弥散强化钨镍铁高比重合金的制备及性能研究

中航工业北京航空制造工程研究所

北京科技大学材料科学与工程学院

摘 要:

钨基高比重合金在航天航空、兵器等行业中有着广泛应用,但传统钨镍铁高比重合金需通过后续形变强化处理提高力学性能,限制了其在国防工业和民用领域的广泛应用。利用弥散强化手段,当强化相在基体内呈弥散质点或粒状分布时,可显著提高合金强度和硬度,且塑性和韧性下降不大。本文研究了Y_2O_3弥散强化95W-3.5Ni-1.5Fe合金的制备工艺及性能。与传统钨镍铁高比重合金制备相比,本文首先利用化学气相迁移机制制备Y_2O_3分布在颗粒内部的弥散强化钨粉,重点研究原料种类对弥散强化钨粉粒度的影响以及成形、烧结工艺,利用X射线衍射(XRD)分析、场发射扫描电子显微镜(FESEM)对弥散强化钨粉及弥散强化钨进行性能表征。结果表明:WO2.9+Y_2O_3体系制备的弥散强化钨粉粒度最小,约1μm;经1480℃烧结90 min,弥散强化钨镍铁高比重合金的相对密度达98.6%,Y_2O_3在钨晶粒内呈弥散分布;钨合金的显微硬度达HV 532,表现出较高韧性。

关键词:

中图分类号: TG146.411

作者简介:王瑞欣(1987-),女,河北沧州人,硕士,研究方向:高温合金、复合材料;E-mail:wrx_ustb@163.com;;郭志猛,教授;电话:010-62334376;E-mail:zmguo@ustb.edu.cn;

收稿日期:2015-11-30

基金:国家科技部“863”计划项目(2013AA031104)资助;

Preparation and Properties of Dispersion Strengthening W-Ni-Fe Heavy Alloy

Wang Ruixin Guo Zhimeng Luo Ji Ye Qing Yang Fang

Avic Beijing Aeronautical Manufacturing Technology Research Institute

School of Material Science and Engineering,University of Science and Technology Beijing

Abstract:

Tungsten heavy alloys were widely used in the realms such as aerospace and ordnance industries. However,the afterward deformation enhancement process which was imperative for traditional tungsten heavy alloy fabrication restrained its further applications in the military and civil industries. Comparatively,using the dispersed strengthening phase such as the dispersoid particles in the matrix,the strength and hardness of the heavy alloy could be noticeably improved and meanwhile the loss of plasticity and toughness remained insignificant via the dispersion strengthening method. The preparation and properties of Y_2O_3 dispersion strengthening 95W-3. 5Ni-1. 5Fe alloy were studied in this work. Different from the traditional methods for preparing the dispersion strengthening alloys,the Y_2O_3 dispersion strengthening tungsten powder was fabricated via chemical vapor transport at first. The influences of raw materials on the particle size of dispersion strengthening tungsten powder were studied. The pressing and sintering process were optimized. The properties of tungsten powder and dispersion strength tungsten were investigated by X-ray diffraction( XRD) and field emission scanning electron microscopy( FESEM). The results showed that the dispersion strengthening tungsten powder prepared from WO2. 9and Y_2O_3 had the minimum size( about 1 μm). After sintering at 1480 ℃ for 90 min,the relative density of the Y_2O_3 dispersion strengthening tungsten alloy achieved 98. 6%,and the Y_2O_3 was well-dispersed in the tungsten grains. The microhardness was HV 532 and dispersion strengthening tungsten heavy alloy showed good toughness.

Keyword:

W-Ni-Fe; tungsten heavy alloy; Y2O3; dispersion strengthening;

Received: 2015-11-30

钨基高比重合金(也称钨基高密度合金、重合金),是钨合金材料的一个重要分支

随各行业的不断发展,对钨基高比重合金的性能提出更高要求,传统钨镍铁高比重合金需通过后续形变强化处理提高力学性能,然而存在变形量大、材料利用率低、加工成本高等问题,限制了其在国防工业和民用领域的广泛应用。弥散强化是一种在均匀材料中加入硬质颗粒的材料强化手段,当强化相在基体内呈弥散质点或粒状分布时,可显著提高合金强度和硬度,且塑性和韧性下降不大。相关研究表明,弥散强化钨基高比重合金的高温力学性能(800℃)和高应变速率下的力学性能显著提高

本文以95W-3.5Ni-1.5Fe为研究对象、Y2O3作为强化相,利用化学气相迁移机制制备Y2O3分布在颗粒内部的弥散强化钨粉,加入Ni粉和Fe粉进行机械合金化,经压制、烧结得到Y2O3分布在晶粒内部的弥散强化钨镍铁高比重合金。重点研究了原料种类对弥散强化钨粉粒度的影响以及成形、烧结工艺,并对弥散强化钨镍铁高比重合金的性能进行表征。

1 实验

1.1 弥散强化钨粉的制备

采用原料仲钨酸铵(APT),分子式5(NH4)2O·12WO3·5H2O,质量标准为仲钨酸铵含量≥99.5%;氧化钇,分子式Y2O3,质量标准为氧化钇含量≥99.5%,粒度为30 nm;无水乙醇,分子式C2H5OH,含量为99.99%,分析纯。按照最终Y2O3在W中为1%(质量分数,下同)的混合比例计算APT+Y(NO3)3·6H2O的混料比例,将粉末装入聚氨酯球磨罐内,以酒精作为湿磨介质,玛瑙球作为球磨珠,球料比例为20∶1,球磨机转速80r·min-1,球磨时间48 h。将混合好的合金粉末浆料经60℃干燥,700℃煅烧2 h,然后再900℃温度下H2还原2 h,得到弥散强化钨粉。对制得的钨粉进行扫描电子显微镜(SEM)和场发射扫描电子显微镜(FESEM)检测,对得到的钨粉形貌进行表征,并进行X射线衍射(XRD)分析检测,确定其物相组成(铜靶,λ=0.15406 nm,管电压为40 k V,管电流为150μA,步长0.02°,扫描速度9(°)·min-1,测量角度为10°~100°)。

1.2 弥散强化钨镍铁合金的制备

按照w(W)∶w(Ni)∶w(Fe)=95.0∶3.5∶1.5的比例称量1%Y2O3-W粉,电解镍粉(镍含量≥99.5%,粒度为40~70μm),电解铁粉(铁含量≥99%,粒度为-40~50μm),以高纯氩气(99.99%)作为保护气氛,不锈钢球作球磨珠,球料比例为10∶1,球磨机转速80 r·min-1,球磨时间48 h得到弥散强化钨镍铁合金粉末。压制成直径Φ10 mm的圆柱坯,H2环境下1480℃进行烧结,保温90min,随炉冷却得到弥散强化钨镍铁合金块体。

利用阿基米德排水法测量烧结体密度,利用XRD(Dmax-RB)分析弥散强化钨粉的物相,利用FESEM(SUPRA-55)观察弥散强化钨粉的形貌、弥散强化钨镍铁高比重合金的显微组织及断口,利用维氏硬度计(HVS-100)测量弥散强化高比重合金的显微硬度。

2 结果与讨论

2.1 原料对弥散强化钨粉的影响

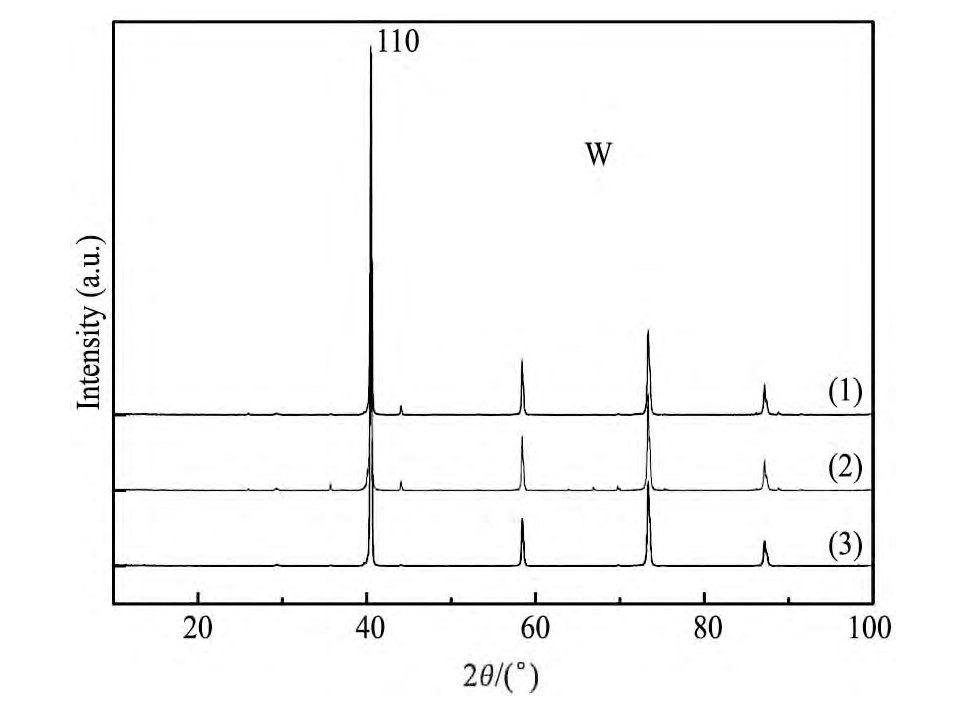

不同原料所得弥散强化钨粉的物相分析结果如图1所示,从图1中可以看出,不同原料制备出的弥散强化钨粉物相相同,表明APT+Y(NO3)3·6H2O,APT+Y2O3,WO2.9+Y2O33种原料体系在900℃条件下均能还原得到弥散强化钨粉,但由于弥散相Y2O3含量较低(1%),不能标定出Y2O3相。

图1 不同原料所得弥散强化钨粉的XRD图谱Fig.1 XRD patterns of dispersion strengthening tungsten pow-der made by different raw materials

(1)APT+Y(NO3)3·6H2O;(2)APT+Y2O3;(3)WO2.9+Y2O3

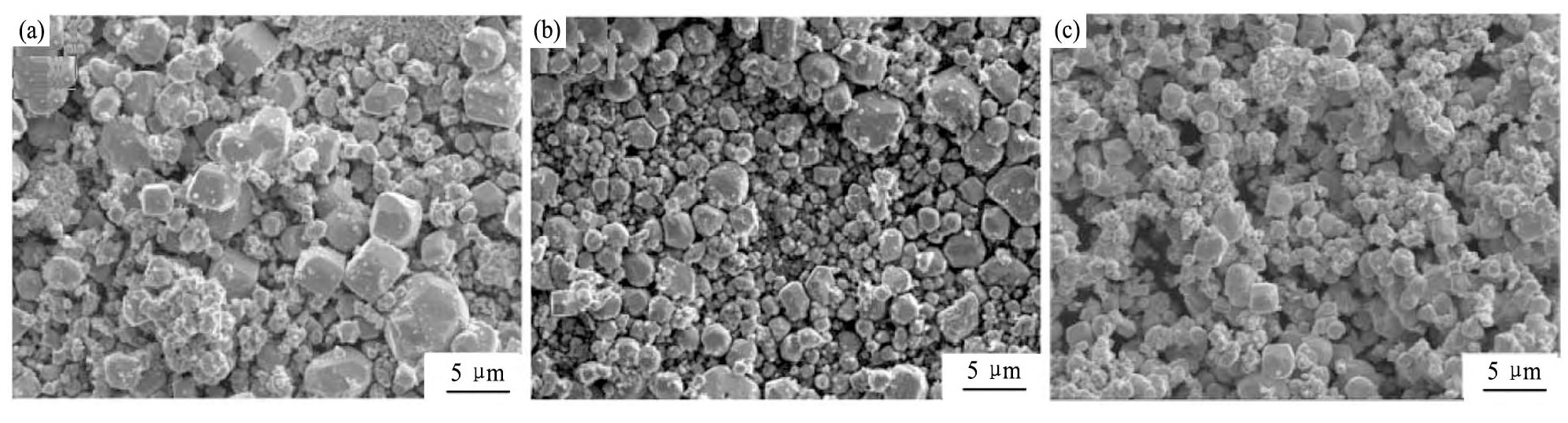

对3种原料体系所得的钨粉进行形貌分析,结果如图2所示。从图2中可以看出,3种原料体系制备出的弥散强化钨粉均结晶良好,而在粒度方面,由APT+Y(NO3)3·6H2O制备出的弥散强化钨粉最粗,WO2.9+Y2O3体系所得的弥散强化钨粉粒度最小。弥散强化钨粉的粒度变化受很多因素影响,除还原温度、H2的湿度和流量、推舟速度、料层厚度、还原时间等与还原过程直接相关的因素外,弥散相Y2O3也是一个很重要的因素。由于APT煅烧产物为针状或棒状、粒度较粗的WO3,且还原形成的H2O也比蓝钨还原产生的多,因而使用APT作为原料还原得到的钨粉比蓝钨还原所得的钨粉粗。此外,Y2O3能够作为钨粉形核长大的抑制剂,Y2O3在氧化钨中分散的越均匀,得到的钨粉越细。当使用Y(NO3)3·6H2O作为原料时,球磨湿混料在干燥过程中Y(NO3)3·6H2O会形核长大,煅烧形成的Y2O3粒度也较大,因而使用Y(NO3)3·6H2O为原料所得的钨粉比直接使用纳米Y2O3为原料得到的钨粉粒度粗。由此可知,WO2.9+Y2O3体系在制备微细弥散强化钨粉方面具有较大优势。

2.2 弥散强化钨的力学性能

以WO2.9+Y2O3体系制备的弥散强化钨粉为原料,经模压、烧结得到弥散强化钨,相对密度为98.6%。对弥散强化钨进行力学性能分析,对比了Y2O3弥散强化95W-3.5Ni-1.5Fe合金与未添加Y2O3的95W-3.5Ni-1.5Fe合金的显微硬度,由HV458提高到HV 532。表明Y2O3弥散强化提高了95W-3.5Ni-1.5Fe合金的性能。

2.3 弥散强化钨的显微组织分析

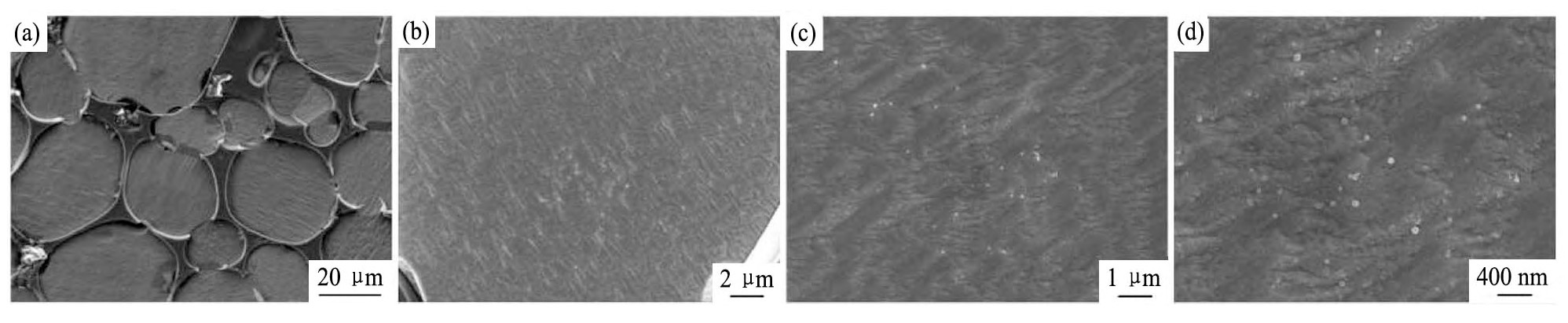

烧结体的显微组织分析结果如图3所示,从图3中可以看出,组织较致密,与密度分析的结果一致。在晶粒内部分布着细小的Y2O3弥散相。

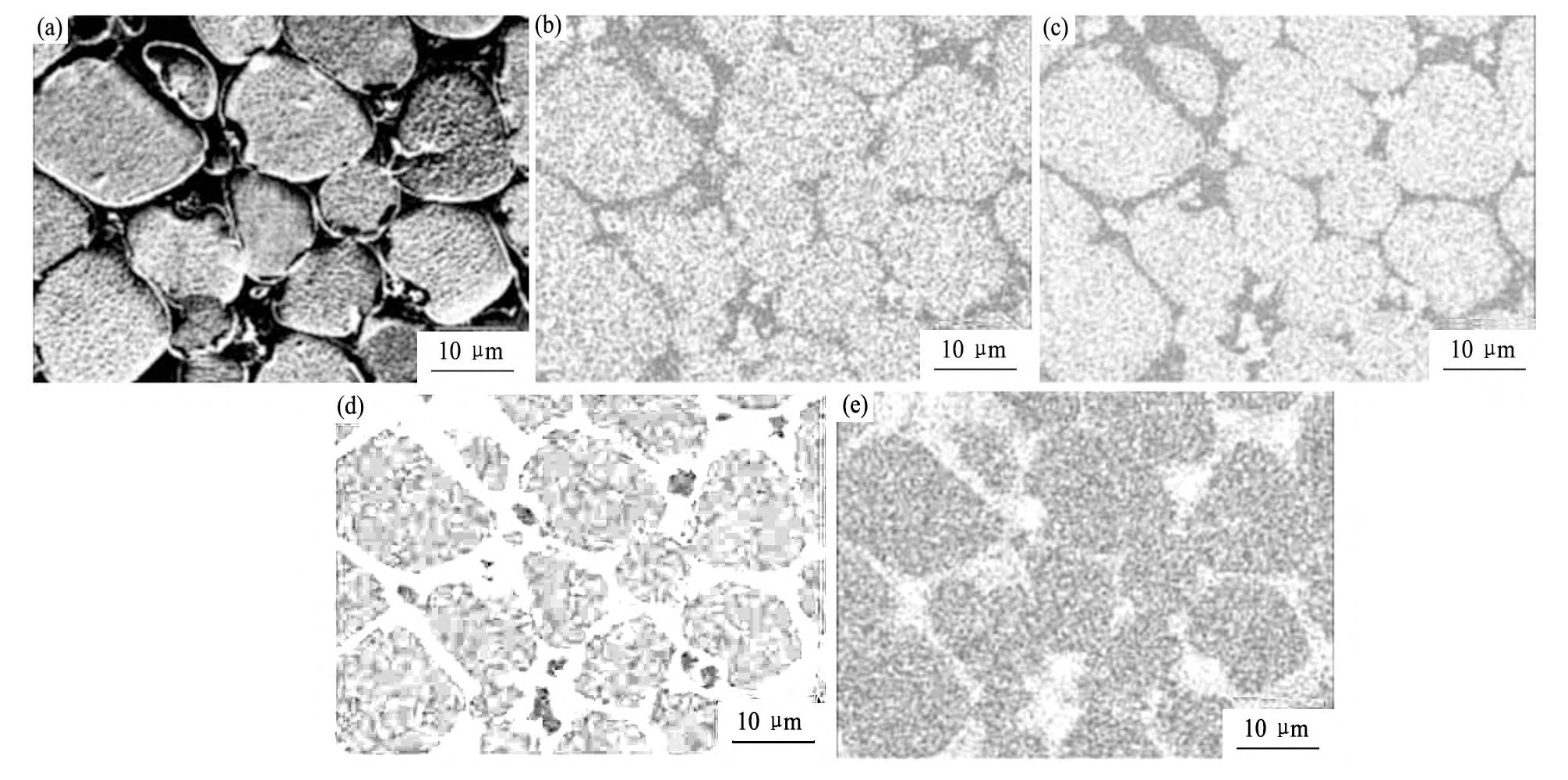

弥散强化钨的元素面分布分析结果如图4所示,钨镍铁合金的显微组织呈现典型的液相烧结组织。在高温烧结时,Ni,Fe全部形成液相,发生液相流动与钨颗粒的重排,由于钨在液相中有一定溶解度,钨颗粒以溶解-析出机制完成球化过程,晶粒逐渐长大,镍铁黏结相分布在钨颗粒周围。绝大部分Y2O3弥散相则分布于钨晶粒内部。

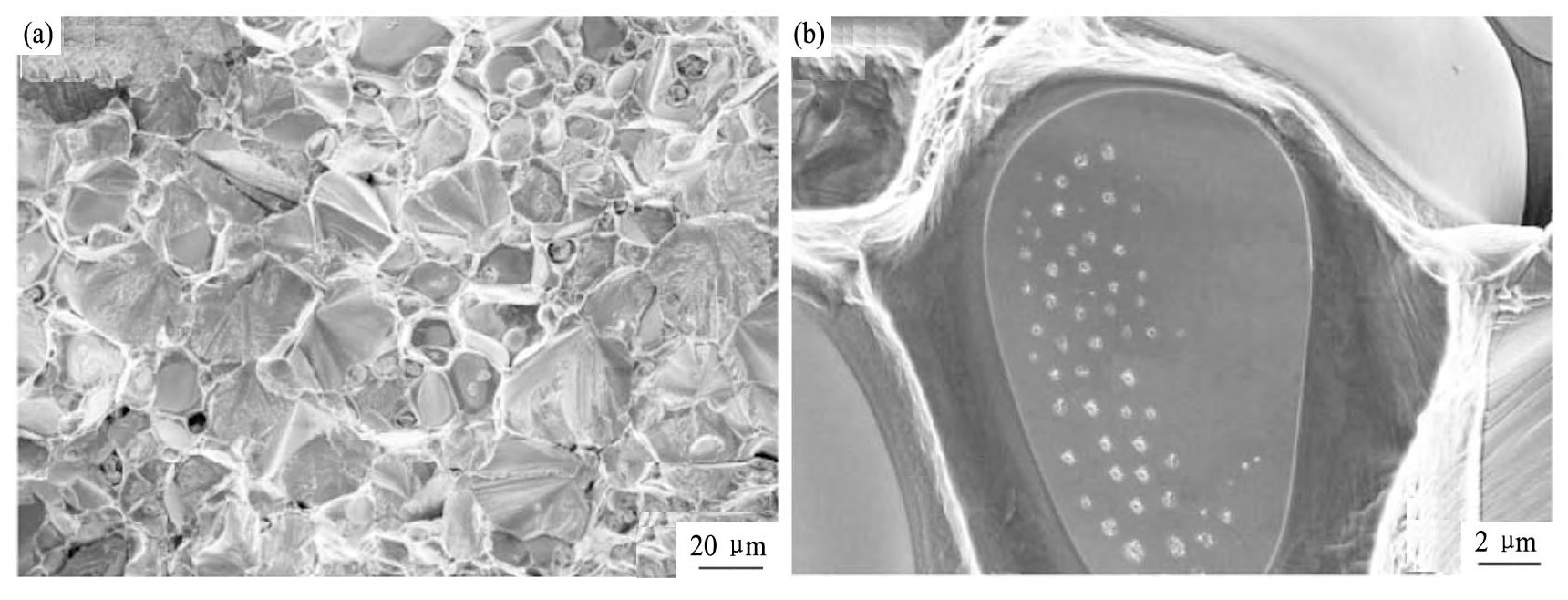

弥散强化钨镍铁合金的断口形貌分析如图5所示,从中可以看出,Y2O3弥散强化95W-3.5Ni-1.5Fe合金的断裂以钨颗粒穿晶解理为主,表明合金的韧性较高。从W-W断裂界面可看出,内部出现弥散的孔洞,说明钨晶粒内部存在弥散强化相;外延光滑是由于晶粒长大过程中,W以溶解析出的方式生长在含弥散相的钨基体上。

图2 不同原料制备的弥散强化钨粉Fig.2 SEM images of dispersion strengthening tungsten powder made by different raw materials

(a)APT+Y(NO3)3·6H2O;(b)APT+Y2O3;(c)WO2.9+Y2O3

图3 弥散强化钨的显微组织照片Fig.3 SEM iamges of dispersion strengthening tungsten with different magnifications

图4 弥散强化钨的元素面分布分析Fig.4 SEM image(a)and section-distribution of elements for dispersion strengthening tungsten(b)Fe;(c)Ni;(d)Y;(e)W

图5 弥散强化钨的断口形貌Fig.5 SEM images of fracture morphology of dispersion strengthening tungsten with different magnifications

3 结论

利用化学气相迁移机制制备Y2O3分布在颗粒内部的弥散强化钨粉,研究了APT+Y(NO3)3·6H2O,APT+Y2O3,WO2.9+Y2O33种原料对弥散强化钨粉粒度的影响。结果表明:WO2.9+Y2O3体系制备的弥散强化钨粉粒度最小,约1μm;经1480℃烧结90 min,弥散强化钨的相对密度达98.6%,Y2O3在钨晶粒内呈弥散分布。得益于弥散强化作用,钨合金的显微硬度达HV 532,且表现出较高韧性。

参考文献

[10] Riley D J.Nano-sized particles and structures[J].Chemistry and Industry(London),2001,18(3):570.