DOI: 10.11817/j.ysxb.1004.0609.2020-39504

Ni中间层超声辅助瞬间液相扩散连接镁合金机制

李一楠1,杨乘飞1,闫久春2,彭子龙1

(1. 青岛理工大学 机械与汽车工程学院,青岛 266520;

2. 哈尔滨工业大学 先进焊接及连接国家重点实验室,哈尔滨 150001)

摘 要:

为了研究超声作用时间对镁合金连接接头显微组织与力学性能的影响,以纯镍中间层对MB8镁合金进行超声辅助瞬间液相扩散焊(U-TLP)。结果表明:在520 ℃时超声作用10 s即可去除母材表面氧化膜。随着超声作用时间的延长,Ni箔与母材Mg发生共晶反应,并逐渐被消耗,α-Mg+Mg2Ni共晶产物开始先增多,而后在超声头压力和声流作用下被逐渐挤出。超声作用30 s时,由于易使接头变脆的Mg2Ni被挤出,钎缝主要以α-Mg(Ni)为主,此时接头剪切强度达到最大(107 MPa),达到母材强度的102%,断裂位置为钎缝中反应生成的α-Mg固溶体区域。

关键词:

文章编号:1004-0609(2020)-05-1065-08 中图分类号:TG456.9 文献标志码:A

镁合金因其具有高的比强度、比刚度、减震性、导热性、可切削加工性和可回收性而被广泛应用于现代制造业[1],一些特定的结构不可避免涉及镁合金的连接。目前,镁合金的连接方法主要有熔焊[2]、钎焊[3]、搅拌摩擦焊[4-5]和瞬间液相扩散焊(TLP)[6]。CHOWDHURY等[7]用激光焊连接AZ31B镁合金时发现有严重的焊接缺陷,如气孔、裂纹及表面凹陷等,MUNITZ等[8]利用钨极氩弧焊焊接了镁合金AZ91D,发现焊后形成了较宽的热影响区,且接头产生了较多的气孔和疏松缺陷。搅拌摩擦焊具有不会产生焊接缺陷等优势,但是不易焊接复杂的工件结构,TLP则存在焊接时间过长且要在真空或保护气氛的环境下完成的问题。

超声辅助瞬间液相扩散连接(U-TLP)是在传统TLP的基础上,通过超声的声流及空化效应破除金属表面的氧化膜[8-11],以实现在大气环境下的快速有效连接。近年来,U-TLP方法已被用于连接不同材料。许志武等[12]以Zn为中间层在超声的辅助下连接Mg合金,钎缝组织以MgZn和MgZn2为主,剪切强度为42 MPa。赖志伟等[13]将超声作用时间延长至120 s,钎缝以α-Mg(Zn)为主,剪切强度达到106.4 MPa。郭卫兵等[14]以Zn为中间层在超声的辅助下连接铝合金,接头在超声作用60 s时形成完全α(Al)固溶体连接。

本文采用镍箔为中间层在30 s内实现MB8镁合金的U-TLP高强度连接。Ni与Zn、Sn、Al等金属相比具有较好的抗氧化性和耐腐蚀性。超声的引入可以有效去除镁表面氧化膜、空化及声流效应可以加快原子之间溶解和扩散,加速共晶反应并且挤出反应生成的脆性金属间化合物,从而实现以镁基固溶体为主的钎缝,提升接头的力学性能。本研究首先通过观察不同的超声时间对钎缝微观组织形貌的影响,然后分析超声作用时间对焊接接头力学性能及断口形貌的影响,最后建立接头形成的物理模型。

1 实验

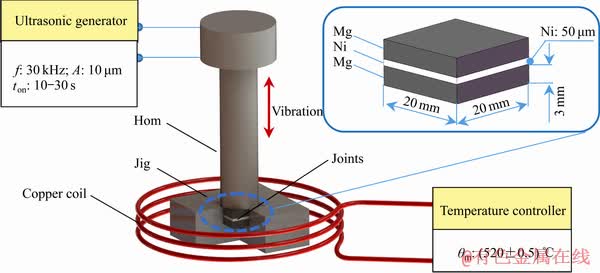

试验中所用的母材为MB8镁合金(Mn:1.3%~ 2.2%,Ce:0.15%~0.35%,Zn:0.3.%,Mg:余量;质量分数),尺寸为20 mm×20 mm×3 mm。试验中所用的钎料为50 μm的纯Ni箔,尺寸为20 mm×20 mm。试验前先使用400#、800#和1200#砂纸对母材进行打磨,然后将母材和镍箔分别在丙酮和酒精中超声清洗15 min。本试验U-TLP连接装置如图1所示。超声波发生器产生的超声频率为30 kHz,超声振幅为9~12 μm。焊件由中频感应系统加热,通过红外测温仪(MIK-AL-10)监测接头反应区温度。按Mg、Ni、Mg连接顺序将其置于固定夹具中。

试验在大气环境下进行,超声工具头施加在焊件顶部的压力为0.15 MPa。当加热温度达到520 ℃时,对试样分别施加10 s、15 s、20 s、25 s、27 s、30 s的超声作用时间,而后空冷完成焊接。采用MERLIN Compact热场发射扫描电子显微镜(SEM)观察显微组织形貌,用SEM自带的能谱仪(EDS)分析成分,采用硬度测试仪(FM-700)进行硬度测试,载荷为0.98 N,保持时间为10 s。使用拉伸机(WDW-50 kN)测试剪切强度,加载速度为0.2 mm/min,用X射线衍射仪(D/max 2200VPC)分析断口的物相组成。

2 结果与分析

2.1 Mg/Ni/Mg接头的微观组织

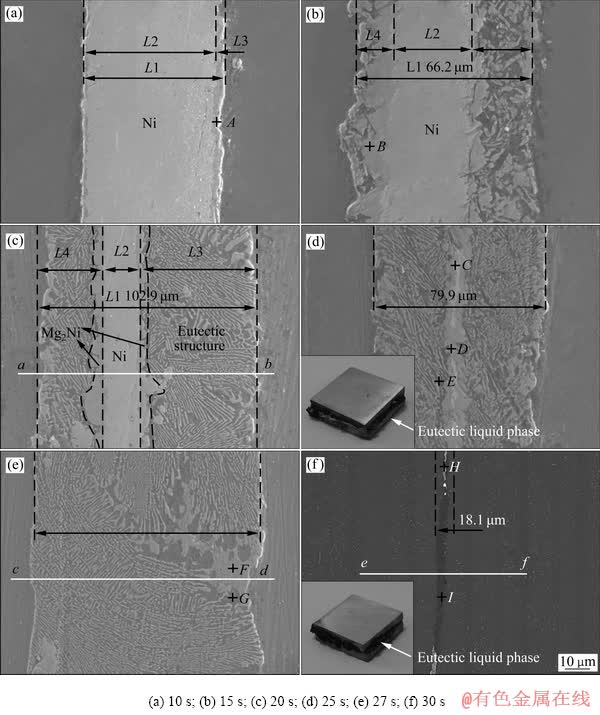

图2所示为520 ℃时不同超声作用时间的钎缝微观组织形貌。表1所列为钎缝中不同点的EDS分析结果。根据MCINTYRE等[15]的研究,镁合金母材在大气条件下放置10 s就会出现2 μm的氧化膜,进而阻止Mg、Ni之间的反应,然而从图2(a)可以看出,当超声作用10 s时,界面生成了一层连续的灰白色物质层(L3)。结合Mg-Ni二元合金相图和表1的元素组成及摩尔比可以推测出,图2(a)中A点为Mg2Ni。表明由于超声波的声塑性效应,母材Mg表面的氧化膜不能随着基体发生相同幅度变形[16-17],从而使氧化膜开裂继而使新鲜Mg、Ni元素接触互扩散和溶解,生成了Mg2Ni金属间化合物层,平均宽度为2.3 μm。此时,钎缝宽度为51.3 μm。超声作用15 s时(见图2(b)),可以观察到钎缝由大块灰白色物质(Mg2Ni)和黑色物质(α-Mg)组成,这是由于发生了共晶反应:

(1)

(1)

此时中间层Ni箔宽度降至37.8 μm,接头宽度为66.2 μm。超声作用20 s时,中间层Ni箔被大量溶解,宽度已减少至15.3 μm,接头宽度增加至102.9 μm。超声作用25 s时,中间层Ni箔几乎完全消失,接头宽度为79.9 μm,并在连接面产生黑色物质。当超声作用27 s时,接头已完全由共晶液相组成,此时接头宽度为110.0 μm。而后随着超声时间延长至30 s,接头反应区宽度急剧下降,此时接头主要由α-Mg(Ni)固溶体和少量共晶组织(Mg2Ni+α-Mg)组成,并且连接面处产生的黑色物质最多。说明在超声作用27 s到30 s的这段时间内,超声的声流效应和超声头压力的共同作用加速了共晶液相在接头界面处的挤出。图3所示为不同超声时间各个区域宽度变化示意图。如图3所示,钎缝宽度(L1)=Ni中间层(L2)+Ni中间层右侧区域(L3)+Ni中间层左侧区域(L4)。可以看出,L3区域宽度明显大于L4区域宽度,这是因为超声工具头施加在L3侧,由于声在固相与液相中存在衰减,所以L3区域内声场作用效果比L4区域的明显,L3区域内的原子扩散溶解速度比L4区域的快。

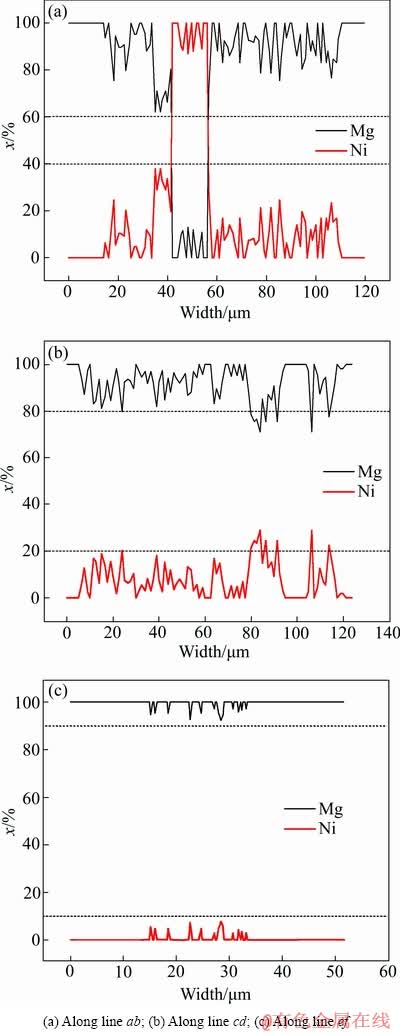

图4所示为分别对超声作用20 s、27 s和30 s的接头进行线扫描分析。可以看到,在超声作用20 s时,接头内Ni元素含量在20%~40%之间,分布宽度是102.9 μm;当超声作用27 s时,Ni元素含量则在20% 以下,分布宽度为110.0 μm;当超声作用30 s时,接头内Ni元素含量降低至10%以下,分布宽度也降至最小,为18.1 μm。结果表明,随着超声作用时间的增加,Ni箔与Mg不断发生扩散及共晶反应,其生成的Mg-Ni共晶液相在超声头压力和超声的声流作用下逐渐挤出直至完全消失,最后实现以α-Mg(Ni)固溶体为主的钎缝。

图1 U-TLP连接装置示意图

Fig. 1 Schematic diagram of U-TLP bonding process

图2 不同超声作用时间下接头微观组织形貌

Fig. 2 Microstructures of joints at different ultrasonic processing time

表1 图 2中不同点的化学成分

Table 1 Chemical composition at different points shown in Fig. 2

图3 图2所示钎缝中不同区域宽度变化

Fig. 3 Variation of width at different regions in joints shown in Fig. 2

图4 沿图2中ab、cd和ef线段的元素分布

Fig. 4 Distribution of elements across joint shown in Fig. 2

2.2 Mg/Ni/Mg接头的力学性能分析

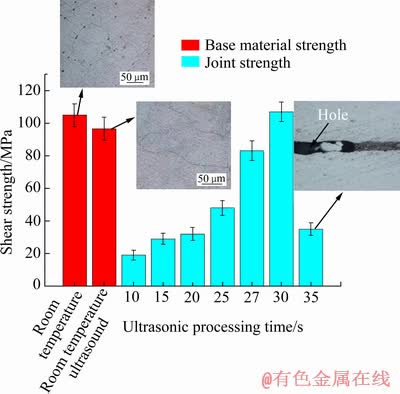

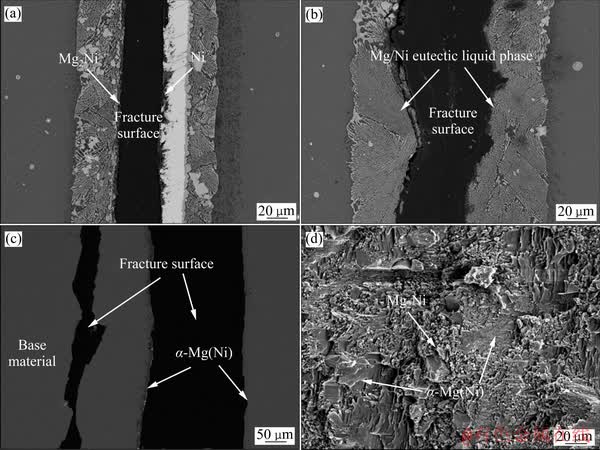

图5所示为母材分别在常温和在520 ℃超声作用30 s以及接头在不同超声作用时间对应的剪切强度。母材MB8镁合金为Mg-Mn系变形镁合金,常温下镁合金组织由细小的等轴晶构成,且晶粒大小比较均匀,平均晶粒尺寸约为70 μm。同时可观察到有细小的第二相粒子(MnAl2)出现在等轴晶粒的晶界上,母材在常温下的强度为105 MPa;在520 ℃超声作用30 s后,看到镁合金晶粒沿横向长大,横向平均长度为约为200 μm,呈现扁平状,说明在声场和热场复合作用下,母材发生了一定的软化发生了变形[18-20],此外第二相粒子明显减少,这是因为第二相粒子在高温及超声作用固溶到α-Mg基体中。此时,母材强度为96 MPa,强度仅下降8.6%,这是由于加热时间及超声作用时间较短,母材强度下降不明显,并不影响结构件的使用。从图5中还可以看出,接头随着超声作用时间的延长,剪切强度呈现先增强再降低的规律。当超声作用10 s时,接头强度为19 MPa,说明由于在界面上出现了Mg2Ni,实现了连接;当超声作用20 s时,剪切强度为32 MPa,断裂路径如图6(a)所示,接头断裂在Ni箔生成的Mg2Ni脆性金属间化合物层上,结合图7硬度结果:接头中Mg2Ni化合物的硬度最大,为142.0HV,表明连续分布的Mg2Ni是整个接头的最脆弱点。

图5 经超声处理后的母材及钎缝的剪切强度

Fig. 5 Shear strength of base materials and joints with the ultrasonic processing

图6 不同超声时间接头断裂路径及断口形貌

Fig. 6 Fracture path at ultrasonic processing time of 20 s(a), 27 s(b), 30 s(c) and fracture morphology of joint at ultrasonic processing time of 30 s(d)

当超声作用27 s时,Ni箔已完全溶解形成共晶液相,接头内亦不存在连续的Mg2Ni脆性金属间化合物层,此时接头强度为83 MPa,断裂路径如图6(b)所示,其断裂在Mg-Ni共晶液相中。结合图7硬度分析,共晶相硬度为130.2HV,比Mg2Ni脆性层有所下降,因此强度有所提升。

当超声作用30 s时,接头内以α-Mg(Ni)固溶体为主,强度达到最高为107 MPa,是常温条件下母材强度的102%和520 ℃超声30 s条件下母材强度的111%,高强度的原因是由于脆性金属间化合物Mg2Ni的挤出及α-Mg(Ni)固溶体的固溶强化作用。接头断裂路径如图6(c)所示,断裂裂纹有两条,主裂纹发生钎缝中反应生成的α-Mg固溶体区域,次裂纹发生在母材,这也表明钎缝强度接近母材的。结合图7硬度分析,α-Mg(Ni)固溶体和Mg基体的硬度相差不大,分别为56.4HV和53.4HV,α-Mg(Ni)固溶体硬度比共晶相低56.7%,相应强度提高28.9%。断口如图6(d)所示,断裂表面主要为平面断口(α-Mg)及少量的韧窝(Mg2Ni),可以判断接头断裂方式为脆性断裂或以脆性断裂主导。而JIN等[21]以Ni为中间层的真空TLP,其在515 ℃下保温60 min,其得到最高剪切强度仅为36 MPa。这是因为本研究中共晶液相在超声头压力和超声的声流效应的共同作用下被挤出,减少了脆性金属间化合物Mg2Ni的数量,接头以镁基固溶体为主,从而提高了强度。随着超声作用时间增加到35s,由于超声的声流效应,导致反应物过度挤出,从而引起气孔、液相填充不足等缺陷,从而导致接头的强度下降。

图7 钎缝内各个相的显微硬度

Fig. 7 Micro-hardness value of phases in joints

图8所示为超声作用20 s、30 s下的断口的XRD测试结果。在超声作用20 s时,断口主要由Ni、Mg2Ni组成,其中以Ni居多,说明Ni没有完全反应完且断裂位置在脆性金属间化合物层(Mg2Ni)上。在超声作用30 s时,断口主要由Mg,Mg2Ni组成,说明接头其中以α-Mg为主,少量共晶组织(α-Mg(Ni)+Mg2Ni)存在。

图8 超声作用20 s和30 s时钎缝断口的XRD谱

Fig. 8 XRD patterns of fracture at ultrasonic treatment time of 20 s and 30 s

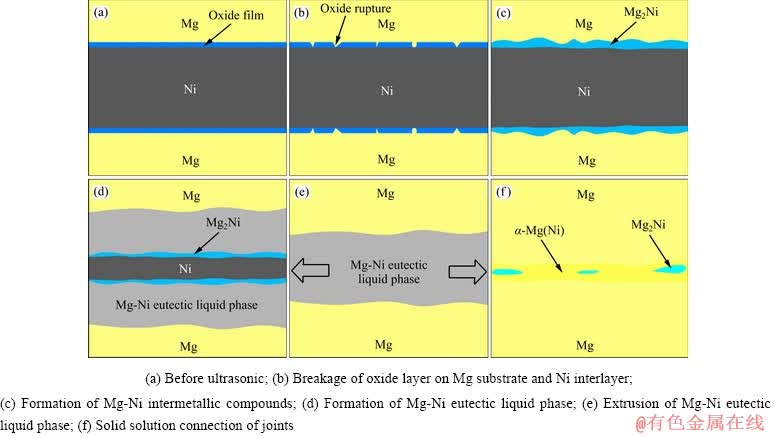

3 接头形成机制

图9所示为Mg/Ni/Mg接头形成物理模型。由于本试验是在大气环境下进行,母材Mg在加热过程中表面会生成氧化膜MgO(约2 μm)[15],从而阻止Mg、Ni元素的直接接触(见图9(a))。镁和镍的熔点分别为648.8 ℃和1453.0 ℃,在连接温度520 ℃下,母材和中间层都为固态。当超声在固态金属中传播时能产生一个额外的应力场并引起母材和中间层表面产生瞬时的软化,即超声波的声塑性效应[22-25]][。镁表面脆性的氧化膜不能够随着基体金属同时发生变形,从而使得氧化膜发生开裂(见图9(b))。由于没有氧化膜的阻隔,Mg和Ni元素直接接触发生扩散溶解反应,在中间层Ni箔表面生成一层厚度约为4.2 μm的金属间化合物层Mg2Ni(见图9(c))。随着超声时间的增加,中间层被大量溶解,产生Mg-Ni共晶液相,共晶液相的产生加速了Mg、Ni元素之间的互相扩散、反应,未被完全溶解的中间层Ni箔表面依然附着一层金属间化合物层Mg2Ni(见图9(d))。最后Ni中间层被完全消耗,Mg-Ni共晶液相在超声头压力和声流搅拌作用下被逐渐挤出,接头宽度变窄(见图9(e)),当超声作用30 s时,接头实现了以α-Mg(Ni)固溶体为主、少量共晶组织(α-Mg(Ni)+Mg2Ni)的连接(见图9(f))。

4 结论

图9 U-TLP过程中连接接头形成过程示意图

Fig. 9 Joint formation mechanism in this work

1) 超声作用时间对Mg/Ni/Mg接头微观组织形貌存在较大影响。在520 ℃超声作用10 s后,母材Mg表面的氧化膜由于超声的声塑性效应被完全去除,反应界面生成一层Mg2Ni。随着超声作用时间的延长,中间层Ni箔逐渐减少直至消失,接头也由Mg-Ni共晶液相与Ni箔共同构成逐渐转变为全部为Mg-Ni共晶液相构成,最后共晶液相在超声波接头压力和超声声流搅拌共同作用下被完全挤出,从而得到以α-Mg(Ni)固溶体为主的钎缝。

2) 随着超声作用时间的延长,钎缝的剪切强度呈现先增强再降低的规律。在520℃超声作用30 s后,接头的平均剪切强度最高,为107 MPa,并且断裂于钎缝中反应生成的α-Mg固溶体区域。接头中Mg2Ni的硬度最大,为142.0HV,表明连续的Mg2Ni金属间化合物是整个接头的最脆弱点。Mg基体和α-Mg(Ni)固溶体的硬度相差不大,分别为53.4HV和56.4HV。

REFERENCES

[1] 冯吉才, 王亚荣, 张忠典. 镁合金焊接技术的研究现状及应用[J]. 中国有色金属学报, 2005, 15(2): 165-178.

FENG Ji-cai, WANG Ya-rong, ZHANG Zhong-dian. Status and expectation of research on welding of magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(2): 165-178.

[2] 初雅杰, 李晓泉, 吴申庆. 热碾压对AZ31镁合金焊接接头组织和性能影响[J]. 中国有色金属学报, 2011, 21(11): 2039-2043.

CHU Ya-jie, LI Xiao-quan, WU Shen-qing. Effect of hot rolling on microstructure and mechanical properties of welded joints of AZ31 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(11): 2039-2043.

[3] 马 力, 龙伟民, 裴夤崟, 张健源, 丁新泉, 孙华为. 钎料元素Al+Zn对镁合金钎焊接头显微组织和抗剪强度的影响[J]. 中国有色金属学报, 2014, 24(2): 317-324.

MA Li, LONG Wei-min, PEI Yin-yin, ZHANG Jian-yuan, DING Xin-quan, SUN Hua-wei. Effect of Al+Zn elements of filler metal on microstructures and shear strength of magnesium alloy AZ31B brazed joint[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(2): 317-324.

[4] 王希靖, 张永红, 张忠科. 异种镁合金AZ31B和AZ61A的搅拌摩擦焊工艺[J]. 中国有色金属学报, 2008, 18(7): 1199-1204.

WANG Xi-jing, ZHANG Yong-hong, ZHANG Zhong-ke. Friction stir welding process of AZ31B and AZ61A magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2008,18(7): 1199-1204.

[5] ZHOU L, YU M R, LIU B Y, ZHANG Z L, LIU S W, SONG X G. Microstructure and mechanical properties of Al/steel dissimilar welds fabricated by friction surfacing assisted friction stir lap welding. Journal of Materials Research and Technology[J]. 2020, 9: 212-221.

[6] SAREMI S G, GHAHRI S, MIRSALEHI A, EHSAN S. Transient liquid phase bonding of AZ31 magnesium alloy: Metallurgical structure and mechanical properties[J]. Journal of Manufacturing Processes, 2018, 35: 140-148.

[7] CHOWDHURY S M, CHEN D L, BHOLE S D, ZHOU Y. Microstructure and mechanical properties of fiber-laser- welded and diode-laser-welded AZ31 magnesium[J]. Metallurgical and Materials Transactions A, 2011, 42(7): 1974-1989.

[8] MUNITZ A, COTLER C, STERN A, KOHN G. Mechanical properties and microstructure of gas tungsten arc welded magnesium AZ91D plates[J]. Materials Science and Engineering: A, 2001, 302(1): 68-73.

[9] XU Z W, LI Z W, PENG B, YAN J C. Application of new ultrasonic-assisted semi-solid brazing on dissimilar Al/Mg alloys[J]. Materials Letters, 2018, 228: 72-76.

[10] WANG Q, FU Y, LANG Q, YAN J C. Microstructure and mechanical properties of magnesium alloy joints with Ag-Cu interlayer by ultrasonic-induced transient liquid phase bonding in air for structure lightweight design[J]. Materials Letters, 2019, 237: 37-40.

[11] CHEN X G, YAN J C, GAO F. Interaction behaviors at the interface between liquid Al-Si and solid Ti-6Al-4V in ultrasonic-assisted brazing in air[J]. Ultrasonics Sonochemistry, 2013, 20: 144-154.

[12] XU Z W, LI Z W. Ultra-rapid transient liquid phase bonding of Mg alloys within 1s in air by ultrasonic assistance[J]. Materials and Design, 2019, 161: 72-79.

[13] LAI Z W, CHEN X G, PAN C, LIU L, ZOU G S. Joining Mg alloys with Zn interlayer by novelty ultrasonic-assisted transient liquid phase bonding method in air. Materials Letters, 2016, 166: 219-222.

[14] GUO W B, LENG X S, LUAN T M. Ultrasonic-promoted rapid TLP bonding of fine-grained 7034 high strength aluminum alloys[J]. Ultrasonics Sonochemistry, 2017, 36: 354-361.

[15] MCINTYRE N S, CHEN C. Role of impurities on Mg surfaces under ambient exposure conditions[J]. Corrosion Science, 1998, 40(10): 1697-1709.

[16] XIE R S, CHEN X G, LAI Z W. Microstructure, mechanical properties and mechanism of ultrasound-assisted rapid transient liquid phase bonding of magnesium alloy in air[J]. Materials and Design, 2016, 91: 19-27.

[17] LANGENECKER B. Effects of ultrasound on deformation characteristics of metals[J]. IEEE Transactions on Sonics & Ultrasonics, 1966, 13(1): 1-8.

[18] SIDDIQ A, TAMER E S. Acoustic softening in metals during ultrasonic assisted deformation via CP-FEM[J]. Materials Letters, 2011, 65: 356-359.

[19] KELLY G S, ADVANI S G, GILLESPIE J W, BOGETTI T A. A model to characterize acoustic softening during ultrasonic consolidation[J]. Journal of Materials Processing Technology, 2013, 213: 1835-1845.

[20] AHMADI F, FARIZN M, MANDEGARI M. Effect of grain size on ultrasonic softening of pure aluminum[J]. Ultrasonics, 2015, 63: 111-117.

[21] JIN Y J, KHAN T I. Effect of bonding time on microstructure and mechanical properties of transient liquid phase bonded magnesium AZ31 alloy[J]. Materials and Design, 2012, 38: 32-47.

[22] LAI Z W, CHEN X G, PAN C. Joining Mg alloys with Zn interlayer by novel ultrasonic-assisted transient liquid phase bonding method in air[J]. Materials Letters, 2016, 166: 219-222.

[23] YAO Z H, KIM G Y, WANG Z H. Acoustic softening and residual hardening in aluminum: Modeling and experiments[J]. International Journal of Plasticity, 2012, 39: 75-87.

[24] SIDDIQ A, GHASSEMIEH E. Thermomechanical analyses of ultrasonic welding process using thermal and acoustic softening effects[J]. Mechanics of Materials, 2008, 20: 982-1000.

[25] HU J, SHIMIZU T, YANG M. Investigation on ultrasonic volume effects: stress superposition, acoustic softening and dynamic impact[J]. Ultrasonic Sonochemistry, 2018, 48: 240-248.

Mechanism of ultrasound-assisted transient liquid phase bonding of magnesium alloy with Ni interlayer

LI Yi-nan1, YANG Cheng-fei1, YAN Jiu-chun2, PENG Zi-long1

(1. School of Mechanical and Automotive Engineering, Qingdao University of Technology, Qingdao 266520, China;

2. State Key Laboratory of Advanced Welding and Joining, Harbin Institute of Technology, Harbin 150001, China)

Abstract: In order to research the effect of ultrasonic processing time on the microstructures and mechanical properties of magnesium alloy joint, ultrasonic-assisted transient liquid phase bonding (U-TLP) of MB8 magnesium alloy was carried out with a pure nickel interlayer. The results show that the oxide film on the surface of Mg alloy is successfully removed at 520 ℃ within ultrasonic processing time of 10 s. With the prolongation of the ultrasonic processing time, a eutectic reaction between Ni foil and Mg base metal proceeds and the Ni foil is consumed gradually. The α-Mg+Mg2Ni eutectic products begin to increase at first and then are extruded under the static pressure of sonotrode and ultrasonic sound flow effect. When the ultrasonic processing time is 30 s, as the Mg2Ni which is easy to make the joint brittle is extruded, the brazing seam is mainly composed of magnesium-based solid solution. At this time, the joint shear strength increases to the maximum of 107 MPa, reaching 102% of that of the base metal, and the fracture is along the α-Mg solid solution in brazing seam.

Key words: magnesium alloy; ultrasonic assistance; transient liquid phase bonding; microstructure; mechanical property

Foundation item: Projects(51871128, 51875300) supported by the National Natural Science Foundation of China; Projects(ZR2017MEE012, ZR2018MEE017) supported by the Natural Science Foundation of Shandong Province, China; Project(2018GGX103036) supported by the Key Program of Research and Development of Shandong Province, China

Received date: 2019-05-18; Accepted date: 2019-11-20

Corresponding author: PENG Zi-long; Tel: +86-18561813900; E-mail: pengzilong@qut.edu.cn

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51871128,51875300);山东省自然科学基金资助项目(ZR2017MEE012,ZR2018MEE017);山东省重点研发计划项目(2018GGX103036)

收稿日期:2019-05-18;修订日期:2019-11-20

通信作者:彭子龙,副教授,博士;电话:18561813900;E-mail:pengzilong@qut.edu.cn

摘 要:为了研究超声作用时间对镁合金连接接头显微组织与力学性能的影响,以纯镍中间层对MB8镁合金进行超声辅助瞬间液相扩散焊(U-TLP)。结果表明:在520 ℃时超声作用10 s即可去除母材表面氧化膜。随着超声作用时间的延长,Ni箔与母材Mg发生共晶反应,并逐渐被消耗,α-Mg+Mg2Ni共晶产物开始先增多,而后在超声头压力和声流作用下被逐渐挤出。超声作用30 s时,由于易使接头变脆的Mg2Ni被挤出,钎缝主要以α-Mg(Ni)为主,此时接头剪切强度达到最大(107 MPa),达到母材强度的102%,断裂位置为钎缝中反应生成的α-Mg固溶体区域。

[1] 冯吉才, 王亚荣, 张忠典. 镁合金焊接技术的研究现状及应用[J]. 中国有色金属学报, 2005, 15(2): 165-178.

[2] 初雅杰, 李晓泉, 吴申庆. 热碾压对AZ31镁合金焊接接头组织和性能影响[J]. 中国有色金属学报, 2011, 21(11): 2039-2043.

[3] 马 力, 龙伟民, 裴夤崟, 张健源, 丁新泉, 孙华为. 钎料元素Al+Zn对镁合金钎焊接头显微组织和抗剪强度的影响[J]. 中国有色金属学报, 2014, 24(2): 317-324.

[4] 王希靖, 张永红, 张忠科. 异种镁合金AZ31B和AZ61A的搅拌摩擦焊工艺[J]. 中国有色金属学报, 2008, 18(7): 1199-1204.