文章编号:1004-0609(2010)S1-s1039-06

表面加工状态对Ti-1023钛合金疲劳性能的影响

齐立春,黄利军,黄 旭,李志燕

(北京航空材料研究院,北京 100095)

摘 要:研究表面加工状态对Ti-1023钛合金疲劳性能的影响,结果表明:经纵抛后的试样表面粗糙度比圆磨试样低1个数量级,其表面压应力是圆磨试样表面压应力的3倍;当循环次数大于107时,Ti-1023钛合金纵抛试样疲劳极限比圆磨试样疲劳极限提高36%;零件可以通过表面喷丸处理在表层引入残余压应力场和表面加工改善表面粗糙度相结合的方法,达到提高零件疲劳性能的目的。

关键词:Ti-1023钛合金;表面完整性;表面粗糙度;表面压应力;疲劳性能

中图分类号:TF 804.3 文献标志码:A

Effect of surface machining state on fatigue property of Ti-1023 titanium alloy

QI Li-chun, HUANG Li-jun, HUANG Xu, LI Zhi-yan

(Beijing Institute of Aeronautical Materials, Beijing 100095, China)

Abstract: The effect of surface machining state on the fatigue property of Ti-1023 titanium alloy was studied. The results show that the test sample surface roughness by longitudinal polishing is one order of magnitude lower than that by circumferential grinding, the surface compressive stress of longitudinal polishing samples is threefold of that of circumferential grinding samples; the rotating bending fatigue limit of longitudinal polishing samples for 1×107 cycles is improved by about 36% than that of circumferential grinding samples. Surface compressive stress field can be induced by shot peening and surface roughness can be improved by surface manufacture to increase the fatigue property of Ti-1023 titanium alloy.

Key words: Ti-1023 titanium alloy; surface integrity; surface roughness; surface compressive stress; fatigue property

Ti-1023钛合金是近β型钛合金,由于具有比强度高、断裂韧度好、各向异性小、锻造温度低和抗应力腐蚀能力强等一系列优点,在飞机和直升机制造中获得了广泛应用。波音777飞机采用Ti-1023钛合金代替钢制起落架后,每架飞机质量减轻大约270 kg。韦斯特兰公司生产的超山猫多用途直升机上采用Ti-1023钛合金制造主旋翼桨毂等零件代替Ti-6Al-4V钛合金零件,质量减轻约20%。在国际上,许多直升机公司都选用Ti-1023钛合金制造半刚性旋翼,其中,包括桨毂、套筒、支座、旋翼轴和桨叶与轴的连接接头等零件[1-2]。但由于Ti-1023钛合金属于高强度钛合金,对应力集中比较敏感,当零件经不当加工后,若表面完整性遭到破坏,表面缺陷等将成为疲劳源,会严重降低零件的使用寿命。本文作者主要研究了表面加工状态对疲劳性能的影响,通过对疲劳试样表面粗糙度、表面压应力和疲劳断口等的测试与分析,得出Ti-1023钛合金的高周疲劳影响因素,提出改善Ti-1023钛合金疲劳性能措施,为提高Ti-1023钛合金零件的疲劳断裂寿命提供依据。

1 实验

试验材料为经过三次真空自耗熔炼制备的Ti-1023钛合金,铸锭经开坯、锻造和热处理,得到的显微组织为时效β基体+球状、条状初生α组织,没有连续、平直的α相网络和粗大的晶界α相组织。

用d4 mm(工作部分)的圆形光滑小试样在SER悬臂式旋转疲劳试验机上进行旋转弯曲疲劳试验,转速5 000 r/min,应力比R=-1。试样工作部分采取两种加工方式即圆磨和纵抛,采用FTS-i120触针式表面粗糙度仪测试圆磨和纵抛两种方式加工的疲劳试样表面粗糙度,测试了圆磨和纵抛两种方式的疲劳试样表面压应力,在QUANTA 600型扫描电子显微镜上观察疲劳断口形貌。

2 结果与讨论

2.1 表面加工状态对表面粗糙度的影响

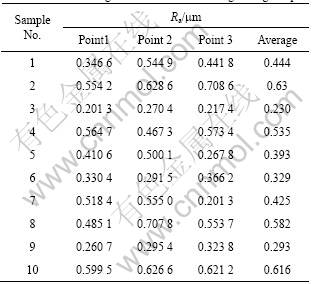

分别对经圆磨和纵抛加工的两组疲劳试样表面粗糙度进行测量,结果如表1和表2所示。从表1中可以看到,圆磨的试样表面粗糙度约在0.20~0.70 mm之间波动,而纵抛的试样表面粗糙度约在0.03~0.07 mm之间波动。从表1和表2可以得出:纵抛试样表面粗糙度比圆磨试样表面粗糙度低一个数量级,这说明纵抛试样表面质量高于圆磨试样。HYUKJAE等[3-4]的研究表明:如果在表面粗糙度对疲劳断裂抗力起主要作用的条件下,表面粗糙度大,裂纹易在表面形核,降低零件的疲劳极限,而且使疲劳曲线左移,降低疲劳寿命;若表面粗糙度较小,疲劳源常在试样内部,疲劳极限提高较大。

表1 圆磨试样表面粗糙度

Table 1 Surface roughness of circumferential grinding sample

表2 纵抛试样表面粗糙度

Table 2 Surface roughness of longitudinal polishing sample

2.2 表面加工状态对表面压应力的影响

试样经不同的表面加工或处理会在表层引入一定的残余应力,残余压应力使疲劳断裂抗力增高,而残余拉应力使疲劳断裂抗力下降。残余压应力提高疲劳断裂抗力机理是当表面层承受外加交变载荷时,表层的残余压应力会抵消外界拉应力对材料的作用,即降低外加交变载荷中的拉应力水平,拉应力越小,材料表面微观裂纹周围的应力集中越低,因此,可以有效地抑制裂纹萌生[5],而且表层的残余压应力可以增加裂纹的闭合效应来减小疲劳短裂纹的扩展速率[6],甚至出现止裂现象[7-9]。另外,残余压应力场可以将疲劳裂纹源由表面驱赶到亚表面层[10],若裂纹萌生于亚表面层,则属于内部裂纹,而内部裂纹可以避免环境中有害因素的影响,其增长的驱动力小于表面裂纹,从而显著提高材料的疲劳寿命。

虽然各种表面处理工艺,如表面化学处理工艺(渗碳、渗氮或碳氮共渗等)、表面喷丸形变处理和表面激光处理等,都能引入表层残余压应力,能不同程度提高零件的疲劳断裂抗力,但在工程应用中各自都存在着一定的局限性。只有表面喷丸形变处理工艺,既不受材料种类的限制,也不受零件几何形状与尺寸大小的限制。其强化效果也是至今任何一种工艺方法无法比拟的[11]。然而,高玉魁[7]研究得出:在气动式喷丸设备上对Ti-1023钛合金进行表面喷丸强化,虽然可以产生深度达260 mm、大小为352~584 MPa的残余压应力场,但是其表面粗糙度却高达1.48~3.41 mm。高的表面粗糙度加速裂纹形核,但不影响裂纹扩展,而残余压应力几乎不影响裂纹形核,对疲劳裂纹形成抗力的影响不大,但能延缓裂纹扩展[12-13]。因此,如果喷丸表面造成的塑性变形层粗糙度越大,应力集中点就会越多,将会抵消喷丸强化在提高抗疲劳性能方面的效果[10,14],表面粗糙度的增大也会降低喷丸引入的最大残余压应力[15],同时喷丸强化易在表面产生弹丸坑,造成材料表面损伤。

经测量,纵抛试样其残余压应力场约为150 MPa,而圆磨试样残余压应力场约为50 MPa。虽然经抛光的试样产生的残余压应力场不如喷丸强化的显著,但是从表1和表2中可知,经抛光的试样表面粗糙度却比喷丸强化后的低1~2个数量级。如果零件经表面喷丸处理在表层引入一定深度的较大残余压应力场后,再经过合理可行的表面加工来改善表面粗糙度,将会显著提高零件的疲劳性能。

2.3 表面加工状态对疲劳性能的影响

采用升降法测试了圆磨和纵抛两种加工方式下Ti-1023钛合金的旋转弯曲疲劳极限,结果表明:当循环次数大于107时,纵抛后试样旋转弯曲疲劳极限约为680 MPa,而圆磨试样旋转弯曲疲劳极限仅约为500 MPa,纵抛试样的疲劳极限比圆磨试样的疲劳极限高36%。

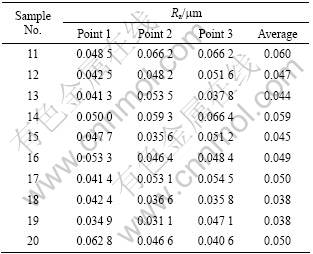

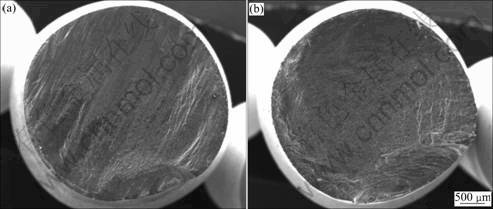

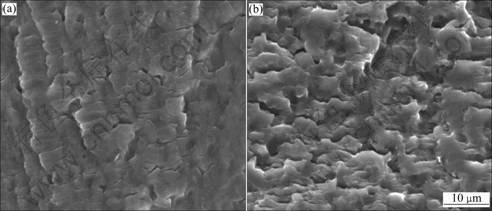

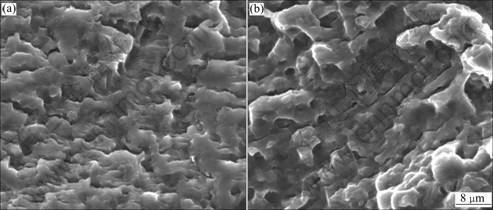

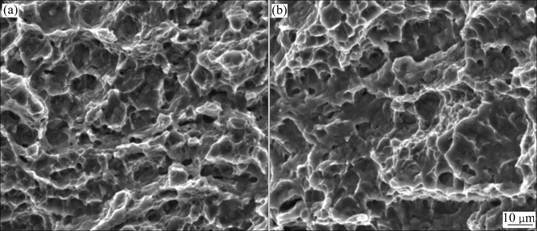

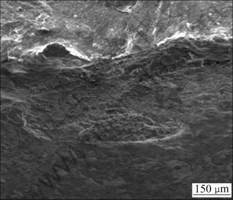

图1~5所示分别为疲劳试样断口形貌、断口疲劳源区形貌、断口疲劳扩展初期疲劳条带特征、断口疲劳扩展后期疲劳条带特征和断口瞬断区韧窝特征。从图1~5可以看到,圆磨试样疲劳断口较平坦,没有大的高度起伏,裂纹起源于试样的表面,呈点源特征,放射特征明显,疲劳扩展区疲劳条带明显、细密,且随着离源区的距离增大,疲劳条带逐渐加宽,并伴有二次裂纹的产生,扩展区面积远大于瞬断区面积。瞬断区位于源区对面,并有剪切唇,瞬断区为等轴韧窝特征。纵抛试样疲劳断口也呈现典型的高周疲劳断口特征,即由源区、扩展区和瞬断区组成。断口粗糙,高低起伏较大,裂纹起源于试样表面,疲劳扩展区疲劳条带明显、细密,且随着离源区的距离增大,疲劳条带逐渐加宽,并伴有二次裂纹。瞬断区韧窝大而深。

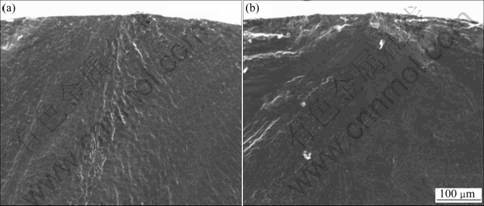

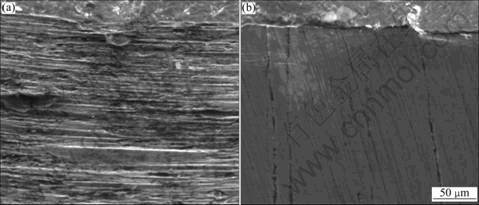

疲劳试样工作部分经圆磨和纵抛加工后的形貌如图6所示。从图6(a)可见,圆磨试样表面存在垂直于

图1 疲劳试样断口形貌

Fig.1 Fractographs of fatigue samples: (a) Circumferential grinding sample; (b) Longitudinal polishing sample

图2 断口疲劳源区形貌

Fig.2 Fractographs of origin zone of cracks: (a) Circumferential grinding sample; (b) Longitudinal polishing sample

图3 断口疲劳扩展初期疲劳条带特征

Fig.3 Fatigue striation features of fatigue crack propagation during initial stage: (a) Circumferential grinding sample; (b) Longitudinal polishing sample

图4 断口疲劳扩展后期疲劳条带特征

Fig.4 Fatigue striation features of fatigue crack propagation during late stage: (a) Circumferential grinding sample; (b) Longitudinal polishing sample

图5 断口瞬断区韧窝特征

Fig.5 Dimple features of eventual failure region: (a) Circumferential grinding sample; (b) Longitudinal polishing sample

图6 疲劳试样工作部分加工形貌(垂直断口方向)

Fig.6 Working portion machining appearance of fatigue sample with perpendicular fracture: (a) Circumferential grinding sample; (b) Longitudinal polishing sample

试样轴向的较深磨痕,表面加工质量差,表面的这些加工磨痕相当于存在裂纹,破坏了材料的表面完整性,将造成严重的应力集中,加之钛合金对于表面完整性具有很强的敏感性,这些加工磨痕极易诱发疲劳裂纹的萌生和扩展,导致疲劳破坏提前发生,从图7可以看到裂纹起源于试样表面的加工磨痕。从图6(b)可见,纵抛试样表面加工磨痕很浅,大致平行于试样轴向,表面加工质量比圆磨试样好。

图7 圆磨试样裂纹源区宏观形貌

Fig.7 Origin macrostructure of circumferential grinding sample

综上所述,经纵抛后试样的表面粗糙度比圆磨试样的低1个数量级,表面压应力是圆磨试样表面压应力的3倍,疲劳极限比圆磨试样疲劳极限高36%。

2.4 Ti-1023钛合金疲劳性能的改善措施

影响零件疲劳断裂的因素有很多,不仅包括材料本身的化学成分、金相组织和冶金缺陷等的内部因素,还包括零件所处的工作条件和表面状态等外部因素。而表面状态包括不同的表面处理或不同的表面加工工艺造成的表面粗糙度和表面残余应力等。

当零件经不同表面处理或不同表面加工工艺加工时,即使在表面造成轻微损伤,如喷丸强化在表面产生的弹丸坑,或加工造成的表面磨痕,打记号等都可能象微小的缺口一样,引起应力集中,使疲劳极限降低。另外,当零件经不同的表面加工或处理时也会在表层引入一定的残余应力,残余压应力使疲劳断裂抗力增高,而残余拉应力使疲劳断裂抗力下降。因此,零件先经表面处理在表层引入一定的残余压应力,再经过合理可行的表面加工改善表面粗糙度即提高表面光洁度,可避免因残余压应力场过小或表面粗糙度过大造成的零件疲劳断裂抗力下降,对改善零件的疲劳性能,提高疲劳寿命具有一定作用。

3 结论

1) Ti-1023钛合金纵抛试样表面粗糙度比圆磨试样的低一个数量级。纵抛试样表面残余压应力场约为150 MPa,而圆磨试样表面残余压应力场约为50 MPa。

2) 当循环次数大于107时,Ti-1023钛合金经纵抛后旋转弯曲疲劳极限约为680 MPa,而圆磨试样旋转弯曲疲劳极限仅约为500 MPa,纵抛试样疲劳极限比圆磨试样疲劳极限高36%。

REFERENCES

[1] 枼菌斯, 皮特尔斯. 钛与钛合金[M]. 陈振华, 等译. 北京: 化学工业出版社, 2005(3): 48.

LEYENS C, PETER M. Titanium and titanium alloys [M]. CHEN Zhen-hua, et al, transl. Beijing: Chemical Industry Press, 2005(3): 48.

[2] 黄伯云, 李成功, 石力开, 邱冠周, 左铁镛主编. 中国材料工程大典[M]. 北京: 化学工业出版社, 2006(1): 663-672.

HUANG Bo-yun, LI Cheng-gong, SHI Li-kai, QIU Guan-zhou, ZUO Tie-yong. Chian materials engineering canon [M]. Beijing: Chemical Industry Press, 2006(1): 663-672.

[3] LEE H, MALL S SOYAMA H. Fretting fatigue behavior of cavitation shotless peened Ti-6Al-4V[J] Materials Science and Engineering A, 2004, 366: 412-417.

[4] 张晓化, 刘道新, 高广睿. 喷丸强化因素对Ti811合金高温徽动疲劳抗力的影响[J]. 稀有金属材料与工程, 2005, 34(12): 1985-1989.

ZHANG Xiao-hua, LIU Dao-xin, GAO Guang-rui. The effect of shot peening factors on fretting fatigue resistance of Ti811 titanium alloy at elevated temperature [J]. Rare Metal Materials and Engineering, 2005, 34(12): 1985-1989.

[5] GAO Y K, YIN Y F, YAO M. Effect of shot peening on fatigue properties of 0Cr13Ni8Mo2Al steel [J]. Materials Science and Technology, 2003, 19(3): 372-374.

[6] MOTOH Y, FAIR G H, NUBLE B, WATERHOUSE R B. The effect of residual stresses induced by shot peening on fatigue crack propagation in two high strengthen aluminum alloy [J]. Fatigue & Fracture Engineering Materials & Structure, 1987, 10(4): 261-272.

[7] 高玉魁. 喷丸对Ti-10V-2Fe-3Al钛合金拉-拉疲劳性能的影响[J]. 中国有色金属学报, 2004, 14(1): 60-63.

GAO Yu-kui. Influence of shot peening on tension-tension fatigue properties in Ti-10V-2Fe-3Al titanium alloy [J]. The Chinese Journal of Nonferrous Metals, 2004, 14(1): 60-63.

[8] NAMJOSHI S A, JAIN V K, MALL S. Effects of shot-peening on fretting-fatigue behavior of Ti-6Al-4V [J]. Journal of Engineering Materials and Technology, 2002, 124: 222.

[9] 张建斌, 王静宜, 王淑琴, 高 巍. Ti 合金喷丸强化研究进展[J] .西安工业学院学报, 1999, 19(4): 308-310.

ZHANG Jian-bin, WANG Jing-yi, WANG Shu-qin, GAO Wei. A review of development in shot peening Titanium alloys [J]. Journal of Xi’an Institute of Technology, 1999, 19(4): 308-310.

[10] 高玉魁, 殷源发, 李向斌, 刘天琦. 喷丸强化对0Cr13Ni8Mo2Al钢疲劳性能的影响[J]. 材料工程, 2001(12): 46-49.

GAO Yu-kui, YIN Yuan-fa, LI Xiang-bin LIU Tian-qi. Influence of shot peening on fatigue property for 0Cr13Ni8Mo2Al steel [J]. Journal of Materials Engineering, 2001(12): 46-49.

[11] 王仁智. 残余应力测定的基本知识-第五讲 金属材料与零件的表面完整性与疲劳断裂抗力间的关系[J]. 理化检验-物理分册. 2007(43): 535-539.

WANG Ren-zhi. Basic Knowledge of Residual Stress Determination——Lecture No.5 Review on the Relationship BETWEEN Surface Integrity and Fatigue Fracture Resistance of Metallic Materails and Components[J]. Physical Testing and Chemical Analysis(Physical Testing), 2007(43): 535-539.

[12] GUAGLIAONO M, VERGANI L. An approach for prediction of fatigue strength of shot peened components [J]. Eng Fract Mech, 2004, 71(4/6): 501-512.

[13] WAGNER L. Mechanical surface treatments on titanium, alum magnesium alloys [J]. Materials Science and Engineering A, 1999, 263(2): 210-216.

[14] 田双印, 王尚志. 喷丸对TC9钛合金表面层质量的影响[J]. 航空制造技术, 1986(4): 36-39.

TIAN Shuang-yin, WANG Shang-zhi. Effect of shot on TC9 quality of titanium surface layer[J]. Aeronautical Manufacturing Technology, 1986(4): 36.

[15] 李金魁, 姚 枚, 王仁智, 李向斌. 喷丸强化的综合效应理论[J]. 航空学报, 1992, 13(11): 670-674.

LI Jin-kui, YAO Mei, WANG Ren-zhi, LI Xiang-bin. Comprehensive effects theory for shot peening strengthening[J]. Acta Aeronautica et Astronautica Sinica, 1992, 13(11): 670-674.

(编辑 刘华森)

基金项目:国家重点研究发展计划项目(2007CB613803)

通信作者:齐立春; 电话: 010-62496624; E-mail: qilichunbiam@163.com