文章编号:1004-0609(2011)06-1359-08

RSiC-WC复相陶瓷的性能及烧结机理

李 青,肖汉宁,高朋召,胡继林,郭文明,汤杰雄

(湖南大学 材料科学与工程学院,长沙 410082)

摘 要:以不同配比的粗、细SiC粉体和WC粉体为原料,在2 200 ℃以上烧结得到RSiC-WC复相陶瓷。采用XRD、SEM和EDS对复相陶瓷的物相组成和微观形貌进行分析,并测定其开口气孔率、抗弯强度和电阻率。结果表明:RSiC-WC复相陶瓷中以6H-SiC和WC为主晶相,存在少量W2C晶相。烧结产物中SiC颗粒再结晶程度良好,WC在烧结温度下与SiC晶粒润湿性好。RSiC-WC复相陶瓷的最低开口气孔率、最高抗弯强度和最低电阻率分别为19.2%、109 MPa和15 mΩ·cm。体系中SiC晶粒生长遵循蒸发-凝聚的烧结机理,WC则以W-C液相在SiC晶粒界面处聚集,抑制了SiC晶粒的长大。高温下形成的W-C液相能明显降低复相陶瓷的开口气孔率,使烧结体致密化。因而,添加一定量的WC改善复相陶瓷的力学性能,并对其电学性能起到调节作用。

关键词:RSiC-WC复相陶瓷;再结晶;烧结机理;力学性能;电学性能

中图分类号:O611.6 文献标志码:A

Properties and sintering mechanism of

RSiC-WC composite ceramics

LI Qing, XIAO Han-ning, GAO Peng-zhao, HU Ji-lin, GUO Wen-ming, TANG Jie-xiong

(College of Materials Science and Engineering, Hunan University, Changsha 410082, China)

Abstract: RSiC-WC composite ceramics were prepared using the coarse and fine SiC powders and WC powder as raw materials, which were well mixed in diverse proportion and ultimately sintered above 2 200 ℃. The phase composition and microstructure of the RSiC-WC composites ceramics were investigated by XRD, SEM and EDS. The open porosity, flexural strength and electrical resistivity were all measured. The results show that in this ceramics, 6H-SiC and WC are the main crystalline phase, and W2C forms in the sintering process. The SiC grains recrystallize well, and the WC grains exist between SiC grains and well wet with SiC grains. The lowest open porosity, the highest flexural strength and the lowest electrical resistivity of the RSiC-WC composite ceramics are 19.2%, 109 MPa and 15 mΩ·cm, respectively. The growth of SiC grains follow the evaporation-agglomeration mechanism, and W-C aggregates among SiC grain boundary in the form of W-C liquid phase, resulting in the inhibition of SiC growth. The W-C liquid phase formed at elevated temperature can evidently decrease the open porosity of the composites and improve the densification. Consequently, a certain addition of WC powder efficiently promotes the mechanical and electrical properties of RSiC-WC composite ceramics.

Key words: RSiC-WC composite ceramics; recrystallization; sintering mechanism; mechanical property; electrical property

碳化硅(SiC)作为一种先进陶瓷材料,具有优良的高温力学性能、热学性能和化学稳定性[1-3],SiC及其SiC复相陶瓷因其良好的高温力学性能和半导体特性而备受关注。SiC在复相陶瓷中可作为基体组元或增强相存在,国内外学者对SiC复相陶瓷进行了诸多研究:WANG等[4]和GUO等[5]通过无压烧结合成ZrB2- SiC复相陶瓷,并讨论其氧化行为对强度的影响,认为表面的玻璃化氧化层能显著提高材料的抗弯强度。LUO等[6]采用放电等离子烧结法(SPS)合成了SiC-TiC复相陶瓷,研究表明材料中SiC与TiC有着良好的化学相容性,其断裂形式为穿晶和沿晶断裂。MICELE等[7]在SiC基体中添加30%MoSi2(体积分数)和少量Al2O3助剂液相烧结得到SiC-MoSi2,讨论复相陶瓷的摩擦行为和耐磨性能。LI等[8]烧结(SiC, TiB2)/B4C复相陶瓷,研究了其微观结构下的晶粒细化机理和网络层积织构,测试洛氏硬度、弯曲强度和断裂韧性分别达到HRA88.6、540 MPa和5.6 MPa?m1/2。大量研究表明,第二相的添加能改善SiC陶瓷的力学性能,促进烧结体的致密化[9-13]。碳化钨(WC)是一类金属间填充型化合物,具有过渡金属碳化物半金属半陶瓷的特性,其显著特点是具有较高的弹性模量、热导率和电导 率[14-15],在高温特殊领域有着日益广泛的应用。WC与SiC有着相似的物理化学性质,在高温下同属六方晶系,热膨胀系数失配低[16]。周松青等[17]对SiC-WC复相陶瓷的前期研究表明,SiC-WC复相陶瓷具有高温自润滑特性和优良的高温耐磨性能,PANG等[18]通过固相反应合成了具有低热膨胀系数的SiC-WC多孔陶瓷,其最低热膨胀系数为4.11×10-6 ℃-1。再结晶碳化硅(RSiC)是一种兼具结构和功能特性的碳化硅材料,其承载能力高,抗热震性能好,具有优异的高温抗氧化和抗侵蚀能力,最高使用温度可达1 700 ℃[19-20]。然而,RSiC的烧结温度高,烧结体开口气孔率较 大,弹性模量和抗弯强度相比其他超高性能陶瓷偏 低,限制了其应用范围。国内外对第二相添加到RSiC陶瓷中对其烧结和力学及电学性能的研究鲜有报 道。本文作者选择WC作为添加第二相,可望通过高温烧结改善RSiC-WC体系的烧结性能,实现对其结构与功能的有效调控,满足结构-功能一体化材料的应用需求。

1 实验

1.1 材料制备

将商业粗SiC粉(约100 ?m,纯度≥99%(质量分数))和细SiC粉(约1 ?m,纯度≥98.5%(质量分数))酸洗后按质量比65:35混合,再分别添加0、1%、5%、10%(体积分数)的WC微粉(1~3 ?m,纯度≥99.5%(质量分数)),SiC与WC粉末在玛瑙研钵中加入适量粘结剂和去离子水进一步混合均匀,陈腐12 h后在钢模中(12 mm×12 mm×65 mm)模压(150 MPa)成型。成型样品分别编号SW0、SW1、SW5、SW10,干燥后置于Ar气氛炉中,在2 200~2 400 ℃下烧结,保温1 h。

1.2 物相表征与性能测试

采用X射线衍射仪(D/max2550PC, Cu Kα)分析所得材料的物相组成;采用环境扫描电子显微镜(FEI quanta 200)表征材料断面的微观形貌;采用电子衍射能谱(EDS,genesis xm-2)对微区进行元素分析。

用Archimedes法测定材料的体积密度和开口气孔率,方法参照GB 7314—87,采用三点弯曲法测试材料的抗弯强度,试样尺寸为12 mm×12 mm×65 mm,跨距50 mm,加压速率0.5 mm/min,测试3~5个样品取平均值;采用四探针法(数字式四探针测试仪,SX 1934)测定材料的电阻率,量程为2、20和200 mV,样品表面抛光,每个样品在抛光面不同区域分别测试4~6次。

2 结果与分析

2.1 WC添加量和烧结温度对RSiC-WC物相的影响

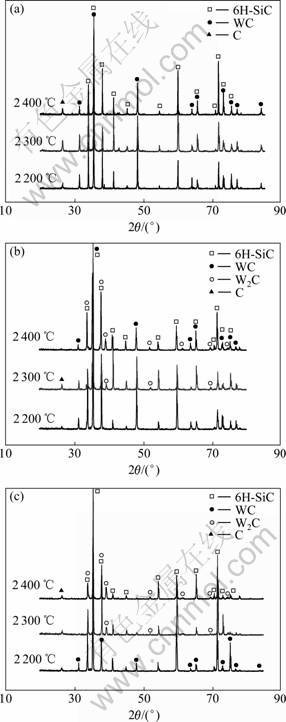

烧结RSiC-WC复相陶瓷的XRD谱如图1所示。SW10的主晶相为6H-SiC和WC。当烧结温度为2 300和2 400 ℃时,SW5、SW1中出现较弱的W2C的特征峰,说明复相陶瓷中存在W2C次晶相。SW1经 2 400 ℃烧结后,WC特征峰几乎完全消失,W2C峰明显。不同WC添加量和不同温度区间烧结得到的复相陶瓷的物相分析结果如表1所列。

RSiC-WC复相陶瓷中SiC(102)的晶面间距在添加WC后增大(见表1),部分WC填充到SiC的晶格之中。同时发现,不同WC含量和不同烧结温度下SiC的晶面间距发生了增大或减小的变化(见表2),说明WC与SiC形成了间隙型的有限固溶体。因固溶体的固溶度有限,这使固溶体在一定温度环境、一定固溶程度下变得不稳定,发生偏析和离解。

2.2 WC添加量和烧结温度对RSiC-WC形貌的影响

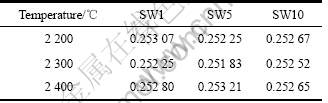

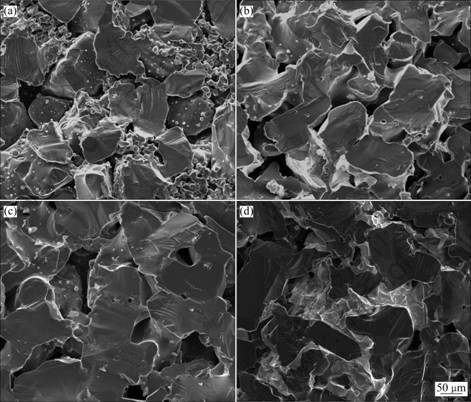

图2所示为RSiC-WC复相陶瓷断面的形貌。由图2可看出,随着烧结温度的升高,RSiC晶粒长大,WC颗粒逐渐减少。2 200 ℃时,SiC小颗粒出现明显的烧结颈,开始与WC颗粒熔合在一起(见图2(a))。 2 300 ℃时,小颗粒SiC已基本烧结长大,WC颗粒明显减少,以液相形式与SiC晶粒润湿,并附着于SiC晶粒表面(见图2(b))。当烧结温度达到2 400 ℃时,SiC晶粒继续烧结长大,WC形成的液相存在于SiC晶粒界面(见图2(c));大量液相则在SiC晶粒空隙聚集(见图2(d))。比较图2(c)和(d)发现,在同一烧结温度下,随着WC含量的增加,复相陶瓷中的空隙有明显减少,SiC晶粒长大不明显。

图1 不同烧结温度下RSiC-WC复相陶瓷的XRD谱

Fig.1 XRD patterns of RSiC-WC composite ceramics sintered at different temperatures: (a) SW10; (b) SW5; (c) SW1

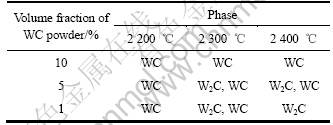

表1 RSiC-WC复相陶瓷物相的XRD结果

Table 1 XRD results of RSiC-WC composite ceramics

表2 WC含量的对SiC(102)晶面间距的影响

Table 2 Effect of WC content on interplanar spacing of (102) SiC (nm)

2.3 WC添加量和烧结温度对RSiC-WC抗弯强度的影响

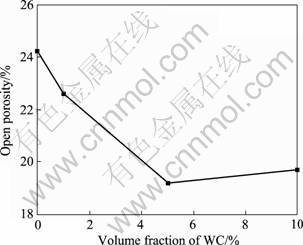

2 400 ℃烧结RSiC-WC复相陶瓷的开口气孔率随着WC含量的增加先降低后增高(见图3),该温度下SW5的开口气孔率最低,为19.2%。SW10的开口气孔率较SW5的略有升高。SEM结果表明:添加一定量的WC可在相对较高温度下形成W-C液相,液相与SiC晶粒润湿性良好,最终聚集在SiC晶粒界面,填充了SiC晶粒烧结形成的空隙。而当WC含量过高时,W-C液相将大量聚集,增加其不均匀分布的可能性。液相大量聚集的区域其空隙较少,液相较少的区域空隙仍然存在,SiC晶粒生长虽然受到抑制,但SiC晶粒界面将受到局部液相不均匀性的影响,使得SiC晶粒不规则长大,导致复相陶瓷中的空隙不能有效减少。

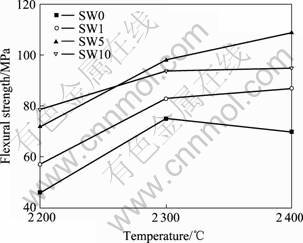

RSiC-WC复相陶瓷的抗弯强度测试结果如图4所示。由图4可看出,SW1、SW5和SW10的抗弯强度在烧结温度下较SW0的均有提高,SW5的抗弯强度在2 400 ℃时增幅最大并达到最高,为109 MPa。SW0抗弯强度在2 400 ℃时有所降低,这是因为高温下SiC晶粒在烧结完成后继续长大,导致抗弯强度降低。当添加WC后,2 400 ℃时,各样品的抗弯强度不再降低,说明WC有效抑制了SiC晶粒长大;2 300 ℃和2 400 ℃时,SW5的抗弯强度均高于SW10的抗弯强度,这是由SW10中大量不均匀分布的液相引起,最终导致了抗弯强度下降。

2.4 WC添加量和烧结温度对RSiC-WC电阻率的 影响

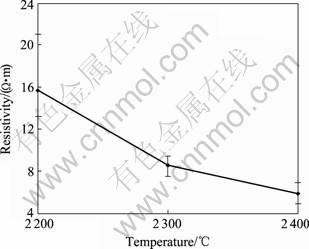

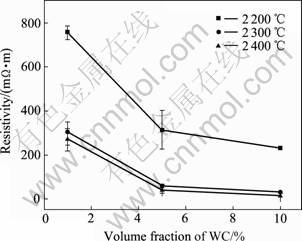

测试烧结RSiC的电阻率约为5~21 Ω·cm(见图5),RSiC-WC复相陶瓷的电阻率较未添加WC的RSiC陶瓷的电阻率有显著降低(见图6)。由图6可看出,SW0、SW1、SW5、SW10的电阻率均随烧结温度的升高而降低,2 200~2 300 ℃时降幅较大。随着WC含量的增加,复相陶瓷的电阻率持续下降,最低为15 mΩ·cm。添加WC形成的W-C液相使体系中空隙减少,电流通过的相对截面积增加,电流通路路径缩短,因而大幅降低复相陶瓷的电阻率,而不同含量WC的添加也可对复相陶瓷的电阻率起到调节作用。

图2 不同温度烧结RSiC-WC复相陶瓷的断面形貌

Fig.2 Fracture surface morphologies of RSiC-WC composite ceramics sintered at different temperatures: (a) SW1, 2 200 ℃; (b) SW1, 2 300 ℃; (c) SW1, 2 400 ℃; (d) SW10, 2 400 ℃

图3 2 400 ℃烧结RSiC-WC复相陶瓷的开口气孔率

Fig.3 Open porosity of RSiC-WC composite ceramics sintered at 2 400 ℃

图4 RSiC-WC复相陶瓷的抗弯强度

Fig.4 Flexural strength of RSiC-WC composite ceramics

2.5 RSiC-WC复相陶瓷反应及烧结机理

RSiC-WC复相陶瓷中SiC晶粒随温度升高烧结长大。SEM形貌表明:SiC颗粒间在颈部烧结并连接成片,因而认为复相陶瓷中SiC遵循蒸发-凝聚的烧结机理[19]。

图5 烧结RSiC(SW0)的电阻率

Fig.5 Resistivity of sintered RSiC

图6 WC添加量对RSiC-WC复相陶瓷电阻率的影响

Fig.6 Effect of WC content on resistivity of RSiC-WC composite ceramics

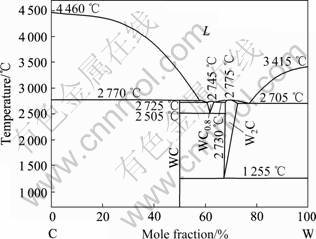

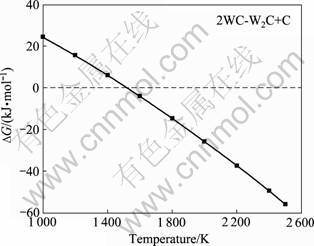

WC晶粒在烧结温度下将逐渐失去表面的C原子,形成WC1-x(见式(1))。WC和W2C的熔点均在2 800 ℃以上,而WC1-x在1 500 ℃以上生成(见图7),并以液相形式存在,2 500 ℃以上仍能稳定存在[21]。因而在烧结温度下,体系中液相的主要成分为WC1-x。XRD分析结果表明:RSiC-WC复相陶瓷中存在W2C相,W2C可由以下反应生成,式(2)的反应热力学?G与温度T的关系如图8所示。

WC1-x(l)→W2C+C1-2x (1)

WC→W2C+C (2)

热力学计算表明,1 500 K左右反应的?G开始大于0,当T=2 500 K时,?G=-55.78 kJ/mol,高于此温度反应将变得更加容易发生。

由表1可知,当WC添加量为1%(体积分数)、烧结温度为2 400 ℃时,复相陶瓷中WC特征峰几乎完全消失,剩下W2C特征峰。这一结果可能是由于原料SiC表面覆盖了SiO2非晶态氧化层,SiO2与WC反应如式(3):

WC+SiO2→W2C+SiC+CO (3)

图7 W-C的相图

Fig.7 Phase diagram of W-C

图8 T与?G的关系

Fig.8 Relationship between T and ?G

高温下WC不完全失去C生成W2C,SiO2不断消耗WC游离出来的C,使得反应式(3)一直向右进行。当WC添加量较少时(1%,体积分数),WC可完全和SiO2反应生成W2C和SiC。同时,在W-Si-C三元体系里,W2C相对于WC是高温稳定相[22-23];W2C与SiC在烧结温度下也几乎不会发生固相反应[24],反应式(3)不可逆,W2C在复相陶瓷中将稳定存在。而当WC含量为10%(体积分数)时,复相陶瓷中没有W2C相。这可能是由于体系中WC相对于SiC的含量较高时,W2C与SiC固溶量增大,W2C将进入SiC晶格,使得SiC晶面间距增大,并生成不稳定W-Si相;当烧结完成温度下降时,固溶体将发生偏析,W-Si相在低共熔点离解。在XRD谱中(见图1),2q=26°左右有较明显的石墨峰,一方面说明体系在烧结过程中,足够的游离C使少量WC和SiO2作用转化为W2C;另一方面说明在有游离C存在的情况下,W-Si相偏析的产物更趋向于形成晶体中有较少C空位的WC,SiC晶面间距则相应减小。

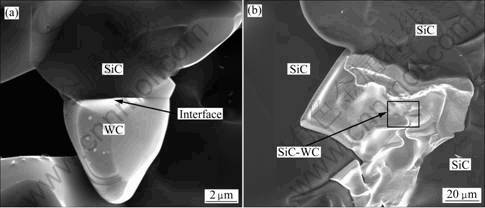

伴随着SiC晶粒蒸发-凝聚的烧结过程,WC发生了自身的液相转变以及与SiC之间的固相反应。在较低烧结温度下(2 200~2 300 ℃),WC颗粒与SiC小颗粒初步润湿,并熔合形成SiC与WC的界面。此时,一方面SiC小颗粒开始烧结长大,另一方面WC颗粒变得圆润,失去棱角(见图9(a))。随着温度的升高 (2 300~2 400 ℃),WC晶粒失去C原子生成高W含量的W-C液相。液相随着烧结的进行逐渐熔合,聚集,以黏性流动的形式迁移到体系中能量最低的SiC晶粒烧结颈部,最终表现为W-C相大量存在于SiC晶粒之间的界面或填充于SiC晶粒之间的空隙(见图9(b))。

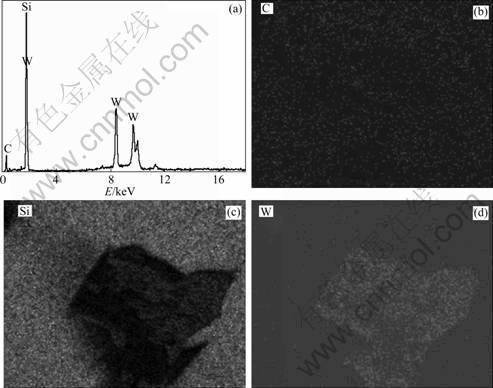

由图9可知,复相陶瓷整体上明暗区域分布均匀,边界明显,有熔合痕迹。对图9(b)中的微区进行EDS能谱分析(见图10(a)),表明该区存在C、W和Si 3种元素。灰色暗区为SiC晶粒;白色亮区则聚集了大量W,该区域具有明显的液相烧结形貌,这是由W-C液相在烧结过程中形成(见图10(b)~(d))。白色亮区中包含Si元素,说明W-C液相在烧结过程中聚集在SiC晶粒界面处,并与SiC固相晶粒反应,两者固溶后又随温度降低变得不稳定,最终离解为SiC和W-C两个紧密结合,相互交融的固相。

图9 WC晶粒与SiC晶粒界面和SiC晶粒与W-C液相固溶析出相的形貌

Fig.9 Morphologies of interface between WC grain and SiC grain(a) and dissociation of SiC grain and liquid W-C phase solid solution(b)

图10 图9(b)能谱分析及其微区元素分布

Fig.10 EDS analysis(a) and scanning map of elements distribution of C(b), Si(c) and W(d) in Fig.9(b)

W-C液相中的WC晶格失去C而产生C原子空位,烧结体系中为了平衡空位将产生的间隙阳离子[25]有利于液相的流动迁移以及液相与固相之间的润湿,促进了界面反应,加快了SiC晶粒表面固相扩散的进程。

从图2中可以发现,2 400 ℃时,烧结SW10复相陶瓷与SW1相比,SiC晶粒未见明显增大,W-C相致密而连续,与SiC晶粒之间结合紧密。说明添加一定量的WC使复相陶瓷中SiC的烧结势垒降低,再结晶更充分,晶粒长大得到抑制。W-C液相存在于SiC晶粒界面,通过烧结应力使SiC晶粒发生滑移与重排,降低了整个烧结体系的表面能,复相陶瓷中空隙被填充,致密度增加,力学和电学性能提高。

3 结论

1) RSiC-WC复相陶瓷中以6H-SiC和WC为主要晶相,存在少量W2C晶相。体系中WC能与SiC发生固溶并使SiC晶格增大。

2) RSiC-WC复相陶瓷的烧结是以SiC的蒸发-凝聚、W-C液相黏性流动的扩散传质为烧结机理。SiC与W-C相在高温下能形成固溶体,低温下发生偏析而离解,析出产物聚集在SiC晶粒界面,填充了SiC晶粒间的孔隙,抑制了SiC晶粒长大。

3) W-C相在RSiC-WC复相陶瓷中起到固溶强化作用,能改善其力学性能,并显著降低复相陶瓷的电阻率。其最低开口气孔率、最高抗弯强度和最低体积电阻率分别为19.2%、109 MPa和15 mΩ·cm。

REFERENCES

[1] HARRIS G L. Properties of silicon carbide[M]. London: INSPEC Institution of Electrical Engineers, 1995: 406-418.

[2] CHOYKE W J, MATSUNAMI H. Silicon carbide: Recent major advances[M]. Berlin, New York: Springer, 2004: 221-225.

[3] B?HME O, SPETZ A L, LUNDSTR?M I. Nanoparticles as the active element of high-temperature metal-insulator-silicon carbide gas sensors[J]. Advanced Materials, 2001, 13(8): 597-601.

[4] WANG Xin-gang, GUO Wei-ming, ZHANG Guo-jun. Pressureless sintering mechanism and microstructure of ZrB2-SiC ceramics doped with boron[J]. Scripta Materialia, 2009, 61: 177-180.

[5] GUO Wei-ming, ZHANG Guo-jun. Oxidation resistance and strength retention of ZrB2-SiC ceramics[J]. Journal of the European Ceramic Society, 2010, 30: 2387-2395.

[6] LUO Yong-ming, LI Shu-qin, PAN Wei, LI Liu. Fabrication and mechanical evaluation of SiC-TiC nanocomposites by SPS[J]. Materials Letters, 2003, 58: 150-153.

[7] MICELE L, PALOMBARINI G, GUICCIARDI S, SILVESTRONI L. Tribological behaviour and wear resistance of a SiC-MoSi2 composite dry sliding against Al2O3[J]. Wear, 2010, 269: 368-375.

[8] LI Ai-ju, ZHEN Yu-hua, YIN Qiang, MA Lai-peng, YIN Yan-sheng. Microstructure and properties of (SiC, TiB2)/B4C composites by reaction hot pressing[J]. Ceramics International, 2006, 32: 849-856.

[9] HU Chun-feng, YOSHIO S, TANAKA H, TOSHIYUKI N, GUO Shu-qi, GRASSO S. Microstructure and properties of ZrB2-SiC composites prepared by spark plasma sintering using TaSi2 as sintering additive[J]. Journal of the European Ceramic Society, 2010, 30: 2625-2631.

[10] GUO Wei-ming, VLEUGELS J, ZHANG Guo-jun, WANG Pei-ling, van der BIEST O. Effects of Re2O3 (Re = La, Nd, Y and Yb) addition in hot-pressed ZrB2-SiC ceramics[J]. Journal of the European Ceramic Society, 2009, 29: 3063-3068.

[11] BALESTRA R M, RIBEIRO S, TAGUCHI S P, MOTTA F V, BORMIO-NUNES C. Wetting behaviour of Y2O3/AlN additive on SiC ceramics[J]. Journal of the European Ceramic Society, 2006, 26: 3881-3886.

[12] RODR?GUEZ-ROJAS F, ORTIZ A L, BORRERO-L?PEZ O, GUIBERTEAU F. Effect of the sintering additive content on the non-protective oxidation behaviour of pressureless liquid-phase- sintered α-SiC in air[J]. Journal of the European Ceramic Society, 2010, 30: 1513-1518.

[13] ZHANG Hui, YAN Yong-jie, HUANG Zheng-ren, LIU Xue-jian, JIANG Dong-liang. Pressureless sintering of ZrB2-SiC ceramics: The effect of B4C content[J]. Scripta Materialia, 2009, 60: 559-562.

[14] RASIT K. Tungsten carbide (WC) synthesis from novel precursors[J]. Journal of the European Ceramic Society, 2000, 20: 1859-1869.

[15] ADORJAN A, SCHUBERT W D. WC grain growth during the early stages of sintering[J]. International Journal of Refractory Metals & Hard Materials, 2006, 24: 365-373.

[16] 肖汉宁, 高朋召. 高性能结构陶瓷及其应用[M]. 北京: 化学工业出版社, 2006: 179.

XIAO Han-ning, GAO Peng-zhao. High-performance structural ceramics and its application[M]. Beijing: Chemical Industry Press, 2006: 179.

[17] 周松青, 肖汉宁, 杨巧勤. SiC和SiC-WC复相陶瓷高温自润滑特性及其机理[J]. 硅酸盐学报, 2004, 32(12): 1470-1475.

ZHOU Song-qing, XIAO Han-ning, YANG Qiao-qin. Self-lubricating property and mechanism of SiC and SiC-WC composite ceramics at high temperature[J]. Journal of the Chinese Ceramic Society, 2004, 32(12): 1470-1475.

[18] PANG Ji-feng, LI Jin-ping. Low thermal expansion porous SiC-WC composite ceramics[J]. Ceramics International, 2009, 35: 3517-3520.

[19] KRIEGESMANN J. Microstructure control during consolidation of fine grained recrystallized silicon carbide[J]. Key Engineering Materials, 2004, 264/268: 2199-2202.

[20] KRIEGESMANN J, SCHUMACHER M. Silicon carbide fiber reinforced recrystallized silicon carbide[J]. Key Engineering Materials, 2004, 264/268: 1063-1066.

[21] HUANG W. Thermodynamic properties of the Nb-W-C-N system[J]. Z Metallkde, 1997, 88: 63-68.

[22] SON S J, PARK K H. Interfacial reactions and mechanical properties of W-SiC in-situ joints for plasma facing components[J]. Journal of Nuclear Materials, 2004, 329/333: 1549-1552.

[23] GOESMANN F, SCHMID-FETZER R. Stability of W as electrical contact on 6H-SiC: phase relations and interface reactions in the ternary system W-Si-C[J]. Materials Science and Engineering B, 1995, 34: 224-231.

[24] BARIN I. Thermochemical Properties of Pure Substances[M]. New York: VCH Publishers, 1989: 1245-1246.

[25] BUHSMER C P, CRAYTON P H. Carbon self-diffusion in tungsten carbide[J]. Journal of Materials Science, 1971, 6: 981.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(50972042)

收稿日期:2010-06-28;修订日期:2010-09-28

通信作者:肖汉宁,教授,博士;电话:0731-88822269;E-mail: hnxiao@hnu.edu.cn