DOI:10.19476/j.ysxb.1004.0609.2019.12.01

微量元素Ge对7020铝合金板材应力腐蚀断裂敏感性的影响

汪 庆1, 2,杨臻珅1, 2,柴文茹1, 2,陈景超1, 2,刘胜胆1, 2, 3,叶凌英1, 2, 4,唐建国1, 2, 4

(1. 中南大学 材料科学与工程学院,长沙410083;

2. 中南大学 有色金属材料科学与工程教育部重点实验室,长沙410083;

3. 中南大学 轻质高强结构材料国防科技重点实验室,长沙 410083;

4. 中南大学 有色金属先进结构材料与制造协同创新中心,长沙 410083)

摘 要:

摘 要:采用慢应变速率拉伸(SSRT)试验、金相显微镜(OM)、扫描电镜(SEM)和透射电镜(TEM)等手段研究了微量元素Ge对7020铝合金板材应力腐蚀断裂敏感性的影响。通过比较不含Ge和含Ge板材中晶内η′强化相尺寸与体积分数的差异分析了合金强度下降的原因;通过比较不含Ge和含Ge板材中晶粒组织和晶界η相的尺寸、间距及化学成分的差异分析了合金应力腐蚀断裂敏感性下降的原因。结果表明:加入Ge元素后,板材SSRT的抗拉强度更低,在NaCl溶液中的强度和伸长率较空气中的下降率也更低,应力腐蚀指数由0.059减小至0.017,应力腐蚀断裂敏感性明显降低。

关键词:

文章编号:1004-0609(2019)-12-2691-09 中图分类号:TG146.2 文献标志码:A

7000系铝合金具有较高的比强度、良好的耐蚀性,被广泛应用在轨道交通和航空航天领域[1-2]。该系合金是典型的可时效强化合金,时效后基体内形成大量细小而弥散的η′强化相,强度大幅度提升[3-4];但同时晶界处会形成η相,其腐蚀电位相对铝基体更低,在腐蚀环境中往往优先溶解,导致腐蚀沿晶扩展[5-6]。在实际服役过程中,应力的作用不可避免,使合金容易出现应力腐蚀开裂(SCC)现象[7-10],严重影响到结构部件的可靠性,缩短使用寿命。

人们一直致力于研究7000系铝合金应力腐蚀断裂机理及影响因素,提出了阳极溶解、氢致开裂等理论[11-12],发现晶界处微观结构和化学成分等对合金应力腐蚀开裂敏感性有着重要的影响。一般而言,晶界处的η相尺寸越大、间距越大,合金的应力腐蚀开裂敏感性越低[9-10];η相中Zn、Mg含量的增加及Cu含量的降低会使得其更活泼,增加合金应力腐蚀开裂敏感性[5-6];较宽的无沉淀析出带(PFZ)往往会导致较大的晶界晶内电势差,导致应力腐蚀开裂敏感性增加[7]。此外,合金的晶粒组织也影响着应力腐蚀性能,当再结晶程度下降、晶粒尺寸减小时,合金应力腐蚀开裂敏感性随之下降[7, 13]。

微合金化是降低7000系铝合金应力腐蚀断裂敏感性的有效途径。例如,DENG等[7]在Al-Zn-Mg合金中复合添加Sc和Zr元素可显著抑制再结晶、细化晶粒,同时晶界PFZ变窄,应力腐蚀开裂敏感性降低;FANG等[14]通过在Al-Zn-Mg-Cu合金中复合添加Yb,Cr和Zr元素后,晶界相分布更加断续,应力腐蚀开裂敏感性降低。最近,LIN等[15-16]发现Ge元素可以抑制Al-Zn-Mg-(Cu)合金在慢速冷却过程中粗大η平衡相的析出,降低合金的淬火敏感性。因此,Ge元素在7000系铝合金中有良好的应用前景。然而,Ge元素对7000系铝合金的应力腐蚀断裂敏感性有着怎样的影响还不清楚。7020铝合金是一种中强7000系铝合金,被广泛应用在高速列车车身结构件中,研究其力学性能、耐腐蚀性能和疲劳性能等对保障列车运行安全有着重大意义[9, 17-19]。因此,本文通过采用慢应变速率拉伸、金相显微镜、扫描电镜和透射电镜等方法研究了Ge元素对7020铝合金应力腐蚀开裂敏感性的影响,以能为进一步提升7020铝合金的综合性能提供参考,并有助于更好地认识Ge元素在7000系铝合金中的微合金化机理。

1 实验

1.1 实验材料

本实验采用高纯铝(99.99%,质量分数)、工业纯镁(99.9%)和工业纯锌(99.9%),及Al-48%Cu、Al-8%Mn、Al-3%Cr、Al-3%Zr和Al-5%Ge中间合金为原料进行熔炼铸造,获得30 mm厚的铸锭,实测化学成分见表1。铸锭均匀化后,经多道次热轧成3 mm厚的板材。板材试样在SX -4-10型箱式电阻炉中进行(470 ℃,1 h)的固溶处理,随后立即在室温水中淬火,最后在120 ℃下进行人工峰时效处理。

1.2 实验方法及条件

按照GB/T 15970.7—2000要求取时效态样品在RW-50型试验机上进行慢应变速率拉伸试验(SSRT),拉伸方向平行于板材轧制方向,应变速率为1×10-6 s-1,试验环境分别为室温空气和室温3.5%NaCl(质量分数)溶液,每个状态测试3个平行试样。试验结束后,采用ZEISS EVO MA10型扫描电镜(SEM)观察试样断口,并使用Oxford X-MaxN型能谱仪(EDS)分析第二相化学成分。

金相试样经水磨、抛光处理后,采用Graff试剂(83 mL H2O+1 mL HF+16 mL HNO3+3 g CrO3)进行浸蚀,然后在Olympus BX51RFX型金相显微镜下观察晶粒组织。采用Tecnai G2 F20型透射电镜(TEM)观察合金晶内微观特征,加速电压为200 kV;采用Titan G2 60- 300型扫描透射电镜(STEM)在高角环形暗场像(HAADF)模式下观察合金晶界处微观特征,采用Super-X型能谱仪检测第二相的化学成分,束斑大小为1 nm,加速电压为300 kV。样品预磨成厚100 μm薄片,冲成直径3 mm的圆片后进行电解双喷减薄,电解液为30% HNO3+70% CH3OH(体积分数),温度控制在-20 ℃以下。

2 实验结果

2.1 慢应变速率拉伸试验结果

图1所示为7020和7020-Ge板材在空气和NaCl溶液中典型的慢应变速率拉伸曲线,抗拉强度和伸长率结果列于表2。由图1可知,无论是7020板材还是7020-Ge板材,NaCl溶液中抗拉强度和伸长率都较空气中的更低,但下降程度不同。7020板材的抗拉强度和伸长率分别下降了3.0%和19.9%;7020-Ge板材的抗拉强度和伸长率分别下降了0.4%和12.4%,下降幅度明显减小(见表2)。此外,加入Ge元素后,板材在空气中抗拉强度由345.1 MPa下降到323.3 MPa,伸长率由12.53%下降到11.73%。这与LIN等[16]的研究结果类似,他们发现在Al-Zn-Mg-Cu合金中加入Ge元素后,合金的室温拉伸抗拉强度和伸长率均下降。

应力腐蚀指数(ISSRT)综合考虑了抗拉强度和伸长率,可更好地用于评价合金应力腐蚀开裂敏感性[9-10],其计算公式为[20]:

(1)

(1)

式中: 为试样在NaCl溶液中的抗拉强度,MPa;

为试样在NaCl溶液中的抗拉强度,MPa; 为试样在NaCl溶液中的伸长率,%;

为试样在NaCl溶液中的伸长率,%; 为试样在空气中的抗拉强度,MPa;

为试样在空气中的抗拉强度,MPa; 为试样在空气中的伸长率,%;ISSRT值从0→1,表明应力腐蚀开裂敏感性不断增加。由表2可知,ISSRT由7020板材的0.059减小至7020-Ge板材的0.017,这表明Ge元素能有效地降低7020铝合金的应力腐蚀开裂敏感性。

为试样在空气中的伸长率,%;ISSRT值从0→1,表明应力腐蚀开裂敏感性不断增加。由表2可知,ISSRT由7020板材的0.059减小至7020-Ge板材的0.017,这表明Ge元素能有效地降低7020铝合金的应力腐蚀开裂敏感性。

2.2 拉伸断口形貌

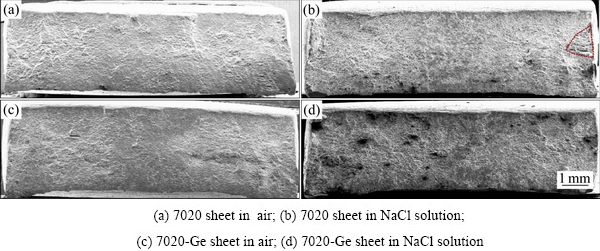

图2所示为7020和7020-Ge板材在空气和NaCl溶液中拉伸断口的低倍SEM像。由图2可知,无论是7020板材还是7020-Ge板材,两种介质中的断口形貌都表现出了较大差异。两种板材在空气中的拉伸断口表面均较干净(见图2(a)和(c)),而NaCl溶液中的断口表面出现了部分黑色腐蚀产物(见图2(b)和(d)),这可能是合金中某些阳极相本身或阴极相周边基体发生了腐蚀溶解所致[10];在7020板材断口的一侧边缘还出现了明显的裂纹(红色虚线区域),这是一种典型的应力腐蚀开裂现象[21],而7020-Ge板材中则无此现象。

表1 实验用合金化学成分

Table 1 Chemical composition of studied alloys

图1 两种时效态板材在不同介质中的慢应变速率拉伸曲线

Fig. 1 SSRT curves of two aged sheets in different media

表2 7020和7020-Ge板材在不同介质中的慢应变速率拉伸试验结果

Table 2 SSRT test results of 7020 and 7020-Ge sheets in different media

图2 两种时效态板材在空气和NaCl溶液中拉伸断口的低倍SEM像

Fig. 2 Low magnification SEM images showing fracture surface morphologies of two aged sheets after SSRT test

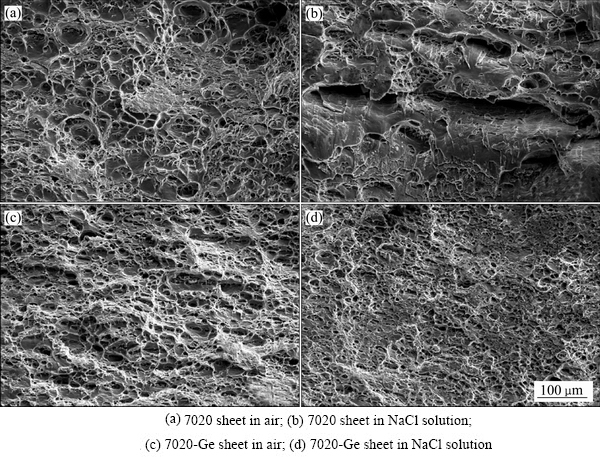

图3所示为7020和7020-Ge板材在空气和NaCl溶液中拉伸断口的典型高倍SEM像。由图3(a)和(b)可知,7020板材在空气中拉伸断口表面被很多大大小小的韧窝覆盖,是典型的穿晶韧断特征,而NaCl溶液中断口表面韧窝数量减少,出现了明显的平滑台阶状特征,呈现出典型的准解理断裂特征,这与伸长率下降的结果一致。由图3(c)和(d)可知,7020-Ge板材在空气和NaCl溶液中的断口表面均被密集的韧窝所覆盖,呈现典型的穿晶韧断特征,但其尺寸和深度相比图3(a)中的均有不同程度的减小,这与表2中的伸长率结果也相一致。

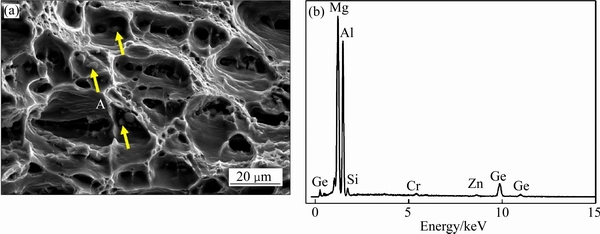

另外发现拉伸断口上有一些韧窝中存在α-Al(FeMn)Si相粒子,这种粗大第二相粒子常常出现在7000系铝合金中[22]。但在7020-Ge板材中还发现了含Ge相粒子,以空气中的断口为例,如图4(a)中黄色箭头所示,它们的尺寸大都在1 μm到8 μm之间。

图3 两种时效态板材在空气和NaCl溶液中拉伸断口的高倍SEM像

Fig. 3 High magnification SEM images of two aged sheets showing fracture surface morphologies of sheets after SSRT test

图4 7020-Ge板材在空气中拉伸断口的SEM像及粒子A的EDS谱

Fig. 4 SEM image showing fracture surface of 7020-Ge sheet after SSRT test(a) and EDS spectrum(b) of particle A

EDS检测结果表明,除Al元素外,它们主要含有Mg元素和Ge元素,含量分别为31.2%~34.8%和15.8%~ 18.6%(摩尔分数),两者的比例约为2:1;图4(b)所示为典型粒子A的EDS谱。据文献[16]可知,这些粒子应该是Mg2Ge相。在铝合金中,Mg2Ge相通常形成于合金凝固过程,具有很高的熔点,在后续热处理过程中不能被消除[16, 23]。

2.3 金相组织

图5所示为7020和7020-Ge板材的金相组织。由图5可知,两种板材中晶粒均沿着轧制方向被拉长而呈纤维状,但发生了部分再结晶,其中白色区域为再结晶晶粒,灰黑色区域为包含着大量亚晶的未再结晶晶粒。使用ImageJ软件对板材的再结晶分数及晶粒尺寸进行分析,得到7020和7020-Ge板材的再结晶分数分别为50.6%和37.8%;再结晶晶粒沿轧向尺寸分别约为42.6 μm和26.1 μm,沿法向尺寸分别约为13.6 μm和11.2 μm。这些结果表明,Ge元素的加入降低了再结晶分数,细化了再结晶晶粒。另外,还能观察到一些黑色的第二相粒子,大都位于再结晶晶粒中,这表明发生了粒子激发形核(PSN)的再结晶机制[24]。7020-Ge板材中黑色第二相粒子数量较7020板材更多,因此可以看到更多的再结晶晶粒(见图5(b))。

图5 两种时效态板材的金相组织

Fig. 5 Optical micrograph of two aged sheets

2.4 透射电镜照片

图6所示为时效态7020和7020-Ge板材晶粒内部的TEM明场像及相应的 选区衍射花样(SADP)。由图6可知,两种板材中合金晶粒内部均分布着细小弥散的第二相,呈现出针状或近球状形貌,在1/3和2/3{220}Al处存在明显的衍射斑点,表明其为强化相η′相[3, 17]。η′相的尺寸差别不大,但数量在加入Ge元素后明显下降。选取多张照片使用ImageJ Pro软件对η′相的尺寸和体积分数进行统计,其中体积分数通过McCall-Boyd公式[25]获得:

选区衍射花样(SADP)。由图6可知,两种板材中合金晶粒内部均分布着细小弥散的第二相,呈现出针状或近球状形貌,在1/3和2/3{220}Al处存在明显的衍射斑点,表明其为强化相η′相[3, 17]。η′相的尺寸差别不大,但数量在加入Ge元素后明显下降。选取多张照片使用ImageJ Pro软件对η′相的尺寸和体积分数进行统计,其中体积分数通过McCall-Boyd公式[25]获得:

(2)

(2)

式中:N为观察面积内析出物粒子数;Dmean为平均析出粒子直径;A为观察面积。7020和7020-Ge板材中η′相的尺寸分别为(6.05±0.43) nm和(5.97±0.36) nm,体积分数分别为(24.9±2.1)%和(15.7±1.5)%,可见Ge元素可以抑制7020铝合金中η′相的形成,但对其尺寸影响很小。

7000系铝合金在时效过程中的析出序列一般为:过饱和固溶体→ GP区→η′亚稳相→ η平衡相[26-27]。

LIN等[15]认为Ge元素能在淬火过程捕捉大量空位,使基体中可动空位浓度降低。因此,在时效初期,Ge元素的存在能降低Zn、Mg等溶质原子的扩散速率,抑制GP区的形成,从而减少了η′相数量。另外,7020-Ge板材中Mg2Ge相的形成(见图4)会消耗一部分Mg原子,也会减少η′相的数量。众所周知,η′相的数量越多,尺寸越小,强化效果越好[3, 4, 28]。因此,7020-Ge板材在空气中的抗拉强度较7020合金板材更低(见表2)。

图6 两种时效态板材沿 方向的晶内明场TEM像及对应的选区衍射花样

方向的晶内明场TEM像及对应的选区衍射花样

Fig. 6 Bright field TEM images and corresponding  SADP of two aged sheets

SADP of two aged sheets

图7 两种时效态板材的晶界处HAADF-STEM像

Fig. 7 HAADF-STEM images showing precipitates and PFZ at grain boundary of two aged sheets

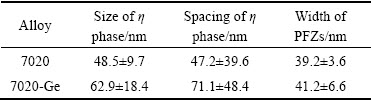

图7所示为时效态7020和7020-Ge板材晶界处典型的HAADF-STEM像。两种板材中晶界处均有大量η相粒子,但7020板材中η相的尺寸和间距更小。为了更好地比较两种板材中晶界处组织特征,对多个晶界上η相的尺寸、间距、化学成分以及PFZ宽度进行统计,结果如表3和4所示。7020板材中η相的尺寸约为48.5 nm,间距约为47.2 nm;加入Ge元素后,η相的尺寸增加到约62.9 nm,间距增加到约71.1 nm,PFZ宽度变化不大。由表4可知,加入Ge元素后,η相中Zn、Mg含量几乎增加一倍,但两者的比例均约为2:1;Cu含量略有下降。ZHAO等[29]在最近的研究中认为,晶界η相的形成经历了时效初期的形核和时效中后期的长大两个过程。在时效初期,晶界周边基体中的Zn、Mg和Cu溶质原子会偏析至晶界,并在晶界上形核成为GP区,这个过程主要是靠大量淬火空位的迁移支撑。然而,在7020-Ge板材中,Ge原子能钉扎淬火空位,减少了可动空位的数量[15],从而抑制晶界相的形核,减少了晶界相数量;在时效中后期,这些晶界相可以吸收更多的溶质原子,最终尺寸更大,Zn、Mg含量更高。在7020板材中,晶界偏析过程中原子扩散无Ge元素的影响,晶界相能大量形核,最终数量更多,而Zn、Mg含量更低,尺寸更小。

表3 两种时效态板材的晶界η相尺寸、间距以及PFZ宽度统计

Table 3 Average size, spacing of η phase at grain boundaries and width of PFZs in two aged sheets

表4 两种时效态板材晶界η相的化学成分

Table 4 Chemical composition of η phase at grain boundaries in two aged sheets

在两种板材中还能看到一些尺寸为50~300 nm的白色第二相粒子,如图7中白色箭头所示,EDS检测结果表明一些粒子中除了Al元素外,主要含有Mn、Si和Fe元素,含量分别为:3.9%~7.2%、1.3%~4.9%和1.2%~2.9%(摩尔分数,下同);另外一些粒子除了Al元素外,主要含有Mn和Cr元素,含量分别为2.7%~4.4%和1.2%~3.1%。这些结果不同于EIVANI等[30]对AA7020铝合金中弥散相的研究结果,但这些粒子似乎不受Ge元素的影响,但因其结构和成分的复杂性还需要进一步的研究。它们在7000系铝合金中通常起到抑制再结晶的作用[30-31],因而两个板材都发生了部分再结晶(见图5)。

3 讨论

在腐蚀介质和外力的共同作用下,7000系铝合金材料常常会发生应力腐蚀断裂。外力的作用可使表面氧化膜破裂,暴露出的新鲜金属会发生腐蚀。晶界处η相在合金中一般充当阳极相,而优先溶解,在外力作用下容易萌生腐蚀微裂纹,并沿晶界扩展导致试样提前断裂。因此,7020和7020-Ge两种板材在NaCl溶液中的强度和伸长率较空气中更低。虽然η相中的化学成分对其电化学腐蚀有着复杂的影响,但一般而言,Zn、Mg元素含量升高及Cu元素含量降低会让η相变得更活泼而容易被腐蚀[5,6]。根据表4可知,加入Ge元素后,η相中Zn、Mg元素含量明显升高;因此7020-Ge板材暴露在NaCl溶液中时,η相更容易溶解,微裂纹也更容易萌生。

大量研究表明[9-10, 32],晶界处更大、更断续的η相能更有效地阻断阳极溶解通道,延缓腐蚀进程;同时,粗大的η相容易成为氢原子陷阱,氢原子在其表面富集后形成氢分子逸出,从而降低晶界处氢含量,抑制氢脆发生[7-8]。根据表2和3可知,加入Ge元素后,η相的尺寸和间距均明显增大,因此抑制腐蚀裂纹扩展的能力更强,最终抵消并超过了Zn、Mg元素含量增加所带来的不利影响,体现在抗拉强度和伸长率的下降率均明显减小,ISSRT值明显降低,应力腐蚀开裂敏感性明显下降。另外,SONG等[11]发现晶界处更高的自由Mg原子浓度会促进Mg-H复合体的形成,从而增强晶界对H原子的吸收,使得合金应力腐蚀断裂敏感性增加。在7020-Ge板材中,晶界η相中Mg含量明显增加,这是其长大过程中大量消耗周边自由Mg原子的结果,因此Ge元素的加入会抑制Mg-H复合体的形成,从而降低合金应力腐蚀开裂敏感性。

另一方面,合金的晶粒组织对应力腐蚀断裂敏感性也有着重要的影响。TSAI等[13]指出在慢应变速率拉伸过程中,晶粒细化可以导致更均匀的滑移,从而降低合金应力腐蚀开裂敏感性。另外,当合金再结晶分数下降时,亚晶数量增多,而亚晶界具有更好的抗晶间腐蚀能力[7, 14],使合金更倾向于发生穿晶韧断,降低沿晶断裂的可能性。由图5可知,7020-Ge板材中再结晶分数明显下降,晶粒尺寸也明显减小,这也有利于降低合金应力腐蚀开裂敏感性。

4 结论

1) 7020和7020-Ge板材在NaCl溶液中慢应变速率拉伸较在空气中的抗拉强度和伸长率均降低,但7020-Ge板材强度和伸长率的下降率明显更低。加入Ge元素后,ISSRT值由0.059减小至0.017,板材的应力腐蚀断裂敏感性明显下降。

2) 加入Ge元素后,7020铝合金板材再结晶分数降低,再结晶晶粒尺寸明显减小;晶粒内部η′强化相尺寸变化不大,但体积分数明显下降;晶界η相中的Zn、Mg元素含量增加,同时尺寸和间距也明显增加。

3) 晶界η相尺寸和间距的增加能有效阻碍腐蚀裂纹沿晶扩展,这种作用能抵消并超过η相中Zn、Mg元素含量升高所带来的不利影响;再结晶分数的下降和晶粒细化也有利于降低板材应力腐蚀断裂敏感性。

REFERENCES

[1] DURSUN T, SOUTIS C. Recent developments in advanced aircraft aluminium alloys[J]. Materials and Design, 2014, 56: 862-871.

[2] 张新明, 刘胜胆. 航空铝合金及其材料加工[J]. 中国材料进展, 2013, 32(1): 39-55.

ZHANG Xin-ming, LIU Sheng-dan. Aerocraft aluminum alloys and their materials processing[J]. Material China, 2013, 32(1): 39-55.

[3] YANG W, JI S, ZHANG Q, WANG M. Investigation of mechanical and corrosion properties of an Al-Zn-Mg-Cu alloy under various ageing conditions and interface analysis of η′ precipitate[J]. Materials and Design, 2015, 85: 752-761.

[4] 刘俊涛, 张永安, 李锡武, 李志辉, 熊柏青, 张济山. 新型7056铝合金双级时效的显微组织和性能[J]. 中国有色金属学报, 2016, 26(9): 1850-1857.

LIU Jun-tao, ZHANG Yong-an, LI Xi-wu, LI Zhi-hui, XIONG Bai-qing, ZHANG Ji-shan. Microstructure and properties of two-step aged novel 7056 aluminum alloy [J]. The Chinese Journal of Nonferrous Metals, 2016, 26(9): 1850-1857.

[5] LIU S D, CHEN B, LI C B, DAI Y, DENG Y L, ZHANG X M. Mechanism of low exfoliation corrosion resistance due to slow quenching in high strength aluminium alloy[J]. Corrosion Science, 2015, 91: 203-212.

[6] KNIGHT S P, BIRBILIS N, MUDDLE B C, TRUEMAN A R, LYNCH S P. Correlations between intergranular stress corrosion cracking, grain-boundary microchemistry, and grain-boundary electrochemistry for Al-Zn-Mg-Cu alloys[J]. Corrosion Science, 2010, 52(12): 4073-4080.

[7] DENG Y, YIN Z, ZHAO K, DUAN J, HU J, HE Z. Effects of Sc and Zr microalloying additions and aging time at 120 ℃ on the corrosion behaviour of an Al-Zn-Mg alloy[J]. Corrosion Science, 2012, 65: 288-298.

[8] SHI Y, PAN Q, LI M, HUANAG X, LI B. Influence of alloyed Sc and Zr, and heat treatment on microstructures and stress corrosion cracking of Al-Zn-Mg-Cu alloys[J]. Materials Science and Engineering A, 2015, 621: 173-181.

[9] 杨 涛, 叶凌英, 单朝军, 王绍玲, 邓运来, 张新明. 预时效工艺对7020铝合金显微组织和应力腐蚀性能的影响[J]. 中国有色金属学报, 2016, 26(5): 947-956.

YANG Tao, YE Ling-ying, SHAN Zhao-jun, WANG Shao-ling, DENG Yun-lai, ZHANG Xin-ming. Effect of pre-aging on microstructure and stress corrosion resistance of 7020 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(5): 947-956.

[10] 钱鹏伟, 邓运来, 张 臻, 赵 龙, 唐鸿远, 叶凌英. 自然时效对Al-Zn-Mg合金型材抗应力腐蚀性能的影响[J]. 中国有色金属学报, 2017, 27(8): 1542-1550.

QIAN Peng-wei, DENG Yun-lai, ZHANG Zhen, ZHAO Long, TANG Hong-yuan, YE Ling-ying. Effect of natural aging time on stress corrosion cracking of aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(8): 1542-1550.

[11] SONG R G, DIETZEL W, ZHANG B J, LIU W J, TSENG M K, ATRENS A. Stress corrosion cracking and hydrogen embrittlement of an Al-Zn-Mg-Cu alloy[J]. Acta Materialia, 2004, 52(16): 4727-4743.

[12] 李安敏, 王 晖, 郭长青, 陈 烨, 于 多. 7xxx系铝合金应力腐蚀的控制[J]. 材料导报, 2015, 29(17): 84-88.

LI An-min, WANG Hui, GUO Chang-qing, CHEN Ye, YU Duo. Control on stress corrosion of 7xxx aluminum alloys[J]. Materials Review, 2015, 29(17): 84-88.

[13] TSAI T C, CHUANG T H. Role of grain size on the stress corrosion cracking of 7475 aluminium alloys[J]. Materials Science and Engineering A, 1997, 225(1): 135-144.

[14] FANG H C, CHEN K H, Chen X, CHAO H, PENG G S. Effect of Cr, Yb and Zr additions on localized corrosion of Al-Zn-Mg-Cu alloy[J]. Corrosion Science, 2009, 51(12): 2872-2877.

[15] LIN L, LIU Z, BAI S, YING P, WANG X. Effects of germanium on quench sensitivity in Al-Zn-Mg-Zr alloy[J]. Materials and Design, 2015, 86: 679-685.

[16] LIN L, LIU Z, BAI S, ZHOU Y, LIU W, Lü Q. Effects of Ge and Ag additions on quench sensitivity and mechanical properties of an Al-Zn-Mg-Cu alloy[J]. Materials Science and Engineering A, 2017, 682: 640-647.

[17] 王 勇, 唐建国, 邓运来, 林化强, 单朝军, 张 勇, 刘胜胆, 叶凌英. 时效状态对7020铝合金疲劳性能的影响[J]. 中南大学学报(自然科学版), 2018, 49(11): 2684-2691.

WANG Yong, TANG Jian-guo, DENG Yun-lai, LIN Hua-qiang, SHAN Zhao-jun, ZHANG Yong, LIU Sheng-dan, YE Ling-ying. Effect of aging conditions on fatigue behavior of 7020 aluminum alloy[J]. Journal of Central South University (Science and Technology), 2018, 49(11): 2684-2691.

[18] 刘蛟蛟, 李红英, 汤 玥, 熊 亮. 连续冷却对7020合金组织与性能的影响[J]. 中国有色金属学报, 2018, 28(5): 897-906.

LIU Jiao-jiao, LI Hong-ying, TANG Yue, XIONG Liang. Effect of continuous cooling on microstructures and properties of 7020 alloy[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(5): 897-906.

[19] 陈向荣, 郑子樵. 7020铝合金搅拌摩擦焊接接头微观组织和力学性能[J]. 粉末冶金材料科学与工程, 2018, 23(2): 172-179.

CHEN Xiang-rong, ZHENG Zi-qiao. Microstructure and mechanical properties of the friction stir welded joint of 7020 aluminum alloy[J]. Materials Science and Engineering of Powder Metallurgy, 2018, 23(2): 172-179.

[20] HB 7235—1995. 慢应变速率应力腐蚀试验方法[S].

HB7235—1995. Standard practice for slow strain rate testing to evaluate stress corrosion cracking susceptibility[S].

[21] PENG X, GUO Q, LIANG X, DENG Y, Gu Y, Xu G, YIN Z. Mechanical properties, corrosion behavior and microstructures of a non-isothermal ageing treated Al-Zn-Mg-Cu alloy[J]. Materials Science and Engineering A, 2017, 688: 146-154.

[22] 戴 芸, 刘胜胆, 邓运来, 张新明. 7020铝合金在3.5%NaCl溶液中的点蚀行为[J]. 中国腐蚀与防护学报, 2017(3): 279-286.

DAI Yun, LIU Sheng-dan, DENG Yun-lai, ZHANG Xin-ming. Pitting corrosion of 7020 aluminum alloy in 3.5%NaCl solution[J]. Journal of Chinese Society for Corrosion and Protection, 2017(3): 279-286.

[23] GAZIZOV M, TELESHOV V, ZAKHAROV V, KAIBISHEV R. Solidification behaviour and the effects of homogenisation on the structure of an Al-Cu-Mg-Ag-Sc alloy[J]. Journal of Alloys and Compounds, 2011, 509(39): 9497-9507.

[24] LIU S D, YUAN Y B, LI C B, YOU J H, ZHANG X M. Influence of cooling rate after homogenization on microstructure and mechanical properties of aluminum alloy 7050[J]. Metals and Materials International, 2012, 18(4): 679-683.

[25] PELLISSIER G E, PURDY S M. Stereology and quantitative metallography[C]// A Symposium Presented at the Seventy-fourth Annual Meeting. Atlantic City, NJ: American Society for Testing and Materials, 1972.

[26] 张 勇, 李红萍, 康 唯, 张新明. 高强铝合金时效微结构演变与性能调控[J]. 中国有色金属学报, 2017, 27(7): 1323-1336.

ZHANG Yong, LI Hong-ping, KANG Wei, ZHANG Xin-ming. Aging microstructure evolution in high strength aluminum alloys and performance controlling, The Chinese Journal of Nonferrous Metals, 2017, 27(7): 1323-1336.

[27] LI H, LIU J, YU W, ZHAO H, LI D. Microstructure evolution of Al-Zn-Mg-Cu alloy during non-linear cooling process[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(5): 1191-1200.

[28] 杨 涛, 叶凌英, 刘胜胆, 单朝军, 王国玮, 陈 敏, 邓运来, 张新明. 预时效对7020铝合金组织与性能的影响[J]. 中南大学学报(自然科学版), 2017, 48(3): 578-584.

YANG Tao, YE Ling-ying, LIU Sheng-dan, WANG Guo-wei, CHEN Min, DENG Yun-lai, ZHANG Xin-ming. Effects of pre-aging on microstructures and mechanical properties of 7020 aluminum alloy, Journal of Central South University (Science and Technology), 2017, 48(3): 578-584.

[29] ZHAO H, DE GEUSER F, DA SILVA A K, Szczepaniak A, GAULT B, PONGE D, RAABE D. Segregation assisted grain boundary precipitation in a model Al-Zn-Mg-Cu alloy[J]. Acta Materialia, 2018, 156: 318-329.

[30] EIVANI A R, AHMED H, ZHOU J, DUSZCZYK J. Correlation between electrical resistivity, particle dissolution, precipitation of dispersoids, and recrystallization behavior of AA7020 aluminum alloy[J]. Metallurgical and Materials Transactions, 2009, 40(10): 2435-2446.

[31] OGURA T, OTANI T, HIROSE A, SATO T. Improvement of strength and ductility of an Al-Zn-Mg alloy by controlling grain size and precipitate microstructure with Mn and Ag addition[J]. Materials Science and Engineering A, 2013, 580: 288-293.

[32] 谢 娟, 孟立春, 陈江华, 杨修波, 刘吉梓, 刘春辉. Al-Zn-Mg-Cu合金的局部腐蚀行为与Zn、Mg含量的关系[J]. 中国有色金属学报, 2017, 27(12): 2473-2482.

XIE Juan, MENG Li-chun, CHEN Jiang-hua, YANG Xiu-bo, LIU Ji-zi, LIU Chun-hui. Behavior of localized corrosion of Al-Zn-Mg-Cu alloys in relation with their Zn and Mg contents[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(12): 2473-2482.

Effect of minor Ge on stress corrosion cracking susceptibility of 7020 aluminium alloy sheet

WANG Qing1, 2, YANG Zhen-shen1, 2, CHAI Wen-ru1, 2, CHEN Jing-chao1, 2, LIU Sheng-dan1, 2, 3, YE Ling-ying1, 2, 4, TANG Jian-guo1, 2, 4

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Metal Materials Science and Engineering, Ministry of Education, Central South University, Changsha 410083, China;

3. The National Key Laboratory of Science and Technology for National Defence on High-strength Lightweight Structural Materials, Central South University, Changsha 410083, China;

4. Nonferrous Metal Oriented Advanced Structural Materials and Manufacturing Cooperative Innovation Center, Central South University, Changsha 410083, China)

Abstract: The effect of minor Ge on susceptibility to stress corrosion cracking (SCC) of 7020 aluminium alloy sheet was investigated by slow strain rate tensile (SSRT) test, optical microscopy (OM), scanning electron microscopy (SEM) and transmission electron microscopy (TEM). The reason for the decreased strength of 7020-Ge sheet was discussed according to the change of the size and volume fraction of η′ strengthening phase inside grains, and the reason for the decreased SCC susceptibility was discussed according to the change of grain structure, and the size, spacing, chemical compositions of η phase at grain boundaries caused by Ge addition. The results show that, after the introduction of Ge, the ultimate strength of sheets subjected to SSRT test decreases; moreover, the decrement of strength and elongation in NaCl solution compared with air decreases, and ISSRT decreases from 0.059 to 0.017, indicating significantly decreased SCC susceptibility.

Key words: 7020 aluminium alloy; Ge; Stress corrosion cracking; microstructure

Foundation item: Project(2016YFB0300901) supported by the National Key Research and Development Program of China; Project(2016GK1004) supported by the Key Project of Science and Technology of Hunan Province; Project(20130603) supported by the Shenghua Yuying Project of Central South University; Project(2016A1001) supported by Municipal Key Research and Development Program of Zhongshan

Received date: 2018-12-14; Accepted date: 2019-03-22

Corresponding author: LIU Sheng-dan; Tel: 0731-88830265; E-mail: lsd_csu@csu.edu.cn

(编辑 何学锋)

基金项目:国家重点研发计划资助项目(2016YFB0300901);湖南省重大科技专项(2016GK1004);中南大学升华育英计划资助项目(20130603);中山市科技计划资助项目(2016A1001)

收稿日期:2018-12-14;修订日期:2019-03-22

通信作者:刘胜胆,教授,博士;电话:0731-88830265;E-mail:lsd_csu@csu.edu.cn

[2] 张新明, 刘胜胆. 航空铝合金及其材料加工[J]. 中国材料进展, 2013, 32(1): 39-55.

[4] 刘俊涛, 张永安, 李锡武, 李志辉, 熊柏青, 张济山. 新型7056铝合金双级时效的显微组织和性能[J]. 中国有色金属学报, 2016, 26(9): 1850-1857.

[9] 杨 涛, 叶凌英, 单朝军, 王绍玲, 邓运来, 张新明. 预时效工艺对7020铝合金显微组织和应力腐蚀性能的影响[J]. 中国有色金属学报, 2016, 26(5): 947-956.

[10] 钱鹏伟, 邓运来, 张 臻, 赵 龙, 唐鸿远, 叶凌英. 自然时效对Al-Zn-Mg合金型材抗应力腐蚀性能的影响[J]. 中国有色金属学报, 2017, 27(8): 1542-1550.

[12] 李安敏, 王 晖, 郭长青, 陈 烨, 于 多. 7xxx系铝合金应力腐蚀的控制[J]. 材料导报, 2015, 29(17): 84-88.

[18] 刘蛟蛟, 李红英, 汤 玥, 熊 亮. 连续冷却对7020合金组织与性能的影响[J]. 中国有色金属学报, 2018, 28(5): 897-906.

[19] 陈向荣, 郑子樵. 7020铝合金搅拌摩擦焊接接头微观组织和力学性能[J]. 粉末冶金材料科学与工程, 2018, 23(2): 172-179.

[20] HB 7235—1995. 慢应变速率应力腐蚀试验方法[S].

[22] 戴 芸, 刘胜胆, 邓运来, 张新明. 7020铝合金在3.5%NaCl溶液中的点蚀行为[J]. 中国腐蚀与防护学报, 2017(3): 279-286.

[26] 张 勇, 李红萍, 康 唯, 张新明. 高强铝合金时效微结构演变与性能调控[J]. 中国有色金属学报, 2017, 27(7): 1323-1336.