J. Cent. South Univ. Technol. (2008) 15: 645-649

DOI: 10.1007/s11771-008-0120-x

Hydraulic calculation of gravity transportation pipeline system for

backfill slurry

ZHANG Qin-li(张钦礼), HU Guan-yu(胡冠宇), WANG Xin-min(王新民)

(School of Resources and Safety Engineering, Central South University, Changsha 410083, China)

Abstract: Taking cemented coal gangue pipeline transportation system in Suncun Coal Mine, Xinwen Mining Group, Shandong Province, China, as an example, the hydraulic calculation approaches and process about gravity pipeline transportation of backfill slurry were investigated. The results show that the backfill capability of the backfill system should be higher than 74.4 m3/h according to the mining production and backfill times in the mine; the minimum velocity (critical velocity) and practical working velocity of the backfill slurry are 1.44 and 3.82 m/s, respectively. Various formulae give the maximum ratio of total length to vertical height of pipeline (L/H ratio) of the backfill system of 5.4, and then the reliability and capability of the system can be evaluated.

Key words: hydraulic calculation; critical velocity; working velocity; pipe length-backfill depth ratio; backfill capability

1 Introduction

Backfill materials are commonly transported into underground stopes by weight force of backfill slurry within vertical drill hole or pipe in mines[1]. Key point is the choice and determination of gravity pipeline transportation parameters in order to transport solid filling materials effectively and safely with the minimum transportation energy loss[2]. Related hydraulic calculation approaches and process about gravity pipeline transportation system were discussed in this work by using data of cemented coal gangue pipeline transportation system in Suncun Coal Mine (SCM), Xinwen Mining Group, Shandong Province, China.

SCM is one of the deepest coal mines with more than 100 years mining history and 1 300 m of mining depth. Gangue site with an area of 13×104 m2 has reached limit. Gangue is still increased by 200 kt every year, but no spared space can accommodate gangue newly produced. Cemented gangue backfill is the best way to recover land occupied by old gangue hill and to treat new gangue.

Laboratory test about recipe of cemented gangue backfill suggested that sizes of coal gangue particles should be less than 5 mm so that coal gangue could be smoothly transported by gravity pipeline transportation system. The result also indicated that high compressive strength could be obtained if mass ratio of Portland cement to fly ash to gangue was 1?4?15, and mass fraction of solid materials varied between 72% and 75%. If 1.0%-1.5% of water-reducing agent to sum of cement and fly ash was added, the rheological properties of backfill slurry such as slump, diffusibility and denseness could be improved obviously[3]. The backfill slurry with suggested dosage was like paste backfill in rheological property, here named as paste-like backfill. It is characterized by excellent floatation of solid materials in pipe, low dewatering in stope, and little wear to pipe wall[4]. Gravity pipeline transportation parameters, such as the capability and the maximum transportation distance of backfill system, should be clarified by hydraulic calculation of the system, in order to obtain good results mentioned above.

It is generally necessary to determine such hydraulic transportation parameters as fluid velocity, pipe pressure and transportation resistance when the pipeline transportation system of natural gas, oil and polluted water is designed. These parameters can be calculated or estimated by theoretical analysis, numeral simulation and semi-empirical equations[5-8] since the transported slurry is usually uniform single phase or two-phase flow[9-10]. The hydraulic transportation parameters of coarse backfill aggregates, however, are commonly estimated by empirical equations because backfill slurry is non-uniform solid-liquid flow in most cases[11-12].

2 Data preparation

2.1 Backfill system in SCM

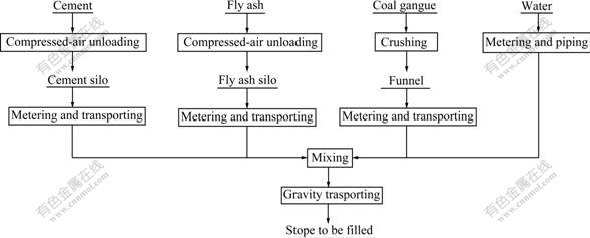

The gravity pipeline transportation system for cemented coal gangue backfill in SCM is shown in Fig.1.

Fig.1 Gravity pipeline transportation system of cemented coal gangue backfill in SCM

The inner diameter and wall thickness of ceramic- lined pipe used for transporting the backfill slurry by gravity are 100 and 10 mm, respectively. The vertical depth from surface to the backfilling level is about 385 m, the maximum horizontal transportation distance is 1 100 m in the first stage, and the L/H ratio is consequently 3.9.

2.2 Designed capability of backfill system in SCM

The yearly productivity (Ty) of ore that is mined using the backfilling method is 4 Mt/a and the necessary backfilling volume required (Va) is calculated as follows:

m3/a (1)

m3/a (1)

where γo denotes the density of ore, here γo=1.34 g/cm3; Z is the volumetric proportion of backfill to the emptied area left by mining activities, here Z=0.8; and K1 is the spare coefficient, here K1=1.15.

The necessary capability (Qr) of the backfill system is

m3/d (2)

m3/d (2)

or 74.4 m3/h if operational time is designed as 330 d/a (Td) or 12 h/d, and where K2 and K3 are the compression and settlement ratio, and the loss factor of backfill mixture while dewatering from stope to be backfilled, here they are 1.05 and 1.02, respectively.

2.3 Physical and mechanical parameters of backfill slurry

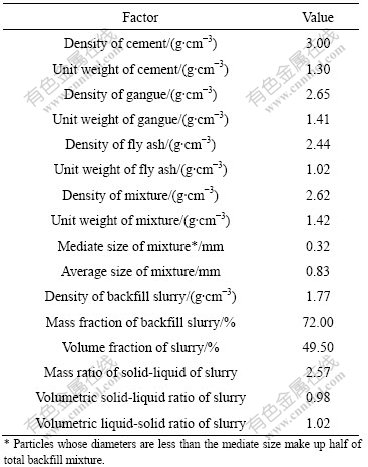

The physical and mechanical parameters of the suggested cemented coal gangue backfill are summarized in Table 1.

Table 1 Physical and mechanical parameters of backfill slurry in SCM

3 Critical and working velocities of backfill slurry

The critical velocity of the backfill slurry is defined as the minimum velocity at which particles are kept in a suspended state within the pipe and the flow resistance of the slurry is minimized. The critical velocity vl can be computed according to the following equation[13]:

(3)

(3)

where Fl is the velocity factor related to the mediate size of the backfill mixture and to the mass fraction of backfill slurry, here it is about 1.15; D and g are the inner diameter of the pipe and the gravity acceleration, respectively; γm is the density of the mixture; and γl is the density of the transportation media composed of water and fine solid particles with sizes less than 100 μm, and here it is 1.46 g/cm3.

By substituting values of the parameters mentioned above into Eqn.(3), the critical velocity of this system is obtained to be about 1.44 m/s. In other words, the working velocity of backfill slurry in SCM should be higher than 1.44 m/s in order to get stable and reliable transportation of backfill slurry.

The stable working velocity(v) depends on many factors, such as the inner diameter(D) of the pipe, L/H ratio and the resistance of the slurry, and it can be estimated by the following empirical equation:

(4)

(4)

where X and N represents volumetric ratio of liquid to solid in slurry and L/H ratio, respectively.

By substituting values of the related parameters into Eqn.(4), the working velocity of the gravity pipeline transportation system is calculated to be 3.82 m/s, which is about 2.7 times as large as that of the critical velocity, implying that the system is reliable in flowability.

4 Hydraulic gradient of backfill slurry

Gravity transportation reliability of backfill slurry depends greatly on hydraulic gradient of backfill slurry, including turbulence resistance in slurry and friction resistance between backfill slurry and pipe. Hydraulic gradient of the backfill slurry must be estimated before backfill system is designed.

4.1 Influencing factors of hydraulic gradient

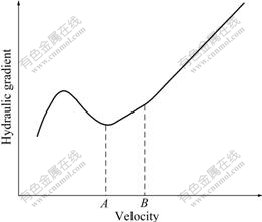

The velocity of backfill slurry is the most important factor influencing the hydraulic gradient. Hydraulic gradient of backfill slurry increases initially with the increasing velocity of the slurry and then decreases until the velocity reaches its critical value vl (point A in Fig.2). If the velocity of backfill slurry continues increasing after point A, the gradient will increase gradually again between points A and B and proportionally after point B. Reasonable velocity of backfill slurry should, therefore, lie between points A and B as shown in Fig.2.

Hydraulic gradient of the backfill slurry also increases with increasing sizes of solid particles and mass

Fig.2 Diagram showing relationship between hydraulic gradient and velocity of backfill slurry

fraction of slurry, and with decreasing diameter and installation quality of pipe.

4.2 Hydraulic gradient of backfill slurry in SCM

Thinking of a fact that hydraulic gradient is affected by many factors, hydraulic gradient of the backfill slurry in SCM can only be approximated by the following empirical equations.

4.2.1 Jinchuan’s equation

Jinchuan Non-ferrous Metal Corporation, a world famous nickel and copper mine situated in the northwest of China, proposed the following empirical equation to calculate the hydraulic gradient of backfill slurry with coarse particles[14]:

(5)

(5)

where i denotes the hydraulic gradient of backfill slurry; Cv is the volume fraction of slurry; γj is the density of backfill slurry; i0 and Cx are the hydraulic gradient of fresh water and the settlement resistance factor of solid particles, respectively.

The following equation can be used to approximate i0:

(6)

(6)

where λ is the friction resistance factor estimated as follows:

=0.024 8 (7)

=0.024 8 (7)

where K4 and K5 are the installation and joint quality factors of the pipeline, each taken as 1.1 here.

By substituting values of the friction resistance factor(λ), the working velocity(v) and other parameters into Eqn.(6), the hydraulic gradient of fresh water

=0.182 6

=0.182 6

is obtained.

The settlement resistance factor of solid particles Cx can be estimated by the following equation:

(8)

(8)

where dcp is the average size of the mixture; ω is the average settlement rate of solid particles and can be calculated according to the temporary parameter A=

= 0.051.

= 0.051.

Since dcp=0.083 is greater than A but less than 4.5A, ω can be estimated by following equation: ω= 102.71dcp(γj-1)0.7=7.1 cm/s and consequently Cx=1.66.

By substituting values of parameters mentioned above into Eqn.(5), the hydraulic gradient of backfill slurry with coarse particles, i, is about 0.22.

4.2.2 Northwest Hydraulic Research Institute’s equation

Experts of Northwest Hydraulic Research Institute, China, put forward the following empirical equation to calculate the hydraulic gradient of backfill slurry[15]:

=0.27 (9)

=0.27 (9)

where γw is the density of water.

In this work, the maximum of two values estimated by Eqns.(5) and (9), i.e. 0.27, is taken as the hydraulic gradient of the backfill slurry in SCM.

5 Estimation of maximum transportation distance of backfill slurry

The maximum distance of pipeline transportation by gravity flow of backfill slurry can be estimated by the allowable maximum L/H ratio, Nmax, which is approximated by the following empirical equation:

(10)

(10)

where K6 is the filled fraction of slurry in the vertical pipe, K6=0.9; K7 is the coefficient of local resistance, K7=1.1; i is the hydraulic gradient of the backfill slurry in SCM, i=0.27.

Eqn.(10) gives the maximum L/H ratio Nmax of 5.4. Since the current L/H ratio N=3.9<Nmax=5.4, the gravity flow transportation is believed to be smooth and reliable. The maximum distance of pipeline transportation by gravity flow of backfill slurry can reach 2 079 m, assuming that the vertical backfill depth is 385 m.

6 Examination of capability of backfill system

The backfill capability of the system (Qj) can be estimated by the working velocity of slurry as follows:

=110.18 m3/h (11)

=110.18 m3/h (11)

The fact that Qj is much greater than Qr means that the backfill system can satisfy the requirement of the necessary backfill volume.

Practical velocity of backfill slurry and backfill capability of the system reach 3.5 m/s and 100 m3/h in site test, implying that the hydraulic calculation approaches used in this work are of enough accuracy.

7 Conclusions

1) Hydraulic calculation process of gravity transportation pipeline system for backfill slurry is demonstrated by a case study of Suncun Coal Mine, Shandong Province, China, where goaf left by coal extraction is filled by cemented coal gangue.

2) The necessary capability of the gravity transportation pipeline system for cemented coal gangue backfill at the Suncun Coal Mine, is about 74.4 m3/h according to the mining production and working times in the mine. The critical velocity of the backfill slurry defined as the minimum velocity for reliable transportation within the pipe is about 1.44 m/s. The working velocity and the maximum L/H ratio of the backfill system are 3.82 m/s and 5.4, respectively and the probable backfill capability of the system is 110.18 m3/h.

3) The results of hydraulic calculations for the backfill transportation system show that the designed backfill system is reliable in flowability and sufficient for the needs of backfill capability.

Acknowledgments

Many thanks are due to President DI Kuang-you and General Engineer ZHANG Dian-zhen of SCM for their support of this research work.

References

[1] YU Bin. Computation and measurement of hydraulic parameters for gravity pipeline transportation [J]. Jiangxi Non-ferrous Metals, 1999, 13(4): 1-3, 10. (in Chinese)

[2] WANG Pei-xun. Hydraulic gradient calculation of mine filling paste [J]. Non-ferrous Mines, 2003, 32(1): 8-11. (in Chinese)

[3] ZHANG Qin-li, WANG Xin-min. Performance of cemented coal gangue backfill [J]. Journal of Central South University of Technology, 2007, 14(2): 216-219.

[4] ZHOU Ai-min. Mining backfill technology in China [C]// Proceedings of the 8th International Symposium on Mining with Backfill. Beijing: Nonferrous Metal Society of China, 2004: 1-11.

[5] RICHARD D P. Flow velocities in pipelines [J]. Journal of Hydraulic Engineering, 1983, 109(8): 108-111.

[6] ZHANG Wei-zhi. Hydraulic and thermal calculation on extra-viscous crude transportation pipeline [J]. Oil and Gas Storage and Transportation, 2007, 26(4): 11-13. (in Chinese)

[7] MAO Ze-yu, ZHAO Xuan, LUO Sheng. Analytic expression for partially-filled flow velocity in pipe of circular section [J]. Advances in Water Science, 2007, 18(2): 170-174. (in Chinese)

[8] YIN Ai-wu, DUAN Yao-guang, SUN Jun. The design of steam pipes hydraulic computing system [J]. Journal of Shandong Jianzhu University, 2007, 22(1): 61-64. (in Chinese)

[9] PENG Xin, LI Xi-bing, ZHANG Qin-li, WANG Xin-min. Quality evaluation of layerlike backfilling and flow pattern of backfill slurry in stope [J]. Journal of Central South University of Technology, 2007, 14(4): 580-583.

[10] CHEN Tao-yu. Theoretical research on the flow resistance of sewage in pipes from two phase fluid [J]. Journal of Kunming University of Science and Technology: Science and Technology, 2007, 32(3): 68-71. (in Chinese)

[11] ZHANG Yao-zhe. Study on theoretic formula of sedimentation velocity in the sediment group settlement zone [J]. Journal of Northwest Sci-tech University of Agriculture and Forestry: Natural Science Edition, 2006, 34(4): 117-120. (in Chinese)

[12] NI Fu-sheng, ZHAO Li-juan. Two-phase flow of highly concentrated slurry in a pipeline [J]. Journal of Hydraulics, Series B, 2004, 16(3): 325-331.

[13] Editorial Committee of the Handbook of Mineral Processing. Handbook of mineral processing [M]. Beijing: Metallurgical Industry Press, 2004. (in Chinese)

[14] Editorial Committee of the Handbook of Mining Design. Handbook of mining design [M]. Beijing: China Architecture and Building Press, 1987. (in Chinese)

[15] LIU Ke-ren. Basis of backfill theory [M]. Beijing: Metallurgical Industry Press, 1982. (in Chinese)

(Edited by CHEN Wei-ping)

Foundation item: Project(50490270) supported by the National Natural Science Foundation of China

Received date: 2008-03-07; Accepted date: 2008-04-10

Corresponding author: ZHANG Qin-li, Professor, PhD; Tel: +86-731-8877225; E-mail: zhangqinli@mail.csu.edu.cn