文章编号:1004-0609(2016)-01-0077-11

铝及铝合金钎焊用硬钎料的研究现状与展望

牛志伟,黄继华,许方钊,刘凯凯,陈树海,赵兴科

(北京科技大学 材料科学与工程学院,北京 100083)

摘 要:

铝及铝合金以其优良的特性,在当代工业材料中占有越来越重要的地位。钎焊作为一种可靠连接铝及铝合金结构件的连接方法而被广泛应用。铝及铝合金钎焊用硬钎料的开发一直是国内外学者争相研究的热点,然而,钎料合金熔化温度高、加工成形性差、钎焊接头强度低等因素严重制约着钎料合金的开发应用,实现商业化的钎料甚少。添加合金元素能够降低钎料熔化温度,改善钎料显微组织和性能,这对铝钎焊用硬钎料的发展是一个行之有效的方法。结合国内外对铝及铝合金钎焊用硬钎料的最新研究成果,全面阐述合金元素的添加对钎料熔化温度、加工成形性及钎焊接头组织性能的影响,指明铝及其合金钎焊用硬钎料目前研究中存在的问题及今后的研究方向。

关键词: 铝合金;硬钎料;加工成形;钎焊接头

中图分类号:TG425+.2 文献标志码:A

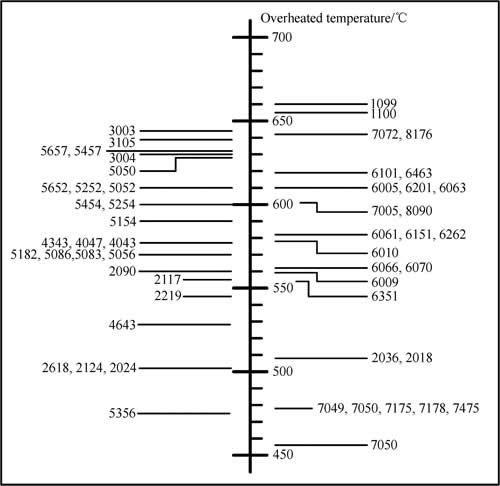

铝及铝合金具有密度小、强度高和耐腐蚀等优点,因而广泛应用于汽车、高速铁路车辆、航空航天和军事工业[1-4]。不同牌号的铝合金及其过烧温度如图1所示。对于铝合金的焊接,传统的方法主要以熔化焊接为主,设备复杂,且对焊工的技术要求比较严格[5-7]。钎焊作为铝合金连接的重要方法,具有钎焊件变形小、尺寸精度高等优点,近年来,在国内外得到广泛的应用[8-10]。铝及铝合金的软钎焊是不常应用的方法,由于铝及铝合金软钎料主要采用以低熔点金属如锡、锌等为基,使得软钎料的成分、组织及电极电位与铝及铝合金母材相差很大,钎焊接头易引起严重的电化学腐蚀[11-12]。铝及铝合金的硬钎焊应用很广,随着新材料的不断开发,铝合金的钎焊不仅只是同种材料之间,还涉及异种材料,包括铝与铜[13]、铝与钢[14]、铝与钛[15]、铝与陶瓷[16]等,这对铝及铝合金钎焊用硬钎料提出了更高的要求和挑战。铝及铝合金钎焊通常采用Al-Si共晶钎料[17],此类钎料润湿性好、强度高、加工性能优异,可以方便制成丝或带,缺点是熔点高、钎焊温度接近母材熔点(590~610 ℃),钎焊时必须严格而精确地控制加热温度,否则将导致母材过烧甚至熔化。部分合金元素Cu、Ge、Ag、Zn等的添加降低了钎料合金的熔化温度,但在一定程度上也容易引起钎料合金加工成形性差、钎焊接头强度低、母材过度溶蚀等问题。本文作者结合当前国内外铝及铝合金钎焊用硬钎料的研究成果,全面阐述合金元素的添加对钎料合金熔化温度、加工成形性以及钎焊接头显微组织和性能的影响,指明铝及铝合金钎焊用硬钎料目前研究中存在的问题及今后的研究方向。

图1 不同铝合金的过烧温度

Fig. 1 Overheated temperature of different aluminum alloys

1 Al-Si系列钎料

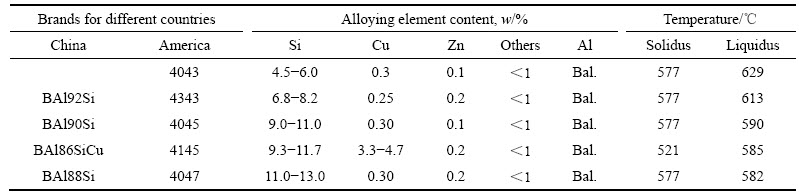

铝及铝合金的钎焊主要使用铝基钎料,现代工业中关于低熔点铝合金钎焊存在较多的技术难题,其中最核心的问题是没有适合低熔点铝合金钎焊的低温铝钎料。由于Al-Si钎料具有良好的润湿性、流动性、抗腐蚀性和可加工性[18],因此,Al-Si钎料是应用最广的一种铝基钎料,此系列钎料熔化温度范围是570~630 ℃。Al-Si二元相图[19]是典型的共晶相图,从相图上可以看出在w(Si)=12.6%处有一共晶点,在亚共晶区(w(Si))<12.6%),随着硅含量的增加,钎料熔点降低;在过共晶区(w(Si)>12.6%),随着硅含量的增加,钎料的熔点将有大幅度的上升。研究表明,亚共晶合金具有较好的流动性、润湿性和抗腐蚀性,而且可以根据母材的特点和工艺要求添加合适的元素,改善钎料的性能,获得优良的焊接接头。而且亚共晶合金作为钎料,可以避免钎焊时因母材向钎料的溶解而导致的母材溶蚀问题,所以一般的Al-Si系列钎料合金,Si含量为7%~12%(质量分数)。典型的Al-Si二元系列钎料的牌号有4343、4045、4047等。其中4343钎料适用于钎焊1060、1100、3003铝合金,潘春旭等[20]在3003铝合金基板上轧制了一层4343型Al-Si钎料合金覆层,并对这种铝合金复合板材料进行了钎焊,获得完整的钎焊接头,钎焊过渡区由单相α(Al)固溶体层和Si扩散层组成;4045和4047钎料适用于钎焊3004、5005、6063、6951铝合金。Al-Si系钎料的基本数据见表1。

Al-Si共晶组织中的Si相在铸态呈现卷曲的片状,金相的截面呈线状,经过微量元素的变质处理[21],Si相变成树枝状,金相的截面呈蠕状,再经一定的保温处理则Si相会进一步变成球粒状[22]。变质的钎料在钎焊后仍能保持某些变质结构[23],钎缝的强度因此大大提高。稀土具有较高的化学活性,在冶金及材料加工中,具有变质强化和改善工艺性能等作用。研究人员对La、Ce、Y、Sc等稀土元素在铝合金中的作用已经做了深入的研究[24-27]。Sc是对铝及其铝合金最有影响的微量稀土元素,其主要原因是由于产生了与基体共格的、稳定的、弥散的Al3Sc粒子,对位错有强烈的钉扎作用,并能阻止晶界的迁移,在高温下仍能保持与基体共格的关系,但Sc的价格昂贵[27]。Er在铝及其合金中的作用与Sc相似,但Er的成本远低于Sc的,具有良好的应用前景[28]。微量元素对Al-Si共晶合金存在变质作用,但是多数元素变质能力较弱,变质效果不佳,如Li、K和Ba等[29];多数元素在较快的冷却速度下才能呈现变质效果,如Bi和Sb等[30]。钎焊后的冷却速度对Al-Si共晶钎料钎缝的组织结构也有很大的影响,在添加某些变质剂元素后这种影响更加敏感[31]。Al-Si共晶合金随着冷却速度加快,一般只是Si相组织变细,但不改变片状晶的外形,加入变质剂后随着冷却速度的加快,Si相形貌开始由片状转变为根枝状。此外,ZHANG等[32]向Al-Si共晶合金中添加了不同含量的Ti,制备了新型Al-Si-xTi(x=0.1%、0.5%、1.0%、3.0%)系三元活性钎料,Ti元素的增加能显著提高Al-Si合金在铝基复合材料上的铺展润湿性,但Ti元素的增加对Al-Si合金的变质作用并不明显。多达20种以上的添加元素对Al-Si共晶合金存在变质作用,但其中最敏感的添加元素是Na、Sr和La,其添加量只需0.01%~0.1%(质量分数)。

Al-Si共晶合金的变质机理目前仍属争论的问题[30,33-35],大量文献的论点虽然立据不同,细节迥异,但基本上可以分为两派:一派从变质剂原子阻碍硅相成核的角度出发,认为硅相延缓析出,体系呈过冷状态,从而使快速析出的硅相细粒化;另一派从晶体生长的角度出发,认为变质剂原子(多为Na)以各种不同方式影响硅晶体某些晶面的生长速率,从而使其按球粒状生长。张启运等[30]主要采用显微结构的方法系统研究了11种单个稀土元素和混合轻稀土元素对Al-Si共晶合金变质的影响,并进一步探讨稀土元素及其它变质元素的变质规律。研究结果表明:在冷却速度为70~80 ℃/min条件下,单个稀土元素中Eu和La(可能还有Yb)对Al-Si共晶合金具有强烈的变质作用;Ce、Pr、Nd以及混合稀土具有中等程度的变质作用;Er和Y并无变质能力;其他稀上元素变质能力均极弱。La为“长效”变质剂,变质温度为750~780 ℃,合金冷却速度不应低于50 ℃/min。单个稀土元素的变质能力随原子半径的减小而迅速减弱,Eu(可能还有Yb)的强烈变质作用产生于其原子半径的突跃增大。根据推论,Ac在ⅢB族中应具有最大的变质能力,联系强烈变质剂Na、Sr和Ac在周期表中位置的关系,可以认为电子层结构、价电荷数、原子半径和原子序数适当的组合是决定元素变质能力的主要因素。

表1 Al-Si系钎料的基本数据

Table 1 Basic date of Al-Si series filler metals

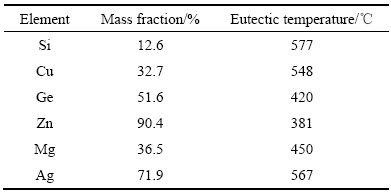

由于Al-Si共晶钎料熔点高达577 ℃,而铝合金母材的固相线温度在600 ℃左右,钎焊温度接近于母材固相线温度,极易引起母材晶粒长大、溶蚀等问题,严重影响钎焊接头的力学性能。因此,开发以Al-Si钎料为基础的低熔点钎料,降低钎焊温度是铝合金钎料重要研究方向之一[36]。作为铝基钎料的主要添加元素,钎料的熔点是首要考虑因素。为降低钎料熔点,选择添加元素必须与铝有低熔点共晶反应,而一些本身蒸汽压较高的元素,如锌、镁等,尽管可以显著降低铝合金的熔点,但添加过多会对真空钎焊炉或甩带室造成污染,因此只能少量添加。综合以上分析并结合铝的合金相图[37]可以知道,能够降低铝熔点的元素主要如表2所列,而各种元素是否能作为添加元素需要综合分析。

表2 可与铝形成低熔点共晶的几种元素

Table 2 Several elements form low melting point eutectic with aluminum

2 Al-Si-Cu系列钎料

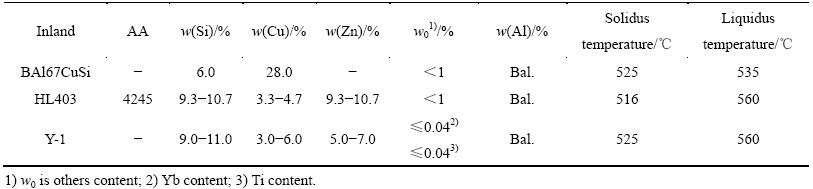

根据Al-Cu二元合金相图,铜与铝在w(Cu)=32.7%时,共晶点为548 ℃,并且在含Cu 32.7%左右时,合金熔点随着铜含量增大先是逐步降低,然后逐步升高。铜在铝中的溶解度随温度降低明显减少,铜在铝中的最大固溶度为5.65%,当温度降低到302 ℃时,溶解度则为0.45%,在沉淀过程中能析出均匀、弥散的共格或半共格的过渡相,所以铜能对铝合金起到弥散强化作用,因此,铜是铝钎料和钎焊接头的重要强化元素。但在室温下,存在一组稳定的金属间化合物:θ相(Al2Cu)、η相(AlCu)、γ相(Al2Cu3)、γ相(AlCu2)、χ相(Al4Cu9)。这些化合物使合金的塑性明显下降,使其加工性能恶化。当在Al-Cu系合金加入一定量的Si时就构成了Al-Cu-Si系三元合金,在Al-CuAl2-Si的赝三元系[29]中有一个三元共晶点,w(Cu)=26.7%、w(Si)=5.1%、温度525 ℃。此共晶点合金常用作液相线较低的钎料,在Al-Si钎料中加入Cu后,钎料的流动性也显著增加[38],缺点是此钎料Cu含量较高,钎料脆性很大。Al-Si-Cu系商用钎料如表3所列,其中HL403应用最为广泛,由于此钎料中铜含量较低,可以制成丝或带的形式,有利于更好地实现铝及铝合金的钎焊。然而,此钎料液相线温度依然很高,限制了大量低温铝合金的应用。

6061 铝合金[39]作为一种Al-Mg-Si系变形铝合金,因其密度小,具有良好的强度及耐腐蚀性,广泛应用于制造汽车管路件及阀件。目前,在该类零部件组装生产过程中,主要采用钎焊连接,钎焊接头在主要考虑气密性的同时对接头强度也有一定要求,由于6061 铝合金熔点较低(固相线温度582 ℃),用传统的Al-Si钎料极易引起母材过烧,因此,该类零部件的钎焊一直比较困难。Al-Si-Cu系钎料合金的出现大大的推进了6061铝合金的钎焊。CHUANG等[8,40]开发了Al-10.8%Si-10%Cu和Al-9.6%Si-20%Cu(质量分数)钎料合金,两种钎料合金熔化温度范围分别为522.3~570.0 ℃和522.9~535.2 ℃,采用Al-10.8%Si-10%Cu钎料钎焊6061铝合金可以获得完整的钎焊接头,钎焊接头剪切强度可达67 MPa;采用Al-9.6%Si-20%Cu钎料钎焊6061铝合金,钎焊接头强度仅为40 MPa。Al-9.6%Si-20%Cu钎料合金虽然钎焊温度较低,然而合金中存在大量的Al2Cu金属间化合物和Al-Si-Cu共晶组织,导致钎料合金脆性很大,极难加工成薄片;同时,钎焊接头组织中也含有大量的Al2Cu金属间化合物,导致钎焊接头具有较低的抗剪强度。

为了降低Cu含量过高带来的不利影响,研究学者利用Cu降低熔点的同时加入少量Ni,以使钎料保持良好的力学性能和抗腐蚀性能。于文花等[41]采用Al-Si-Cu-Ni钎料钎焊6063铝合金时发现,Cu、Ni、Si对钎焊接头剪切强度的影响由大到小依次为Cu、Si、Ni;随着钎料中Cu、Ni、Si 含量的增加,钎焊接头的剪切强度先增加后减小,分别为10%、2.6%、7.5%附近剪切强度达到最高;当Cu含量超过20%时,钎料合金中会形成连续的Al-Cu金属间化合物,恶化了钎焊接头的力学性能。HUMPSTON等[42]研制的Al-5Si-20Cu-2Ni钎料熔化温度在518~538 ℃范围内,钎焊3001防锈铝合金,钎焊接头强度最大仅为75 MPa。因此,20% Cu含量的Al-Si-Cu钎料,虽然熔化温度大大降低,然而钎焊接头强度较低。针对上述问题,LUO等[43]开发一系列低Cu含量的Al-Si-Cu-Ni钎料用于钎焊低熔点高强铝合金。研究表明,当采用Al-10Si-15Cu-4Ni钎料(熔化温度范围519.3~540.2 ℃)在570 ℃下钎焊6061铝合金时,随着钎焊时间的增加,钎焊接头强度逐渐增加,钎焊时间达到60 min时钎焊接头可以获得超过100 MPa的抗剪切强度。Al-Si-Cu系合金中添加Sn可以进一步降低钎料的熔化温度,TSAO等[9]研究的Al-7Si-20Cu-2Sn钎料合金的熔化温度范围为504~526 ℃,在钎焊6061-T6铝合金时,钎焊接头剪切强度最大可达121MPa。邹家生等[44]在Al-Si-20Cu钎料的基础上添加了5%Zn,钎料合金的熔化温度为499.5~523 ℃,用此钎料配合氟化物钎剂钎焊6063铝合金钎焊接头强度最大可达132 MPa。CHUANG等[40]研制的Al-7Si-20Cu-2Sn-1Mg合金钎料的熔化温度降为501~522 ℃,少量Mg的添加不仅降低了钎料的熔化温度,而且钎料组织中生成了细小的CuMgAl2和Mg2Si金属间化合物;采用此钎料钎焊6061-T6铝合金时,钎焊接头获得了较高的抗拉强度。少量Ni、Sn、Zn、Mg的添加虽然降低了Al-Si-Cu钎料合金的熔化温度,提高了钎焊接头的强度,然而钎料中依然存在粗大的脆性金属间化合物,合金很难被加工成箔或片状。HU等[45]向Al-7Si-20Cu中添加了不同含量的稀土元素Sm,研究了Sm元素对Al-Si-Cu钎料熔化温度、显微组织以及力学性能的影响,结果表明:添加Sm对钎料熔化温度无显著影响,随着Sm含量的增加,钎料显微组织细化,特别是针状共晶Si的长度逐渐减小,钎料合金的硬度也随之增加。孙力力等[46]制备了含Ce的Al-Si-Cu系列钎料,用于6061铝合金和1Cr18Ni9Ti奥氏体不锈钢异质钎焊的研究。研究表明:加入少量的Ce(≤3.0%,质量分数)不改变Al-Si-Cu钎料熔点,但使钎料熔化温度区间变窄,提高了钎料合金的铺展润湿性。不同Ce含量对钎焊接头的力学性能影响不同,当钎料中Ce含量为1.0%(质量分数)时,钎缝显微组织细化,钎焊接头剪切强度最高,达到118 MPa;当钎料中Ce含量为3.0%(质量分数)时,钎缝组织中针状富Ce脆性化合物相明显增多,钎焊接头剪切强度降低为92 MPa。研究报道[47-49],采用快速凝固技术不仅可以降低钎料的熔点,而且可以制得塑性良好的带材。因此,曹金山等[50]采用快速凝固的方法成功制备低Cu含量的Al-6Si-7Cu-2Zn-2Sn薄带钎料。实验结果表明:普通钎料固、液相线温度分别为549 ℃和562 ℃,钎料熔化温度区间为13 ℃;快冷钎料的固、液相线温度分别为552 ℃和560 ℃,钎料熔化温度区间仅为8 ℃,另外,快冷钎料组织细小均匀,钎料薄带具有优良的加工成形性能。

表3 Al-Si-Cu系商用钎料的基本数据

Table 3 Basic date of Al-Si-Cu series commercial filler metals

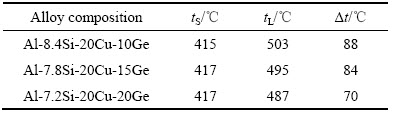

为了满足更低过烧温度铝合金(如硬铝合金LY12)的钎焊,张福礼等[51]向Al-Si-Cu钎料合金中添加Ge,开发出新型Al-Si-Cu-Ge系钎料,具体成分和熔化温度见表4。Al-9.6Si-20Cu合金中添加10%(质量分数)的Ge,钎料合金的液相线温度可降为482℃,成功实现了LY12硬铝合金的钎焊。然而Ge的增加导致钎料合金中 Al2Cu 金属间化合物大量聚集,Si-Ge先析出相的尺寸增大,从而导致钎焊接头强度较低;对钎焊接头断口进行观察可知,断口存在大量的 Si-Ge 先析出相及 Al2Cu 脆性相,呈明显的沿晶断裂特征。为改善钎焊接头的组织,提高钎焊接头强度,添加了0.6%(质量分数)的 Er 元素对钎料合金进行变质处理,发现钎料熔点下降不明显,但钎料铺展面积、钎焊接头强度有所提高,主要原因是Er作为活性元素能显著降低母材表面张力,并能细化晶粒从而提高接头强度。除了用于钎焊LY12铝合金,Al-Si-Cu-Ge钎料也成功应用于铝合金与钛合金之间的钎焊,CHANG等[52]分别采用Al-8.4Si-20Cu-10Ge和Al-8.4Si-20Cu-10Ge-0.1Re钎料实现了6061铝合金和TC4钛合金的钎焊,Re的添加细化了α(Al)相,使针状的Al2Cu相转变为块状;采用Al-8.4Si-20Cu-10Ge钎料钎焊铝合金和钛合金,接头平均抗剪强度为20MPa,添加Re后钎焊接头抗剪强度最大可达51MPa;钎焊接头断裂主要发生在TC4一侧,断口表面检测到大量Al5Si12Ti7金属间化合物颗粒。

表4 钎料成分和熔化温度

Table 4 Chemical compositions and melting temperature of filler metals

3 Al-Si-Ge系列钎料

根据Al-Ge二元合金状态图,铝与锗在w(Ge)=51.6%时的共晶点温度为423℃,正好处于难得的中温铝钎焊范围内,钎料流动性很好,铺展性极佳,能沿母材表面大面积流布;但是由于此钎料含Ge量较高,脆性较大,铸条几乎无强度,落地便碎[19],当前研究主要集中在改善Al-Ge钎料合金的性能上。研究表明:溶入Ti等难熔金属具有将Ge片状晶聚集为块状晶的趋势[53];此外,向Al-Ge合金中添加Si也能降低钎料合金的脆性。Al-Si-Ge钎料作为典型的低温钎料,当Ge元素含量较低时,Ge对钎料熔化温度的降低作用不大[54],因而高Ge含量的Al-Si-Ge钎料是研究的重点。近年来,日本研究的Al-30Ge-Si钎料,可用于6061铝合金及复合材料在550 ℃以下进行钎焊,但由于脆性大不易加工,一般用急冷凝固制箔法直接生产出成品。KAYAMOTO等[55]研制的Al-35Ge-Si-Mg钎料可在575 ℃钎焊6061铝合金,所得接头的抗拉强度接近母材的,但锗的含量较高,钎料成本显著增加。采用Al-35Ge-Si-Mg钎焊7003铝合金,接头强度高于340 MPa,达到母材强度的85%以上[56],同时,还研究了Al-Ge-Cu-Si-Mg系钎料,钎料熔化温度降低至457 ℃,成功实现了2017铝合金的钎焊,钎焊接头抗拉强度最高可达290 MPa,但没有做成合金薄带。

SCHUBERT等[57]采用熔纺技术(快速凝固技术的一种)制备了韧性较好的Al-Si-Ge钎料薄带,制备工艺为首先对熔融态的钎料合金进行淬火,然后在适当的温度下进行退火处理,得到均匀细小的β-Ge(Si)颗粒,极大地改善了钎料合金的加工性能。另外,Na、Sr、La等稀有元素的添加可以使Al-Si-Ge合金产生明显的变质结构[22],随着Si含量的逐渐增加,Ge-Si固溶体分散相被变质的倾向也随之加强,由片条状转变为块状,改善了钎料合金的加工成形性能。

4 Al-Si-Zn系列钎料

Al-Si-Zn系的相图[58]中存在三元共晶点E,其组成为w(Al)=5.10%、w(Si)=0.04%、w(Zn)=94.86%。Al-Si共晶钎料中加入Zn后,钎料的润湿性和流动性均有加强。由于没有化合物生成,Al-Si-Zn钎料的热加工性能比Al-Si-Cu系的好,可以方便地制成钎料丝或带。研究报道,在Al-Si-Zn钎料中加入少量Cu可以减少与母材的色差,加入少量Mg可以提高抗腐蚀性能。SUZUKI等[58]研制的 Al-4.2Si-40Zn 钎料,熔点为535 ℃,由于钎料中Zn含量过高,钎焊过程中极易引起母材的溶蚀,降低钎焊接头强度。DAI等[59]利用Al-6.5Si-42Zn钎料在火焰钎焊条件下实现了6061铝合金的钎焊,对钎焊接头进行抗拉强度测试,最大抗拉强度为129 MPa,由于粗大初晶Si和针状共晶Si的存在,接头断裂在钎缝处,断口表现为沿晶和穿晶断裂形式。因此,有效抑制钎料内部初晶硅的生长,同时细化钎料组织成为提高Al-Si-Zn钎料性能的关键。

目前工业生产中广泛采用的也是效果最为稳定的方法是对合金进行变质细化处理。张帅等[60]向Al-Si-Zn钎料合金中添加了不同含量的P,结果表明P元素的加入不仅能有效细化钎料组织中粗大的块状初晶硅,也能使长针状的共晶硅“钝化”成短杆状;当Al-Si-Zn钎料中的P含量为0.06%(质量分数)时,初晶硅和共晶硅的平均尺寸最小,且弥散分布在钎料组织中,此时钎焊接头强度最大;随着P元素含量的增加,当P含量达到0.12%时,初晶硅和共晶硅的尺寸又有长大的趋势。研究表明:这是由于磷为表面活性元素,当把Al-P合金加入到Al-Si-Zn熔体后,磷迅速与铝形成大量的AlP颗粒,AlP对初晶硅的析出提供了现成的结晶衬底,使硅的结晶核心数目增加,从而使得初晶硅得以细化[61],但是过量的P反而会减弱对Si的变质细化效果,即所谓的“过变质现象”。Al-6.5Si-42Zn中添加微量的Sr,长针状的共晶Si可以转变为细小的纤维状,钎焊接头强度也显著提高[62]。添加0.08%Ti(质量分数)可以使Al-Si-Zn组织中α(Al)相明显细化,Al-Si共晶相分布也更加均匀[63]。Ce、La、B等元素也均能对Al-Si-Zn钎料组织进行变质处理[64],但准确的添加量是获得良好钎料组织的关键。

由于快冷钎料成分均匀,熔化区间窄,俞伟元等[65]采用快速凝固的方式也制备了一系列Al-Si-Zn钎料,并与普通钎料进行了对比。结果表明:快冷的钎料润湿性和抗拉强度都高于普通钎料;快冷钎料晶粒尺寸为0.6 μm以下,且分布均匀。刘树英等[66]采用快冷Al-Si-Zn钎料实现了铝合金与不锈钢的钎焊,快冷钎料具有窄的熔化区间和良好的润湿性,缩短了对不锈钢的润湿时间,能够同步润湿不锈钢和铝合金,使不锈钢和铝合金之间形成牢固的接头。快冷钎料活性大,在钎焊过程中与母材作用能力强,是快冷钎料润湿性和接头抗拉强度高的主要原因,然而生产工艺较为复杂,且成本较高,也极大地制约了快冷工艺的发展。

5 Al-Si-Mg系列钎料

镁可以使铝的熔点降低,但共晶点处镁的含量达到了36.5%,含有这么高成分镁的铝合金会生成一些β相而使合金变脆。但实际应用时钎料中镁的含量并没有超过5%,甚至没有超过3%,原因就是镁在铝合金中的作用并不是要降低钎料的熔点,而是利用镁的化学性质比铝的要活泼的特点,对铝起到保护的作用。同时,镁对铝合金的强化是明显的,每增加1%镁,抗拉强度大约升高34 MPa[67-69]。同时,锻铝合金(LD系列)本身就是含镁的合金,在钎焊过程中如果钎料中的镁含量低于母材中的含量时必然使母材中的镁向钎料合金中扩散,从而导致母材强度的下降。当然镁的含量也不是越多越好,随着镁含量的增多,钎料的流动系数虽然有所提高,但钎料对铝的溶蚀作用也加剧,这是由于形成了Al-Si-Mg三元低熔点共晶的缘故,因此,钎料合金中镁的含量达到强化合金和起到活化剂的作用就行了。Al-Si-Mg三元系钎料主要应用于真空钎焊,Mg在钎焊初期能升华形成Mg蒸汽,吸收炉膛内的氧气和水汽,即发生如下反应:1) 2Mg+O2→ 2MgO;2) Mg+H2O→MgO+H2除去了炉内的氧气和水汽,净化、抑制了铝的再氧化。随着温度的继续升高,又发生如下反应:3) 3Mg+Al2O3→3MgO+2Al母材表面Al2O3被还原,使表面活化,易于钎料的流动,由此可知,镁元素实际上起了溶剂的作用[70]。常用的Al-Si-Mg系钎料有4N04、4104、4004等,由于此钎料中Mg含量较低,从而钎料的熔化温度较高,主要用于钎焊熔化温度较高的铝合金,如3003、6063等铝合金。此外,Al-Si-Mg钎料因其优异的加工和钎焊性能而被应用于Al与Ti之间的连接,SOHN等[71]采用100 μm厚的Al-10Si-1Mg钎料薄带实现1050Al与CP-Ti的液态扩散焊接,Ti和钎料之间形成两层金属间化合物Al5Si12Ti7和Al12Si3Ti5;随着保温时间的延长,接头结合强度先增加后减小,在620 ℃保温25 min时,接头强度达到最大,长时间的保温导致Al侧界面处产生大量空洞。张丽霞等[72]采用Al-Si-Mg钎料实现了5005铝合金与4J34可伐合金(铁镍钴合金)的真空钎焊,随着钎焊温度的升高和保温时间的延长,接头的抗剪强度先升高后降低;当钎焊温度为580 ℃、保温时间为15 min时,接头抗剪强度达到最大值81 MPa,此时,接头的典型界面结构为4J34可伐合金/FeAl/FeAl3/FemAln+α(Al)/5005铝合金。接头的断裂形式主要受钎焊温度的影响,当钎焊温度较低时,接头断裂于铝合金侧氧化膜层及铝合金内;当温度升高至 580 ℃时,接头断裂于FemAln+α(Al)反应层中。

6 Al-Ag-Cu-Zn系列钎料

Al-Ag合金中Ag含量为71.9%(质量分数)时,有一共晶点为567℃,此共晶组织含有大量Ag2Al脆性金属间化合物,且该化合物在铝合金中为正电性,因此,含有Ag2Al相的合金很容易被腐蚀;另外Ag对降低钎料熔化温度的作用明显不如Cu的,且比Cu昂贵。Al-Ag-Cu三元相图[73-74]中在Al角的Al-Al2Cu-Ag2Al赝三元系中有一个三元共晶点,此共晶点成分为w(Al)=40.0%,w(Cu)=19.3%,w(Ag)=40.7% (质量分数),共晶点处合金的熔点为500 ℃。此共晶点成分钎料有很大优点,其色泽与Al母材的比较一致,钎焊的流动性极佳,镀覆性能很好,缺点是较脆,但比Al-Si-Cu的脆度要低。向Al-Ag-Cu共晶成分钎料合金中添加Zn,可以进一步降低钎料合金的熔化温度,当Zn的添加量不超过70%(质量分数)时,合金的液相线温度随Zn含量的增加而降低。薛松柏等[75]采用改进的KF-CsF-AlF3中温无腐蚀钎剂与Al-Ag-Cu-Zn中温钎料,实现对LY12铝合金的中温钎焊,对接接头的抗拉强度可达到母材强度的70%,突破了“热处理强化铝合金通常不能钎焊”的传统论断。然而,由于钎料含有大量的Ag和Cu,极易生成Al2Cu和Ag2Al脆性金属间化合物,导致钎料合金加工成形性能很差。

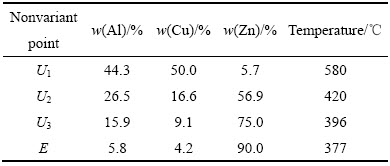

Al-Ag-Cu-Zn系中可用作钎料的另一个三元系是Al-Cu-Zn[76]。Al-Cu-Zn相图比较复杂,适合用作钎料的几个无变点的温度与组成如表5所列。研究结果表明,在Al-Cu-Zn钎料中加入0.05%~0.08%(质量分数)Mg、0.05%Ni或0.05%Cr(质量分数)均能提高其抗腐蚀能力[77-78]。另外,本钎料的色泽比较接近母材的,加工性能较好。

表5 Al-Cu-Zn系无变点的组成和温度

Table 5 Composition and temperature of nonvariant points in system Al-Cu-Zn

7 结论与展望

无论是二元的Al-Si、Al-Cu及Al-Ge钎料,还是三元的Al-Si-Cu、Al-Si-Zn,Al-Si-Mg及Al-Si-Ge等钎料,不是因为钎料的熔化温度依然过高,就是由于Cu、Ge、Ag等降低熔化温度元素的添加量太大,从而使钎料的脆性严重,与实际应用要求相差太远。因此,综合以上分析,铝及铝合金钎焊用硬钎料的发展方向主要集中在以下几个方面:1) 从多元化角度设计合金成分,可以考虑采用4种甚至4种以上的元素组成多元钎料,发挥各元素的作用,在降低钎料熔化温度的同时,保证钎料具有一定的塑性;2) 通过在金属及其合金中加入微量元素,使其起变质作用,从而改变合金的组织和性能,这是提高合金性能的一种简单而行之有效的方法,通过添加变质剂使合金的组织得到改善,脆化作用减小,显著地提高合金塑性、强度等力学性能。另外,微量元素的加入还能起到改善合金流动性、提高抗氧化性、铸造性能等作用,使合金在生产、使用中具有更优良的综合性能。但非常重要的一点就是变质剂的加入量一定要少,以避免合金性能下降;3) 快速凝固技术的出现无论对合金成分的设计还是对合金的微观结构以及宏观特性都产生了深刻的影响,它给新型合金的制备开辟了一条崭新的道路,有力地推动了材料科学的发展,但其生产工艺和成本是值得考虑的问题。

REFERENCES

[1] DONG X H, CHEN F, CHEN S, LIU Y, HUANG Z Y, CHEN H, FENG S F, ZHAO L, WU Z L, ZHANG X P. Microstructure and microhardness of hot extruded 7075 aluminum alloy micro-gear[J]. Journal of Materials Processing Technology, 2015, 219: 199-208.

[2] ROBINSON J S, REDINGTON W. The influence of alloy composition on residual stresses in heat treated aluminium alloys[J]. Materials Characterization, 2015, 105: 47-55.

[3] VARGAS J A, TORRES J E, PACHECO J A, HERNANDEZ R J. Analysis of heat input effect on the mechanical properties of Al-6061-T6 alloy weld joints[J]. Materials and Design, 2013, 52: 556-564.

[4] 盈 亮, 戴明华, 胡 平, 闫巧云. 6061-T6铝合金高温本构模型及温成形数值模拟[J]. 中国有色金属学报, 2015, 25(7): 1815-1821.

YING Liang, DAI Ming-hua, HU Ping, YAN Qiao-yun. Thermal constitutive model and numerical simulation of hot forming for 6061-T6 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(7): 1815-1821.

[5] LI D X, YANG X Q, CUI L, HE F Z, ZHANG X. Investigation of stationary shoulder friction stir welding of aluminum alloy 7075-T651[J]. Journal of Materials Processing Technology, 2015, 222: 391-398.

[6] LEE H, PARK S, KANG C. Effect of plasma current on surface defects of plasma-MIG welding in cryogenic aluminum alloys[J]. Journal of Materials Processing Technology, 2015, 223: 203-215.

[7] MAZAR A M, MA J, LIU W, KOVACEVIC R. Hybrid laser/arc welding of advanced high strength steel to aluminum alloy by using structural transition insert[J]. Materials and Design, 2015, 75: 120-135.

[8] CHANG S Y, TSAO L C, LI T Y, CHUANG T H. Joining 6061 aluminum alloy with Al-Si-Cu filler metals[J]. Journal of Alloys and Compounds, 2009, 488(1): 174-180.

[9] TSAO L C, TSAI T C, WU C S, CHUANG T H. Brazeability of the 6061-T6 aluminum alloy with Al-Si-20Cu-based filler metals[J]. Journal of Materials Engineering and Performance, 2001, 10(6): 705-709.

[10] ZHANG G W, BAO Y F, JIANG Y F, ZHU H. Microstructure and mechanical properties of 6063 aluminum alloy brazed joints with Al-Si-Cu-Ni-RE filler metal[J]. Journal of Materials Engineering and Performance, 2011, 20(8): 1451-1456.

[11] NAZERI M F M, AFFENDY M G, MOHAMAD A A. Corrosion study of Sn-9Zn lead-free solder in alkaline solution[J]. International Journal of Electrochemical Science, 2012, 7(5): 4182-4191.

[12] WANG S S, CHENG M D, TSAO L C, CHUANG T H. Corrosion behavior of Al-Si-Cu-(Sn, Zn) brazing filler metals[J]. Materials Characterization, 2001, 47(5): 401-409.

[13] XIA C, LI Y, PUCHKOV U A, GERASIMOV S A, WANG J. Microstructure and phase constitution near the interface of Cu/Al vacuum brazing using Al-Si filler metal[J]. Vacuum, 2008, 82(8): 799-804.

[14] YANG J L, XUE S B, XUE P,  , DAI W, ZHANG J X. Development of novel CsF-RbF-AlF3 flux for brazing aluminum to stainless steel with Zn-Al filler metal[J]. Materials and Design, 2014, 64: 110-115.

, DAI W, ZHANG J X. Development of novel CsF-RbF-AlF3 flux for brazing aluminum to stainless steel with Zn-Al filler metal[J]. Materials and Design, 2014, 64: 110-115.

[15] CHEN S H, LI L Q, CHEN Y B, LIU D J. Si diffusion behavior during laser welding-brazing of Al alloy and Ti alloy with Al-12Si filler wire[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(1): 64-70.

[16] MICHALSKI J, WEJRZANOWSKI T, GIERLOTKA S, BIELINSKI J, KONOPKA K, KOSMAC T, KURZYDLOWSKI K. The preparation and structural characterization of Al2O3/Ni-P composites with an interpenetrating network[J]. Journal of the European Ceramic Society, 2007, 27(2/3): 831-836.

[17] HAYES F H, LONGBOTTOM R D, AHMAD E, CHEN G. On the Al-Si, Al-Ge, and Al-Ge-Si systems and their application to brazing in high power semiconductor devices[J]. Journal of Phase Equilibria, 1993, 14(4): 425-431.

[18] HE P, LIU Y Z, LIU D. Interfacial microstructure and forming mechanism of brazing Cf/Al composite with Al-Si filler[J]. Materials Science and Engineering A, 2006, 422(1/2): 333-338.

[19] 张启运, 庄鸿寿. 钎焊手册[M]. 北京: 机械工业出版社, 2008.

ZHANG Qi-yun, ZHUANG Hong-shou. Brazing and soldering manual[M]. Beijing: China Machine Press, 2008.

[20] 潘春旭, DUSAN P, SEKULIC D P. AA4343/AA3003铝合金薄板钎焊接头的显微组织特征[J]. 中国有色金属学报, 2002, 12(3): 481-485.

PAN Chun-xu, DUSAN P, SEKULIC D P. Microstructural characteristics of AA4343/AA3003 Al-alloy sheet brazed joints[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(3): 481-485.

[21] WANG A, ZHANG L, XIE J. Effects of cerium and phosphorus on microstructures and properties of hypereutectic Al-21%Si alloy[J]. Journal of Rare Earths, 2013, 31(5): 522-525.

[22] 张启运, 刘淑祺, 樊晓红. Al-Si共晶合金变质机理的探讨[J]. 金属学报, 1982, 18(5): 581-585.

ZHANG Qi-yun, LIU Shu-qi, FAN Xiao-hong. The modification of Si phase in Al-Si eutectic alloys[J]. Acta Metallurgica Sinica, 1982, 18(5): 581-585.

[23] 张启运, 刘淑祺. 高温铝钎料的选择及其与母材的相互作用[J]. 金属学报, 1981, 17(3): 300-306.

ZHANG Qi-yun, LIU Shu-qi. Selection of filler metal for aluminum brazing and its reaction with base metal[J]. Acta Metallurgica Sinica, 1981, 17(3): 300-306.

[24] OUYANG Z Y, MAO X M, HONG M. Multiplex modification with rare earth elements and P for hypereutectic Al-Si alloys[J]. Journal of Shanghai University, 2007, 11(4): 400-402.

[25] KAUR P, DWIVEDI D K, PATHAK P M. Effects of electromagnetic stirring and rare earth compounds on the microstructure and mechanical properties of hypereutectic Al-Si alloys[J]. The International Journal of Advanced Manufacturing Technology, 2012, 63(1): 415-420.

[26] YAN F, XU D, WU S C, SUN Q D, WANG C M, WANG Y J. Microstructure and phase constitution near the interface of Cu/3003 torch brazing using Al-Si-La-Sr filler[J]. Journal of Mechanical Science and Technology, 2012, 26(12): 4089.

[27] ZHANG Y H, XIAO Y Z, MA H S. Effect of trace Sc on recrystallization of industrial pure aluminum[J]. The Chinese Journal of Nonferrous Metals, 1998, 8(1): 85-88.

[28] LI Q L, XIA T D, LAN Y F, LI P F, FAN L. Effects of rare earth Er addition on microstructure and mechanical properties of hypereutectic Al–20% Si alloy[J]. Materials Science and Engineering A, 2013, 588: 97-102.

[29] MONDOLFO L F. Aluminum alloys: Structure and properties[M]. London: Butter Worths, 1976: 513.

[30] 张启运, 郑朝贵, 韩万书. 稀土元素对Al-Si共晶合金的变质作用[J]. 金属学报, 1981, 17(2): 130-136.

ZHANG Qi-yun, ZHENG Cao-gui, HAN Wan-shu. The modification of Al-Si eutectic alloys with rare-earth elements [J]. Acta Metallurgica Sinica, 1981, 17(2): 130-136.

[31] 郑朝贵, 姚连克, 张启运. 冷却速度和变质剂添加浓度对Al-Si共晶合金变质作用的影响[J]. 金属学报, 1982, 18(6): 661-670.

ZHENG Cao-gui, YAO Lian-ke, ZHANG Qi-yun. Effects of cooling rate and modifier concentration on modification of Al-Si eutectic alloys[J]. Acta Metallurgica Sinica, 1982, 18(6): 661-670.

[32] ZHANG G F, SU W, ZHANG J X, SUZUMURA A. Development of Al-12Si-xTi system active ternary filler metals for Al metal matrix composites[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(3): 596-603.

[33] ZUO M, LIU X F, DAI H S, LIU X J. Al-Si-P master alloy and its modification and refinement performance on Al-Si alloys[J]. Rare Metals, 2009, 28(4): 412-417.

[34] HEGDE S, PRABHU K N. Modification of eutectic silicon in Al-Si alloys[J]. Journal of Materials Science, 2008, 43(9): 3009-3027.

[35] AL-HELAL K, STONE I C, FAN Z. Simultaneous primary si refinement and eutectic modification in hypereutectic Al-Si alloys[J]. Transactions of the Indian Institute of Metals, 2012, 65(6): 663-667.

[36]  J. The precipitation strengthening of directionally solidified Al-Si-Cu alloys[J]. Materials Science and Engineering A, 1997, 234: 169-172.

J. The precipitation strengthening of directionally solidified Al-Si-Cu alloys[J]. Materials Science and Engineering A, 1997, 234: 169-172.

[37] 虞觉奇, 易文质. 二元合金状态图集[M]. 上海: 上海科学技术出版社, 1994.

YU Jue-qi, YI Wen-zhi. Binary alloy phase-diagrams[M]. Shanghai: Shanghai Scientific & Technical Publishers, 1994.

[38] 虞觉奇, 陈明安, 高香山. 快速凝固Al-Si基钎料性能的研究[J]. 焊接学报, 1994, 15(2): 67-74.

YU Jue-qi, CHEN Ming-an, GAO Xiang-shan. Properties of rapidly solidified Al-Si base filler alloys[J]. Transactions of the China Welding Institution, 1994, 15(2): 67-74.

[39] CHEN Y S, CHEN T J, ZHANG S Q, LI P B. Effects of processing parameters on microstructure and mechanical properties of powder-thixoforged 6061 aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(3): 699-712.

[40] CHUANG T H, TSAO L C, TSAI T C, YEH M S, WU C S. Development of a low-melting-point filler metal for brazing aluminum alloys[J]. Metallurgical and Materials Transactions A, 2000, 31(9): 2239-2245.

[41] 于文花, 朱 颖, 康 慧, 曲 平, 胡 刚. 合金元素Cu, Si, Ni对Al基钎料的影响[J]. 焊接技术, 2003, 32(2): 33-35.

YU Wen-hua, ZHU Ying, KANG Hui, QU Ping, HU Gang. Influence of alloy element Cu,Si,Ni on the performance of Al-base filler metal[J]. Welding Technology, 2003, 32(2): 33-35.

[42] HUMPSTON G, SANGHA S P S, JACOBSON D M. New filler metals and process for fluxless brazing of aluminium engineering alloys[J]. Materials Science and Technology, 1995, 11(11): 1161-1168.

[43] LUO W, WANG L T, WANG Q M, GONG H L, YAN M. A new filler metal with low contents of Cu for high strength aluminum alloy brazed joints[J]. Materials and Design, 2014, 63: 263-269.

[44] 邹家生, 罗新锋, 赵宏权. Al-Si-Cu-Zn钎料性能研究[J]. 焊接技术, 2007, 36(1): 50-52.

ZOU Jia-sheng, LUO Xin-feng, ZHAO Hong-quan. Study on properties of Al-Si-Cu-Zn filler metals[J]. Welding Technology, 2007, 36(1): 50-52.

[45] HU Z, YAN H, RAO Y S. Effects of samarium addition on microstructure and mechanical properties of as-cast Al-Si-Cu alloy[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(11): 3228-3234.

[46] 孙力力, 李 宁, 颜家振, 苑 博. Al-Si-Cu-Ce钎料钎焊的铝合 金/不锈钢接头的组织与性能[J]. 焊接, 2013(12): 47-50.

SUN Li-li, LI Ning, YAN Jia-zhen, YUAN Bo. Microstructure and property of Al-Si-Cu-Ce filler metal for brazing aluminum alloy/stainless steel[J]. Welding and Joining, 2013(12): 47-50.

[47] KENEL C, LEINENBACH C. Influence of cooling rate on microstructure formation during rapid solidification of binary TiAl alloys[J]. Journal of Alloys and Compounds, 2015, 637: 242-247.

[48] HAKIMI O, AGHION E, GOLDMAN J. Improved stress corrosion cracking resistance of a novel biodegradable EW62 magnesium alloy by rapid solidification, in simulated electrolytes[J]. Material Science and Engineering C, 2015, 51: 226-232.

[49] MCKEOWN J T, KULOVITS A K, LIU C, ZWEIACKER K, REED B W, LAGRANGE T, WIEZOREK J K, CAMPBELL G H. In situ transmission electron microscopy of crystal growth-mode transitions during rapid solidification of a hypoeutectic Al-Cu alloy[J]. Acta Materialia, 2014, 65: 56-68.

[50] 曹金山, 路文江, 俞伟元, 刘安华, 张凌云. A1-Si-Cu-Zn-Sn快速凝固薄带钎料的制备及其性能研究[J]. 热加工工艺, 2009, 38(11): 34-35.

CAO Jin-shan, LU Wen-jiang, YU Wei-yuan, LIU An-hua, ZHANG Ling-yun. Preparation and its property research of Al-Si-Cu-Zn-Sn brazing foils by rapid solidification[J]. Hot Working Technology, 2009, 38(11): 34-35.

[51] 张福礼, 李晓延, 王志升, 刘海霞. 新型Al-Si-Cu-Ge系钎料研究[J]. 电子工艺技术, 2005, 26(2): 68-70.

ZHANG Fu-li, LI Xiao-yan, WANG Zhi-sheng, LIU Hai-xia. Study of new-type Al-Si-Cu-Ge series filler metals [J]. Electronics Process Technology, 2005, 26(2): 68-70.

[52] CHANG S Y, TSAO L C, LEI Y H, MAO S M, HUANG C H. Brazing of 6061 aluminum alloy/Ti-6Al-4V using Al-Si-Cu-Ge filler metals[J]. Journal of Materials Processing Technology, 2012, 212(1): 8-14.

[53] 张启运, 刘淑祺. 高温铝钎料的选择及其与母材的相互作用[J]. 金属学报, 1981, 17(3): 300-306.

ZHANG Qi-yun, LIU Shu-qi. Selection of filler metal for aluminum brazing and its reaction with base metal[J]. Acta Metallurgica Sinica, 1981, 17(3): 300-306.

[54] 刘淑祺, 孙国平, 张启运. Al-Si-Ge三元合金相图的研究[J]. 金属学报, 1982, 18(4): 451-455.

LIU Shu-qi, SUN Guo-ping, ZHANG Qi-yun. The phase diagram of system Al-Si-Ge[J]. Acta Metallurgica Sinica, 1982, 18(4): 451-455.

[55] KAYAMOTO T, KIM J H, SAITO S, ONZAWA T. Brazing of Al-Mg alloy and Al-Mg-Si alloy with Al-Ge based filler metals[J]. Proceedings of Workshop of the Japanese Welding Society, 1994, 12: 495-501.

[56] KAYAMOTO T, ONZAWA T. The study of Al-Ge-Si-Mg filler metals[J]. Light Metal Dissolution, 1995, 33(10): 20-24.

[57] SCHUBERT T H, LOSER W, TERESIAK A, MATTERN N, BAUER H D. Preparation and phase transformations of melt-spun Al-Ge-Si brazing foils[J]. Journal of Materials Science, 1997, 32(8): 2181-2189.

[58] SUZUKI K, KAGAYAMA M, TAKEUCHI Y. Eutectic phase equilbrium of Al-Si-Zn system and its applicability for lower temperature brazing[J]. Light Metal, 1993, 43(10): 533-538.

[59] DAI W, XUE S B, LOU J Y, WANG S Q. Microstructure and properties of 6061 aluminum alloy brazing joint with Al Si Zn filler metal[J]. Materials Transactions, 2012, 53(9): 1638-1643.

[60] 张 帅, 薛松柏, 杨金龙, 娄 江, 王水庆. P元素对Al-Si-Zn钎料显微组织及性能的影响[J]. 焊接学报, 2013, 34(5): 103-107.

ZHANG Shuai, XUE Song-bai, YANG Jin-long, LOU Jiang, WANG Shui-qing. Effects of P element on microstructure and properties of Al-Si-Zn filler metal[J]. Transactions of the China Welding Institution, 2013, 34(5): 103-107.

[61] 刘相法, 乔进国, 刘玉先, 李士同, 边秀房. Al-P中间合金对共晶和过共晶Al-Si合金的变质机制[J]. 金属学报, 2004, 40(5): 471-476.

LIU Xiang-fa, QIAO Jin-guo, LIU Yu-xian, LI Shi-tong, BIAN Xiu-fang. Modification performance of the Al-P master alloy for eutectic and hypereutectic Al-Si alloys[J]. Acta Metallurgica Sinica, 2004, 40(5): 471-476.

[62] DAI W, XUE S B, JI F, LOU J, SUN B, WANG S Q. Brazing 6061 aluminum alloy with Al-Si-Zn filler metals containing Sr[J]. International Journal of Minerals, Metallurgy, and Materials, 2013, 20(4): 365-370.

[63] DAI W, XUE S B, SUN B, LOU J, WANG S Q. Study on microstructure of 6061 aluminum alloy brazed with Al-Si-Zn filler metals bearing Sr and Ti[J]. Rare Metal Materials and Engineering, 2013, 42(12): 2442-2446.

[64] WANG S H, ZHOU H P, KANG Y P. The influence of rare earth elements on microstructures and properties of 6061 aluminum alloy vacuum-brazed joints[J]. Journal of Alloys and Compounds, 2003, 352(1/2): 79-83.

[65] 俞伟元, 路文江, 陈学定, 王艳红. 快速凝固Al-Zn-Si基钎料性能的研究[J]. 兰州理工大学学报, 2004, 30(6): 13-15.

YU Wei-yuan, LU Wen-jiang, CHEN Xue-ding, WANG Yan-hong. Investigation of characteristics of rapidly solidified brazing ribbon of Al-Zn-Si based alloy[J]. Journal of Lanzhou University of Technology, 2004, 30(6): 13-15.

[66] 刘树英, 张 垒, 张 鑫, 闫焉服, 曹聪聪, 铃村晓男. 铝合金/不锈钢钎焊用Al-Si-Zn急冷钎料的制备方法[P]. 2012-06-20.

LIU Shu-ying, ZHANG Lei, ZHANG Xin, YAN Yan-fu, CAO Cong-cong, SUZUMURA A. Preparation of rapidly solidified filler metal of Al-Si-Zn for brazing aluminum alloy/stainless steel[P]. 2012-06-20.

[67] UEYAMA D, SAITOH Y, ISHIKAWA N, OHMURA T, SEMBOSHI S, HORI F, IWASE A. Hardness modification of Al-Mg-Si alloy by using energetic ion beam irradiation[J]. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms, 2015, 351: 1-5.

[68] RAO P N, KAURWAR A, SINGH D, JAYAGANTHAN R. Enhancement in strength and ductility of Al-Mg-Si alloy by cryorolling followed by warm rolling[J]. Procedia Engineering, 2014, 75: 123-128.

[69] PATAKHAM U, LIMMANEEVICHITR C. Effects of iron on intermetallic compound formation in scandium modified Al-Si-Mg alloys[J]. Journal of Alloys and Compounds, 2014, 616: 198.

[70] 李培森. 真空钎焊[M]. 北京: 国防工业出版社, 1985.

LI Pei-sen. Vacuum brazing[M]. Beijing: National Defence of Industry Press, 1985.

[71] SOHN W H, BONG H H, HONG S H. Microstructure and bonding mechanism of Al/Ti bonded joint using Al-10Si-1Mg filler metal[J]. Materials Science and Engineering A, 2003, 355(1/2): 231-240.

[72] 张丽霞, 孟德强, 亓钧雷, 郑文龙, 冯吉才. 5005铝合金与4J34可伐合金的真空钎焊工艺[J]. 中国有色金属学报, 2015, 25(6): 1435-1440.

ZHANG Li-xia, MENG De-qiang, QI Jun-lei, ZHENG Wen-long, FENG Ji-cai. Process of vacuum brazing 5005 aluminum alloy to 4J34 Kovar alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(6): 1435-1440.

[73] 刘淑祺, 赵世民, 张启运. Al-Cu-Ag三元合金体系相图[J]. 金属学报, 1983, 19(2): 114-117.

LIU Shu-qi, ZHAO Shi-min, ZHANG Qi-yun. Note on the phase diagram of Al-Cu-Ag system[J]. Acta Metallurgica Sinica, 1983, 19(2): 114-117.

[74] RAGHAVAN V. Ag-Al-Cu (silver-aluminum-copper)[J]. Journal of Phase Equilibria and Diffusion, 2008, 29(3): 256-258.

[75] 薛松柏, 董 健, 吕晓春, 钱乙余. LYl2铝合金中温钎焊技术[J]. 焊接学报, 2003, 24(3): 21-22.

XUE Song-bai, DONG Jian, LV Xiao-chun, QIAN Yi-yu. Brazing technology of LY12 Al-alloy at middle temperature[J]. Transactions of the China Welding Institution, 2003, 24(3): 21-22.

[76] VILARINHO C, SOARES D, CASTRO F. Phase equilibria of the Al-Cu-Zn system for compositions close to brass alloys[J]. Journal of Phase Equilibria, 2003, 24(3): 236-239.

[77] FANG H C, CHAO H, CHEN K H. Effect of Zr, Er and Cr additions on microstructures and properties of Al-Zn-Mg-Cu alloys[J]. Materials Science and Engineering A, 2014, 610: 10-16.

[78] LI L, ZHOU T T, LI H X, CHEN C Q, QING X B, SHI L K. Effect of additional elements on aging behavior of Al-Zn-Mg-Cu alloys by spray forming[J]. Transactions of Nonferrous Metals Society of China, 2006, 16(3): 532-538.

Current research status and prospect of brazing filler metals for aluminum and aluminum alloys

NIU Zhi-wei, HUANG Ji-hua, XU Fang-zhao, LIU Kai-kai, CHEN Shu-hai, ZHAO Xing-ke

(School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: Owing to the excellent properties, aluminum and aluminum alloys are playing an increasingly important role in modern industrial materials. Brazing is used widely as an excellent assembly method for the bonding of aluminum components. The development of brazing filler metals for aluminum and aluminum alloys is a hotspot into which all countries competitively research. However, the factors of high melting temperature, poor processability and low joint strength make the brazing alloys application difficulty, and commercial brazing filler metals are few. The addition of alloying elements can reduce the melting temperature and improve the microstructure and properties of filler metals, which is an effective method for the development of brazing filler metal. Based on the development of brazing filler metals for aluminum and aluminum alloys at home and abroad, the effects of alloying elements on the melting temperature, processability, joint microstructure and properties of brazing filler metals were summaried. The present problems in their research process of brazing filler metal for aluminum and aluminum alloys were reviewed, and some proposals were put forward which may provide a guide for the study of aluminum-based brazing alloy.

Key words: aluminum alloy; brazing filler metal; processability; brazed joint

Foundation item: Project (2010A080402014) supported by Guangdong Provincial Science and Technology, China

Received date: 2015-06-09; Accepted data: 2015-09-14

Corresponding author: HUANG Ji-hua; Tel: +86-10-62334859; E-mail: hjihua62@sina.com

(编辑 李艳红)

基金项目:广东省科技计划资助项目(2010A080402014)

收稿日期:2015-06-09;修订日期:2015-09-14

通信作者:黄继华,教授,博士;电话:010-62334859;E-mail:hjihua62@sina.com

摘 要:铝及铝合金以其优良的特性,在当代工业材料中占有越来越重要的地位。钎焊作为一种可靠连接铝及铝合金结构件的连接方法而被广泛应用。铝及铝合金钎焊用硬钎料的开发一直是国内外学者争相研究的热点,然而,钎料合金熔化温度高、加工成形性差、钎焊接头强度低等因素严重制约着钎料合金的开发应用,实现商业化的钎料甚少。添加合金元素能够降低钎料熔化温度,改善钎料显微组织和性能,这对铝钎焊用硬钎料的发展是一个行之有效的方法。结合国内外对铝及铝合金钎焊用硬钎料的最新研究成果,全面阐述合金元素的添加对钎料熔化温度、加工成形性及钎焊接头组织性能的影响,指明铝及其合金钎焊用硬钎料目前研究中存在的问题及今后的研究方向。

[4] 盈 亮, 戴明华, 胡 平, 闫巧云. 6061-T6铝合金高温本构模型及温成形数值模拟[J]. 中国有色金属学报, 2015, 25(7): 1815-1821.

[19] 张启运, 庄鸿寿. 钎焊手册[M]. 北京: 机械工业出版社, 2008.

ZHANG Qi-yun, ZHUANG Hong-shou. Brazing and soldering manual[M]. Beijing: China Machine Press, 2008.

[20] 潘春旭, DUSAN P, SEKULIC D P. AA4343/AA3003铝合金薄板钎焊接头的显微组织特征[J]. 中国有色金属学报, 2002, 12(3): 481-485.

[22] 张启运, 刘淑祺, 樊晓红. Al-Si共晶合金变质机理的探讨[J]. 金属学报, 1982, 18(5): 581-585.

[23] 张启运, 刘淑祺. 高温铝钎料的选择及其与母材的相互作用[J]. 金属学报, 1981, 17(3): 300-306.

[29] MONDOLFO L F. Aluminum alloys: Structure and properties[M]. London: Butter Worths, 1976: 513.

[30] 张启运, 郑朝贵, 韩万书. 稀土元素对Al-Si共晶合金的变质作用[J]. 金属学报, 1981, 17(2): 130-136.

[31] 郑朝贵, 姚连克, 张启运. 冷却速度和变质剂添加浓度对Al-Si共晶合金变质作用的影响[J]. 金属学报, 1982, 18(6): 661-670.

[37] 虞觉奇, 易文质. 二元合金状态图集[M]. 上海: 上海科学技术出版社, 1994.

[38] 虞觉奇, 陈明安, 高香山. 快速凝固Al-Si基钎料性能的研究[J]. 焊接学报, 1994, 15(2): 67-74.

[41] 于文花, 朱 颖, 康 慧, 曲 平, 胡 刚. 合金元素Cu, Si, Ni对Al基钎料的影响[J]. 焊接技术, 2003, 32(2): 33-35.

[44] 邹家生, 罗新锋, 赵宏权. Al-Si-Cu-Zn钎料性能研究[J]. 焊接技术, 2007, 36(1): 50-52.

[46] 孙力力, 李 宁, 颜家振, 苑 博. Al-Si-Cu-Ce钎料钎焊的铝合 金/不锈钢接头的组织与性能[J]. 焊接, 2013(12): 47-50.

[50] 曹金山, 路文江, 俞伟元, 刘安华, 张凌云. A1-Si-Cu-Zn-Sn快速凝固薄带钎料的制备及其性能研究[J]. 热加工工艺, 2009, 38(11): 34-35.

[51] 张福礼, 李晓延, 王志升, 刘海霞. 新型Al-Si-Cu-Ge系钎料研究[J]. 电子工艺技术, 2005, 26(2): 68-70.

[53] 张启运, 刘淑祺. 高温铝钎料的选择及其与母材的相互作用[J]. 金属学报, 1981, 17(3): 300-306.

[54] 刘淑祺, 孙国平, 张启运. Al-Si-Ge三元合金相图的研究[J]. 金属学报, 1982, 18(4): 451-455.

[60] 张 帅, 薛松柏, 杨金龙, 娄 江, 王水庆. P元素对Al-Si-Zn钎料显微组织及性能的影响[J]. 焊接学报, 2013, 34(5): 103-107.

[61] 刘相法, 乔进国, 刘玉先, 李士同, 边秀房. Al-P中间合金对共晶和过共晶Al-Si合金的变质机制[J]. 金属学报, 2004, 40(5): 471-476.

[65] 俞伟元, 路文江, 陈学定, 王艳红. 快速凝固Al-Zn-Si基钎料性能的研究[J]. 兰州理工大学学报, 2004, 30(6): 13-15.

[66] 刘树英, 张 垒, 张 鑫, 闫焉服, 曹聪聪, 铃村晓男. 铝合金/不锈钢钎焊用Al-Si-Zn急冷钎料的制备方法[P]. 2012-06-20.

[70] 李培森. 真空钎焊[M]. 北京: 国防工业出版社, 1985.

LI Pei-sen. Vacuum brazing[M]. Beijing: National Defence of Industry Press, 1985.

[72] 张丽霞, 孟德强, 亓钧雷, 郑文龙, 冯吉才. 5005铝合金与4J34可伐合金的真空钎焊工艺[J]. 中国有色金属学报, 2015, 25(6): 1435-1440.

[73] 刘淑祺, 赵世民, 张启运. Al-Cu-Ag三元合金体系相图[J]. 金属学报, 1983, 19(2): 114-117.

[75] 薛松柏, 董 健, 吕晓春, 钱乙余. LYl2铝合金中温钎焊技术[J]. 焊接学报, 2003, 24(3): 21-22.