AZ91镁合金热轧退火过程中的织构演变

来源期刊:中国有色金属学报(英文版)2013年第8期

论文作者:B. ALILI H. AZZEDDINE K. ABIB D. BRADAI

文章页码:2215 - 2221

关键词:AZ91镁合金;织构;热轧;再结晶

Key words:AZ91 alloy; texture; hot rolling; recrystallization

摘 要:将具有随机初始织构的工业AZ91镁合金在450 °C进行均匀化热处理。经热处理后,合金中出现弱的{0001}– – 三重纤维织构。经400 °C热轧后, 合金的变形织构是典型的(0001)基面,其基极沿轧制方向分裂。在450 °C 退火36 h后, 其残余变形织构中的基极沿基面分布更均匀,没有出现晶粒的异常长大。

Abstract: A commercial AZ91 magnesium alloy with a random initial texture was subjected to homogenization heat treatment (solution annealing) at 450 °C. This resulted in the appearance of a weak triple (0001)–(1010)–(1120) fibber texture. After hot rolling at 400 °C, the deformation texture was typically (0001) basal with splitting of the basal poles in the rolling direction. After annealing at 450 °C for 36 h, the annealing texture was the retained deformation texture with more homogeneous distribution of poles around the ideal basal orientation. There was no trace of abnormal grain growth.

Trans. Nonferrous Met. Soc. China 23(2013) 2215-2221

B. ALILI, H. AZZEDDINE, K. ABIB, D. BRADAI

Faculty of Physics, University of Sciences and Technology Houari Boumediene (USTHB), BP32, El-Alia, Bab Ezzouar, 16111 Algiers, Algeria

Received 13 September 2012; accepted 28 December 2012

Abstract: A commercial AZ91 magnesium alloy with a random initial texture was subjected to homogenization heat treatment (solution annealing) at 450 °C. This resulted in the appearance of a weak triple (0001)– –

– fibber texture. After hot rolling at 400 °C, the deformation texture was typically (0001) basal with splitting of the basal poles in the rolling direction. After annealing at 450 °C for 36 h, the annealing texture was the retained deformation texture with more homogeneous distribution of poles around the ideal basal orientation. There was no trace of abnormal grain growth.

fibber texture. After hot rolling at 400 °C, the deformation texture was typically (0001) basal with splitting of the basal poles in the rolling direction. After annealing at 450 °C for 36 h, the annealing texture was the retained deformation texture with more homogeneous distribution of poles around the ideal basal orientation. There was no trace of abnormal grain growth.

Key words: AZ91 alloy; texture; hot rolling; recrystallization

1 Introduction

Over the last decades, the world has had an increasing interest in the Mg-based alloys for applications in the aerospace, aircraft, and automotive industries due to their low density and high specific strength. The AZ91 (Mg-9Al-1Zn-0.2Mn, mass fraction, %) is the most favored magnesium alloy used in approximately 90% of all magnesium cast products [1]. Structural applications of Mg alloys depend on the development of plastic-forming technologies, such as hot rolling, extrusion, forging, and press forming [2]. The main obstacle to the development of such technologies is the poor workability of Mg alloys due to their crystallographic structure, and often, the presence of a basal texture [3,4]. A subsequent recrystallization of Mg alloys such as AZ31 retains this texture after full recrystallization [5,6]. The basal texture is considered inadequate for deformation because it places most of the grains in an orientation that is difficult to deform. This results in stress concentration and premature failure.

Many processing technologies of Mg alloys (e.g. equal channel angular extrusion (ECAE) [7], differential speed rolling [8], torsion extrusion [9] and continuous extrusion [10]) were effective in developing weak or non-basal textures. Recently, it has been reported that more randomized texture could be obtained through alloying additions of yttrium (Y) and rare-earth elements such as neodymium (Nd) and cerium (Ce) [11,12]. A strong on-going research activity is devoted to this goal.

Grain refinement and texture control could improve the plastic workability, as well as the strength and mechanical anisotropy at ambient temperature [13,14]. Many authors attempted to study the texture evolution during and after thermo mechanical processing of Mg-based alloys [5,6,13-15]. Most of them were dedicated to the commercial wrought AZ31 alloy. However, a study of the texture evolution of the as-received, homogenized, hot deformed and annealed AZ91 alloy is still lacking.

In this study, the texture of a commercial AZ91 magnesium alloy was studied after homogenization, hot rolling, and recrystallization treatment.

2 Experimental

The AZ91 alloy investigated was provided by Hydro Aluminium R&D Bonn in the form of rolled cast sheets with 4.5 mm in thickness. Before rolling, in order to dissolve the precipitates and ensure a solute homogenization as already shown by XU et al [16], the material was solution annealed at 450 °C for 72 h. The rolling experiment was conducted at a nominal rolling temperature of 400 °C, with the aim of avoiding precipitation of the β-phase (Mg17Al12). The total reduction in thickness was 80% with a 10% reduction per pass. The samples were heat treated at 400 °C for 10 min between passes to stabilize the rolling temperature. After rolling, the samples were directly quenched in water then annealed at 450 °C for 36 h. It is to be noted that at this temperature, the alloy could not undergo any massive phase transformation like continuous or discontinuous precipitation of the Mg17Al12 equilibrium phase.

Specimens for optical microscopy were prepared by conventional grinding and diamond polishing, finishing with a colloidal silica solution. Etching was done with acetic picral solution to visualize the grains and grain boundaries.

The macrotexture was determined in the mid-plane of the specimens by measuring incomplete pole figures (5°≤α≤75°) in the back reflection mode using Co Kα radiation in an X-ray-texture goniometer. A set of six pole figures [ , {0002},

, {0002},  ,

,  ,

,  , and

, and  ] was used to calculate the orientation distribution functions (ODF) using MTEX toolbox [17]. Sample symmetry in the ODF calculation was assumed to be triclinic.

] was used to calculate the orientation distribution functions (ODF) using MTEX toolbox [17]. Sample symmetry in the ODF calculation was assumed to be triclinic.

3 Results and discussion

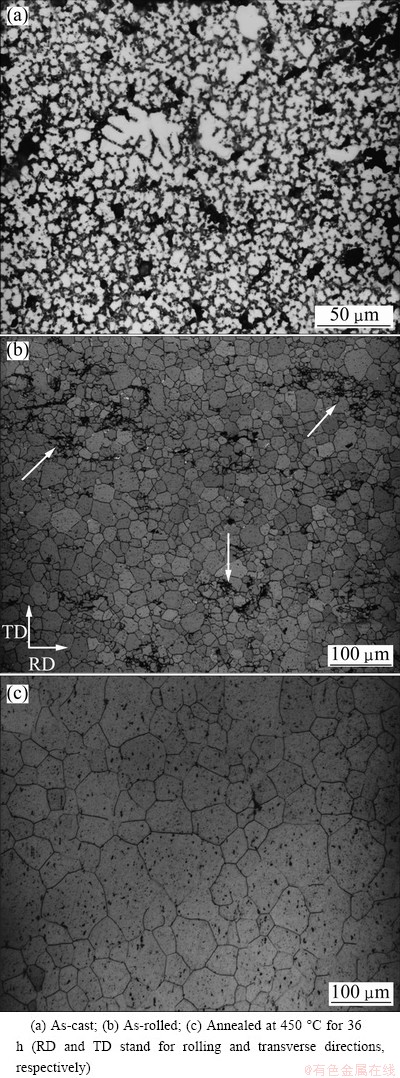

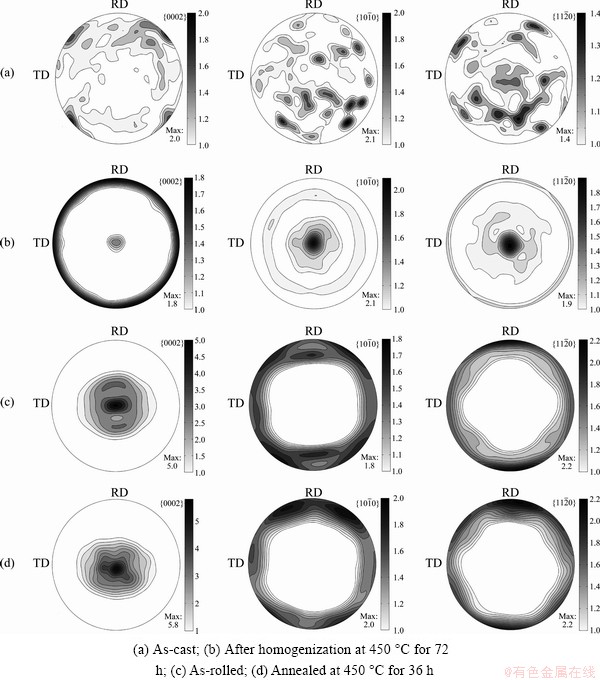

The optical micrographs of AZ91 alloys and their pole figures are shown in Fig. 1 and Fig. 2, respectively.

The as-cast microstructure of the AZ91 alloy shown in Fig. 1(a) is mainly composed of a semi-dendritic microstructure of the δ-Mg solid solution and the β-Mg17Al12 intermetallic phase precipitated in the interdendritic spaces (dark phase).

Figure 2(a) shows the recalculated (0002),  , and

, and  poles figures of the as-received AZ91 alloy. The texture of the alloy is random, a typical case for as-cast Mg alloys with grain inoculants [18,19]. It is believed that the semi-dendritic microstructure is responsible for the absence of evident texture.

poles figures of the as-received AZ91 alloy. The texture of the alloy is random, a typical case for as-cast Mg alloys with grain inoculants [18,19]. It is believed that the semi-dendritic microstructure is responsible for the absence of evident texture.

The texture of the supersaturated AZ91 alloy after homogenization and solution annealing at 450 °C for 24 h is shown in Fig. 1(c). As shown, the texture strength is obviously the same as that of the as-cast one, but it is clear that certain weak (0001),  , and

, and  fibber textures are starting to build up. Such a triple fibber texture emerging after solutioning could result from a mechanism of discontinuous dissolution that can appear in Mg-based alloy as reported in Ref. [20], but it cannot be the case presently because the original as-cast structure is of dendritic type as evidenced in Fig. 1(a).

fibber textures are starting to build up. Such a triple fibber texture emerging after solutioning could result from a mechanism of discontinuous dissolution that can appear in Mg-based alloy as reported in Ref. [20], but it cannot be the case presently because the original as-cast structure is of dendritic type as evidenced in Fig. 1(a).

Figure 1(b) presents the microstructure of the alloy in the as-deformed state. Non-uniform dynamically recrystallized grains (DRXed grains) visible with the un-DRXed original grains (see arrows) then produced a microstructure with a bimodal distribution of grain sizes with mean values of 5 and 25 μm, belonging to DRXed and un-DRXed, respectively. The DRXed grains exhibit

the well-known necklace microstructure [21]. DRX has not developed considerably, leaving large zones of deformed grains. Here, twins are seldom revealed by optical micrography.

Fig. 1 Optical micrographs showing microstructure of AZ91 alloy

In a recent work on the same alloy hot deformed by compression at 400 °C, XU et al [16,22] observed that, contrarily to us, an almost uniform DRXed grains with few relatively coarse un-DRXed grains were obtained. This microstructure difference may be explained by the deformation process (hot rolling versus hot compression), as well as deformation conditions (temperature, strain, and strain rate). Furthermore, it is worth noting that there was a temperature drop during rolling that increased with decreasing thickness, and the real hot rolling temperature was not 400 °C. This temperature drop affected the hot rolled microstructure, dynamic recovery, and recrystallization as well as precipitation stability. According to results of Al-samman et al [23], when deforming at a relatively low temperature and a high strain rate, DRX is postponed until a certain critical strain is reached.

Fig. 2 (0002),  and

and  recalculated pole figures of AZ91 alloy

recalculated pole figures of AZ91 alloy

MweMbela et al [24] pointed out that in Mg the level of dynamic recovery (DRV) is sufficiently low that DRX ensues above 240 °C, giving rise to new fine grains at the boundaries of the initial grain.

Figure 1(b) shows also a general thickening of the grain boundaries. This thickening is probably associated in some cases with the initiation of discontinuous precipitation, as already mentioned by Bettles [25]. At this magnification (Fig. 1(b)), we cannot see any extended cells of discontinuous precipitation.

In our opinion, up to now, discontinuous and continuous precipitation domains of Mg17Al12 precipitation in AZ91 alloy are not definitively established like in binary Mg-Al system [26]. XU et al [16,22] studied the effect of Mg17Al12 precipitate on the microstructural changes and mechanical properties of hot compressed AZ91 alloy. They evidenced a concomitant discontinuous and continuous precipitation when deforming the alloy up to 360 °C, while at 400 °C only the second type of precipitation was present. They assumed that the Mg17Al12 precipitated phase exhibited a strong influence on the DRX behaviour, and the change in amount and morphology of the precipitates were expected to result in the change in DRXed grain size and DRX ratio even the orientation of new DRX grains.

Figure 2(c) presents the texture of supersaturated solid solution AZ91 alloy after hot rolling at 400 °C (80% thickness reduction). It is characterized by the basal planes (i.e. c-axis) parallel to normal direction of the sheet with a certain slight splitting of the poles in the rolling direction. This type of texture has often been observed in conventional Mg sheet alloys [5,6,15], and was considered a result of increasing the activity of pyramidal <c+a>-slip and double-twinning, which causes a tilt of basal poles about ND of approximately 35°.

In the case of increased thermal activation of non-basal slip modes, the splitting of basal poles around TD is expected [27]. Moreover, the appearance of the basal texture depends strongly on the initial texture of the material [16]. A recent work of Abdessameud et al [6], devoted to studying the impact of initial texture on its evolution after uniaxial compression at 430 °C of an extruded AZ31 alloy, showed that the deformation of initial samples with compression direction parallel or normal to the extrusion direction led to a weak or strong basal texture, respectively.

The disappearance of the two  and

and  fibers is due to the activation of the basal slip and twinning during the deformation. The activation of twinning would cause an immediate 86°

fibers is due to the activation of the basal slip and twinning during the deformation. The activation of twinning would cause an immediate 86° reorientation of the twinned part of grains.

reorientation of the twinned part of grains.

The only difference of AZ91 alloy compared to AZ31 is that the maximum intensity is lower for the former. Recently, ABDESSAMEUD et al [5] have shown that the same texture evolution was evidenced in AZ31 alloy under the same deformation conditions. The maximum intensity of the basal texture was found 14 multiple of random distribution (mrd), while in the present work it is only 5 mrd. This considerable difference could be explained by the effect of Mg17Al12 precipitates. We can speculate then that new DRX grains may exhibit orientations that can be far from basal texture, weakening the overall texture intensity.

Very recently, LI et al [28] have addressed the role of Mg17Al12 equilibrium precipitate in the deformation mechanisms and the texture for AZ Mg alloys. They found that this phase reduced twinning activity, and then enhanced DRX, leading to weak deformation textures at high strains. While at 400 °C and 10-4 s-1, the dissolution of the Mg17Al12 equilibrium phase resulted in a sharp texture.

Many studies [29-31] have addressed the texture evolution of Mg-based alloys; they found that the texture of the DRX grains followed that of the parent grains closely in all alloys, implying that the DRX texture is dominated by the deformation conditions, rather than by the preferred nucleation or growth.

Figure 1(c) presents the microstructure of hot deformed AZ91 alloy annealed at 450 °C for 36 h. The annealing treatment resulted in a fully recrystallized microstructure, and in normal grain growth with an average grain size of 56 μm. Normal grain growth has been already evidenced in hot rolled AZ31 alloy (d ~30 μm for 10-2 s-1 and 450 °C) [6], and WE54 hot deformed by uniaxial and plane strain compression (d ~20 μm for 10-2 s-1 and 400 °C) [11]. Our results are in agreement with those of Al-Samman et al [32], who have assumed that, contrary to pure Mg and some other binary Mg alloys, AZ91 did not undergo considerable grain growth. This must be caused by a strong effect of solutes (Zener Drag) or precipitates that are more present in this alloy than AZ31 alloy.

The recrystallization-annealing texture of the AZ91 alloy is shown in Fig. 2(d) through recalculated {0002},  , and

, and  poles figures. It can be seen that it is almost the same as the deformation texture, i.e., retained basal texture with no other texture components. Similar observations were made for AZ31 alloy [5,13]. These authors have shown that such a stable basal texture existed even after full annealing at high temperature without emerging or strengthening any minor components. It should be noted that the splitting of basal poles has been replaced by a homogeneous distribution around the ideal basal orientation. Such a texture has already been observed in AZ31 alloy hot rolled at 400 °C after 80% of thickness reduction, and annealed at 450 °C for 10 d [8]. Unlike the cubic materials, the annealing texture in Mg and its alloys is often close to the deformation one [5,6,13], and is interpreted as continuous recrystallization or strong recovery. It has been reported that static annealing after deformation leads to only small texture changes [33,34].

poles figures. It can be seen that it is almost the same as the deformation texture, i.e., retained basal texture with no other texture components. Similar observations were made for AZ31 alloy [5,13]. These authors have shown that such a stable basal texture existed even after full annealing at high temperature without emerging or strengthening any minor components. It should be noted that the splitting of basal poles has been replaced by a homogeneous distribution around the ideal basal orientation. Such a texture has already been observed in AZ31 alloy hot rolled at 400 °C after 80% of thickness reduction, and annealed at 450 °C for 10 d [8]. Unlike the cubic materials, the annealing texture in Mg and its alloys is often close to the deformation one [5,6,13], and is interpreted as continuous recrystallization or strong recovery. It has been reported that static annealing after deformation leads to only small texture changes [33,34].

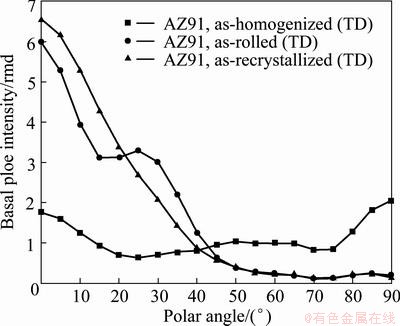

Of particular interest is the intensity of the basal poles for different state of AZ91 alloy as a function of tilt angle towards TD (Fig. 3). As pointed out by ION et al [29], this is a more convenient presentation of the texture and depicts the most important features of pole figures. In the case of as-rolled and recrystallized AZ91 alloy, a sudden drop of texture intensity was observed within 0-20° about ND (typical basal texture). By contrast, the basal pole intensity of as-cast AZ91 alloy dropped randomly along the tilt angles. With respect to tilt towards TD, the intensity distribution of homogenous AZ91 alloy increased between 80 and 90°, which is attributable to the  and

and  fibbers.

fibbers.

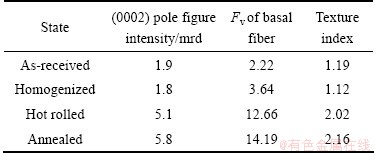

Table 1 summarizes the quantitative texture parameters determined by the MTEX software, which are: the maximum basal pole intensity, volume fraction of the basal fiber, and the texture index given by [35]

(1)

(1)

where f(g) is the ODF value and G is the Euler space.

Fig. 3 Basal pole intensity distribution for different states of AZ91 alloy as function of tilt towards TD

Table 1 Quantitative texture parameters determined by MTEX software for different states of AZ91 alloy

There is a substantial increase of the parameters from the as-received/homogenized to hot rolled/ recrystallized alloys, and these parameters are very close for the as-received and homogenized alloy, but a very slight increase for the annealed and rolled alloy.

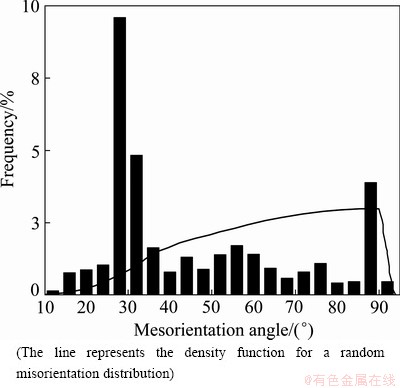

and RUANO [33] discussed the case where a single strong texture is present in the microstructure with a large number of lower-angle boundaries in a random distribution of grains. They assumed that relative growth of the grains depends strongly on the grain boundary character distribution, with a certain privilege for grains with high angle grain boundaries. Very recently, some of the present authors have studied the grain boundary character distribution effect on the discontinuous precipitation in AZ91 alloy [36]. Figure 4 shows the histogram of the grain boundary misorientation, corresponding to the supersaturated solid solution AZ91 after hot rolling and annealing at 450 °C for 36 h. The random distribution of grain boundaries is given in full line. In agreement with Ref. [37], the distribution revealed common special boundaries, with the maximum densities near 30° and 86°-90°, as well as in the absence of other orientation relationships with perceivable densities that could be indicative of new special boundaries. Following Refs. [22,38], these peaks correspond to

and RUANO [33] discussed the case where a single strong texture is present in the microstructure with a large number of lower-angle boundaries in a random distribution of grains. They assumed that relative growth of the grains depends strongly on the grain boundary character distribution, with a certain privilege for grains with high angle grain boundaries. Very recently, some of the present authors have studied the grain boundary character distribution effect on the discontinuous precipitation in AZ91 alloy [36]. Figure 4 shows the histogram of the grain boundary misorientation, corresponding to the supersaturated solid solution AZ91 after hot rolling and annealing at 450 °C for 36 h. The random distribution of grain boundaries is given in full line. In agreement with Ref. [37], the distribution revealed common special boundaries, with the maximum densities near 30° and 86°-90°, as well as in the absence of other orientation relationships with perceivable densities that could be indicative of new special boundaries. Following Refs. [22,38], these peaks correspond to  double twin, and

double twin, and  primary tensile twin, respectively. The misorientation distribution peak at 30° is very common in hexagonal materials, but the mechanisms behind it are not always the same. In the current case, one could expect that it is attributed to basal poles rotation about the c-axis during static recrystallization after rolling.

primary tensile twin, respectively. The misorientation distribution peak at 30° is very common in hexagonal materials, but the mechanisms behind it are not always the same. In the current case, one could expect that it is attributed to basal poles rotation about the c-axis during static recrystallization after rolling.

Fig. 4 Histogram of measured misorientation angle distribution for AZ91 alloy hot rolled and recrystallized at 450 °C for 36 h

As a result, neither the volume fraction of the basal fibber is strong nor the frequency of low angle grain boundaries is high. These observations allow us to conclude that the speculations in Ref. [33] may not be valid in our present study. A special thermo- mechanical processing and/or rare earth (RE) elements alloying (weak non-basal textures are often associated with complex mischmetal additions, rather than a single alloying element) [11,39] is necessary in order to promote randomized texture in the present alloy. This is the subject of ongoing research activity.

4 Conclusions

1) The as-received commercial AZ91 magnesium exhibited a random initial texture.

2) Homogenization heat treatment at 450 °C for 72 h resulted in the appearance of triple fiber texture basal,  , and

, and  .

.

3) After hot rolling at 400 °C, deformation texture was typically basal with splitting of the basal poles in the rolling direction.

4) Annealing texture after annealing at 450 °C for 36 h was the same and retained basal deformation texture with a homogeneous distribution of basal poles around the ideal basal orientation. Annealing also resulted in normal grain growth.

Acknowledgments

Miss H. AZZEDDINE wishes to heartily thank Pr. G. GOTTSTEIN and Dr. T. Al-SAMMAN from the Institüt für Metallkunde und Metallphysik, RWTH Aachen, Germany, for their assistance and help.

References

[1] CELOTTO S. TEM study of continuous precipitation in Mg- 9wt%Al-1wt%Zn alloy [J]. Acta Materialia, 2000, 48: 1775-1787.

[2] MOHRI T, MABUCHI M, NAKAMURA M, ASAHINA T, IWASAKI H, AIZAWA T, HIGASHI Y K. Microstructural evolution and superplasticity of rolled Mg-9Al-1Zn [J]. Materials Science and Engineering A, 2000, 290: 139-144.

[3] BOHLEN J, NURNBERG M R, SENN J W, LETZIG D, AGNEW S R. The texture and anisotropy of magnesium–zinc–rare earth alloy sheets [J]. Acta Materialia, 2007, 55: 2101-2112.

[4] YOSHINAGA H, HORIUCHI R. On the flow stress of α solid solution Mg-Li alloy single crystals [J]. Transaction of the Japan Institute of Metals, 1963, 4: 134-141.

[5] ABDESSAMEUD S, BRADAI D. Microstructure and texture evolution in hot rolled and annealed magnesium alloy TRC AZ31 [J]. Canadian Metallurgical Quarterly, 2009, 48: 433-442.

[6] ABDESSAMEUD S, AZZEDDINE H, ALILI B, BRADAI D. Grain growth in AZ31 alloy after uniaxial compression [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 2215-2222.

[7] AGNEW S R, J, HORTON J A, LILLO T M, BROWN D W. Enhanced ductility in strongly textured magnesium produced by equal channel angular processing [J]. Scripta Materialia, 2004, 50: 377-381.

[8] HUANG X, SUZUKI K, WATAZU A, SHIGEMATSU I, SAITO N. Mechanical properties of Mg–Al–Zn alloy with a tilted basal texture obtained by differential speed rolling [J]. Materials Science and Engineering A, 2008, 48: 214-220.

[9] CHINO Y, SASSA K, MABUCHI M. Enhancement of tensile ductility of magnesium alloy produced by torsion extrusion [J]. Scripta Materialia, 2008, 59: 399-402.

[10] ZHANG H, YAN Q, LI L. Microstructures and tensile properties of AZ31 magnesium alloy by continuous extrusion forming process [J]. Materials Science and Engineering A, 2008, 486: 295-299.

[11] AZZEDDINE H, BRADAI D. On the texture and grain growth in hot-deformed and annealed WE54 alloy [J]. International Journal of Materials Research, 2012, 103: 1351-1359.

[12] AZZEDDINE H, BRADAI D. Texture and microstructure of WE54 alloy after hot rolling and annealing [J]. Materials Science Forum, 2012, 702-703: 453-456.

[13] YANG Xu-yue, MIURA H, SAKAI T. Recrystallization behaviour of fine-grained magnesium alloy after hot deformation [J]. Transactions of Nonferrous Metals Society of China, 2007, 17: 1139-1142.

[14] GOTTSTEIN G, AL-SAMMAN T. Texture development in pure Mg and Mg alloy AZ31 [J]. Materials Science Forum, 2005, 495-497: 623-632.

[15] AL-SAMMAN T, GOTTSTEIN G. Influence of strain path change on the rolling behavior of twin roll cast magnesium alloy [J]. Scripta Materialia, 2008, 59: 760-763.

[16] XU S W, KAMADO S, HONMA T. Recrystallization mechanism and the relationship between grain size and Zener–Hollomon parameter of Mg–Al–Zn–Ca alloys during hot compression [J]. Scripta Materialia, 2010, 63: 293-296.

[17] HIELSCHER R, SCHAEBEN H. A novel pole figure inversion method: Specification of the MTEX algorithm [J]. Journal of Applied Crystallography, 2008, 41: 1024-1037.

[18]  M T, del VALLE J A, CONTRERAS M, RUANO O A. Microstructural evolution during large strain hot rolling of an AM60 Mg alloy [J]. Scripta Materialia, 2004, 50: 661-665.

M T, del VALLE J A, CONTRERAS M, RUANO O A. Microstructural evolution during large strain hot rolling of an AM60 Mg alloy [J]. Scripta Materialia, 2004, 50: 661-665.

[19] AGNEW S R, YOO M H,  C N. Application of texture simulation to understanding mechanical behaviour of Mg and solid solution alloys containing Li or Y [J]. Acta Materialia, 2001, 49: 4277-4289.

C N. Application of texture simulation to understanding mechanical behaviour of Mg and solid solution alloys containing Li or Y [J]. Acta Materialia, 2001, 49: 4277-4289.

[20] BRADAI D, ZIEBA P, BISCHOFF E, GUST W. A new mode of the discontinuous dissolution reaction in Mg-10wt.%Al alloy [J]. Materials Chemistry and Physics, 2001, 72: 401-404.

[21] DEL VALLE J A,  M T, RUANO O A. Texture evolution during large-strain hot rolling of the Mg AZ61 alloy [J]. Materials Science and Engineering A, 2003, 355: 68-78.

M T, RUANO O A. Texture evolution during large-strain hot rolling of the Mg AZ61 alloy [J]. Materials Science and Engineering A, 2003, 355: 68-78.

[22] XU S W, MATSUMOTO N, KAMADO S, HONMA T, KOJIMA Y. Effect of Mg17Al12 precipitates on the microstructural changes and mechanical properties of hot compressed AZ91 magnesium alloy [J]. Materials Science and Engineering A, 2009, 523: 47-52.

[23] AL-SAMMAN T, LI X, CHOWDHURY S G. Orientation dependent slip and twinning during compression and tension of strongly textured magnesium AZ31 alloy [J]. Materials Science and Engineering A, 2010, 527: 3450-3463.

[24] MWEMBELA A, McQUEEN H J. High temperature mechanical forming of Mg alloys [C]//Proceedings of the International Symposium on Enabling Thechnologies for Light Metals and Composite Materials and Their End-products. Canada, 2002: 915-929.

[25] BETTLES C J. The effect of gold additions on the ageing behaviour and creep properties of the magnesium alloy AZ91E [J]. Materials Science and Engineering A, 2003, 348: 280-288.

[26] DULY D, SIMON J P, BRECHET Y. On the competition between continuous and discontinuous precipitation in binary Mg-Al alloys [J]. Acta Metallurgica et Materialia, 1995, 43: 101-106.

[27] AL-SAMMAN T, GOTTSTEIN G. Deformation conditions and stability of the basal texture in magnesium [J]. Materials Science Forum, 2007, 539-543: 3401-3406.

[28] LI X, JIAO F, AL-SAMMAN T, CHOWDHURY S G. Influence of second-phase precipitates on the texture evolution of Mg–Al–Zn alloys during hot deformation [J]. Scripta Materialia, 2012, 66: 159-162.

[29] ION S E, HUMPHREYS F J, WHITE S H. Dynamic recrystallisation and the development of microstructure during the high temperature deformation of magnesium [J]. Acta Metallurgica, 1982, 30: 1909-1919.

[30] XIONG F, DAVIES C H J. Strain path and temperature effects on texture and microstructure evolution of AZ31 [C]//Magnesium Technology. San Francisco: TMS, 2005: 217-222.

[31] COTTAM R, ROBSON J, LORIMER G, DAVIS B. Dynamic recrystallization of Mg and Mg-Y alloys: Crystallographic texture development [J]. Materials Science and Engineering A, 2008, 485:375-382.

[32] AL-SAMMAN T, GOTTSTEIN G. Dynamic recrystallization during high temperature deformation of magnesium [J]. Materials Science and Engineering A, 2008, 490: 411-420.

[33]  M T, RUANO O A. Texture evolution during grain growth in annealed Mg AZ61 alloy [J]. Scripta Materialia, 2003, 48: 59-64.

M T, RUANO O A. Texture evolution during grain growth in annealed Mg AZ61 alloy [J]. Scripta Materialia, 2003, 48: 59-64.

[34] WAGNER F, BOZZOLO N, van LANDUYT O, GROSDIDIER T. Evolution of recrystallisation texture and microstructure in low alloyed titanium sheets [J]. Acta Materialia, 2002, 50: 1245-1259.

[35] BUNGE H J. Texture analysis in materials science–mathematical methods [M]. London: Butterworths Publishers, 1982.

[36] AZZEDDINE H, ABDESSAMEUD S, ALILI B, BRADAI D. Grain boundary misorientation effect on discontinuous precipitation in AZ91 Alloy [J]. Bulletin of Material Science, 2011, 34: 1471-1476.

[37] EDDAHBI M, del VALLE J A,  M T, RUANO O A. Comparison of the microstructure and thermal stability of an AZ31 alloy processed by ECAP and large strain hot rolling [J]. Materials Science and Engineering A, 2005, 410-411: 308-311.

M T, RUANO O A. Comparison of the microstructure and thermal stability of an AZ31 alloy processed by ECAP and large strain hot rolling [J]. Materials Science and Engineering A, 2005, 410-411: 308-311.

[38] CHOI S H,SHIN E J,SEONG B S. Simulation of deformation twins and deformation texture in an AZ31 Mg alloy under uniaxial compression [J]. Acta Materialia, 2007, 55: 4181-4192.

[39] MACKENZIE L W F, PEKGULERYUZ M O. The recrystallization and texture of magnesium–zinc–cerium alloys [J]. Scripta Materialia, 2008, 59: 665-668.

B. ALILI, H. AZZEDDINE, K. ABIB, D. BRADAI

Faculty of Physics, USTHB, BP32, El-Alia, Bab Ezzouar, 16111 Algiers, Algeria

摘 要:将具有随机初始织构的工业AZ91镁合金在450 °C进行均匀化热处理。经热处理后,合金中出现弱的{0001}– –

– 三重纤维织构。经400 °C热轧后, 合金的变形织构是典型的(0001)基面,其基极沿轧制方向分裂。在450 °C 退火36 h后, 其残余变形织构中的基极沿基面分布更均匀,没有出现晶粒的异常长大。

三重纤维织构。经400 °C热轧后, 合金的变形织构是典型的(0001)基面,其基极沿轧制方向分裂。在450 °C 退火36 h后, 其残余变形织构中的基极沿基面分布更均匀,没有出现晶粒的异常长大。

关键词:AZ91镁合金;织构;热轧;再结晶

(Edited by Hua YANG)

Corresponding author: H. AZZEDDINE; Tel: +213-771-359113; Fax: +213-21-247344; E-mail: azehibou@yahoo.fr

DOI: 10.1016/S1003-6326(13)62720-X