DOI:10.19476/j.ysxb.1004.0609.2017.08.15

金/钯基贵金属钎料研究进展

方继恒,谢 明,张吉明,田娟娟,陈静洪,胡洁琼

(昆明贵金属研究所 稀贵金属综合利用新技术国家重点实验室,昆明 650106)

摘 要:

贵金属钎料在电子工业、微电子封装、真空多级钎焊、高温技术、饰品制造业及航空航天等诸多领域占据重要地位,金/钯基贵金属钎料的研发及应用一直是国内外研究的热点。详细介绍工业生产、军工及民用等领域中常用的低/中/高温金基钎料,电子工业分级钎焊用、高温耐热型和具备特殊性能的钯基钎料,总结各个系列钎料特点、钎焊性能及用途,并简单概述银基钎料特性。综合评述贵金属钎料发展和应用中出现的加工性能差、经济成本高、含致毒污染元素、焊点可靠性不理想及模拟基础数据库匮乏等问题,从制备工艺、微合金化、添加强化相、匹配助焊剂和钎料计算机模拟等方面展望贵金属钎料未来发展趋势,并从中寻求对现存问题的解决措施,为贵金属钎料的开发、应用及推广提供基础支撑。

关键词:

文章编号:1004-0609(2017)-08-1659-11 中图分类号:TD923 文献标志码:A

20世纪40年代以后,随着电子、航空、航天等高新技术的出现,银基钎接材料的品种和功能得以日新月异的发展。金、钯钎料的开发和应用较银钎料晚,而铂、铱、铑、钌等作为钎料合金化元素应用还较少,所以贵金属钎料按其组元来分,主要有金基钎料、银基钎料和钯基钎料,其产品形态为片、丝、带、棒、箔、膏状、粉末及预先成形的框和环件等。国内外钎料系列中的贵金属钎料多达近千种之多,钎料熔化温度250~1600 ℃,能满足高性能、高稳定、高可靠及高寿命等各种工艺要求。其中银基钎料型号系列最丰富、用途最广泛,特别是在电子工业、电真空器件和分级钎焊用的硬钎料多为银基钎料[1-3],据统计,我国每年银基钎料的消耗量仅用在化工、机械、军工、电子等领域就达200 t以上[4-5]。在异种材料高强度连接和高温条件下具有特殊性能的钎料多为金基和钯基钎料,贵金属钎料不仅在电子、航空和航天领域应用广泛,在化工、石油、机械、核能、轻工业领域中,贵金属钎料也占有重要地位[6-10]。贵金属钎料项目更是被列入“十三五”规划重点项目之一。

国内外学者对贵金属钎料进行了大量理论与实验研究:卢方焱等[11]介绍了Ag-Cu-Zn系钎料的发展历史过程和研究现状,并认为以Ag-Cu-Zn为主要合金体系,适当添加Ga、Sn、In、Ni及稀土等元素而形成的Ag-Cu-Zn-Ga-In-RE-X钎料可能会成为未来的发展方向。尹立孟等[12]阐述了无铅低银钎料的研究与发展现状,同时分析了其应用情况,并对该钎料及其可靠性的发展趋势进行了分析和展望。COLLINS等[13]将Sb、Bi和Ni添加到高银无铅焊料中,改善了界面金属间化合物层的韧性,并通过固溶强化弥补了强度损失,使钎料具备较强的抗热及抗机械载荷性能,从而开发出新的第三代无铅银基钎料。崔大田等[14]采用单辊旋淬法制备Au-19.25Ag-12.80Ge钎料薄带,其液相线温度比钎料母合金的有所降低,熔化温度区间缩小了约4 ℃,单辊旋淬工艺使钎料薄带显微组织分布均匀且显著细化,并且钎料与Ni基体表面润湿优良,形成了可靠的冶金结合界面。谢元锋等[15]为研究Pd基钎料钎焊SiC陶瓷与其他材料的接合机制,研究了PdAgMn+Ti钎料对SiC陶瓷的润湿规律,发现元素Ti显著影响钎料对SiC陶瓷的润湿性,PdAgMn+Ti能够润湿SiC陶瓷,并与SiC陶瓷形成冶金结合。

综上所述,当前银基钎料研究应用体系较成熟,相关文献、专利及著作较多,而金/钯基钎料领域由于起步较晚,其研究还不够全面深入,缺乏对其综合性评述,其研究领域需进一步拓展加深。因此,本文作者对工业生产、军工及民用等领域中涉及到的常用金基钎料和钯基钎料进行分类介绍,并详细总结各个系列钎料的特点、性能及用途,同时简单概述银基钎料特性。综合评述目前国内外贵金属基钎料研究发展中存在的问题,并对贵金属钎料发展趋势进行展望。

1 金基钎料

金基合金钎料主要特点为:1) 优良的耐腐蚀和抗氧化性能;2) 低蒸气压,熔点温度的蒸汽压为1×10-6~1×10-7Pa;3) 良好的流散性、浸润性及高温稳定性;4) 焊接接头优异的物理与力学性能。它的缺点是成本高、密度大。金基钎料可焊接Cu、Ni、Mo、石墨、不锈钢和可伐合金等[16],主要有低温共晶型和高温固溶体型,其中软钎料主要用于微电子器件装配工艺,硬钎料则主要用于真空器件、航空发动机等重要零部件连接、电子工业多级钎焊及饰品制造业[17-18]。金基钎料根据熔点温度及实用性可细分为:低温金基钎料(400 ℃以下)、中温金基钎料(400~600 ℃)、高温金基钎料(600 ℃以上)。

1.1 金基低温钎料

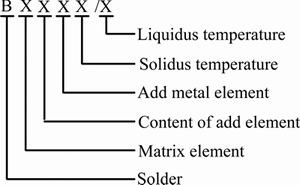

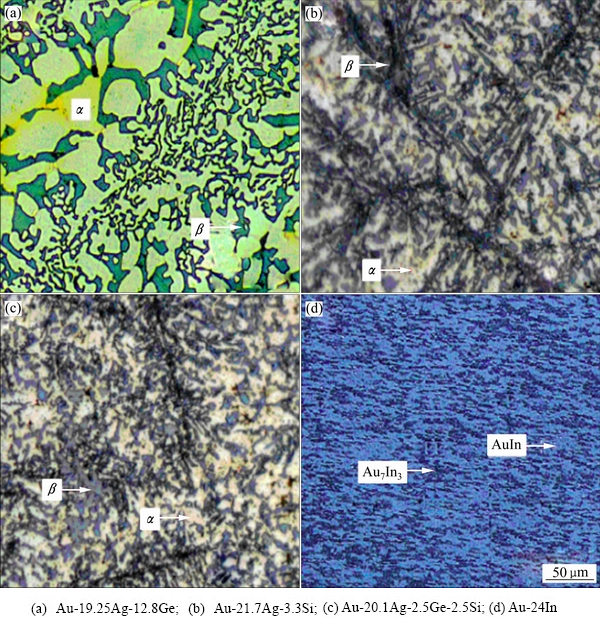

金基低温钎料由Au与 Sn、Ge、Si、Sb、In 等元素形成低熔点共晶合金,熔点在270~400 ℃之间,尽管从熔点考虑其应用范围受到很大的限制,但由于该系列钎料具有低粘性、耐腐蚀、优异的抗疲劳和蠕变性能、导热和导电性好、易焊接、无需助焊剂等诸多优点,广泛应用于光电子器件和微电子器件的芯片贴装、陶瓷封装封盖、大功率半导体激光器芯片的焊接以及金属封装的陶瓷绝缘子焊接中[19-20]。常用的金基低温钎料如表1所列,表1中钎料牌号表示方法如图1所示,部分金基低温钎料的显微组织如图2所示[21]。

图1 钎料牌号表示方法

Fig. 1 Method for expressing brand of solder

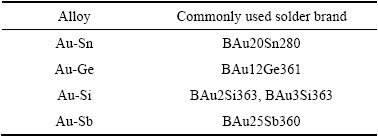

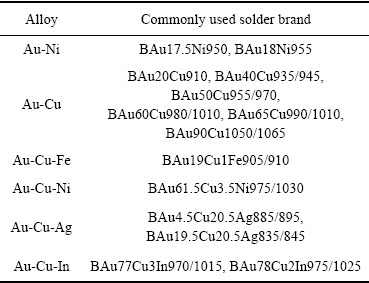

表1 常用金基低温钎料

Table 1 Commonly used Au-based low temperature solders

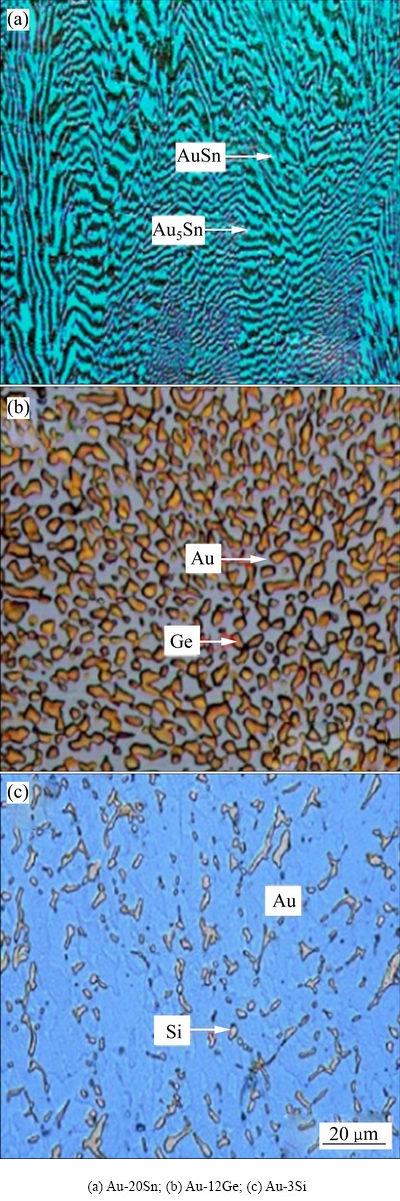

图2 金基低温钎料合金的显微组织[21]

Fig. 2 Microstructures of Au-based low temperature solder alloys[21]

Au-20Sn的钎焊温度适中,仅比熔点高20~30 ℃,无需助焊剂,可避免光学界面污染,液态Au-20Sn合金具有很低的粘滞性,可填充一些很大的空隙。同时,Au-20Sn是熔点在270~360 ℃内唯一可以替代高熔点铅基合金的焊料,在微波封装、射频和气密性封装、倒装芯片(Flip-Ship)、发光二极管(LED)等方面广泛应用[22-23]。不足之处在于其显微组织由镁型密排六方结构ζ相(Au5Sn)和δ相(AuSn)两种脆性金属间化合物组成,如图2(a)所示,导致钎料脆性大,伸长率小,可采用多层叠轧+扩散合金化技术克服难加工问题生产箔带材及其深加工产品[24]。

Au-12Ge钎焊温度为380~400 ℃,其接触面的电阻远远小于半导体的电阻,因此,常用作制备半导体芯片过程中形成欧姆接触的衔接材料,AuGe的热膨胀系数(10.3×10-6 ℃-1)比同样用作电子封装的AuSn(16×10-6 ℃-1)和AuSi(13×10-6 ℃-1)都低,能更好地与相互连接的硅元件特性匹配[25]。室温下,Ge在Au中的固溶度≤0.1%(质量分数),而Au在Ge中实际不固溶,因此,该合金固态是由富Au固溶体和脆性相纯Ge组成的共晶体,由于AuGe很难加工成片材,一般采用均匀化+热轧工艺制备0.04~0.3 mm AuGe箔材[26]。

Au-Si系在微波等混合集成电路的芯片装配中广泛应用,同时备受高可靠器件封装的青睐,在硅芯片与基体之间形成共晶焊合时,其共晶体的Si成分即为预键合材料硅本身,这降低了键合工艺难度,AuSi钎料与铜和镍基体均有良好的润湿性,但合金本身塑性差,因为其显微组织为富Au固溶体和脆性相纯Si[27]。

Au-Sb在焊接接头要求良好耐蚀性和导电性的半导体钎接中应用广泛,微量锑可大大降低熔点,而合金良好的塑性、耐蚀性和导电性不变,其中Au-25Sb因360 ℃的低熔点而广泛应用作低温钎料[28]。

1.2 金基中温钎料

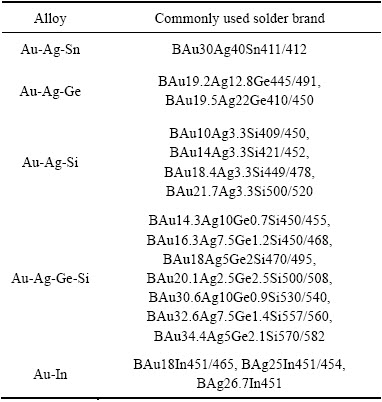

在微电子器件装配工艺中,随着大功率器件和高温半导体新材料的应用,单位面积芯片产生的热量急剧增加,现有的低温共晶型金基钎料不再满足封装工艺技术要求,熔化温度在400~600 ℃的中温金基钎料更加适应钎焊部件工作环境而广泛应用,中温金基钎料主要分为Au-Ag系和Au-In系两类。常用的金基中温钎料如表2所列,部分金基中温钎料合金的显微组织如图2所示。

Sn、Si、Ge组元添加至Au-Ag基合金中形成中温金基钎料。1) Au-30Ag-40Sn的熔化区间为411~412 ℃,固液相线的温度间隔非常小,保证了钎料在母材上优良的间隙填充性和漫流性,但合金含有NiAs结构的δ相(AuSn)和正交结构的ε相(AuSn2)两种脆性中间化合物;2) Au-Ag-Ge系的熔点在450~500 ℃之间,Au-Ag-Si系熔点在450~520 ℃之间,金银硅系合金的熔点在所选定的合金成分范围内随Ag含量的增加而升高[29],Ge和Si是同一主族元素,性质相似,Au-Ag-Ge系与Au-Ag-Si系钎料也存在许多相似处,许多航空电子器材采用密度较低的材料,如表面镀Ni的铝材,而这两个系列钎料与Ni浸润良好,具有一定的加工性,满足该类材料电子器件的封装焊接要求,但在焊接界面处形成一条不均匀的Ni3Si或Ge3Ni5金属间化合物过渡层,Ni3Si和Ge3Ni5晶体结构对称性较低显脆性,将会降低焊接的可靠性,故应控制焊接工艺以获得连续均匀且厚度适当的金属间化合物层[30]。此外,合金均由初晶α相和共晶β相组成共晶组织,其中β相(富Si相或富Ge相)为脆性相,使合金塑性降低,难加工,通常采用先包覆Al热轧再进行冷轧结合中间退火的工艺制得0. 1 mm的钎料薄带[31];3) Au-Ag-Ge-Si系钎料也具有优良的钎焊特性、满足熔化温度要求,且形成α+β共晶组织,但由于Ge和Si的同时加入,共晶组织显著细化,使合金具有一定的塑性,改善了合金力学性能[32]。

表2 常用金基中温钎料

Table 2 Commonly used Au-based medium temperature solders

图2 金基中温钎料合金的显微组织[21]

Fig. 2 Microstructures of Au-based medium temperature solder alloys[21]

Au-In系熔点在450~500 ℃,在Ar或H2等保护气氛下,钎焊温度为500~550 ℃的Au-In系钎料对金、银、镍、无氧铜或表面覆有这些金属镀层的母材有优良钎焊特性。由Au-In二元相图可知,当In的含量为19%~27%(质量分数)时,金铟合金的液相线温度为450~500 ℃,且固-液相线温度间隔小,特别是In含量在24%~27%时,固-液相温度间隔为0~3 ℃,属于共晶型或接近共晶型合金,在钎焊工艺中,固-液相线温度间隔小的钎料合金可提高钎料在紧密构件母材上的间隙填充性和漫流性,从而提高接头综合质量,增强钎焊器件工作稳定性和可靠性。但是合金由三斜结构的β相(AuIn)和立方结构的立方结构的γ相(Au7In3)两种金属间化合物组成,如图2(d)所示,合金脆性大,可采用多层叠加轧制的方法制备钎料箔带材[33]。

1.3 金基高温钎料

金基高温钎料熔点在800 ℃以上,钎料件接头在高温工作坏境下仍然具备高性能和高可靠性,广泛应用于卫星、导弹、飞机发动机及陶瓷件连接中[34-35],Au-Ni系和Au-Cu系为两个典型高温金基系列。常用的金基高温钎料如表3所列。

表3 常用金基高温钎料

Table 3 Commonly used Au-based high temperature solders

Au-Ni二元相图为典型的匀晶相图,金与镍形成无限固溶体,往金里面加入适量镍可以降低合金熔点,Au-Ni系钎料中应用最广的为Au-18Ni和Au-17.5Ni,当Ni含量为17.5%时,合金熔点最低(950 ℃),两种钎料固液相线温度几乎一致,属于理想的共晶钎料,熔化冷却后不易发生成分偏析,其耐蚀性和高温抗蠕变性能优异,焊接接头强度高,并拥有良好的流布性和润湿性能,广泛应用于飞机、卫星和导弹的制造中[36],缺点是加工性能差,成材率低。此外,金镍钎料中还有镍含量为16%、25%、35%、55%的4种钎料,但目前市场应用很少。

Au-Cu相图仍然为匀晶相图,金和铜形成连续固溶体,不同Cu含量的金铜合金的固液相线间隔都很小,所以按照不同含量配比可以得到不同熔点的共晶或类共晶钎料,但随着含铜量的增加,钎料耐蚀性有所降低。Au-20Cu是Au-Cu系列中应用最广泛的钎料,其熔点为910 ℃,对Cu、Fe、Co、Ni、W、Mo、Ta、Nb等金属及其合金都有良好的润湿性[37],它与母材不发生化学反应,因此不会降低工件的强度及尺寸精度,但合金由高温冷却至400 ℃以下时会产生脆性有序相,会引起焊接接头体积变化,且对压力加工造成困难,可通过添加小于1%的Fe来防止有序化的产生[38]。此外,Au-20Cu、Au-40Cu与Au-Ag-Cu构成梯度焊料,广泛用于电真空器件的分级钎焊,如波导管、大功率多注速调管等。Au-50Cu和Au-65Cu可用于金属与陶瓷间的连接,是典型的瓷封钎料,同时它还可以代替Ag-28Cu作为能量输出窗的焊接材料,避免银蒸气挥发对输出窗片的污染,以及金基钎料优良的流散性使输出窗能量输出特性更佳[39]。

在Au-Cu钎料中添加少量的Ni,合金熔点升高,其润湿性能、焊接强度比Au-Cu钎料更优异,通常作为电真空器件的第一级钎料[40]。向其中添加少量Ag时,合金熔点降低,Au-Cu-Ag系列的熔点在780~950 ℃,介于Ag-28Cu与Au-17.5Ni的熔点之间,常作为电子管用的中间一级钎料[41]。改变银铜比例可调节合金外观颜色,因此可用于装饰品钎焊。加入1%~10%的In,可降低Au-Cu钎料的使用成本,如Au-77Cu-3In钎料熔点为1015 ℃,其塑性好、蒸汽压和使用成本低,可用来替代Au-65Cu钎料,但该合金还未产业化[42]。

2 钯基钎料

含钯或以钯为基的合金钎料称为钯基钎料,其主要特点为:1) 不腐蚀母材、不发生晶间浸蚀、适用于细小工件、薄件的钎焊,钎后无应力破裂;2) 与母材钎焊中不生成脆性化合物相,产生可塑性接头,且钎料本身有优良的可塑性,可加工成细丝或薄片;3) 钎料优异的润湿性和漫流性使其具有宽广的间隙填充性,从而使耗费的钎料量降低,并允许钎件加工时有宽余的公差;4) 多数钯系钎料蒸汽压低,适合真空钎焊或真空中应用器件的钎焊。按其用途分类,钯基钎料可分为电子工业分级钎焊用钎料、高温耐热型钎料和具备特殊性能的钎料三类。

2.1 电子工业分级钎焊用钎料

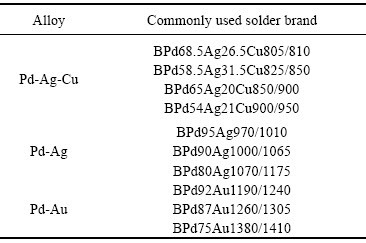

由相图分析可知:Pd-Ag和Pd-Au均形成连续固溶体,各成分合金固液相线的温度间隔很小,多种成分合金可形成较宽温度区间系列钎料,熔化温度区间在800~1420 ℃的Pd-Ag-Cu系、Pd-Ag系和Pd-Au系为典型的多级钎焊用钎料[43],如表4所列,它们均有良好的钎焊工艺性能、耐蚀性和塑性,但硬度和强度不高,不适于用作高强度钎焊接头的钎料,通过时效处理可提高其硬度。

表4 常用分级钎焊用钯基钎料

Table 4 Commonly used Pd-based solders for grade brazing

2.2 高温耐热型钎料

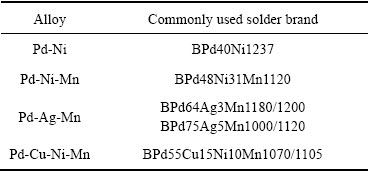

高温耐热钎料要求有良好的高温强度和抗蠕变特性,一般用来钎焊高温工作零件,合金通常含Ni、Mn元素,以熔点在1000~1237 ℃的Pd-Ni、Pd-Ni-Mn、Pd-Ag-Mn和Pd-Cu-Ni-Mn为代表,详见表5,其工作温度可达650~850 ℃,主要用于金属与石墨、陶瓷的衔接、钎焊Mo、Ti、W、Zr、Nb等高温金属及合金、焊接表面容易形成致密氧化膜的含Ti、Cr合金以及燃气涡轮机叶片,广泛涉及航空航天、冶金、化工、核能等工业的高温技术中[44-45]。其中Pd-Ni-Mn钎料还可抵抗钠和钠钾共晶浸蚀,但Mn易氧化,含Mn钎料适于在保护气氛(氢、氩及混合型气体)或真空条件下钎焊[46]。

表5 常用高温耐热型钯基钎料

Table 5 Commonly used Pd based high temperature heat- resistant solders

2.3 具备特殊性能的钎料

近年来,有关特殊用途的钯系钎料专利报道很多,例如Pd-0.2Ga-6In-0.3Ag-7Zn-86.4Sn钎料具有高洁净度、低熔点的特点,作为钎料用于锌合金钎焊时,具有润湿性强、有助于减少气孔、沙眼、夹杂等钎焊缺陷,钎缝强度高等特点[47];Pd-0.7Nb-5Ni-3.5Co- 1.5Mn-73.3Ag多元合金钎料在氢气、氩气及真空环境下钎焊不锈钢、镍基、铁基和钴基高温合金的接头强度高,钎缝接头室温抗拉强度达400~600 MPa,同时,钎焊接头有较高的高温强度,600 ℃时,钎缝接头抗拉强度仍达到220~260 MPa[48];不同含量配比的钯镍系合金也具有特殊钎焊特性[49]:Pd-5Ni抗晦暗能力强、色泽美丽,适合钎焊饰品钎料,本身也是很好的首饰原材料;Pd-68Ni-9Ti的熔、流点极其接近Pd-40Ni的,适合作金属陶瓷-金属,金属陶瓷-金属陶瓷的钎接材料;Pd-20Ni抗有机污染能力强、电腐蚀速率小,可焊接电接触材料;此外,Pd-7.5Cu-5.5In-84.6Ag-0.2Li钎料热导性较低[50];Pd-Si-Ni-Cr钎料可用在高温条件下的石墨材料,并获得坚固连接;Pd-Ni-Si钎料以粉末或铸条形态使用,在1130~1150 ℃温度下钎焊耐蚀钢及镍合金,可获得耐蚀及所要求的强度[51];Pd-Ag-Cu-Ni钎料可衔接X光管上的铍窗、磁控管及孟乃尔合金(Ni-Fe-Mn)支架[52];在Pd-Au-Cr-Ni钎料中添加难熔金属和稀有金属Y,可确保接头在870~982 ℃时工作400 h的高强度和抗氧化性[50]。

3 银基钎料

银基钎料是目前应用最广泛的硬钎料,具有适宜的熔点、良好的润湿性和流散性、优良的工艺性能,且钎料和钎缝的强度、耐蚀性和导电性优良。银钎料对绝大部分金属材料均具有很好的润湿性,可用于钎焊不锈钢、低碳钢、可伐合金、高温合金、难熔合金、铜及铜合金等,特别适用于航空发动机以及电子真空器件等重要零件的钎焊,所以在航空、电子等工业中得到广泛的应用。目前,600~1100 ℃熔点范围内的钎料仍以银基钎料为主,其温度跨度大,能适用于很多电真空器件的分级钎焊。银基钎料的主要合金组元有Cu、Zn、Ni、Mn、Sn、Cd、In、Ga、Re、P等,Cu和Zn是最主要的合金元素,因添加Cu可降低Ag的熔化温度,又不会形成脆性相,添加Zn可进一步降低银铜钎料的熔化温度,大部分银基钎料就是以不同含量配比的银铜二元系和银铜锌三元系合金为基础,添加Ni、Mn、Sn、Cd、In、Ga、P等元素来满足熔化特性及力学性能要求组成合金钎料,按组元数目分类,可将其分为二元、三元、四元及多元银基钎料几类,而纯银本身就是一种熔点在960 ℃的钎料。

由于银基钎料研究应用体系已经很成熟,国内外研究成果丰富,此处不再对其详细分类介绍。常用银基钎料牌号可参考GB/T 18762—2002《贵金属及其钎料》[53]和GB/T 10046—2008《银钎料》[54],对于国内外银钎料的研究现状、发展趋势,特别是最近5~10年里关于Ga、In、RE元素对于Ag-Cu-Zn影响的研究,可参考文献[55-58]。

4 贵金属钎料当前存在的问题

贵金属钎料性能优异,但仍然有一些不足之处限制其应用发展,目前研发与应用中出现的问题多集中在以下几个方面:

1) 加工性能差。为了降低钎料熔化温度,通常选择往合金体系中加入Sn、In、Ge、Si 等低熔点组元,但这些组元在钎料组织中易形成脆性中间化合物相,恶化加工性能,难于采用轧制、冷拉拔等传统压力加工方法制备出理想的丝材或箔片材,尤其以熔点在600 ℃以下的中低温金基钎料和400~600 ℃的中温银基钎料表现突出[59-60]。

2) 钎料成本高。我国贵金属资源稀缺,近年来贵金属价格更是节节攀升,大部分贵金属基钎料中贵金属元素所占比例大,使成本急剧上升,成本因素大大限制其研发、使用和推广[61]。

3) 含致毒污染元素。银基钎料中经常添加Cd来提高钎料性能[62-64],含镉银基钎料由于优异的钎焊工艺性和技术经济性而应用广泛,尤其是在制冷配件的生产中,但镉是重金属元素,镉蒸汽对人体危害极大,含镉钎料的生产和使用已经上升为全球性环境问题,代镉钎料的研发具有重要的现实意义及紧迫性[65]。

4) 焊点可靠性不理想及实验测试分析难。电子产品正向微型化、轻量化和集成化方向发展,对焊点的可靠性提出更高要求。研究表明,电子器件、钎料焊点和电路板之间存在材料线膨胀系数差异,由于电子产品长期的开-关,整个结构中会出现交变的温度场,接头易产生低周热应力疲劳,引起焊点塑性变形,导致蠕变断裂而致使焊点失效,进而使电子产品失效,这是包括贵金属钎料在内的许多钎焊性能优异的钎料在实际应用中面临的新问题[66-67],尤其以熔点在450 ℃以下的电子工业用金银基软钎料突出。此外,焊点尺寸越来越小,对试验获得焊点服役过程中的应力应变和分析微焊点可靠性及其失效机制提出了新的挑战。

5) 基础数据库匮乏。有限元分析方法已逐渐成为研究焊接接头应力应变关系、揭示界面润湿机理、分析焊点失效机制、评价微焊点可靠性、预测焊点疲劳寿命最有力的工具[68]。而钎料有限元模拟分析的进行必须有相应钎料基础数据库的支撑。目前,国内外对贵金属基钎料基础数据库的研究报道还较少。

6) 成分偏析及表面氧化。如Au-Sn钎料的成分偏析问题、表面氧化问题,致使国内一些重要生产企业、一些重要产品,仍然进口国外的Au-Sn钎料,以确保能够在“无钎剂”条件下进行钎焊[69]。此外,Ni含量较高的Au-Ni及Ag-Cu-Ni容易引起成分偏析[70-71],Ag、Cu含量高的贵金属钎料表面则会出现氧化问题[72]。

5 贵金属钎料的未来发展趋势

经笔者分析,贵金属钎料未来发展趋势主要集中在以下几个方面,并从中寻求现存问题的解决思路以及提高贵金属钎料品质、综合性能的方法。

1) 探索特殊的材料制备工艺。国内外的研究成果中包含以下方法:膏状或粘带状制备法、磁控溅射和电镀沉积法[73]、热机械加工法、包覆热轧+冷轧结合中间退火[74]、叠层复合+扩散合金化法(D-KH法)[75]、快速凝固法[31]、气雾化法和高真空旋淬法[76]等,这些制备工艺对贵金属脆性钎料加工成型有积极改善作用,但由于效率低、成本高、操作繁琐和影响钎料清洁型等单一或复合因素使某些材料制备工艺应用和推广受到限制,有待进一步改善现有钎料制备工艺及探索新的特殊制备工艺。

2) 设计开发新的多元合金体系钎料。从多元化角度设计合金成分,考虑采用4种甚至4种以上的元素组成多元钎料,综合协调各元素的作用,降低成本的同时使钎料具备良好的钎焊性能和加工性能,代替现有的贵金属钎料,使其应用更加广泛。

3) 微合金化。往金属及其合金中添加微量元素,在合金中起变质作用,改善钎料组织及性能,消除成分偏析,这是提高钎料品质及综合性能的一种简单而行之有效的方法。添加的合金元素可以为稀土元素(La、Ce、Er、Y、Pr、Nd、Lu)以及Ga、In 、Co、Bi、Cr等,特别是稀土元素在改善钎料自身与界面组织、提高钎料与焊接接头性能以及焊点可靠性等方面的研究广受国内外研究者关注。

4) 添加颗粒增强相形成复合钎料。强化相与现有钎料结合即形成复合钎料,强化相的添加并不会严重改变原钎料基体的熔点、润湿性等工艺性能,钎料内部能保持稳定的显微组织及均匀变形,改善及弥补合金性能上的某些不足,尤其在提高焊点性能(特别是热疲劳性能及蠕变性能)和使用寿命方面效果显著。颗粒强化主要有固溶强化和弥散强化两种机制,是提高合金性能的重要手段。颗粒增强相主要有微米级和纳米级的金属/非金属以及相关的氧化物等。例如微米Fe颗粒、微米Cu6Sn5颗粒、纳米Mo颗粒、纳米Al2O3颗粒、纳米TiO2颗粒、碳纳米管(CNTs)等。

5) 钎焊计算机模拟技术及数据库开发。随着钎焊技术向数字化、精密化和模拟化方向发展,精密控制、焊接接头疲劳寿命、焊点可靠性和钎焊机理的研究成为关注的焦点。钎焊接头温度场和应力场的有限元模拟、固液界面润湿行为的分子动力学模拟、焊钎料液滴铺展过程流场、速度场的数值模拟等对于采用计算机辅助钎焊接头设计、揭示界面润湿机理等具有重要的意义[77]。与模拟技术发展相对应,国内外研究学者应着手加强贵金属钎料基础数据库的开发。

6) 匹配助焊剂研究。助焊剂的添加能改善钎料润湿性、减少钎料用量降低成本、降低钎料表面张力、提高钎料钎焊性能和抗氧化性等诸多优点,而在各种助焊剂中,免清洗助焊剂具有成本低、焊接生产周期短、环境友好等优点,是助焊剂未来发展趋势,因此,探索与贵金属钎料相匹配的免清洗型助焊剂对提高钎料工艺性能有极大益处。

7) 新的钎焊工艺。探索诸如超声波辅助钎焊[78]、气体保护电弧钎焊[79]、等离子-激光复合钎焊[80]等特殊的钎焊新技术为实现非真空和无钎剂环境下材料的液相连接提供了新颖的解决思路。

6 结语

综上所述可知,低成本、无毒化、易制备、高性能、高可靠性和复合性能成为新型贵金属钎料合金研制的主要特征,对新型合金钎料的设计与评定应综合考虑性能、成本、与现有工艺设备的兼容性及社会效益。

近几年来,新型贵金属钎料不断涌现,但由于许多未知因素的存在,新型钎料仍然需要大量实验数据积累,才能保证钎料在应用推广时的高品质和高可靠性。同时,新型钎料的研发应与具体的使用坏境和工业产品相结合,通过多因素耦合分析才能得到夯实可靠的数据,为新型贵金属钎料的应用和推广提供数据支撑。

REFERENCES

[1] ERDOGAN A T, NALBANTGIL D, ULKUR F, SAHIN F. Metal ion release from silver soldering and laser welding caused by different types of mouthwash[J]. The Angle orthodontist, 2015, 85(4): 665-672.

[2] HAMMAD A E. Investigation of microstructure and mechanical properties of novel Sn-0.5Ag-0.7Cu solders containing small amount of Ni[J]. Materials and Design, 2013, 50(9): 108-116.

[3] KIM Y K, PARK S, KIM K S, LEE M H. The effects of adding elements of zinc and magnesium on Ag-Cu eutectic alloy for warming acupuncture[J].Evidence-based Complementary and Alternative Medicine, 2013, 27(7): 4-6.

[4] YAMAZAKI T, SUZUMURA A. Reaction products at brazed interface between Ag-Cu-V filler metal and diamond (111)[J]. Journal of Materials Science, 2006, 41(19): 6409-6416.

[5] LIU Yan, HUANG Zheng-ren, LIU Xue-jian, YUAN Ming. Brazing of SiC ceramics using Ag-Cu-In-Ti filler metal[J].Journal of Inorganic Materials, 2009, 24(4): 817-820.

[6] SONG H G, AHH J P, MORRIS J W. The microstructure of eutectic Au-Sn solder bumps on Cu/electroless Ni/Au[J]. Journal of Electronic Materials, 2001, 30(9): 1083-1087.

[7] JULIAN T, CLAUDIA P S, HECTOR S. Manufacture of Au-Si alloys for use in the soldering of gold alloys[J]. Welding International, 2015, 29(8): 594-599.

[8] ZHU Xue-wei, WANG Ri-chu, PENG Chao-qun, WEI Xiao-feng, PENG Jian. Reactions and mechanical properties between AuSn20 solders and metalized Al-Si alloys for electronic packaging application[J]. Journal of Materials Science: Materials in Electronics, 2014, 25(2): 742-748.

[9] WANG Chao-hong, LI Kuan-ting. Study of electromigration resistance of (Pd,Ni)Sn4 phase in lead-free solder joints[J]. Journal of Alloys and Compounds, 2016, 654(2): 546-553.

[10] LIU Hui-jie, FENG Ji-cai. Vacuum brazing TiAl-based alloy to 40Cr steel using Ag-Cu-Zn filler metal[J]. Journal of Materials Science Letters, 2002, 21(1): 9-10.

[11] 卢方焱, 薛松柏, 张 亮, 赖忠民. Ag-Cu-Zn系钎料的研究现状及发展趋势[J]. 焊接, 2008(10): 13-19.

LU Fang-yan, XUE Song-bai, ZHANG Liang, LAI Zhong-min. Research status and prospect of Ag-Cu-Zn series brazing filler metals[J]. Welding & Joining, 2008(10): 13-19.

[12] 尹立孟, 位 松, 李望云. 电子封装用低银含量无铅钎料的研究和应用进展[J]. 焊接技术, 2011, 40(2): 1-5.

YIN Li-meng, WEI Song, LI Wang-yun. Research and application progress in low-Ag lead-free solder for electronic packaging[J]. Welding Technology, 2011, 40(2): 1-5.

[13] COLLINS M N, DALTON E, PUNCH J. Microstructural influences on thermomechanical fatigue behaviour of third generation high Ag content Pb-Free solder alloys[J]. Journal of Alloys & Compounds, 2016, 688: 164-170.

[14] 崔大田, 王志法, 胡忠举, 刘文辉, 刘龙飞. 单辊旋淬Au-19.25Ag-12.80Ge钎料薄带的显微组织与焊接性能[J]. 稀有金属材料与工程, 2012, 41(3): 442-446.

CUI Da-tian, WANG Zhi-fa, HU Zhong-ju, LIU Wen-hui, LIU Long-fei. Microstructure and welding properties of single-roller melt spinned Au-19.25Ag-12.80Ge solder ribbon[J]. Rare Metal Materials and Engineering, 2012, 41(3): 442-446.

[15] 谢元锋,吕 宏,康志君,楚建新,张小勇,王林山. Pd基活性钎料对SiC陶瓷的润湿研究[J]. 稀有金属, 2007, 31(4): 507-509.

XIE Yuan-feng,  Hong, KANG Zhi-jun, CHU Jian-xin, ZHANG Xiao-yong, WANG Lin-shan. Wetting mechanism of Pd based active brazing alloys on SiC ceramic[J]. Rare Metals, 2007, 31(4): 507-509.

Hong, KANG Zhi-jun, CHU Jian-xin, ZHANG Xiao-yong, WANG Lin-shan. Wetting mechanism of Pd based active brazing alloys on SiC ceramic[J]. Rare Metals, 2007, 31(4): 507-509.

[16] VIVEK C, HO B Y, GAO S. Reliability of Au-Ge and Au-Si eutectic solder alloys for high-temperature electronics[J]. Journal of Electronic Materials, 2012, 41(8): 2107-2117.

[17] LANG Feng-qun, HIROSHI N, HIROSHI Y. Soldering of non-wettable Al electrode using Au-based solder[J]. Gold Bulletin, 2014, 47(1/2): 109-118.

[18] WEN Ming, TANG An-qiang, HE Qi-liu. Fabrication and microstructures of sequentially electroplated Sn-rich Au-Sn alloy solders[J].Journal of Electronic Materials, 2008, 37(6): 837-844.

[19] VIVEK C, JOHN H, JESPER H H. Development of gold based solder candidates for flip chip assembly[J]. Microelectronics Reliability, 2009, 49(1): 323-330.

[20] LEE S H, HWANG G S. Structure, energetics and bonding of amorphous Au-Si alloys[J]. The Journal of Chemical Physics, 2007, 127(22): 2247-2249.

[21] 张利广, 许 昆, 赵 明, 刘 毅, 李 伟, 罗锡明, 徐永涛, 郝 斌. 电子工业用贵金属中低温脆性钎料研究进展[J]. 贵金属, 2014, 35(3): 72-73.

ZHANG LI-guang, XU Kun, ZHAO Ming, LIU Yi, LI Wei, LUO Xi-ming, XU Yong-tao, HAO Bin. Research progress on precious metals medium-low temperature brittle filler metals for electronic industry[J]. Precious Metals, 2014, 35(3): 72-73.

[22] OPPERMANN H, HUTTE M, KLEIN M. Flip chip reliability of GaAs on Si thin film substrates using AuSn solder bumps[J]. Materials, Technology and Reliability of Advanced Interconnects, 2005, 863(35): 327-338.

[23] KIM S, KIM K S, KATSUAKI S. Interfacial reactions of Si die attachment with Zn-Sn and Au-20Sn high temperature lead-free solderson Cu substrates[J].Journal of Electronic Materials, 2009, 38(6): 873-883.

[24] SONG H G, MORRIS J W, MCCORMACK M T. The microstructure of ultrafine eutectic Au-Sn solder joints on Cu[J]. Journal of Electronic Materials, 2000, 29(8): 1038-1046.

[25] LEINENBACH C, VALENZA F, GIURANNO D, ELSENER H R, JIN S, NOVAKOVIC R. Wetting and soldering behavior of eutectic Au-Ge alloy on Cu and Ni substrates[J]. Journal of Electronic Materials, 2011, 40(7): 1533-1541.

[26] LI Ju-zi, ACOFF V L, GONG Xi-bing. Characterization of the brittle mechanism in a Au-Ge microalloy[J]. Gold Bulletin, 2015, 48(1/2): 47-56.

[27] JULIAN T, CLAUDIA P, SERNA G, HECTOR S. Manufacture of Au-Si alloys for use in the soldering of gold alloys[J]. Welding International, 2015, 29(8): 594-599.

[28] PAVLOVA G G, BORO A A. Physicochemical factors of formation of Au-As, Au-Sb and Ag-Sb deposits[J]. Geology of Ore Deposits, 2008, 50(6): 433-444.

[29] HASSAM S, AGREN J, GAUNE E M. Experimental and calculated phase diagram[J]. Metallurgical Transactions A, 1990, 21(7): 1877-1884.

[30] WANG J, LIU Y J, TANG C Y. Thermodynamic description of the Au-Ag-Ge ternary system[J]. Thermo-chimica Acta, 2011, 512(1): 240-246.

[31] 崔大田, 王志法. 快速凝固新型Au-Ag-Ge合金薄带的制备[J]. 材料热处理学报, 2010, 31(1): 40-43.

CUI Da-tian, WANG Zhi-fa. Preparation of rapidly solidified new-type An-Ag-Ge alloy ribbon[J]. Transactions of Materials and Heat Treatment, 2010, 31(1): 40-43.

[32] 崔大田, 王志法, 周 俊. Au-20.1Ag-2.5Si-2.5Ge新型中温钎料的组织与性能[J]. 中国有色金属学报, 2007, 17(9): 1501-1505.

CUI Da-tian, WANG Zhi-fa, ZHOU Jun. Microstructure and properties of new type Au-20.1Ag-2.5Si-2.5Ge medium- temperature solder[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(9): 1501-1505.

[33] 刘泽光, 陈登权, 李 伟. 新型中温金基钎料研究[J]. 贵金属, 2010, 31(2): 41-48.

LIU Ze-guang, CHEN Deng-quan, LI Wei. Research of new mid-temperature solder of Au-based alloy[J]. Precious Metals, 2010, 31(2): 41-48.

[34] CHANG Kuo-chin, CHANG Kuo-ning. Aging study on interfacial microstructure and solder-ball shear strength of a wafer-level chip-size package with Au/Ni metallization on a Cu pad[J].Journal of Electronic Materials, 2004, 33(11): 1373-1380.

[35] BYKOV A, PASTUKHOV E. A calorimetric study of alloy formation in Au-Cu and Au-In systems[J]. Journal of Thermal Analysis and Calorimetry, 2000, 60(3): 845-850.

[36] ANIS Z, PETER B, LUBOV Z, ERIC J C. Growth of Cu-Ni-Sn alloys in Pb free CuSnAg solder/Au-Ni metallization reactions[J]. Mrs Online Proceeding Library, 2000, 652(12): 1120-1124.

[37] YIN Na, QU Wen-qing, YANG Shu-juan, LI Rui, DING Ying. Welding technology of gold alloy[J]. Advanced Materials Research, 2013, 2177(629): 214-219.

[38] KANG U B, KIM Y H. The microstructure characterization of ultrasmall eutectic Bi-Sn solder bumps on Au/Cu/Ti and Au/Ni/Ti under-bump metallization[J].Journal of Electronic Materials, 2004, 33(1): 567-569.

[39] KARAMIS M B, TASDEMIRCI A, NAIR F. Microstructure analysis and discontinuities in the braze zone of copper tubes[J]. Journal of Materials Processing Technology, 2003, 45(4): 302-312.

[40] KIM K S, RYU K W, YU C H, KIM J M. The formation and growth of intermetallic compounds and shear strength at Sn-Zn solder/Au-Ni-Cu interfaces[J]. Microelectronics Reliability, 2005, 45(22): 678-681.

[41] OKAMOTO H, CHAKRABARTI D J, LAUGHLIN D E, MASSAl SKI T B. The Au-Cu(gold-copper) system[J]. Bull Alloy Phase Diagram, 1987, 8(5): 454-473.

[42] OKAMOTO H. Au-In (gold-indium)[J]. Journal of Phase Equilibria and Diffusion, 2004, 25(2): 197-198.

[43] SONWANE C G, WILCOX J, MA Yi-hua. Achieving optimum hydrogen permeability in PdAg and PdAu alloys[J].The Journal of Chemical Physics, 2006, 125(18): 128-130.

[44] HASHIBA M, SHINMEI W, KAJIHARA M. Kinetics of solid-state reactive diffusion in the (Pd-Ni)/Sn system[J]. Journal of Electronic Materials, 2012, 41(1): 32-43.

[45] VIENNOT S, DALARD F, LISSAC M. Corrosion resistance of cobalt-chromium and palladium-silver alloys used in fixed prosthetic restorations[J].European Journal of Oral Sciences, 2005, 113(1): 178-181.

[46] FLANAGAN T B, LUO S. Thermodynamics of hydrogen solution and hydride formation in Pd-Mn alloys. Disordered alloys and a correlation effect[J].The Journal of Physical Chemistry, 2006, 110(15): 456-459.

[47] 黄俊龙, 龙伟民, 张青科. 一种含钯的少缺欠洁净Sn-Zn钎料及其制备方法: 中国, CN104191101 B[P]. 2016-03-23.

HUANG Jun-long, LONG Wei-min, ZHANG Qing-ke. Containing palladium fewer imperfections clean Sn-Zn solder and preparation method: China, CN104191101B[P]. 2016-03-23.

[48] 余新泉, 张 强, 张 雷, 朱 坤. 一种含铌和钯的高热强度多元钎料合金: 中国, CN 102601541 A[P]. 2012-07-25.

YUE Xin-quan, ZHANG Qiang, ZHANG Lei, ZHU Kun. High heat intensity multielement solder alloy containing niobium and palladium: China,CN 102601541A[P]. 2012-07-25.

[49] CHEN Gang, ZHANG Peng, LIU Hong-wei, AMIR K. Analysis of Pd-Ni nanobelts melting process using molecular dynamics simulation[J]. Journal of Nanomaterials, 2013, 10(2): 112-115.

[50] 宁远涛, 郭根生, 李永年. 贵金属焊料及焊膏[J]. 贵金属, 1989, 10(2): 3-6.

NING Yuan-tao, GUO Gen-sheng, LI Yong-nian. Precious metal solder and solder paste[J]. Precious Metals, 1989, 10(2): 3-6.

[51] LEKOVA E, AMBROVIC P, DUHAJ P. Isothermal study of crystallization of Pd-Ni-Si amorphous metallic materials[J]. Journal of Thermal Analysis, 1983, 28(2): 413-419.

[52] SHAHROUZ N, JOHN S, DAVID B. Effects of low Ag additions on the hydrogen permeability of Pd-Cu-Ag hydrogen separation membranes[J]. Journal of Membrane Science, 2014, 451(1): 216-225.

[53] GB/T 18762-2002. 贵金属及其钎料[S].

GB/T 18762-2002. Filler precious metal and their alloy brazing material[S].

[54] GB/T 10046-2008. 银钎料[S].

GB/T 10046-2008. Silver brazing filler metals[S].

[55] MA Chao-li, XUE Song-bai, WANG Bo. Study on novel Ag-Cu-Zn-Sn brazing filler metal bearing Ga[J]. Journal of Alloys & Compounds, 2016, 688: 854-862.

[56] NTASI A, JABBARI Y S A, SILIKAS N, TAWEEL S M A, ZINELIS S. Metallurgical characterization of experimental Ag-based soldering alloys[J]. Saudi Dental Journal, 2014, 26(4): 139-144.

[57] 张 涛, 薛松柏, 马超力. Ag-Cu-Zn系钎料的研究现状[J]. 焊接, 2014(10): 10-15.

ZHANG Tao, XUE Song-bai, MA Chao-li. Research status of Ag-Cu-Zn based solder[J]. Welding & Joining, 2014(10): 10-15.

[58] 王星平, 赖忠民, 薛松柏, 张 亮, 卢方焱. 合金元素对Ag-Cu-Zn系钎料影响的研究现状及发展趋势[J]. 电焊机, 2009, 39(11): 1-6.

WANG Xing-ping, LAI Zhong-min, XUE Song-bai, ZHANG Liang, LU Fang-yan. Present situation and development trends of influence of alloying elements on Ag-Cu-Zn brazing filler metals[J]. Electric Welding Machine, 2009, 39(11): 1-6.

[59] 赵 明, 许 昆, 张海龙, 刘 毅, 罗锡明, 李 伟, 徐永涛, 郝 斌. D-KH法制备AgCuSn合金钎料的性能研究[J]. 贵金属, 2016, 37(3): 11-17.

ZHAO Ming, XU Kun, ZHANG Hai-long, LIU Yi, LUO Xi-ming, LI Wei, XU Yong-tao, HAO Bin. Properties of AgCuSn solder alloy prepared by D-KH method[J]. Precious Metals, 2016, 37(3): 11-17.

[60] JIN S, DUARTE L I, LEINENBACH C. Experimental study and thermodynamic description of the Au–Cu–Ge system[J]. Journal of Alloys & Compounds, 2014, 588(5): 7-16.

[61] TAKEDE S, FUJII H, KAWAKITA Y, TAHARA S, NAKASHIMA S, KOHARA S. Structure of eutectic alloys of Au with Si and Ge[J].Journal of Alloys & Compounds,2008, 452(1): 149-153.

[62] 韩宪鹏, 薛松柏, 赖忠民, 顾文华, 顾立勇. 无镉银钎料研究现状与发展趋势[J]. 焊接, 2007(6): 19-23.

HAN Xian-peng, XUE Song-bai, LAI Zhong-min, GU Wen-hua, GU Li-yong. Research status and prospect of cadmium free silver filler metal for brazing[J]. Welding & Joining, 2007(6): 19-23.

[63] KOTADIA H R, HOWES P D, MANNAN S H. A review: On the development of low melting temperature Pb-free solders[J]. Microelectronics Reliability, 2014, 54(6/7): 1253-1273.

[64] SCHOELLER H, BANSAL S, KNOBLOCH A, SHADDOCK D, CHO J. Effect of alloying elements on the creep behavior of high Pb-based solders[J]. Materials Science & Engineering A, 2011, 528(3): 1063-1070.

[65] ZAHROWSKI J J. Silver solder toxicity? Show me the evidence[J]. American Journal of Orthodontics and Dentofacial Orthopedics, 2011, 140(6): 757-758.

[66] SHNAWAH D A, SABRI M F M, BADUDDIN I A. A review on thermal cycling and drop impact reliability of SAC solder joint in portable electronic products[J]. Microelectronics Reliability, 2012, 52(1): 90-99.

[67] CHOI H, LEE T K, KIM Y. Improved strength of boron-doped Sn-1.0Ag-0.5Cu solder joints under aging conditions[J]. Intermetallics, 2012, 20(1): 155-159.

[68] ZENG Guang, XUE Song-bai, ZHANG Liang, SHENG Zhong, GAO Li-li. Reliability evaluation of SnAgCu/SnAgCuCe solder joints based on finite element simulation and experiments[J]. Soldering & Surface Mount Technology, 2010, 22(4): 57-64.

[69] 韦小凤, 王 檬, 王日初, 彭超群, 冯 艳. AuSn钎料及AuSn/Ni焊点的组织性能研究[J]. 稀有金属材料与工程, 2013, 42(3): 639-643.

WEI Xiao-feng,WANG Meng,WANG Ri-chu, PENG Chao-qun, FENG Yan. Microstructure and properties of AuSn solder and AuSn/Ni joint[J]. Rare Metal Materials and Engineering, 2013, 42(3): 639-643.

[70] 王卫杰, 何晓梅. Ag-Cu-Ni焊料在真空开关管中的应用研究[J]. 真空电子技术, 2004(4): 45-48.

WANG Wei-jie, HE Xiao-mei. Study of Ag-Cu-Ni brazing material applied for vacuum interrupter[J]. Vacuum Electronics, 2004(4): 45-48.

[71] LI Fu-quan, WANG Chun-qing. Influence of interfacial reaction between molten SnAgCu solder droplet and Au/Ni/Cu pad on IMC evolution[J]. Transactions of Nonferrous Metals Society of China, 2006, 16(1): 18-22.

[72] 武 信. 焊料合金粉在熔化过程中的氧化分析[J]. 金属材料与冶金工程, 2012(4): 3-6.

WU Xin. Oxidation analysis on the melting process of solder alloy powder[J]. Metal Materials and Metallurgy Engineering, 2012(4): 3-6.

[73] 刘 欣, 胡立雪, 罗 驰. 电化学制备金锡合金薄膜技术研究[J]. 微电子学, 2010, 40(3): 430-433.

LIU Xin, HU Li-xue, LUO Chi. Study on AuSn alloy thin-film technology using electrochemistry[J]. Microelectronics, 2010, 40(3): 430-433.

[74] HOSKING F M, STEPHENS J J, REJENT J A. Intermediate temperature joining of dissimilar metals[J]. Welding Journal, 1999, 78(5): 127-136.

[75] 赵 明, 许 昆, 张海龙. D-KH法及其在贵金属钎料制备中的应用[J]. 贵金属, 2015, 36(4): 81-87.

ZHAO Ming, XU Kun, ZHANG Hai-long. D-KH method and its application in preparation of precious metal-based brittle solder alloys[J]. Precious Metals, 2015, 36(4): 81-87.

[76] 倪广春, 陈 旭, 周 健. 低银焊料超声雾化制粉及焊膏性能研究[J]. 电子工艺技术, 2013, 34(1): 18-21.

NI Guang-chun, CHEN Xu, ZHOU Jian. Ultrasonic atomization of low Ag lead-free solder and properties of solder paste[J]. Electronics Process Technology, 2013, 34(1): 18-21.

[77] DUTKA V A. Computer modeling of temperature field formation in a carbide cutter during its induction brazing and quenching[J].Journal of Superhard Materials, 2008, 30(2): 128-132.

[78] ZHANG Ke-ke, ZHANG Xiao-jiao, QIU Ran-feng. The combined effects of ultrasonic wave and electric field on the microstructure and properties of Sn2.5Ag0.7Cu0.1RE/Cu soldered joints[J]. Journal of Materials Science: Materials in Electronics, 2014, 25(4): 1681-1686.

[79] MIDDELDORF K. Trends in joining technology=production, value added and employment by joining[R]. Germany: DVS (German Welding Society), 2012.

[80] 李 红, WOLF G T, 栗卓新, 冯宗会, 麦小波. 高品质高可靠性钎料的技术发展及应用[J]. 焊接学报, 2014, 35(4): 108-112.

LI Hong, WOLF G T, LI Zhuo-xin, FENG Zong-hui, MAI Xiao-bo. Development and application of high quality and high relia-bility brazing filler materials[J]. Transactions of the China Welding Institution, 2014, 35(4): 108-112.

Review of gold/palladium based precious metal solders

FANG Ji-heng, XIE Ming, ZHANG Ji-ming, TIAN Juan-juan, CHEN Jing-hong, HU Jie-qiong

(Kunming Institute of Precious Metals, State Key Laboratory of Advanced Technologies for Comprehensive Utilization of Platinum Metals, Kunming 650106, China)

Abstract: Precious metal solders occupy an important position in the electronics industry, microelectronic packaging, multi-stage vacuum brazing, high temperature technology, jewelry manufacturing, aerospace industry and other fields, the development and applications of gold/palladium based solders is the focus both home and abroad. The low/medium/high temperature gold-based solders which were commonly used in industrial production, military and civil fields were described particularly, as well as the presentation of the palladium-based brazing filler metals for the electronics industry classification brazing, high temperature resistant and special functions, besides that, the characteristics, properties and applications of each series of solders were summarized, and there is a brief overview for the properties of silver-based brazing filler metals. Problems still exist in poor processing performance, high economic costs, toxic elements pollution,lack of basic database of simulation, low reliability of solder joint etc. Accordingly, the future trend of precious metal solders was prospected and solutions to existing problems were seeked mainly from the preparation process, the micro-alloying, adding strengthening phase, matching solder flux, computer simulation and other aspects, which also provides a basic support for the development, application and promotion of precious metal solders.

Key words: precious metal solder; brazing property; application; brittle intermediate compound

Foundation item: Projects(U1302272, 51267007) supported by the National Natural Science Foundation of China; Project(2013DC016) supported by the Yunnan Province Institute of Technology Development, China; Project(2015IB012) supported by the Yunnan Provincial Scientific and Technological Cooperation Project, China; Project(2015IC046) supported by the Academician Expert Workstation Project, China

Received date: 2016-06-28; Accepted date: 2016-11-11

Corresponding author: XIE Ming; Tel: +86-871-8328841;E-mail: powder@ipm.com.cn

(编辑 王 超)

基金项目:国家自然科学基金资助项目(U1302272,51267007);云南省院所技术开发专项(2013DC016);云南省院省校科技合作项目(2015IB012);院士专家工作站项目(2015IC046)

收稿日期:2016-06-28;修订日期:2016-11-11

通信作者:谢 明,研究员,博士;电话:0871-8328841;E-mail: powder@ipm.com.cn

摘 要:贵金属钎料在电子工业、微电子封装、真空多级钎焊、高温技术、饰品制造业及航空航天等诸多领域占据重要地位,金/钯基贵金属钎料的研发及应用一直是国内外研究的热点。详细介绍工业生产、军工及民用等领域中常用的低/中/高温金基钎料,电子工业分级钎焊用、高温耐热型和具备特殊性能的钯基钎料,总结各个系列钎料特点、钎焊性能及用途,并简单概述银基钎料特性。综合评述贵金属钎料发展和应用中出现的加工性能差、经济成本高、含致毒污染元素、焊点可靠性不理想及模拟基础数据库匮乏等问题,从制备工艺、微合金化、添加强化相、匹配助焊剂和钎料计算机模拟等方面展望贵金属钎料未来发展趋势,并从中寻求对现存问题的解决措施,为贵金属钎料的开发、应用及推广提供基础支撑。

[11] 卢方焱, 薛松柏, 张 亮, 赖忠民. Ag-Cu-Zn系钎料的研究现状及发展趋势[J]. 焊接, 2008(10): 13-19.

[12] 尹立孟, 位 松, 李望云. 电子封装用低银含量无铅钎料的研究和应用进展[J]. 焊接技术, 2011, 40(2): 1-5.

[15] 谢元锋,吕 宏,康志君,楚建新,张小勇,王林山. Pd基活性钎料对SiC陶瓷的润湿研究[J]. 稀有金属, 2007, 31(4): 507-509.

[21] 张利广, 许 昆, 赵 明, 刘 毅, 李 伟, 罗锡明, 徐永涛, 郝 斌. 电子工业用贵金属中低温脆性钎料研究进展[J]. 贵金属, 2014, 35(3): 72-73.

[31] 崔大田, 王志法. 快速凝固新型Au-Ag-Ge合金薄带的制备[J]. 材料热处理学报, 2010, 31(1): 40-43.

[32] 崔大田, 王志法, 周 俊. Au-20.1Ag-2.5Si-2.5Ge新型中温钎料的组织与性能[J]. 中国有色金属学报, 2007, 17(9): 1501-1505.

[33] 刘泽光, 陈登权, 李 伟. 新型中温金基钎料研究[J]. 贵金属, 2010, 31(2): 41-48.

[47] 黄俊龙, 龙伟民, 张青科. 一种含钯的少缺欠洁净Sn-Zn钎料及其制备方法: 中国, CN104191101 B[P]. 2016-03-23.

[48] 余新泉, 张 强, 张 雷, 朱 坤. 一种含铌和钯的高热强度多元钎料合金: 中国, CN 102601541 A[P]. 2012-07-25.

[50] 宁远涛, 郭根生, 李永年. 贵金属焊料及焊膏[J]. 贵金属, 1989, 10(2): 3-6.

[53] GB/T 18762-2002. 贵金属及其钎料[S].

GB/T 18762-2002. Filler precious metal and their alloy brazing material[S].

GB/T 10046-2008. Silver brazing filler metals[S].

[57] 张 涛, 薛松柏, 马超力. Ag-Cu-Zn系钎料的研究现状[J]. 焊接, 2014(10): 10-15.

[58] 王星平, 赖忠民, 薛松柏, 张 亮, 卢方焱. 合金元素对Ag-Cu-Zn系钎料影响的研究现状及发展趋势[J]. 电焊机, 2009, 39(11): 1-6.

[59] 赵 明, 许 昆, 张海龙, 刘 毅, 罗锡明, 李 伟, 徐永涛, 郝 斌. D-KH法制备AgCuSn合金钎料的性能研究[J]. 贵金属, 2016, 37(3): 11-17.

[62] 韩宪鹏, 薛松柏, 赖忠民, 顾文华, 顾立勇. 无镉银钎料研究现状与发展趋势[J]. 焊接, 2007(6): 19-23.

[69] 韦小凤, 王 檬, 王日初, 彭超群, 冯 艳. AuSn钎料及AuSn/Ni焊点的组织性能研究[J]. 稀有金属材料与工程, 2013, 42(3): 639-643.

[70] 王卫杰, 何晓梅. Ag-Cu-Ni焊料在真空开关管中的应用研究[J]. 真空电子技术, 2004(4): 45-48.

[72] 武 信. 焊料合金粉在熔化过程中的氧化分析[J]. 金属材料与冶金工程, 2012(4): 3-6.

[73] 刘 欣, 胡立雪, 罗 驰. 电化学制备金锡合金薄膜技术研究[J]. 微电子学, 2010, 40(3): 430-433.

[75] 赵 明, 许 昆, 张海龙. D-KH法及其在贵金属钎料制备中的应用[J]. 贵金属, 2015, 36(4): 81-87.

[76] 倪广春, 陈 旭, 周 健. 低银焊料超声雾化制粉及焊膏性能研究[J]. 电子工艺技术, 2013, 34(1): 18-21.

[80] 李 红, WOLF G T, 栗卓新, 冯宗会, 麦小波. 高品质高可靠性钎料的技术发展及应用[J]. 焊接学报, 2014, 35(4): 108-112.