文章编号:1004-0609(2010)S1-s0992-05

高速压制技术成形Ti粉的过程

闫志巧,蔡一湘

(广州有色金属研究院 粉末冶金研究所,广州 510650)

摘 要:采用高速压制(HVC)技术成形Ti粉,研究润滑剂、两次压制对成形效果的影响,探讨适合HVC技术特点的表征方式。结果表明:与高速压制纯Ti粉相比,含0.3%(质量分数)润滑剂的粉末能在更大的冲击行程下成形而获得更高的压坯密度,并且有利于减少表面剥落和分层等缺陷;两次高速压制时,压坯内应力聚集导致分层和烧结后出现膨胀;HVC的成形效果同时取决于冲击能量和装粉量,质量能量密度能全面表征装粉量和冲击能量等不同参数下的压坯密度;纯Ti粉末在质量能量密度为118 J/g时,所获得的压坯致密度为96.0%。

关键词:Ti粉;高速压制(HVC);分层;质量能量密度

中图分类号:TF 124.36 文献标志码:A

Process of high velocity compaction in forming Ti powder

YAN Zhi-qiao, CAI Yi-xiang

(Department of Powder Metallurgy, Guangzhou Research Institute of Nonferrous Metals, Guangzhou 510650, China)

Abstract: High velocity compaction (HVC) was adopted to press Ti powder. The effects of lubricant and two impacts on the green bodies were investigated, and the representation of HVC was discussed. The results indicate that compared with pure Ti powder without lubricant, the powder containing 0.3% (mass fraction) lubricant is able to form at larger stroke length to attain higher green density. In addition, green surface peeling and delamination of this powder are lessened. For two impacts, stress gets together in the green body and causes delamination and swell after sintering. The forming ability of HVC lies on impact energy and powder filling amount simultaneously. Therefore, mass energy density can characterize the green density achieved at different powder filling amount and impact energy. For pure Ti powder, the green relative density is 96.0% when the mass energy density is 118 J/g.

Key words: Ti powder; high velocity compaction; delamination; mass energy density

钛合金及复合材料是一种在民用领域有广泛应用前景的轻质材料,然而高的生产成本严重阻碍了钛材的应用和发展。粉末冶金是一种近净成形、低成本的钛材制备技术,但钛塑性差、加工硬化速率高的特性使其用传统的模压方法成形十分困难,需要借助热压或热等静压等工艺提高密度,导致制造成本急剧升高。SAITO[1]指出,如果钛材的性价比不能与铁基合金相近,那么钛很难在民用领域得到广泛应用。因此,寻求高性能、低成本的制备技术一直是钛材的发展目标。而一种新型的粉末冶金成形技术—高速压制(HVC)技术的出现则有望解决钛难致密和制造成本高的 难题。

HVC是近10年来出现的一项高效率、低成本制备高性能粉末冶金零件的新技术,具有成本低、压坯密度高且分布均匀、弹性后效低和精度高、模具使用寿命长等特点,为制备“三高一低”(高密度、高强度、高精度和低成本)的粉末冶金零件提供了一种极具优势的成形方法[2-4]。目前,国外已经用该技术大规模生产铁基和不锈钢零件。近3年来,国内也开展了HVC技术成形延性好的Cu粉[5-6]、Fe粉[7-8]的研究,而对传统模压难成形的粉末,如Ti粉[9]、Mo粉的高速压制研究较少,研究重点主要集中在冲击能量、冲击速度等对压制效果的影响和压制过程中的脱模力、弹性后效等方面,关于HVC过程及成形特征的研究鲜见报道。本文作者以Ti粉为原料,研究润滑剂、两次压制对HVC成形效果的影响,探讨适合HVC技术特点的表征方式,有利于深化对HVC过程特征的认识,同时为粉末冶金法高密度成形Ti和其他高硬化速率粉末提供参考。

1 实验

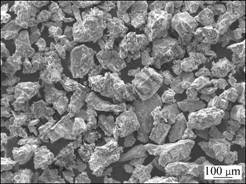

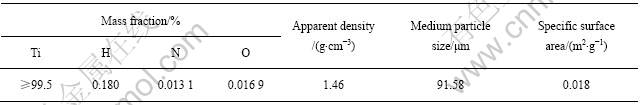

实验用原料粉末为粒度<150 μm的氢化脱氢Ti粉,为不规则形状,其性能和显微形貌分别如表1和图1所示。

图1 Ti粉的SEM像

Fig.1 SEM image of Ti powder

将部分Ti粉与0.3%(质量分数)的硬脂酸锌均匀混合。随后在HYP35-7型高速冲击成形压机上对纯Ti粉末和含0.3%润滑剂的粉末进行高速压制。采用内、外径分别为30 mm和60 mm的圆环模具,装粉量为56.5 g。压制过程中可获得的最大冲击行程为88 mm,最大装料高度为140 mm,装料位置精度为±0.01 mm。在进一步的实验中,采用直径为20 mm的圆柱模具,装粉量为10.3 g。用Archimedes法测试压坯密度。

2 结果与讨论

2.1 润滑剂对HVC效果的影响

HVC的基本原理是通过液压驱动的重锤产生强烈的冲击波,在极短的时间内将冲击能量(或冲击功)通过压模传递到粉末上实现致密化[10],其压制过程如图2所示,其中,冲击行程(简称冲程)为重锤由初始位置运动至冲击上模冲时所运行的距离。在重锤质量一定的情况下,冲程直接决定了冲击能量的大小和材料的致密化程度。

图2 HVC的基本原理

Fig.2 Basic principle of HVC

与传统模压成形相比,HVC成形可显著减少润滑剂的添加量,甚至是无润滑剂也可以成形[11]。HVC成形的压坯缺陷如图3所示。可见,含0.3%润滑剂的粉末在冲程为50 mm时,所成形压坯的上表面开始出现剥落(见图3(a)),而其下表面完好;不含润滑剂的纯Ti粉末在冲程为35 mm时,所成形压坯即出现显著分层(见图3(b)),表明少量的润滑剂能使Ti粉在更大的冲程下成形,从而有利于获得更高的压坯密度。在本

表1 Ti粉的性能

Table 1 Characteristics of Ti powder

图3 HVC成形的压坯缺陷

Fig.3 Defects of green bodies formed by HVC: (a) 0.3% lubricant, and stroke length of 50 mm; (b) Without lubricant, and stroke length of 35 mm

研究中,含0.3%润滑剂的粉末可成形的最大压坯致密度为88.8%,不含润滑剂的纯Ti粉末的最大压坯致密度为76.2%。显然,少量的润滑剂能显著提高HVC的成形能力而获得更高的压坯密度。压坯上表面出现剥落和分层可能是由于冲击波在自由端面反射时产生的拉应力造成的。AZHDAR等[12]研究发现,在上模冲的下方和下模冲的上方各加装一段模冲,可以显著改善压坯的表面质量,降低重锤冲击后上模冲的反弹速度,当冲击波反射回上表面时压坯依然和上模冲接触,从而改善冲击波在上表面的反射方式,消除拉伸应力,避免了表面剥落和分层。

2.2 两次压制对HVC效果的影响

在常规的压制条件下,压坯密度主要取决于压制压力,并不随压制次数的增加而显著提高。在高速压制时,压坯的密度取决于重锤提供给他的能量。该能量是可以累加的,即随着压制次数的增加密度可以不断地提高。但两次高速压制纯Ti粉时发现,在冲程为25 mm时,所成形压坯大部分出现分层(和图3(b)类似),且宏观无分层的压坯烧结后出现膨胀(见图4)。含0.3%润滑剂的粉末在两次压制时没有出现宏观分层,但同样地部分压坯烧结后出现膨胀(和图4类似)。这是由于HVC是一种瞬间绝热成形高密度压坯的过程,颗粒之间发生黏结甚至熔焊。经一次HVC后,压坯内的颗粒则因内部含有较多的缺陷(如位错、空位和晶格畸变)而处于高能状态。进行第2次HVC时,由于与第1次HVC间隔极短,压坯内的产生的应力来不及释放,进一步迅速累积,直至大于压坯的强度而导致出现分层。显然,少量润滑剂改善了颗粒边缘的结合程度,降低了应力聚集,因而能减少多次压制时的分层缺陷。

图4 两次HVC压坯烧结后的膨胀缺陷

Fig.4 Swell defects of green body formed by two impacts after sintering

HVC过程的能量可以叠加,即可以通过多次小冲击能量的压制得到与一次大冲击能量压制相同的效果。DOREMUS等[13]采用高速压制RI-180粉末时发现,进行一次或分多次高速压制所制备的压坯密度相近,如依次进行一次冲程为103 mm、两次冲程均为50 mm和三次冲程均为36 mm的高速压制,所获得的压坯密度分别为7.40,7.40和7.41 g/cm3。而WANG等[14]采用多次高速压制Fe粉时发现,在总冲击能量相同的情况下,分两次压制制备的压坯密度最大,分三次压制的最小,一次压制的居中,而且一次压制与两次压制的压坯密度—冲击能量曲线呈塑性粉末的压制特征,而三次压制的压坯密度—冲击能量曲线则近似呈脆性粉末的压制特征。因此,多次高速压制的能量是否具有叠加性有待进一步的验证。

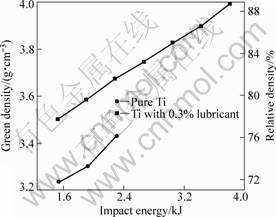

2.3 质量能量密度对压坯密度的影响

Ti粉的压坯密度与冲击能量的关系如图5所示。由图5可知,纯Ti粉末在冲击能量为2 306 J时,可成形的最大压坯密度为3.43 g/cm3,致密度为76.2%。文献[15]采用335 J的冲击能量高速压制纯Ti粉,所成形直径为14 mm、质量为3.0 g圆柱压坯的致密度为93.5%。本研究与文献[15]的压制效果存在明显差距。这是由于高速压制的压坯密度不仅取决于重锤提供给它的能量,而且还与压坯的质量有很大关系[9, 16]。随着粉末质量增加,外加的能量密度减小,所以压坯密度减小。因此,可采用质量能量密度(单位质量的压坯在压制过程中所受到的冲击能量,即冲击能量与装粉量之比,单位:J/g)[9]将本文结果与文献[15]的结果进行对比,对比结果如图6所示。

图5 压坯密度与冲击能量的关系

Fig.5 Relationship between green density and impact energy

图6 压制密度与质量能量密度的关系

Fig.6 Relationship between relative density and mass energy density

为进一步考察质量能量密度对压坯密度的影响,以纯Ti粉为原料,高速压制直径为20 mm、质量为10.3 g的圆柱试样。在冲击能量为1 217 J时,所成形压坯的密度为4.32 g/cm3,即在质量能量密度为118 J/g时,所获得的压坯致密度为96.0%(见图6)。文献[15]在质量能量密度为112 J/g时,所获得的压坯致密度为93.5%。对比可知,在质量能量密度相近的情况下,所达到的压坯致密度相近。因此,质量能量密度能全面表征装粉量和冲击能量对HVC成形效果的影响。采用质量能量密度对HVC技术进行表征,可以在冲击能量、压坯密度和装粉量三者之间实现可设计性。

3 结论

1) 少量润滑剂能显著改善HVC的成形效果,减少剥落和分层等缺陷,提高两次HVC的成形能力。

2) 两次HVC时,压坯内应力的迅速累积而导致压坯出现分层,多次HVC的能量是否具有叠加性有待进一步研究。

3) 采用质量能量密度能同时表征冲击能量和装粉量对压坯密度的影响。在质量能量密度为118 J/g时,所成形纯Ti粉的压坯密度为96.0 %。

REFERENCES

[1] SAITO T. The automotive application of discontinuously reinforced TiB-Ti composites[J]. JOM, 2004, 56(5): 33-36.

[2] ORBAN P L. New research directions in powder metallurgy[J]. Romanian Reports in Physics, 2004, 56 (3): 505-516.

[3] DORE F, LAZZAROTTO L, BOURDIN S. High velocity compaction: overview of materials, applications and potential[J]. Materials Science Forum, 2007, 534/536: 293-296.

[4] 闫志巧, 蔡一湘, 陈 峰. 粉末冶金高速压制技术及其应用[J]. 粉末冶金技术, 2009, 27(6): 455-460.

YAN Zhi-qiao, CAI Yi-xiang, CHEN Feng. High velocity compaction in powder forming and the promising applications[J]. Powder Metallurgy Technology, 2009, 27(6): 455-460.

[5] 王建忠, 曲选辉, 尹海清, 周晟宇, 易明军. 电解铜粉高速压制成形[J]. 中国有色金属学报, 2008, 18(8): 1498-1503.

WANG Jian-zhong, QU Xuan-hui, YIN Hai-qing, ZHOU Sheng-yu, YI Ming-jun. High velocity compaction of electrolytic copper powder[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(8): 1498-1503.

[6] YI M J, YIN H Q, WANG J Z, YUAN X J, QU X H. Comparative research on high-velocity compaction and conventional rigid die compaction[J]. Frontiers of Materials Science in China, 2009, 3(4): 447-451.

[7] WANG J Z, QU X H, YIN H Q, YI M J, YUAN X J. High velocity compaction of ferrous powder[J]. Powder Technology, 2009, 192(1): 131-136.

[8] 邓三才, 肖志瑜, 陈 进, 张富兵, 许 阳. 模壁润滑高速压制成形Fe-2Cu-1C 粉末的研究[J]. 粉末冶金工业, 2009, 19(6): 28-32.

DENG San-cai, XIAO Zhi-yu, CHEN Jin, ZHANG Fu-bing, XU Yang. Investigation on Fe-2Cu-1C powder forming by high velocity compaction with die-wall lubrication[J]. Powder Metallurgy Industry, 2009, 19(6): 28-32.

[9] 闫志巧, 陈 峰, 蔡一湘, 崔 亮. Ti粉的高速压制成形及表征[J]. 金属学报, 2010, 46(2): 227-232.

YAN Zhi-qiao, CHEN Feng, CAI Yi-xiang, CUI Liang. High velocity compaction and characteristics of Ti powder[J]. Acta Metallurgica Sinica, 2010, 46(2): 227-232.

[10] SKOGLUND P. High density P/M components by high velocity compaction[J]. Powder Metallurgy, 2001, 44(3): 15-17.

[11] SOURIOU D, GOEURIOT P, BONNEFOY O, THOMAS G, DRAPIER S, BOURDIN S, LAZZAROTTO L. Comparison of conventional and high velocity compaction of alumina powders[J]. Advances in Science and Technology, 2006, 45: 893-898.

[12] AZHDAR B, STENBERG B, KARI L. Determination of dynamic and sliding friction, and observation of stick-slip phenomenon on compacted polymer powders during high-velocity compaction[J]. Polymer Testing, 2006, 25(8): 114-123.

[13] DOREMUS P, Le GUENNEC Y, IMBAULT D, PUENTE G. High-velocity compaction and conventional compaction of metallic powders; comparison of process parameters and green compact properties[J]. Journal of Process Mechanical Engineering, 2010, 224(3): 177-185.

[14] WANG J Z, YIN H Q, QU X H, JOHNSON J L. Effect of multiple impacts on high velocity pressed iron powder[J]. Powder Technology, 2009, 195(1): 184-189.

[15] ERIKSSON M, ANDERSSON M, ADOLFSSON E, CARLSTR?M E. Titanium-hydroxyapatite composite biomaterial for dental implants[J]. Powder Metallurgy, 2006, 49(1): 70-77.

[16] 张启旺, 王志法, 余 惺, 姜国圣, 阮 涛. 高速压制法制备90W-10Cu 复合材料[J]. 粉末冶金材料科学与工程, 2010, 15(1): 27-31.

ZHANG Qi-wang, WANG Zhi-fa, YU Xing, JIANG Guo-sheng, RUAN Tao. 90W-10Cu composite materials fabricated by high velocity compaction technology[J]. Materials Science and Engineering of Powder Metallurgy, 2010, 15(1): 27-31.

(编辑 赵 俊)

基金项目:国家自然科学基金资助项目(51004040)

通信作者:闫志巧;电话:020-61086627;E-mail:zhiqiaoyan@sina.com