure.

2 Experimental

The nominal compositions of the base and modified alloys were Mg-3Cu-1Mn and Mg-3Cu-1Mn-2Zn-1Y (mass fraction, %) respectively. The alloy was obtained by induction melting pure Zn, pure Mg, high purity Mg-30%Cu, Mg-4.1%Mn and Mg-30.3%Y (mass fraction) master alloys in a mild steel crucible under argon at 850 ℃. Cubic samples for annealing were cut from the cast ingot, and encapsulated in a glass tube filled with argon, then annealed at 450 ℃ for 48 h, followed by water quenching. Thin foil specimens for TEM observations were prepared by twin-jet electropolishing in a solution containing 3 mL perchloric acid and 297 mL ethanol at -50 ℃. Characterizations of the microstructure and phase analysis were performed in a JSM6301 scanning electron microscope (SEM), JEOL 200CX, JEM-2011 and TecnaiG2 F20 transmission electron microscope (TEM) equipped with energy dispersive spectrometer (EDS).

3 Results and discussion

3.1 SEM microstructure of as-cast base and modified alloys

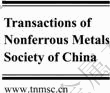

Figures 1(a) and (b) show the SEM micrographs of the as-cast microstructures in the modified Mg-3Cu- 1Mn-2Zn-Y alloy. It is seen in Fig. 1(a) that the secondary phases exhibit a discontinuous skeleton morphology along the grain boundaries. The contrast in the skeleton is not even, and it contains local lamellar-like morphology, probably from the eutectic reaction. A higher magnification using backscattered electron (BSE-SEM) imaging (Fig. 1(b)) indicates that two kinds of secondary phases arrange along the grain boundaries. One exhibits bright contrast (called bright phase hereafter) and the other exhibits grey contrast (called grey phase hereafter) which arranges alternately with the bright phase at the lamellar-like areas. Both the bright and grey phases are brighter than the Mg solid solution (α-Mg) matrix, indicating that heavier elements are contained in these two phases. In contrast, in the Mg-3Cu-1Mn base alloy (Fig. 1(c)), a typical eutectic structure containing alternating bright phase and α-Mg forms along grain boundaries. The bright phase in this alloy should be Mg2Cu as previously reported [13-15]. By comparing Figs. 1(b) and (c), it can be seen that the addition of Zn and Y changes the microstructure significantly. According to the TEM results, the grey phase is LPSO structure (Fig. 2(b)) and the bright phase is Mg2Cu compound (Fig. 2(a)).

Fig. 1 SEM image of secondary electron image of as-cast Mg-3Cu-1Mn-2Zn-1Y alloy (a), backscattered electron (BSE) image of as-cast Mg-3Cu-1Mn-2Zn-1Y alloy (b), BSE image of as-cast base Mg-3Cu-1Mn alloy (c) and BSE image of annealed Mg-3Cu-1Mn-2Zn-1Y alloy at 450 ℃ for 48 h (d)

In order to examine the thermal stability of the LPSO structure in Mg-3Cu-1Mn-2Zn-1Y alloy, a sample from the cast alloy was annealed at 450 ℃ for 48 h. The microstructure of the annealed sample is shown in Fig. 1(d). It appears that only one kind of the secondary phase, i.e. blocky bright Mg2Cu compound, exists both along grain boundaries and within grains. No grey phase corresponding to the LPSO structure is found. It can thus be concluded that the LPSO structures are unstable upon annealing at 450 ℃.

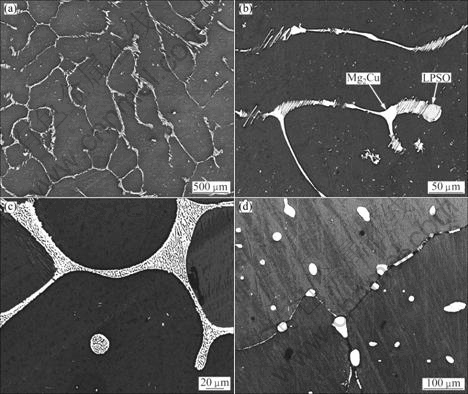

3.2 14H LPSO structure in Mg-Cu-Mn-Zn-Y alloy

A TEM bright-field image recorded from lamellar-like area is shown in Fig. 2(a). Similarly, two phases with different contrast are present at the grain boundary. The major phase exhibits a dark contrast in the skeleton along a grain boundary. By comparing the TEM and SEM observations, this phase must correspond to the bright phase in Fig. 1(b). This major phase is identified as Mg2Cu by the selected area electron diffraction (SAED) pattern in Fig. 2(c), which is along [001]Mg2Cu zone axis. The remaining regions of the skeleton must correspond to the grey phase in Fig. 1(b) which contains fine lamellar structures. The EDS analysis indicates that Mg, Y, Cu and Zn are contained in these fine-lamellar regions, suggesting that they are quaternary phases. A typical EDS spectrum of the lamellar areas is shown in Fig. 2(b). Figure 2(d) gives a SAED pattern from the fine-lamellar structure. Thirteen additional uniform spots are readily observed between the transmission spot and (0002)α spot in the ![]() zone axis, which is a typical pattern of 14H LPSO structure in the Mg-RE-Zn systems [2,3,16].

zone axis, which is a typical pattern of 14H LPSO structure in the Mg-RE-Zn systems [2,3,16].

Fig. 2 TEM image of intermetallics along grain boundary showing LPSO structures arranged with Mg2Cu (a), typical EDS spectrum recorded from lamellar areas (b), SAED pattern corresponding to [001] zone axis of Mg2Cu (c), SAED pattern recorded from fine lamellar area in Fig. 2(a) (d)

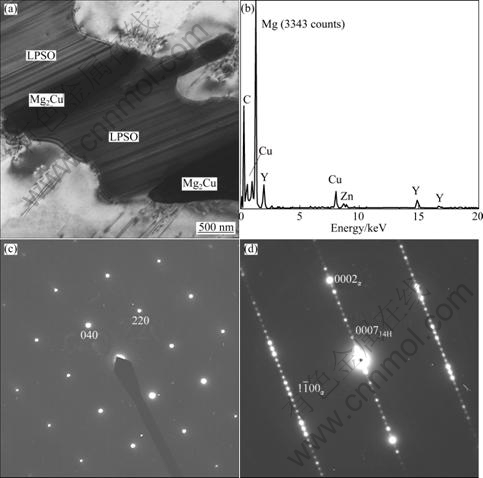

Though Mg2Cu usually alternates with 14H structure in the eutectic structure, α-Mg is also occasionally observed to partially replace the 14H structure, leading to a contact of 14H structure with α-Mg at (0001)α plane, as shown in Fig. 3(a). The SAED patterns of the regions marked by A and B in Fig. 3(a) are shown in Figs. 3(b) and (c), respectively. They are both close to ![]() zone axis. Note that a few additional spots in Fig. 3(c) appear in contrast to the standard

zone axis. Note that a few additional spots in Fig. 3(c) appear in contrast to the standard ![]() pattern, but are not as dense and regular as those in Fig. 2(d) or Fig. 3(b). The additional spots indicate that a locally ordered structure probably exists within area B. The more magnified areas A and B are shown in Figs. 3(e) and (f), respectively. Uniformly distributed lattice fringes are observed from region A. The spacing of the lattice fringe is approximately 1.8 nm, corresponding consistently to the 7(0002)α, which agrees with the 14H structure in Mg-Y-Zn alloys [3,17] . In region B, isolated bands consisting of one or a couple of layers exhibiting a spacing of 1.8 nm are also observed. These bands are similar to the P2 plates in Mg-Y-Ag- Zn alloy, which are also identified as the 14H phase [17].

pattern, but are not as dense and regular as those in Fig. 2(d) or Fig. 3(b). The additional spots indicate that a locally ordered structure probably exists within area B. The more magnified areas A and B are shown in Figs. 3(e) and (f), respectively. Uniformly distributed lattice fringes are observed from region A. The spacing of the lattice fringe is approximately 1.8 nm, corresponding consistently to the 7(0002)α, which agrees with the 14H structure in Mg-Y-Zn alloys [3,17] . In region B, isolated bands consisting of one or a couple of layers exhibiting a spacing of 1.8 nm are also observed. These bands are similar to the P2 plates in Mg-Y-Ag- Zn alloy, which are also identified as the 14H phase [17].

Fig. 3 TEM images of 14H LPSO structure: (a) Bright-field image of 14H structure arranged with α-Mg in eutectic structure; (b) SAED patterns recorded from regions marked by A in Fig. 3(a); (c) SAED patterns recorded from regions marked by B in Fig. 3(a) (d) magnification of region A in Fig. 3(a); (e) Magnification of region B in Fig. 3(a)

3.3 18R LPSO structure in Mg-Cu-Mn-Zn-Y alloy

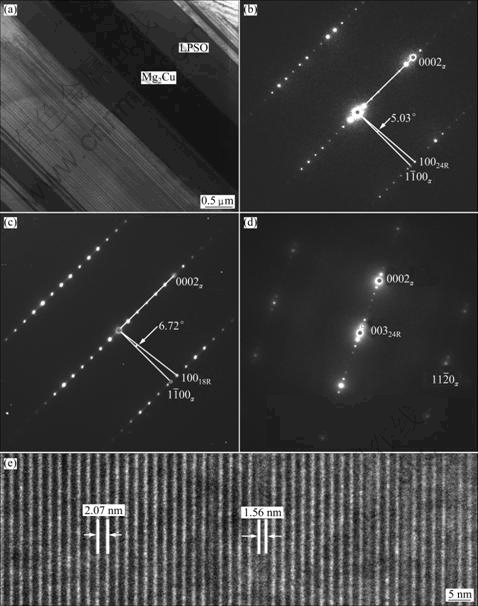

In addition to the frequently observed 14H LPSO structure, the 18R LPSO structure is also occasionally observed in the grain boundaries of the as-cast Mg-3Cu-1Mn-2Zn-1Y alloy. These 18R structures also arrange alternately with Mg2Cu at the grain boundaries, as shown in Fig. 4(a). In the diffraction pattern (DP) from the 18R structures (Fig. 4(b)), extra spots located at positions are defined 1/6(0002)Mg, 2/6(0002)Mg, 3/6(0002)Mg, 4/6(0002)Mg and 5/6(0002)Mg along the ![]() zone axis. The measured angle between

zone axis. The measured angle between ![]() and g10018R is 6.72°, which is consistent with the shear angle of 6.75° between each building block of 18R unit cell proposed by ZHU et al [3].

and g10018R is 6.72°, which is consistent with the shear angle of 6.75° between each building block of 18R unit cell proposed by ZHU et al [3].

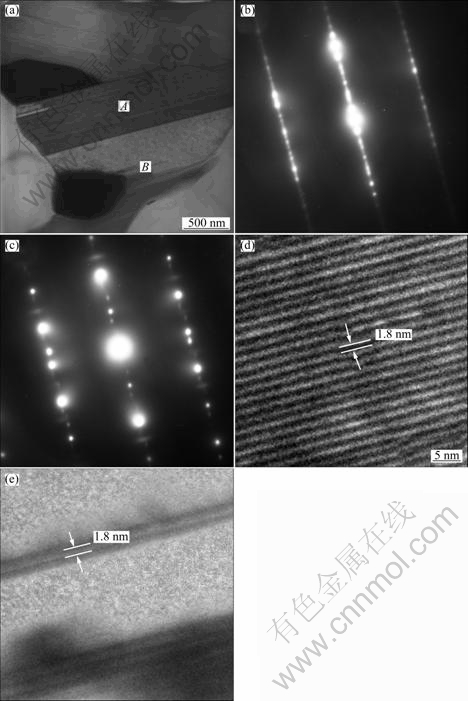

3.4 Defects in 24R LPSO structure and its building blocks

According to the DP, some regions within the lamellar areas in Fig. 4(a) corresponding to the 24R structure are also observed. As seen in Fig. 4(c), extra spots are readily observed at positions of 1/8(0002)α, 2/8(0002)α, 3/8(0002)α, 4/8(0002)α, 5/8(0002)α, 6/8(0002)α and 7/8(0002)α along the ![]() zone axis which is similar to the 24R structure found in the Mg-Y-Zn alloy [12]. SAED pattern along

zone axis which is similar to the 24R structure found in the Mg-Y-Zn alloy [12]. SAED pattern along ![]() zone axis (Fig. 4(d)) further confirms the additional diffraction spots. The angle measured between

zone axis (Fig. 4(d)) further confirms the additional diffraction spots. The angle measured between ![]() and g10024R is 5.03°. Following the structure model of the 18R structure in the Mg-Y-Zn alloy [3], the angle deviation probably results from the shear between building blocks of the 24R unit cell with the same shear direction. Careful measurements of lattice fringes image from 24R structure in Fig. 4(e) indicate that most fringes have a spacing of 2.07 nm, which corresponds to the 8d(0002)Mg, though the other spacing of 1.56 nm corresponding to 6d(0002)Mg is also occasionally observed, where d is the interplanar spacing.

and g10024R is 5.03°. Following the structure model of the 18R structure in the Mg-Y-Zn alloy [3], the angle deviation probably results from the shear between building blocks of the 24R unit cell with the same shear direction. Careful measurements of lattice fringes image from 24R structure in Fig. 4(e) indicate that most fringes have a spacing of 2.07 nm, which corresponds to the 8d(0002)Mg, though the other spacing of 1.56 nm corresponding to 6d(0002)Mg is also occasionally observed, where d is the interplanar spacing.

Fig. 4 TEM image of 24R and 18R LPSO structures (a), SAED pattern of ![]() zone axis of 18R structure (b), SAED pattern of

zone axis of 18R structure (b), SAED pattern of ![]() zone axis of 24R structure (c), SAED pattern of

zone axis of 24R structure (c), SAED pattern of ![]() zone axis of 24R structure (d), Enlargement of 24R structure (e)

zone axis of 24R structure (d), Enlargement of 24R structure (e)

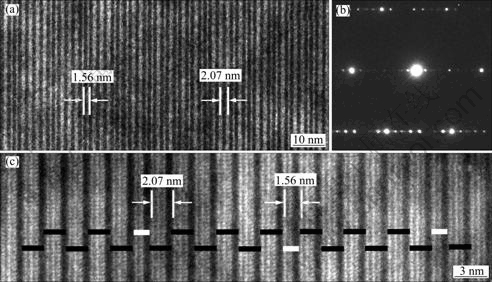

In contrast to the sharp and uniform additional spots between the g0000α and g0002α from perfect 24R DPs as previously described, irregular arrangement or faint of some diffraction spots with respect to the 24R DPs are also observed in Fig. 4(b). It should be noted that the irregularly distributed spots also exist in the previously reported 24R structure [12]. HRTEM lattice fringe imaging indicates that this area contains a considerable number of 1.56 nm-spaced fringes (Fig. 4(a)), which are mixed with the 2.07 nm-spaced-fringes without long- range regularity. However, a locally ordered structure, i.e., one 1.56 nm-spaced fringe followed by six 2.07 nm- spaced fringes to form the periodic structure is readily observed in part of the regions. This mixture of two different fringes can be understood in terms of different arrangements of two characteristic building blocks. One is the building block of the 18R unit cell containing an ordered arrangement of 6 layers of closely-packed planes, and the other is the building block of the 24R unit cell containing an ordered arrangement of 8 layers of closely-packed planes. These building blocks can be called 6H and 8H, respectively. Similarly, the building block of 14H unit cell is 7H. Using an atom-resolution HADDF-STEM in Mg-Y-Zn alloys, ZHU et al [3,18] reported the structures of both 14H and 18R in terms of building blocks defined by particular stacking orders, such as ABCA and ACBA, with several close packed planes in between. [3,18]. These building blocks can also be specified as 7H and 6H for the 14H and 18R, respectively. Therefore, an ideal LPSO structure contains only one kind of building block with a specific shear between blocks. The shear is reflected by a shear angle in diffraction pattern, e.g. 5.03° for 24R and 6.75° for 18R. As a result, the fringes in the HRTEM image of a perfect LPSO structure are even and the spacings between fringes are the same, as shown in Figs. 3(d) and 4(e). The lattice-fringe spacing, which is the characteristic of the building block, is different for different LPSO structures. Coexistence of lattice fringes with different spacing indicates the building blocks, rather than the unit cell of the LPSO structure, can be mixed and arranged individually in a LPSO structure. Accordingly, a LPSO structure usually contains the principal building blocks, together with minor building blocks which may be viewed as defects. In the present study, it can be seen that the imperfect 24R structure contains the principal 8H and minor 6H building blocks (Fig. 5(a)). They can arrange in an ordered or disordered manner. The ordered stacking of these two building blocks in Fig. 5(c) can be described as 6H-8H-8H-8H-8H-8H-8H-6H-8H-8H-8H-8H-8H-8H- 6H…. This double-block model is also applicable to other reported LPSO structures. For example, the LPSO shown in Fig. 2(c) in Ref. [18] can be described as a mixture of 7H (principal) and 6H (minor), in the following order 7H-7H-7H-7H-7H-7H-6H-6H-7H-7H…. Diffusion or irregularity in the DPs of LPSO structures can be frequently seen in Refs. [2,12,19], indicating possible existence of mixed building blocks.

Fig. 5 HRTEM image showing locally ordered structure in 24R LPSO structure (a), SAED pattern of area in Fig. 5(a) (b), HRTEM lattice fringes image of portion of areas showing two characteristic periods arranged in locally ordered manner (Black and white bold lines correspond to 8H and 6H building blocks, respectively) (c)

4 Conclusions

1) 14H, 18R and 24R LPSO structures are observed in Mg-3Cu-1Mn-2Zn-1Y damping alloy. These LPSO structures alternate with Mg2Cu as constituents of the eutectic structure along the grain boundaries. They are unstable upon annealing at 450 ℃.

2) In addition to the diffraction pattern of 14H and 18R structure, sharp diffraction pattern of the 24R structure is obtained and the angle between ![]() and g10024R is measured to be 5.03°. 6H, 7H and 8H are suggested as the building blocks of the unit cells of 18R, 14H and 24R structures, respectively.

and g10024R is measured to be 5.03°. 6H, 7H and 8H are suggested as the building blocks of the unit cells of 18R, 14H and 24R structures, respectively.

3) The 24R unit cell can be interpreted as a stacking of 8H building blocks in the same shear direction, with a shear angle of about 5.03°. The imperfect 24R structure has a mixed arrangement of the principal 8H and minor 6H building blocks. If they align with a short-range order, a locally modulated 6H-8H structure is formed. This double-block model is also applicable to other reported LPSO structures.

References

[1] KAWAMURA Y, HAYASHI K, INOUE A, MASUMOTO T. Rapidly solidified powder metallurgy Mg97Zn1Y2 alloys with excellent tensile yield strength above 600 MPa [J]. Mater Trans, 2001, 42: 1172-1176.

[2] ITOI T, SEIMIYA T, KAWAMURA Y, HIROHASHI M. Long period stacking structures observed in Mg97Zn1Y2 alloy [J]. Scripta Mater, 2004, 51: 107-111.

[3] ZHU Y M, MORTON A J, NIE J F. The 18R and 14H long-period stacking ordered structures in Mg-Y-Zn alloys [J]. Acta Mater, 2010, 58: 2936-2947.

[4] MATSUDA M, ANDO S, NISHIDA M. Dislocation structure in rapidly solidified Mg97Zn1Y2 alloy with long period stacking order phase [J]. Mater Trans, 2005, 46: 361-364.

[5] LUO Z, ZHANG S. High-resolution electron microscopy on the X-Mg12ZnY phase in a high strength Mg-Zn-Zr-Y magnesium alloy [J]. J Mater Sci Lett, 2000, 19: 813-815.

[6] SHAO X H, YANG Z Q, MA X L. Strengthening and toughening mechanisms in Mg-Zn-Y alloy with a long period stacking ordered structure [J]. Acta Mater, 2010, 58: 4760-4771.

[7] LUO Z P, SONG D Y, ZHANG S Q. Strengthening effects of rare earths on wrought Mg-Zn-Zr-RE alloys [J]. J Alloy Compd, 1995, 230: 109-114.

[8] LUO Z P, ZHANG S Q, TANG Y L, ZHAO D S. Microstructures of Mg-Zn-Zr-Re alloys with high Re and low Zn contents [J]. J Alloy Compd, 1994, 209: 275-278.

[9] KAWAMURA Y, KASAHARA T, IZUMI S, YAMASAKI M. Elevated temperature Mg97Y2Cu1 alloy with long period ordered structure [J]. Scripta Mater, 2006, 55: 453-456.

[10] YAMASAKI M, ANAN T, YOSHIMOTO S, KAWAMURA Y. Mechanical properties of warm-extruded Mg-Zn-Gd alloy with coherent 14H long periodic stacking bordered structure precipitate [J]. Scripta Mater, 2005, 53: 799-803.

[11] ITOI T, TAKAHASHI K, MORIYAMA H, HIROHASHI M. A high-strength Mg-Ni-Y alloy sheet with a long-period ordered phase prepared by hot-rolling [J]. Scripta Mater, 2008, 59: 1155-1158.

[12] MATSUDA M, II S, KAWAMURA Y, IKUHARA Y, NISHIDA M. Variation of long-period stacking order structures in rapidly solidified Mg97Zn1Y2 alloy [J]. Mater Sci Eng A, 2005, 393: 269-274.

[13] WANG Jing-feng, WEI Wen-wen, LI Long, LIANG Hao, PAN Fu-sheng. Effects of Y and Zn on mechanical properties and damping capacity of Mg-Cu-Mn alloy [J]. Transctions of Nonferrous Metals Society of China, 2010, 20(10): 1846-1850.

[14] NISHIYAMA K, MATSUI R, IKEDA Y, NIWA S, SAKAGUCHI T. Damping properties of a sintered Mg-Cu-Mn alloy [J]. J Alloy Compd, 2003, 355: 22-25.

[15] ZHANG Zhen-yan, PENG Li-ming, ZENG Xiao-qin, DING Wen-jiang. Effects of Cu and Mn on mechanical properties and damping capacity of Mg-Cu-Mn alloy [J]. Transctions of Nonferrous Metals Society of China, 2008, 18: s55-s58.

[16] MATSUDA M, II S, KAWAMURA Y, IKUHARA Y, NISHIDA M. Interaction between long period stacking order phase and deformation twin in rapidly solidified Mg97Zn1Y2 alloy [J]. Mater Sci Eng A, 2004, 386: 447-452.

[17] ZHU Y M, MORTON A J, NIE J F. Characterisation of intermetallic phases in an Mg-Y-Ag-Zn casting alloy [J]. Phil Mag Lett, 2010, 90: 173-181.

[18] ZHU Y M, WEYLAND M, MORTON A J, OH-ISHI K, HONO K, NIE J F. The building block of long-period structures in Mg-RE-Zn alloys [J]. Scripta Mater, 2009, 60: 980-983.

[19] ABE E, KAWAMURA Y, HAYASHI K, INOUE A. Long-period ordered structure in a high-strength nanocrystalline Mg-1at% Zn- 2at% Y alloy studied by atomic-resolution Z-contrast STEM [J]. Acta Mater, 2002, 50: 3845-3857.

Mg-3Cu-1Mn-2Zn-1Y阻尼合金中的长周期结构

黄雪飞1,张文征1,王敬丰2,魏文文2

1. 清华大学 材料科学与工程系,先进材料教育部重点实验室,北京 100084;

2. 重庆大学 材料科学与工程学院,重庆 400044

摘 要:通过透射电子显微镜对铸态Mg-3Cu-1Mn-2Zn-1Y阻尼合金进行表征,观察到14H、18R 和24R三种类型的长周期结构。这些长周期结构含有Mg、Y、Zn 和Cu的四元相。获得了24R结构的明锐衍射斑点,并测得衍射斑中![]() 与 g10024R的夹角为5.03°。高分辨晶格条纹显示,24R结构中经常包含两种类型的特征条纹间距。基于实验结果提出,将 6H、 7H 和8H 分别作为 18R、14H 和 24R 长周期结构的结构单元。24R结构的单胞可以认为是由三个8H 单元沿相同的方向切变5.03°堆垛而成的,具有缺陷的24R结构主要是由8H单元和少量的6H单元通过有序或者无序的方式堆垛而成的。这种双单元结构模型也可以解释之前观察到的长周期结构中的缺陷。

与 g10024R的夹角为5.03°。高分辨晶格条纹显示,24R结构中经常包含两种类型的特征条纹间距。基于实验结果提出,将 6H、 7H 和8H 分别作为 18R、14H 和 24R 长周期结构的结构单元。24R结构的单胞可以认为是由三个8H 单元沿相同的方向切变5.03°堆垛而成的,具有缺陷的24R结构主要是由8H单元和少量的6H单元通过有序或者无序的方式堆垛而成的。这种双单元结构模型也可以解释之前观察到的长周期结构中的缺陷。

关键词:镁合金;长周期结构;透射电镜;堆垛单元

(Edited by FANG Jing-hua)

Foundation item: Project (2009CB623704) supported by the National Basic Research Program of China; Project (50971076) supported by the National Natural Science Foundation of China

Corresponding author: ZHANG Wen-zheng; Tel: +86-10-62773795; Fax: +86-10-62771160; E-mail: zhangwz@tsinghua.edu.cn

DOI: 10.1016/S1003-6326(11)61412-X

Abstract: 14H, 18R and 24R long-period stacking ordered (LPSO) structures were observed in the as-cast Mg-3Cu-1Mn-2Zn-1Y damping alloy using transmission electron microscopy (TEM). These LPSO structures contained Mg, Y, Cu and Zn and thus they were quaternary phases. Sharp diffraction pattern of the 24R structure was obtained and the angle between ![]() and g10024R was measured to be 5.03°. During high resolution TEM observations, lattice fringes with two characteristic spacings were observed within the 24R structure. Based on the experimental results, 6H, 7H and three 8H are suggested as the building blocks of 18R, 14H and 24R structures, respectively. The 24R unit cell can be interpreted as the stacking of 8H building blocks in the same shear direction with a shear angle of about 5.03°. The imperfect 24R structures are in order or disorder arrangements of principal 8H and minor 6H blocks. This double-block structure model is also applicable to other reported defects in LPSO structures.

and g10024R was measured to be 5.03°. During high resolution TEM observations, lattice fringes with two characteristic spacings were observed within the 24R structure. Based on the experimental results, 6H, 7H and three 8H are suggested as the building blocks of 18R, 14H and 24R structures, respectively. The 24R unit cell can be interpreted as the stacking of 8H building blocks in the same shear direction with a shear angle of about 5.03°. The imperfect 24R structures are in order or disorder arrangements of principal 8H and minor 6H blocks. This double-block structure model is also applicable to other reported defects in LPSO structures.