DOI:10.19476/j.ysxb.1004.0609.2019.02.02

中高应变速率轧制AZ31镁合金的边裂、组织与性能

刘 筱1,朱必武1,吴远志2,王洋洋1,唐昌平1,刘文辉1

(1. 湖南科技大学 高温耐磨材料及制备技术湖南省国防科技重点实验室,湘潭 411201;

2. 湖南工学院 汽车零部件技术研究院,衡阳 421002)

摘 要:对铸态AZ31镁合金进行温度350~450 ℃、平均应变速率为2.26~8.3 s-1的中高应变速率轧制,研究轧制后镁板的边裂和组织性能。研究结果表明:随着平均应变速率增加,轧制边裂得到改善;轧后镁板室温拉伸断裂方式具有韧-脆性断裂向韧性断裂转变的趋势,在拉伸断口中观察到拉长形孔洞和夹着韧窝的层状结构;镁合金抗拉强度受细晶强化和孪晶强化的共同作用,建立了考虑细晶强化和孪晶强化叠加的本构关系。

关键词:AZ31镁合金;中高应变速率轧制;边裂;组织;断裂方式

文章编号:1004-0609(2019)-02-0232-09 中图分类号:TG339 文献标志码:A

镁合金作为21世纪的绿色环保材料之一,近年来已成为全球的一个研究热点,越来越受到工业界的重视,其中镁合金板材被广泛用于交通运输、航空航天和电子等领域[1-2]。轧制是镁合金板材生产的最主要方式,但是由于镁合金的密排六方结构导致其塑性成形能力差,传统的镁合金轧制过程多采用多道次小下压量且道次间需要多次退火,以防止边裂和裂纹及加工硬化[3-4],因此生产效率低。

近年来,日本大阪大学[5-10]、湖南大学[11-14]和加拿大麦吉尔大学[15-17]相继提出一种高效短流程制备细晶镁合金的有效方法—高应变速率轧制,实现了单道次塑性大变形获得了晶粒细小性能优异的镁合金轧板。USTUNOMIYA等[5-10]采用高应变速率轧制制备了AZ31、AZ31B和AZ80镁合金板材,发现采用不同的应变速率和预热温度能够实现单道次下压量达60%,并获得晶粒细小(平均晶粒尺寸2~3 μm)且性能良好的镁合金轧板。ZHU等[11-12]和朱素琴[13]对ZK60镁合金开展了中高应变速率轧制的研究,发现在温度为250、300、350和400℃,平均应变速率在7.8~9.6 s-1之间能够制备获得细晶镁合金(平均晶粒0.4~2.5 μm)。SANJARI等[16]对AZ31镁合金进行高应变速率轧制,成功实现单道次60%的变形量,获得均匀的等轴晶粒(平均晶粒尺寸9~16 μm)。JIANG等[18]通过预轧制后再进行温度为300 ℃、平均应变速率为9.1 s-1的高应变速率轧制制备ZM61镁合金板材,实现单道次下压量80%,并获得平均晶粒尺寸为0.8 μm且力学性能优良的镁合金板材,并指出预轧制后的板材比铸态板材通过高应变速率轧制后获得的组织更均匀。由此可见,高应变速率轧制突破了常规轧制过程中加工窗口的局限性。

前期高应变速率轧制的研究未对边裂和组织与性能的关系展开了深入研究。本文作者以商用AZ31镁合金连铸板坯为研究对象,进行平均应变速率为2.26~8.3 s-1、轧制温度为350~450 ℃的单道次大变形轧制,实现将镁板从10 mm厚一次轧制成形到2.1 mm厚的镁合金薄板。通过宏观形貌观察不同轧制工艺下边裂并测量边部裂纹长度,利用光学显微镜观察终轧组织,并对终轧镁板不同方向进行力学性能测试,分析拉伸断口形貌,研究不同轧制工艺对镁板断裂方式的影响,并建立考虑细晶强化和孪晶强化叠加的本构关系深入研究终轧组织与力学性能的关系。

1 实验

实验采用10 mm厚商用AZ31镁合金连铸板坯,其主要成分为3.19%Al、0.81%Zn、0.33%Mn,其余为Mg(质量分数),其初始组织如图1所示。将板坯加工成123 mm×50 mm×10 mm板料作为轧制坯料,在d 400 mm×400 mm二辊热轧机上对AZ31板坯进行单道次中高应变速率轧制,轧辊转速分别为114、272和418.7 mm/s。轧制前,合金分别进行350、400和450 ℃预热10~20 min,然后从10 mm厚一次轧制成形到2.1 mm厚,对应的轧制工艺如下。

工艺1:400 ℃, 2.26 s-1;工艺2:400 ℃,

2.26 s-1;工艺2:400 ℃, 5.4 s-1;工艺3:400 ℃,

5.4 s-1;工艺3:400 ℃, 8.3 s-1;工艺4:450 ℃,

8.3 s-1;工艺4:450 ℃, 8.3 s-1;工艺5:350 ℃,

8.3 s-1;工艺5:350 ℃, 8.3 s-1。

8.3 s-1。

图1 AZ31镁合金板坯的初始组织

Fig. 1 Initial microstructure of AZ31 magnesium alloy

由于轧制过程中应变速率不是常数,目前通用方法是计算变形区各断面应变速率平均值,称为平均应变速率,其计算公式如式(1):

(1)

(1)

式中:r为轧辊半径;v为轧辊圆周速度;H为轧前板材厚度;h为终轧板材厚度。

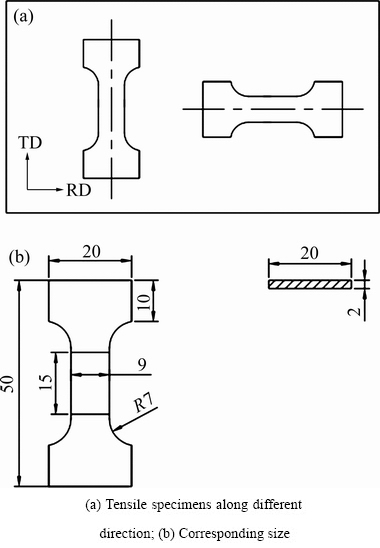

为分析轧后微观组织,在轧后镁板中部沿纵截面(轧制方向-轧面法线方向(Rolling direction- normal direction, RD-ND))及横截面(轧面法线-轧件横向(Normal direction-transverse direction, ND-TD))取样品制成金相试样,依次用500#、800#、2000#水砂纸打磨,0.3 μm抛光膏抛光,4.2 g苦味酸+10 mL水+10 mL冰醋酸+70 mL酒精混合溶液腐蚀进行10~20 s的腐蚀,然后采用德国蔡司Axiovert 40 MAT金相显微镜进行金相观察。沿轧后镁板RD和TD两个方向加工拉伸试样,在WDW-E200型万能试验机上进行室温拉伸,拉伸速率为1mm/min,取样方式及试样尺寸如图2所示,然后采用JSM-6380LV型扫描电子显微镜观察拉伸断口。

图2 拉伸试样取样方式及尺寸示意图

Fig. 2 Schematic diagrams of specimens extracted from rolled alloys (Unit: mm)

2 结果与讨论

2.1 轧制板材宏观形貌和边裂

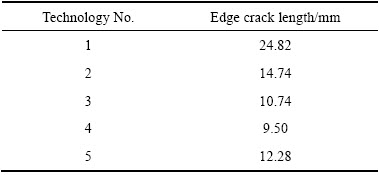

图3所示为不同轧制工艺下轧制镁板的宏观形貌。由图3可知,在温度为400 ℃、平均应变速率为2.26 s-1下进行轧制(见图3(a)),轧板产生边裂且贯穿整个镁板;保持温度不变,当平均应变速率增加到5.4 s-1时(见图3(b)),轧后镁板并未出现贯穿整个镁板的裂纹,但边裂仍然存在;温度保持不变,当平均应变速率继续增加至8.3 s-1时(见图3(c)),边裂得到明显改善;当保持平均应变速率为8.3 s-1,温度增加到450 ℃时(见图3(d)),边裂情况与温度为400 ℃时情况相差不大;当保持平均应变速率为8.3 s-1,温度降低至350 ℃时(见图3(e)),边裂长度明显增加。为了清楚地了解边裂情况,在镁板左右两侧边裂部分随机测量6条裂纹长度并取平均值列于表1。由表1可知,保持轧制温度不变时,裂纹长度随着平均应变速率增加而减小;当保持平均应变速率不变,裂纹长度随着温度增加而减小。

图3 不同轧制工艺下轧制镁板宏观形貌

Fig. 3 Macroscopic features of rolling magnesium alloy sheets under different rolling technologies

表1 不同轧制工艺下边裂平均长度

Table 1 Length for edge cracks under different rolling technologies

镁板轧制边裂受到板坯规格、初始织构、轧制工艺及微观组织演变的综合影响。从力学角度来看,根据Cockcraft & Latham损伤模型[19-20],可对轧制边裂进行判定,其计算式如式(2)所示:

(2)

(2)

式中: 为等效应变;

为等效应变; 为等效应力;

为等效应力; 为峰值应力;

为峰值应力; 为断裂应变;C为损伤因子。镁板边部最大拉伸主应力及主应变达到临界值时,会导致轧制边裂产生,下压量增加导致镁板边部逐渐减薄,同时,随平均应变速率增加,峰值应力也会增加,导致C值增加,更加容易达到损伤临界值。但实验结果表明,随平均应变速率增加边裂趋势减小,这是由于随着平均应变速率增加,塑性变形功和轧辊与板材之间摩擦导致轧制过程中温度升高[17, 21]。栾娜等[22]发现预设温度为350 ℃、应变速率≥10 s-1、应变达到1时,材料温升达到50 ℃以上时。镁板轧制温度与边裂现象存在较强的相关性[20]。从力学角度来看,轧制温度是影响镁板边部拉伸力的主要因素,温度升高,拉应力减小。因此,随着应变速率增加,实际轧制温度升高,镁板边裂现象得到明显改善。

为断裂应变;C为损伤因子。镁板边部最大拉伸主应力及主应变达到临界值时,会导致轧制边裂产生,下压量增加导致镁板边部逐渐减薄,同时,随平均应变速率增加,峰值应力也会增加,导致C值增加,更加容易达到损伤临界值。但实验结果表明,随平均应变速率增加边裂趋势减小,这是由于随着平均应变速率增加,塑性变形功和轧辊与板材之间摩擦导致轧制过程中温度升高[17, 21]。栾娜等[22]发现预设温度为350 ℃、应变速率≥10 s-1、应变达到1时,材料温升达到50 ℃以上时。镁板轧制温度与边裂现象存在较强的相关性[20]。从力学角度来看,轧制温度是影响镁板边部拉伸力的主要因素,温度升高,拉应力减小。因此,随着应变速率增加,实际轧制温度升高,镁板边裂现象得到明显改善。

2.2 轧制板材的微观组织

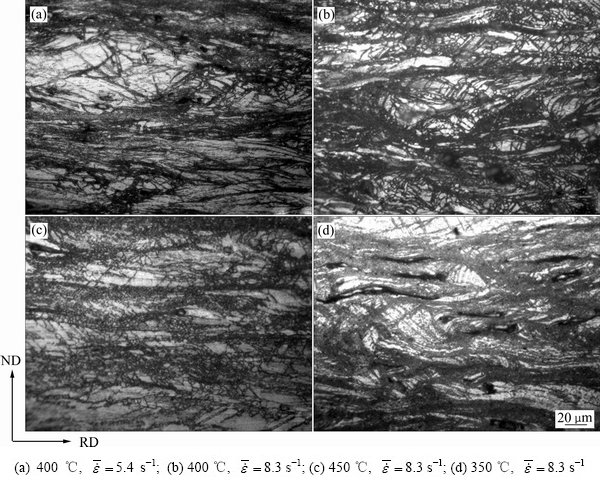

图4所示为不同轧制工艺下镁板(ND-RD)面的显微组织。当温度为400 ℃、平均应变速率为5.4 s-1时(见图4(a)),观察到粗大的初始组织,在这些组织内部观察到孪晶,且孪晶内部具有细小再结晶晶粒,说明孪生诱导动态再结晶。此外,粗大组织周围有大量细小再结晶晶粒形成的细晶带。当温度为400 ℃、平均应变速率增加到8.3 s-1时(见图4(b)),被拉长的粗大晶粒内部孪晶数量增多且相互交叉,并发现孪生诱导动态再结晶现象;被拉长的粗大晶粒之间有细小再结晶晶粒组成的细晶带,其晶粒尺寸较平均应变速率为5.4 s-1时粗大,是由于平均应变速率增加温升增加导致再结晶晶粒尺寸增加。当温度为450 ℃、平均应变速率为8.3 s-1时(见图4(c)),被拉长的原始晶粒仍然存在,再结晶晶粒沿着RD方向生长。当温度为350 ℃、平均应变速率为8.3 s-1时(见图4(d)),粗大的原始组织被细小的再结晶晶粒成形的细晶带和孪晶包围,同时,还观察到大量的裂纹。ZHU等[12]和YOO[23]提出孪生和裂纹在母相晶粒内存在竞争关系。在内应力作用下,母相晶粒中到底是孪生形核还是裂纹产生取决于孪生和裂纹形成的临界应力之比。当应力集中首先达到裂纹形核的临界应力时产生裂纹,裂纹释放应力集中,如果内应力降低到低于孪生形成所需的临界条件,孪生被抑制。在目前研究中,由于内应力集中达到裂纹产生的临界条件导致裂纹产生,内应力释放;但是内应力未下降到低于孪生和动态再结晶产生的临界值,再结晶晶粒和孪生在裂纹附近形成,释放大量的应力集中,消耗了裂纹扩展产生新界面所需表面能,使裂纹扩展得到抑制。

图4 不同轧制工艺下镁板(ND-RD)面的显微组织

Fig. 4 Microstructures of (ND-RD) surface of magnesium alloy under different rolling technologies

图5所示为不同轧制工艺下镁板(ND-TD)面的显微组织。在图5(a)~(d)中都可以观察到原始粗大晶粒。在温度为450 ℃、平均应变速率为8.3 s-1时,组织相对其它工艺均匀,再结晶比较完全且未观察到孪晶,是由于在高温下 锥面滑移和棱柱面滑移的临界剪切应力大幅度降低,其值分别为2 MPa和0.9 MPa[24],低于产生拉伸孪生的临界剪切应力,因此不需要大量孪生来协调均匀塑性变形;另外也有可能是变形温度较高使再结晶较完全,再结晶在孪晶界和孪晶内形成导致孪晶失去本来形貌。

锥面滑移和棱柱面滑移的临界剪切应力大幅度降低,其值分别为2 MPa和0.9 MPa[24],低于产生拉伸孪生的临界剪切应力,因此不需要大量孪生来协调均匀塑性变形;另外也有可能是变形温度较高使再结晶较完全,再结晶在孪晶界和孪晶内形成导致孪晶失去本来形貌。

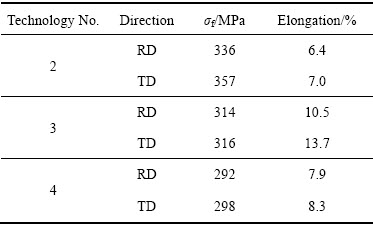

2.3 轧制板材力学性能

表2所示为不同轧制工艺下镁板平行于轧制方向和垂直于轧制方向的力学性能。由表2可知,经工艺2和3处理的合金具有比经工艺4处理的合金更高的抗拉强度。材料强度不仅与晶粒尺寸减小引起的强化有关[25]。同时,孪生边界对位错运动有很强的阻碍作用也会提高材料的强度[26]。因此,在考虑晶粒尺寸、位错密度和孪晶对材料强度叠加影响的本构模型[27]的基础上建立考虑晶粒尺寸和孪晶对材料强度叠加影响的本构关系,其计算式如下:

(3)

(3)

式中: 为抗拉强度;

为抗拉强度; 为屈服强度;k为与晶粒尺寸相关的参数,其描述的是晶界对强度的贡献;d为平均晶粒尺寸;k1为与孪晶距离有关的参数;dts为孪晶间距。由图4和5可知,通过工艺4轧制后获得的组织相对均匀,其再结晶程度高,平均晶粒尺寸相对工艺2和3细小,但是工艺2和3轧制的镁板存在大量孪晶,这些孪晶对材料具有强化作用,因此,工艺2和工艺3由于孪晶的强化作用导致了工艺2和3轧制后的镁板抗拉强度高于工艺4轧制镁板的抗拉强度。

为屈服强度;k为与晶粒尺寸相关的参数,其描述的是晶界对强度的贡献;d为平均晶粒尺寸;k1为与孪晶距离有关的参数;dts为孪晶间距。由图4和5可知,通过工艺4轧制后获得的组织相对均匀,其再结晶程度高,平均晶粒尺寸相对工艺2和3细小,但是工艺2和3轧制的镁板存在大量孪晶,这些孪晶对材料具有强化作用,因此,工艺2和工艺3由于孪晶的强化作用导致了工艺2和3轧制后的镁板抗拉强度高于工艺4轧制镁板的抗拉强度。

图5 不同轧制工艺下镁板(ND-TD)面的显微组织

Fig. 5 Microstructures of (ND-TD) surfaces of magnesium alloy under different rolling technologies

表3 不同工艺下的镁板平行于和垂直于轧制方向的力学性能

Table 3 Mechanical properties of magnesium alloy along RD and TD under different rolling technologies

2.4 拉伸断口形貌

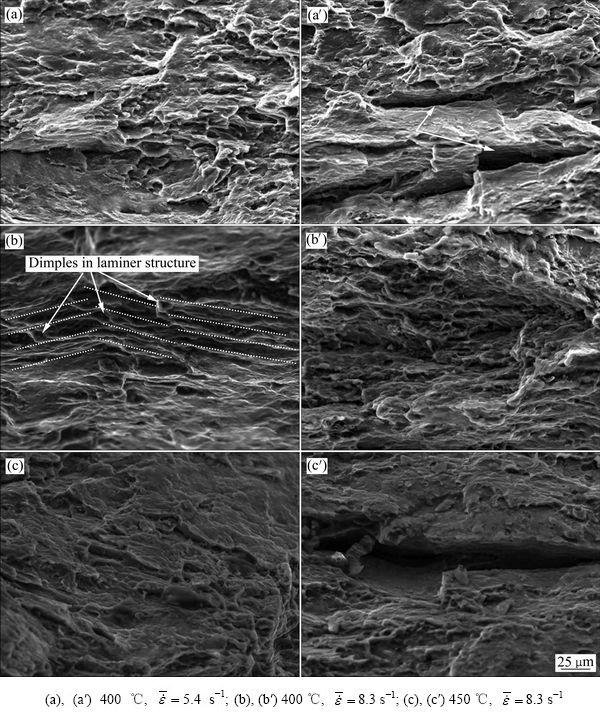

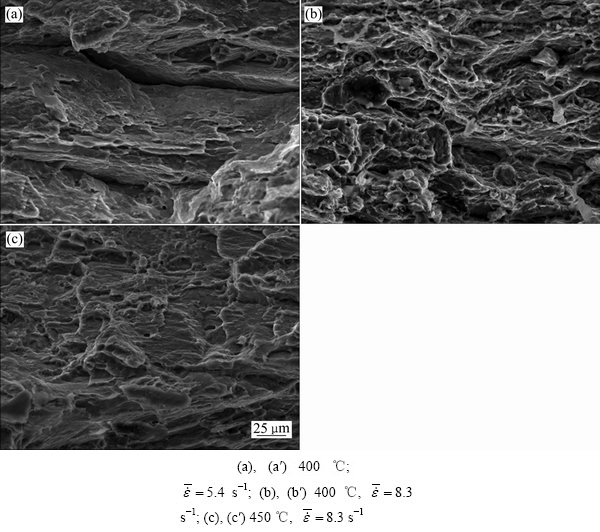

图6所示为不同轧制工艺下镁板平行于轧制方向拉伸断口形貌。图7所示为不同轧制工艺下镁板垂直于轧制方向拉伸断口形貌。由图6(a)、(a′)和图7(a)可知,观察到长条形孔洞(见图6(a′)中剪头),这些孔洞起始于拉长的初始晶粒和孪晶边界,同时如图6(a)和(a′)所示断口中观察到大量的韧窝,部分韧窝分布在长条形孔洞的边界(见图6(a')),说明在粗大晶粒边界和孪晶边界产生了再结晶,根据断口形貌可判定为 韧-脆性断裂方式。通过温度400 ℃、平均应变速率8.3 s-1轧制后镁板室温拉伸的断口形貌以韧窝为主(见图6(b)、(b')和图7(b)),同时观察到细小韧窝(见图6(b)中红色箭头)分布于层状形貌内部(见图6(b)中黄色虚线部分),这与金相观察到的孪晶和细晶带内形成细小再结晶形貌相符,而韧窝深度大于图6(a)、(a')和图7(a)的深度,进一步证实了拉伸试验结果,根据断口形貌可判定在该条件下主要是韧性断裂为主。通过温度为450 ℃、平均应变速率为8.3 s-1轧制后镁板室温拉伸的断口观察到长条形孔洞(见图6(c'))、韧窝(见图6(c)、(c')和图7(c))和微坑(见图7(c)),同时也观察到撕裂棱和河流花样,可判定为韧-脆性断裂方式。

在粗晶镁合金中,裂纹沿着粗大晶粒边界、孪晶和交叉孪晶边界形核和扩展,因为粗大晶粒边界、孪晶和交叉孪晶边界的位错缠结导致应力集中,这些应力集中,容易达到裂纹产生的临界条件[28-30]。在细晶镁合金中,裂纹主要由晶界尤其是三晶交界处的空洞形成、合并和长大引起[31]。FEDOROVO等[32]指出,晶界处的位错缠结在三晶交界处堆积,导致了严重的应力集中,这时需要空洞来消除应力集中。由此可见,目前的长条形孔洞是由裂纹沿大晶粒边界和孪晶边界形核和扩展而形成,而细小的韧窝由空洞合并和长大最终沿着细小晶界断裂引起。

图6 不同轧制工艺下镁板平行于轧制方向的拉伸断口

Fig. 6 Tensile fracture of magnesium alloy along RD under different rolling technologies

图7 不同轧制工艺下镁板垂直于轧制方向的拉伸断口

Fig. 7 Tensile fracture of magnesium alloy vertical to RD under different rolling condition

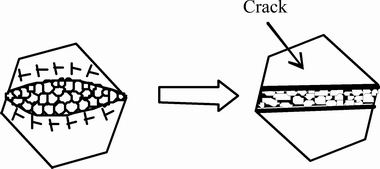

图8 夹着韧窝的层状结构形成示意图

Fig. 8 Schematic diagram for formation of laminar structure with dimples

此外,断口中观察到夹着韧窝的层状结构,这种形貌的形成与孪生诱导动态再结晶有关,其断裂机理如图8所示。在拉伸过程中,位错塞积在孪晶界和孪晶内细小再结晶晶界,导致裂纹和空洞的产生,裂纹沿着孪晶界扩展形成层状结构,空洞在细小再结晶晶界处合并和长大形成韧窝,从而形成夹着韧窝的层状结构。

3 结论

1) 当轧制温度大于350 ℃、平均应变速率大于5.4 s-1时,能获得外观形貌良好的镁合金轧板。随着平均应变速率提高,塑性变形产生的热量增加,温升增加,边裂扩展得到抑制,边裂长度降低。

2) 镁合金抗拉强度同时受到细晶强化和孪晶强化的影响,建立考虑晶粒尺寸和孪晶对材料强度叠加影响的本构关系 。孪晶强化作用导致工艺2和工艺3条件下轧制获得的镁板相对工艺4具有更高的抗拉强度。

。孪晶强化作用导致工艺2和工艺3条件下轧制获得的镁板相对工艺4具有更高的抗拉强度。

3) 随着平均应变速率提高,轧后镁板室温拉伸的断裂方式具有韧-脆性断裂向韧性断裂转变的趋势。拉伸断口中发现夹着韧窝的层状结构和长条形孔洞。夹着韧窝的层状结构与孪生诱导动态再结晶有关。AZ31镁板拉伸断口呈现出长条形孔洞,是由于裂纹沿粗大晶粒边界、孪晶和交叉孪晶边界形成和扩展。

REFERENCES

[1] 王尔德. 镁合金塑性加工产业技术研究进展[J]. 精密成形工程, 2014, 6(6): 22-30.

WANG Er-de. Recent researches in industrial plasticity processing of magnesium alloy [J]. Journal of Netshape Forming Engineering, 2014, 6(6): 22-30.

[2] 丁文江, 吴玉娟, 彭立明, 曾小勤, 林栋梁, 陈 彬. 高性能镁合金研究及应用的新进展[J]. 中国材料进展, 2010, 29(8): 37-45.

DING Wen-jiang, WU Yu-juan, PENG Li-ming, ZENG Xiao-qin, LIN Dong-liang, CHEN Bin. Research and application development of advanced magnesium alloys [J]. Materials China, 2010, 29(8): 37-45.

[3] 张丁非, 戴庆伟, 胡耀波, 兰 伟, 方 霖. 镁合金板材轧制成型的研究进展[J]. 材料工程, 2009, 10: 85-90.

ZHANG Ding-fei, DAI Qing-wei, HU Yao-bo, LAN Wei, FANG Lin. Progress in the research on rolling formation of magnesium alloy sheet [J]. Journal of Materials Engineering, 2009, 10: 85-90.

[4] 杨 平, 孟 利, 毛卫民, 蔡庆武. 利用道次间退火改善镁合金轧制成形性的研究[J]. 材料热处理学报, 2005, 26(2): 34-40.

YANG Ping, MENG Li, MAO Wei-min, CAI Qing-wu. Study on the improvement of formability of magnesium alloy sheet using annealing during rolling pass intervals [J]. Transactions of Materials and Heat Treatment, 2005, 26(2): 34-40.

[5] UTSUNOMIYA H, SAKAI T, MINAMIGUCHI S, KOH H. High-speed heavy rolling of magnesium alloy sheets[C]// LUO A A. Magnesium Technology. USA: San Antonio, 2006: 201-204.

[6] SAKAI T, UTSUNOMIYA H, MINAMIGUCHI S, KOH H. Single pass large draught rolling of magnesium alloy sheets by high speed rolling[C]// PEKGULERYUZ M. O, MACKENZIE W F. Proceedings of Magnesium Technology in the Global Age. Canada: Montreal, 2006: 205-215.

[7] MINAMIGUCHI S, UTSUNOMIYA H, KOH H. Improvement of mechanical properties of AZ31B sheets by high speed rolling[C]// PEKGULERYUZ M O, MACKENZIE W F. Proceedings of Magnesium Technology in the Global Age. Canada: Montreal, 2006: 217-227.

[8] KOH H, SAKAI T, UTSUNOMIYA H, MINAMIGUCHI S. Deformation and texture evolution during high-speed rolling of AZ31 magnesium sheets[J]. Materials Transactions, 2007, 48(8): 2023-2027.

[9] HAMADA G, SAKAI T, UTSUNOMIYA H. Effect of rolling speed on deformability and microstructure in rolling of AZ31B magnesium alloy[J]. Advanced Materials Research, 2010: 227-231.

[10] SAKAI T, WATANADE Y, UTSUNOMIYA H. Microstructure and texture of AZ80 magnesium alloy sheet rolled by high speed warm rolling[J]. Materials Science Forum, 2009: 483-486.

[11] ZHU S Q, YAN H G, CHEN J H, WU Y Z, TIAN J. Effect of twinning and dynamic recrystallization on the high strain rate rolling process[J]. Scripta Materialia, 2010, 63: 985-988.

[12] ZHU S Q, YAN H G, CHEN J H. WU Y Z, SU B, DU Y G, LIAO X Z. Feasibility of high strain-rate rolling of a magnesium alloy across a wide temperature range[J]. Scripta Materialia, 2012, 67: 404-407.

[13] 朱素琴. 中高应变速率轧制制备超细晶镁合金板材原理探索及相关基础研究[D]. 长沙: 湖南大学, 2012.

ZHU Su-qin. An exploratory study on the principle of the fabrication of ultrafine grained magnesium sheets using medium-high strain rate rolling technique and the related fundamental research[D]. Changsha: Hunan University, 2012.

[14] ZHU S Q, YAN H G, LIAO X Z, MOODY S J, SHA G, WU Y Z, RINGER S P. Mechanisms for enhanced plasticity in magnesium alloys [J]. Acta Materialia, 2015, 82: 344-355.

[15] LI H L, HSU E, SZPUNAR J, UTSUNOMIYA H, SAKAI T. Deformation mechanism and texture and microstructure evolution during high-speed rolling of AZ31B Mg sheet[J]. Journal of Materials Science, 2008, 43: 7148-7156.

[16] SANGJARI M, FARZADFAR S A, UTSUNOMIYA H, SAKAI T. ESSADIQI E, YUE S. High speed rolling of Mg-3Al-1Zn alloy: Texture and microstructure analysis[J]. Materials Science and Technology, 2012, 28(8): 928-933.

[17] SU J, SANJARI M, KABIR A S H, JUNG I H, YUE S, UTSUNOMIYA H. Characteristics of magnesium AZ31 alloys subjected to high speed rolling[J]. Materials Science and Engineering A, 2015, 636: 582-592.

[18] JIANG J M, WU J, NI S, YAN H G, SONG M. Improving the mechanical properties of a ZM61 magnesium alloy by pre-rolling and high strain rate rolling[J]. Materials Science and Engineering A, 2018, 712: 478-484.

[19] 马立峰, 庞志宁, 黄庆学, 黄志权. AZ31B镁合金板材轧制变裂与温度场研究[J]. 稀有金属工程材料与工程, 2014, 43(S1): 387-392.

MA Li-feng, PANG Zhi-ning, HUANG Qing-xue, HUANG Zhi-quan. Edge cracks and temperature field of AZ31B magnesium alloy sheet[J]. Rare Metal Materials and Engineering, 2014, 43(S1): 387-392.

[20] 徐海洁, 马立峰, 刘光明, 黄志权, 刘鹏涛, 林金宝. AZ31B镁合金板材多道次轧制路径研究[J]. 机械工程学报, 2017, 53(10): 43-51.

XU Hai-jie, MA Li-feng, LIU Guang-ming, HUANG Zhi-quan, LIU Peng-tao, LIN Jin-bao. Research of multi-pass rolling routes for AZ31B Magnesium alloy sheet[J]. Journal of Mechanical Engineering, 2017, 53(10): 43-51.

[21] 张丁非, 戴庆伟, 方 霖, 张钧萍. 递温镁合金轧制的数值仿真和验证实验[J]. 中国有色金属学报, 2011, 21(1): 185-190.

ZHANG Ding-fei, DAI Qing-wei, FANG Lin, ZHANG Jun-ping. Simulation and confirmatory experiment on rolling of magnesium sheets with temperature gradient[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(1): 185-190.

[22] 栾 娜, 李落星, 李光耀, 钟志华. AZ80镁合金的高温热压缩变形行为[J]. 中国有色金属学报, 2007, 17(10): 1678-1684.

LUAN Na, LI Luo-xing, LI Guang-yao, ZHONG Zhi-hua. Hot compression deformation behaviors of AZ81 magnesium alloy at elevated temperature[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(10): 1678-1684.

[23] YOO M H. Slip, twinning, and fracture in hexagonal close-packed metals[J]. Metallurgical and Materials Transactions A, 1981, 12(3): 409-418.

[24] LIU X, JONAS J J, LI L X, ZHU B W. Flow softening, twinning and dynamic recrystallization in AZ31 magnesium[J]. Materials Science and Engineering A, 2013, 583: 242-253.

[25] KAMIKAWA N Y, HUANG X X, TSUJI N, HANSEN N. Strengthening mechanisms in nanostructured high-purity aluminum deformed to high strain and annealed[J]. Acta Materialia, 2009, 57(14): 4198-4208.

[26] TAO N R, LU K. Nanoscale structural refinement via deformation twinning in face-centered cubic metals[J]. Scripta Materialia, 2009, 60(12): 1039-1043.

[27] BALOGH L, FIGUEIREDO R B, UNGAR T, LANGDONG T G. The contributions of grain size, dislocation density and twinning to the strength of a magnesium alloy processed by ECAP[J]. Materials Science and Engineering A, 2010, 528: 533-538.

[28] SOMEKAWA H, SINGH A, MIKAI T. Fracture mechanism of a coarse-grained magnesium alloy during fracture toughness testing[J]. Philosophical Magazine Letters, 2009, 89: 2-10.

[29] YUE H Y, FU P H, LI Z M, PENG L M. Tensile crack initiation behavior of cast Mg-3Nd-0.2Zn-0.5Zr magnesium alloy [J], Materials Science and Engineering A, 2016, 673: 458-466.

[30] XIE C, FANG Q H, LIU X, GUO P C, CHEN J K, ZHANG M H, LIU Y W, Theoretical study on the  deformation twinning and cracking in coarse-grained magnesium alloys[J]. International Journal of Plasticity, 2016, 82: 44-61.

deformation twinning and cracking in coarse-grained magnesium alloys[J]. International Journal of Plasticity, 2016, 82: 44-61.

[31] SOMEKAWA H, NAJAJIMAM K, SINGH A, MUKAI T. Ductile fracture mechanism in fine-grained magnesium alloy [J], Philosophical Magazine Letters, 2010, 90: 831-839.

[32] FEDOROV A A, GUTKIN M Y, OVID’KO I A. Transformations of grain boundary dislocation pile-ups in nano- and polycrystalline materials[J]. Acta Materialia, 2003, 51(4): 887-898.

Edge crack, microstructure and mechanical property of AZ31 magnesium alloy sheets rolled by medium-high strain rate

LIU Xiao1, ZHU Bi-wu1, WU Yuan-zhi2, WANG Yang-yang1, TANG Chang-ping1, LIU Wen-hui1

(1. Key Laboratory of High Temperature Wear Resistant Materials Preparation Technology of Hunan Province, Hunan University of Science and Technology, Xiangtan 411201, China;

2. Research Institute of Automobile Parts Technology, Hunan Institute of Technology, Hengyang 421002, China)

Abstract: The medium-high strain rate rolling was carried out on as-casting AZ31 magnesium alloys over the temperature ranges from 350 to 450 ℃ with average strain rates of 2.26-8.3 s-1. The edge cracks, microstructures and mechanical properties were investigated. The results show that the edge crack is improved and the fracture mechanism of magnesium rolling sheet tends to transform from ductile-brittle fracture to ductile fracture with increasing average strain rate. The tensile fracture displays elongated holes and laminar structure with dimples. The tensile strength of magnesium alloy is affected by fine-grain strengthening and twins strengthening. A constitutive relation considering the fine-grain strengthening and twins strengthening was built.

Key words: AZ31 magnesium alloy; medium-high strain rate rolling; edge crack; microstructure; fracture mechanism

Foundation item: Projects(51601062,51601059, 51501063) supported by the National Natural Science Foundation of China; Project(2018JJ3180) supported by the Natural Science Foundation of Hunan, China

Received date: 2018-01-19; Accepted date: 2018-04-20

Corresponding author: ZHU Bi-wu; Tel:+86-731-58290847; E-mail: zmbh4538@163.com

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51601062,51605159,51501061);湖南省自然科学基金资助项目(2018JJ3180)

收稿日期:2018-01-19;修订日期:2018-04-20

通信作者:朱必武,讲师,博士:电话:0731-58290874;E-mail:zmbh4538@163.com