DOI: 10.11817/j.issn.1672-7207.2018.08.005

低含铟浸出渣中铟的氧压酸浸实验及动力学研究

李学鹏1,刘大春1,王娟2

(1. 昆明理工大学 真空冶金国家工程实验室,云南 昆明,650093;

2. 云南大学 数理与统计学院,云南 昆明,650093)

摘要:采用氧压酸浸的方法浸出低含铟浸出渣中的铟,研究铟的氧压酸浸过程及动力学;研究搅拌速率、浸出温度、初始硫酸浓度、氧分压、物料粒度对铟浸出率的影响。研究结果表明:在浸出温度为220 ℃,物料粒度为75~80 μm,硫酸浓度为1.53 mol/L,转速为650 r/min,氧分压为0.60 MPa时,铟、锌和铜的浸出率分别为99.5%,95.36%和95.94%;铟的浸出过程符合未反应收缩核模型,前期受化学反应控制,然后转为混合控制,后期受固体产物层扩散控制;化学反应控制和固体产物层扩散控制过程的表观活化能分别为46.09 kJ/mol和11.62 kJ/mol。

关键词:铟;氧压浸出;浸出渣;动力学

中图分类号:TQ013.2 文献标志码:A 文章编号:1672-7207(2018)08-1869-09

Experimental and kinetic study on oxygen pressure acid leaching of indium from low-content indium-containing leaching residue

LI Xuepeng1, LIU Dachun1, WANG Juan2

(1. National Engineering Laboratory for Vacuum metallurgy Kunming University of Science and Technology,Kunming 650093, China;

2. School of Mathematics and Statistics, Yunnan University, Kunming 650093, China)

Abstract: Low indium-containing leaching residue was treated by oxygen pressure acid leaching, and dissolution kinetics and behavior of indium extraction from indium-containing leaching residue were investigated. Effects of stirring speed, temperature, sulfuric acid concentration, oxygen partial pressure and particle size on extraction rate of indium were studied. The results show that leaching rates of In, Zn and Cu are 99.5%, 95.36% and 95.94% respectively when leaching temperature is 220 ℃, particle size is 75-80 μm, initial sulfuric acid concentration is 1.53 mol/L, stirring speed is 650 r/min and oxygen partial pressure is 0.60 MPa. The indium leaching process is conformed to shrinking ore model. It is controlled by chemical reaction in its early stage, then switches to mix-controlled stage, and finally to the stage in which diffusion is controlled by the solid product layer. Activation energy is 46.09 kJ/mol in chemical reaction control stage and 11.62 kJ/mol in the later product layer diffusion control.

Key words: indium; oxygen pressure leaching; leaching residue; kinetics

铟是具有良好光化学性能的低熔点金属,在电子、半导体、航空航天、医药、化工等方面应用广泛[1-3]。铟属于稀散金属,在地壳中的质量分数为1×10-7。铟的独立矿物极少,主要伴生于其他矿物中,生产铟的原料通常为冶炼副产物或含铟二次资源。铟的提取原料主要有锌冶炼渣、冶炼二次烟尘、瓦斯灰、铟锡氧化物(ITO)废靶、含铟元器件等[3]。目前,铟的富集方法主要有氧化造渣富集法、挥发富集法和湿法浸出富集法[4-7]。氧化造渣富集法是在含铟粗铅物料加入锌,在800~900 ℃鼓入空气氧化,锌铟以浮渣的形式与铅分离,浮渣经过浸出—萃取—反萃—电解后得到精铟[8]。挥发富集法是依据铟及铟的氧化物可挥发的性质,采用还原挥发、硫酸化焙烧挥发、真空蒸馏的方法将铟与其他金属分离[9-11]。湿法浸出富集法是依据铟及铟的化合物可溶于酸的性质,采用湿法酸浸方法将铟与其他金属分离。湿法酸浸又分为常压酸浸和加压酸浸,浸出剂常采用硫酸或盐酸。刘大春等[12]采用常压酸浸方法处理铟质量分数为8.29%的富铟渣,在浸出温度为80 ℃、硫酸质量浓度为160~180 g/L、液固比为8:1、浸出时间为8~10 h的实验条件下,铟的浸出率大于85%。谌斯等[13]采用常压浸出方法处理铟质量分数为1.38%的锌渣,在浸出温度为85 ℃、硫酸质量浓度为300 g/L、液固比为3:1、机械活化1 h的实验条件下,铟的浸出率为90.9%。与常压浸出相比,氧压浸出技术可以显著提高浸出温度和浸出体系中氧的浓度,可用于处理低含铟物料、复杂含铟物料及提高物料中铟的浸出率[14-16]。罗文波等[17]采用加压酸浸方法处理铟质量分数为0.066%的氧化锌烟尘,在浸出温度为140 ℃、硫酸质量浓度为160 g/L、液固比为8:1、浸出时间为1.5 h的实验条件下,铟的浸出率为91.96%。王继民等[18]采用氧压酸浸的方法处理铟质量分数为0.028%的炼锌流程置换渣,在浸出温度为150 ℃、硫酸浓度为3.1 mol/L,液固比为4:1、浸出时间为3 h的实验条件下,铟的浸出率为98%。铟的富集方法较多,各有特点,在实际工作中应根据不同的含铟物料、不同的铟质量分数而采用不同的工艺。本文作者采用氧压酸浸的方法处理低含铟浸出渣,在充分研究各因素对铟浸出率影响的前提下,研究低含铟浸出渣中铟的浸出行为并获得铟的浸出动力学规律,以期实现铟的高效浸出。

1 实验

1.1 实验原料

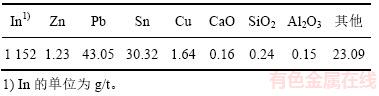

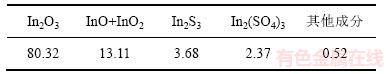

实验原料为云南某铜冶炼厂的铜烟尘经焙烧—硫酸浸铜锌后得到的浸出渣,其化学成分如表1所示。原料中主要成分为Pb和Sn,而Zn,Cu,CaO,SiO2和Al2O3质量分数较低,其他主要指元素氧。铟的质量分数较低(1 152 g/t),采用化学物相法分析物料中铟的物相,分析结果如表2所示。由表2 可知:原料中In主要以氧化物的形式存在,少量以In2S3和In2(SO4)3的形式存在。

表1 低含铟浸出渣的化学成分(质量分数)

Table 1 Chemical composition of low-content indium-containing leaching residue %

表2 低含铟浸出渣中铟的化学物相分析(质量分数)

Table 2 Chemical phase analysis of indium in low-content indium-containing leaching residue %

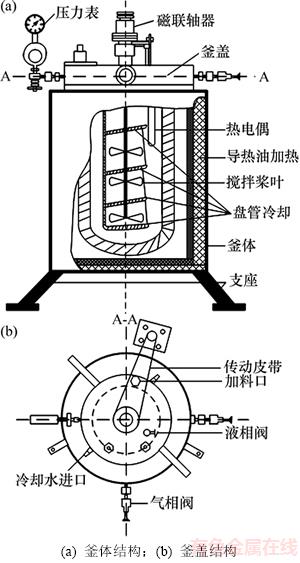

1.2 实验设备、方法与分析检测

实验装置主要为钛材压力釜,有效容积为2 L。采用导热油加热,精确温度控制范围为20~220 ℃,控温精度为±5 ℃。采用FKM-A型控制器控制。实验装置如图1所示。

实验方法:在动力学实验中,为保持浸出剂浓度基本不变,适当增大液固比,实验液固比为10:1,每次实验取50 g物料与500 mL相应浓度的硫酸溶液,调浆后加入2 L内衬钛压力釜内,通入氧气并保持氧分压恒定下反应。每间隔10 min 取样1次。

元素浸出率计算公式如下:

(1)

(1)

式中:x为元素浸出率,%;V0为浸出液的总体积,L;Vi为每i次间隔时间取出的液体体积,L;ρ为取出液中该元素的质量浓度,g/L;m0为实验渣的质量,g;w为实验渣样中该元素的质量分数,%。

采用碘量法测定Sn质量,原子吸收法测定In质量,其他元素质量采用电感耦合时离子体-原子发射光谱法(ICP-AES)法测定。

图1 实验装置

Fig. 1 Experimental device

2 浸出原理

氧压酸浸出过程中,原料中的铟主要发生如下化学反应(其中,O2(g)为反应过程中通入的氧气):

(2)

(2)

(3)

(3)

(4)

(4)

(5)

(5)

同时,原料中少量锌、铜硫化物和氧化物也会发生下列反应:

(Me=Cu,Zn) (6)

(Me=Cu,Zn) (7)

3 结果与讨论

3.1 搅拌速率对铟浸出率的影响

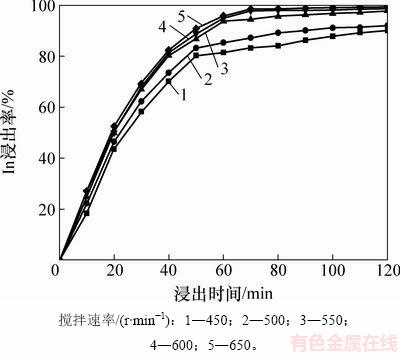

考察不同搅拌速率对铟浸出率的影响,实验条件如下:浸出温度为220 ℃,物料粒度为[75,80) μm,硫酸浓度为1.53 mol/L,釜内氧分压为0.60 MPa。不同搅拌速率对铟浸出率的影响如图2所示。由图2可知:物料中铟浸出率随着搅拌速率增加而增加,当搅拌速率大于650 r/min时,铟的浸出率基本不变。这表明,当搅拌速率≥650 r/min时,有利于氧气在浸出液中的扩散及物料颗粒的悬浮[19]。为消除外扩散对实验结果的影响,后续实验设定搅拌速率为650 r/min。

图2 搅拌速率对铟浸出率的影响

Fig. 2 Effects of stirring speeds on leaching rates of indium

3.2 浸出温度对铟浸出率的影响

考察不同浸出温度对铟浸出率的影响,实验条件如下:物料粒度为[75,80) μm,硫酸浓度为1.53 mol/L,搅拌速率为650 r/min,釜内氧分压为0.60 MPa。不同浸出温度对铟浸出率的影响如图3所示。由图3可知:升高温度可显著提高铟浸出率。当温度为160 ℃时,在所设定的实验条件下,铟浸出率较低(<55%);在220 ℃下浸出120 min,铟浸出率升至99.50%;当浸出时间超过70 min后,铟浸出速率显著减小,这可能是由于浸出过程的控制步骤发生了改变,通过实验确定较佳的浸出温度为220 ℃。

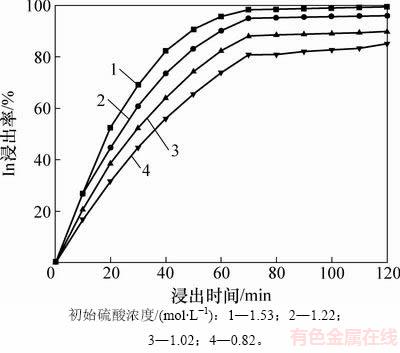

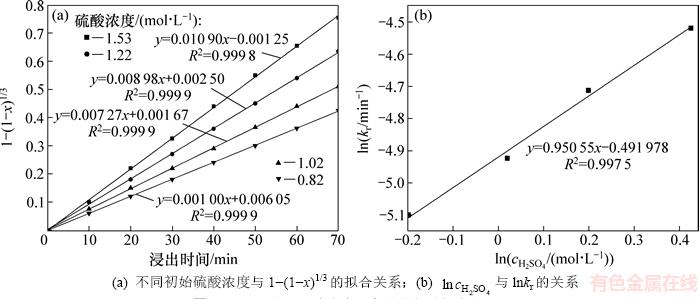

3.3 初始硫酸浓度对铟浸出率的影响

考察不同初始硫酸浓度对铟浸出率的影响,实验条件如下:浸出温度为220 ℃,物料粒度为[75,80) μm,搅拌速率为650 r/min,釜内氧分压为0.60 MPa。不同初始硫酸浓度对铟浸出率的影响如图4所示。由图4可知:铟浸出率随初始硫酸浓度升高而增加,在设定的实验条件下,当初始硫酸浓度为1.53 mo/L,浸出时间为120 min时,铟浸出率已高达99.50%。通过实验确定较佳的初始硫酸浓度为1.53 mo/L。

图3 浸出温度对铟浸出率的影响

Fig. 3 Effects of leaching temperatures on leaching rates of indium

图4 初始硫酸浓度对铟浸出率的影响

Fig. 4 Effects of initial sulfuric acid concentrations on leaching rates of indium

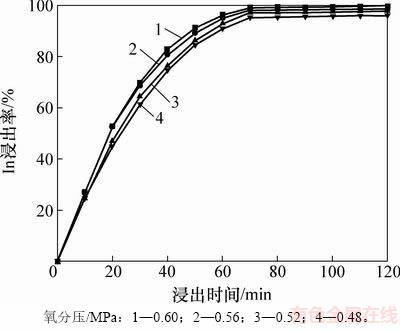

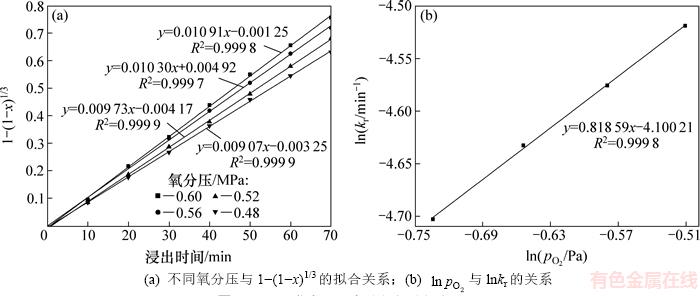

3.4 氧分压对铟浸出率的影响

考察不同氧分压对铟浸出率的影响,实验条件如下:浸出温度为220 ℃,物料粒度为[75,80) μm,硫酸浓度为1.53 mol/L,搅拌速率为650 r/min。不同氧分压对铟浸出率的影响如图5所示。由图5可知:铟浸出率随氧分压升高而增加,这是由于原料中含有少量的In2S3,提高氧分压有利于In2S3转化为In2(SO4)3。当浸出过程中维持氧分压为0.60 MPa时,铟便具有很高的浸出率。通过实验确定较佳的氧分压为0.60 MPa。

图5 氧分压对铟浸出率的影响

Fig. 5 Effects of oxygen partial pressures on leaching rates of indium

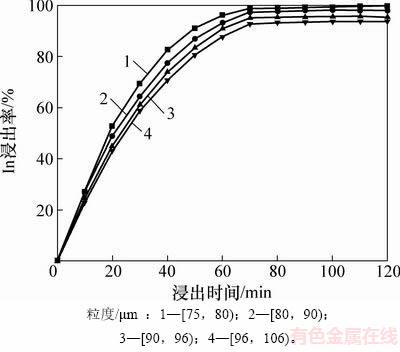

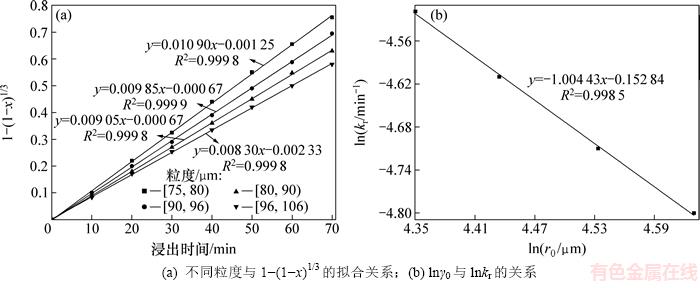

3.5 粒度对铟浸出率的影响

考察不同粒度对铟浸出率的影响,实验条件如下:浸出温度为220 ℃,硫酸浓度为1.53 mol/L,搅拌速率为650 r/min,釜内氧分压为0.6 MPa。不同粒度对铟浸出率的影响如图6所示。由图6可知:铟浸出率随物料粒度减小而增加,这是由于随着物料粒度减小,浸出颗粒的比表面积增大,因而铟浸出率增加[20-21]。

图6 粒度对铟浸出率的影响

Fig. 6 Effects of particle sizes on leaching rates of indium

但物料粒度过小会增加磨矿难度,造成成本上升。在设定实验条件下,当物料粒度为[75,80) μm,浸出时间为120 min,铟的浸出率达到99.50%。通过实验确定较佳的物料粒度为75~80 μm。

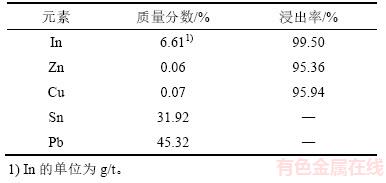

3.6 浸出渣的成分及各元素的浸出率

实验条件如下:浸出温度为220 ℃,物料粒度为[75,80) μm,硫酸质量浓度为1.53 mol/L,搅拌速率为650 r/min,氧分压为0.60 MPa,浸出时间为120 min。浸出渣的成分及各元素的浸出率如表3所示。

表3 浸出渣的成分及各元素的浸出率

Table 3 Composition of leaching residue and leaching rates of various elements

由表3可知:采用氧压酸浸的方法可以有效地浸出低含铟浸出渣中的In,Zn和Cu,而Sn和Pb则留在渣中并少量富集。

4 动力学分析

4.1 铟氧压浸出动力学控制过程分析

物料中铟的氧压酸浸过程为固—液—气的多相反应体系,矿物溶解的动力学主要受浸出剂通过产物层的扩散控制、固体颗粒表面的化学反应控制及两者共同作用的混合控制。采用未反应收缩核模型(SCM)对铟的氧压酸浸过程进行动力学研究。未反应收缩核模型(SCM)[22-23]的速率方程如下:

(8)

(8)

(9)

(9)

(10)

(10)

式中:x为In的浸出率,%;a为含铟化合物与硫酸反应中硫酸的计量系数;MB为颗粒的摩尔分子质量,g/mol;r0为颗粒初始半径,μm;cA为硫酸浓度,mol/L;De为通过固体产物层的扩散系数,μm/min;kc为化学反应速率常数,min-1;ρB为颗粒的密度,g/cm3;t为反应时间,min;kr,kd和km分别为由化学反应、通过固体产物层及混合控制的表观速率常数,min-1。

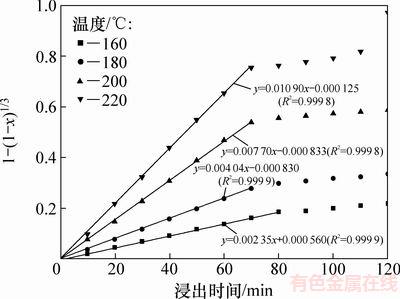

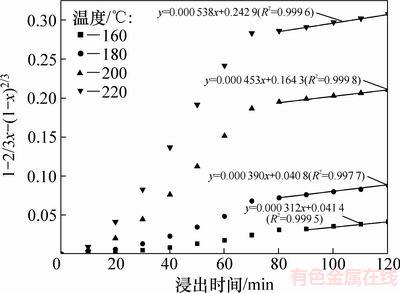

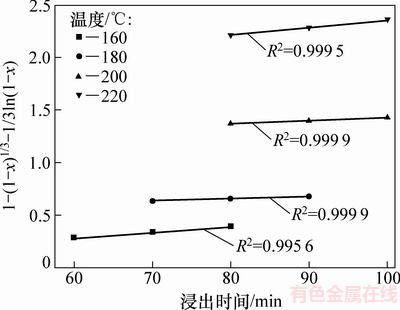

为确定物料中铟氧压酸浸的动力学参数及控制步骤,将图2中不同浸出温度下的铟浸出率数据代入式(8)和式(9)并进行拟合,结果分别如图7和图8所示(其中R2为拟合直线的相关系数)。

图7 不同温度下1-(1-x)1/3与浸出时间的拟合关系

Fig. 7 Fitting relationship between 1-(1-x) 1/3 and leaching time at different temperatures

图8 不同温度下1-2/3x-(1-x)2/3与浸出时间的拟合关系

Fig. 8 Fitting relationship between 1-2/3x-(1-x)2/3 and leaching time at different temperatures

由图7和图8可知:在反应初期,采用式(8)拟合结果较好,在反应后期,采用式(9)拟合结果较好,表明物料中铟的浸出过程符合未反应收缩核模型。物料中铟的浸出过程首先由化学反应控制,之后再转为通过固体产物层的扩散控制。将拟合得到的不同温度下的反应速率常数k代入阿累尼乌斯(Arrhenius)方程:

(11)

(11)

式中:A为频率因子;Ea为表观活化能,kJ/mol;R为气体平衡常数,R=8.314 J/mol;T为热力学温度,K。

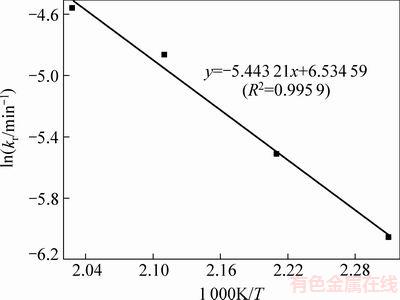

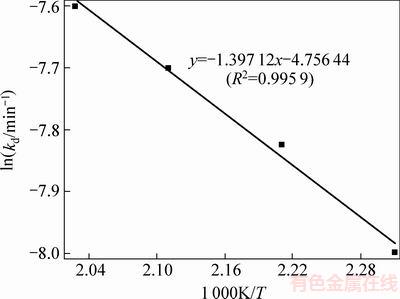

以lnk对1/T作图,拟合结果分别如图9和图10所示。

由图9和图10中拟合方程的斜率,求出2个控制阶段表观活化能分别为46.09 kJ/mol和11.62 kJ/mol,分别在化学反应控制(>42 kJ/mol)和通过固体产物层扩散控制(4~12 kJ/mol)的表观活化能范围内[24-25],这也进一步证明了物料中铟的浸出是由化学反应控制转向通过固体产物层的扩散控制的过程。将图2中的数据代入式(10),结果如图11所示。

由图11可知:在不同浸出温度下均有某一段温度1-(1-x)1/3-1/3ln(1-x)与浸出时间t呈较好的拟合关系,表明不同浸出温度下均存在混合控制阶段,本实验混合控制阶段时间不长,且与化学反应控制阶段和扩散控制阶段有交叉。

4.2 铟氧压浸出主控过程的宏观动力学方程

由各因素对铟浸出率的影响可知:当浸出时间大于70 min后,铟浸出率随浸出时间变化较小,70 min内铟的浸出过程主要受化学反应控制,即铟浸出的主控过程为化学反应控制,混合控制和扩散控制对铟浸出率影响较小。在化学反应控制阶段,铟氧压浸出的宏观动力学方程可表述为[26]

(12)

(12)

式中:n1,n2和n3分别为硫酸浓度、氧分压和物料初始半径的反应级数;K0为与温度有关的速率常数; 为硫酸浓度,mol/L;

为硫酸浓度,mol/L; 为氧分压,MPa。

为氧分压,MPa。

图9 化学反应控制阶段Arrhenius方程拟合结果

Fig. 9 Fitting result for Arrhenius equation in chemical reaction control stage

图10 固体产物层扩散控制阶段Arrhenius方程拟合结果

Fig. 10 Fitting result for Arrhenius equation in diffusion controlled by the solid product layer stage

图11 混合控制1-(1-x)1/3-1/3ln(1-x)与浸出时间的拟合关系

Fig. 11 Fitting relationship between 1-(1-x)1/3-1/3ln(1-x) and leaching time in mix-controlled stage

根据图3~6所示实验结果,以1-(1-x)1/3对浸出时间作图,得到不同初始硫酸浓度、不同氧分压、不同粒度与1-(1-x)1/3的拟合方程,分别如图12(a),13(a)和14(a)所示。由拟合所得结果可知,不同浸出时间下不同初始硫酸浓度、不同氧分压、不同粒度铟浸出率的实验数据与1-(1-x)1/3呈良好的线性关系。图12(a),13(a)和14(a)中各拟合直线的斜率kr即为不同初始硫酸浓度、不同氧分压、不同粒度下的速率常数,以lnkr分别对lncH2SO4,lnpO2和lnr0作图,结果分别如12(b),13(b)和14(b)所示。通过直线的斜率求得初始硫酸浓度、氧分压、粒度的反应级数分别为0.95,0.82和-1.00。将上述数据、化学反应控制阶段的表观活化能及相关实验数据代入式(12)可得K0为6.623 6×104,则化学反应控制阶段铟氧压浸出的宏观动力学方程为

(13)

(13)

图12 不同初始硫酸浓度下实验数据的拟合结果

Fig. 12 Fitting results of experimental data at different sulfuric acid concentrations

图13 不同氧分压下实验数据的拟合结果

Fig. 13 Fitting results of experimental data at different oxygen partial pressures

图14 不同粒度下实验数据的拟合结果

Fig. 14 Fitting results of experimental data at different particle sizes

5 结论

1) 采用氧压酸浸的方法可以有效地浸出低含铟浸出渣中的In,Zn和Cu;在浸出温度为220 ℃,物料粒度为75~80 μm,硫酸浓度为1.53 mol/L,搅拌速率为650 r/min,釜内氧分压为0.60 MPa的条件下,物料中In,Zn和Cu的浸出率分别为99.5%,95.36%和95.94%,Sn和Pb留在渣中并少量富集。

2) 低含铟浸出渣中铟的氧压酸浸过程符合未反应收缩核模型,其前期受化学反应控制,然后转为混合控制,后期受固体产物层扩散控制。受化学反应控制和固体产物层扩散控制过程的表观活化能分别为 46.09 kJ/mol和11.62 kJ/mol。

3) 化学反应控制过程是影响铟浸出的主要过程,对初始硫酸浓度、氧分压及粒度的反应级数分别为0.95,0.82和-1.00,化学反应控制过程阶段铟浸出的宏观动力学方程为

。

。

参考文献:

[1] 王树楷. 铟冶金[M]. 北京:冶金工业出版社, 2007: 1-2.

WANG Shukai. Indium metallurgy[M]. Beijing: Metallurgical Industry Press, 2007: 1-2.

[2] LI Yuan, WANG Wenwen, ZHANG Junying, et al. Preparation and properties of tungsten-doped indium oxide thin films[J]. Rare Metals, 2012, 32(2): 158.

[3] 冯强, 魏昶, 邓志敢, 等. 高铁硫酸锌浸出液中铟的富集[J]. 稀有金属, 2014, 38(4): 687-692.

FENG Qiang, WEI Chang, DENG Zhigan, et al. Enriching indium from zinc sulfate solution bearing high iron and indium containing[J]. Chinese Journal of Rare Metals, 2014, 38(4): 687-692.

[4] 王树楷. 铟的应用与提取进展[J]. 中国工程科学, 2008, 10(5): 85-94

WANG Shukai. Progress of extraction and application of indium[J]. Engineering Sciences, 2008, 10(5): 85-94.

[5] 姚艳清, 刘四清, 董旭, 等. 铟的富集分离工艺技术现状及展望[J]. 金属矿山, 2016, 45(9): 132-136.

YAO Yanqing, LIU Siqing, DONG Xu, et al. Current situation and outlook on indium enrichment and separation technology[J]. Metal Mine, 2016, 45(9): 132-136.

[6] 沈丽娟, 吴克明, 袁芳沁, 等. 锌冶炼过程中铟的富集与回收技术研究进展[J]. 矿产综合利用, 2012(4): 3-6.

SHEN Lijuan, WU Keming, YUAN Fangqing, et al. Research progress of technologies for indium recovery and pre-concentration in zinc smelting[J]. Multipurpose Utilization of Mineral Resources, 2012(4): 3-6.

[7] 周智华, 莫红兵, 徐国荣, 等. 稀散金属铟富集与回收技术的研究进展[J]. 有色金属, 2005, 57(1): 71-80.

ZHOU Zhihua, MO Hongbin, XU Guorong, et al. Progress in indium recovery and pre-concentration technology[J]. Nonferrous Metals, 2005, 57(1): 71-80.

[8] 杜云鹏, 谢贤, 童雄, 等. 铟提取与富集的技术现状[J]. 价值工程, 2017: 217-220.

DU Yunpeng, XIE Xian, TONG Xiong, et al. A review of extraction and enrichment technology for indium[J]. Value Engineering, 2017: 217-220.

[9] 袁铁锤, 陶政修, 周科朝. 提高含铟锌精矿中锌铟回收率的方法[J]. 中南大学学报(自然科学版), 2006, 37(5): 874-877.

YUAN Tiechui, TAO Zhengxiu, ZHOU Kechao. Methods for improving recovery of zinc and indium from indium-contained zinc concentrate[J]. Journal of Central South (Science and Technology), 2006, 37(5): 874-877.

[10] 巨少华, 彭金辉, 刘超. 一种微波硫酸化焙烧水浸处理铁矾渣的方法: CN 103589861A[P]. 2015-07-22.

JU Shaohua, PENG Jinhui, LIU Chao. A method for treating iron vitriol residue by microwave sulfuric acid roasting: CN 103589861A[P]. 2015-07-22.

[11] 刘环, 魏钦帅, 刘大春, 等. 真空蒸馏铟锡合金回收金属铟的研究[J]. 真空与科学技术学报, 2012, 32(10): 902-906.

LIU Huan, WEI Qinshuai, LIU Dachun, et al. Indium recovery from indium-tin alloy by vacuum distillation[J]. Chinese Journal of Vacuum Science and Technology, 2012, 32(10): 902-906.

[12] 刘大春, 杨斌, 戴永年, 等. 从富铟渣提取金属铟的研究[J]. 稀有金属, 2005, 29(4): 574-577.

LIU Dachun, YANG Bin, DAI Yongnian, et al. Extracting indium metal from indium-enriched slag[J]. Chinese Journal of Rare Metals, 2008, 29(4): 574-577.

[13] 谌斯, 杨利姣, 陈南春, 等. 锌渣氧粉两段浸出铟的试验研究[J]. 湿法冶金, 2013, 32(5): 312-315.

CHEN Si, YANG Lijiao, CHEN Nanchun, et al. Test research on two-stages leaching of indium from zinc oxidation slag[J]. Hydrometallurgy of China, 2013, 32(5): 312-315.

[14] 陈永明, 唐谟堂, 杨声海, 等. NaOH分解含铟铁矾渣新工艺[J]. 中国有色金属学报, 2009, 19(7): 1322-1331.

CHEN Yongming, TANG Motang , YANG Shenghai, et al. Novel technique of decomposition of ammonium jarosite bearing indium in NaOH medium[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(7): 1322-1331.

[15] 罗文波, 王吉坤, 王国卫. 从氧化锌烟尘中加压浸出铟的动力学[J]. 湿法冶金, 2016, 35(2): 106-109.

LUO Wenbo, WANG Jikun, WANG Guowei. Pressure leaching kinetics of indium in zinc oxide dust[J]. Hydrometallurgy of China, 2016, 35(2): 106-109.

[16] 闫书阳, 谢刚, 于站良, 等. 复杂多金属高铟高铁闪锌矿的氧压酸浸[J]. 稀有金属, 2016, 40(4): 378-384.

YAN Shuyang, XIE Gang, YU Zhanliang, et al. Pressure oxidative acid leaching of complex polymetallic sphalerite containing high iron and indium[J]. Chinese Journal of Rare Metals, 2016, 40(4): 378-384.

[17] 罗文波, 王吉坤, 赵兴凡, 等. 含铟氧化锌烟尘加压硫酸浸出工艺优化[J]. 过程工程学报, 2015, 15(6): 982-987.

LUO Wenbo, Wang Jikun, ZHAO Xingfan, et al. Optimization of pressure leaching process of indium-bearing zinc oxide dust with sulfuric acid[J]. The Chinese Journal of Process Engineering, 2015, 15(6): 982-987.

[18] 王继民, 曹洪杨, 陈少纯, 等. 氧压酸浸炼锌流程中置换渣提取锗镓铟[J]. 稀有金属, 2014, 38(3): 471-479.

WANG Jiming, CAO Hongyang, CHEN Shaochun, et al. Recovery of Ge/Ga/In from replacement slag in pressure oxidation leaching process of zinc sulfide concentrate[J]. Chinese Journal of Rare Metals, 2014, 38(3): 471-479.

[19] DIMITRIOS F, RAO K, GEORGE P D. A kinetic study on the acid pressure leaching of pyrrhotite[J]. Hydrometallurgy, 1997, 47(1): 1-18.

[20] QIU Shuang, WEI Chang, LI Mingting, et al. Dissolution kinetics of vanadium trioxide at high pressure in sodium hydroxide-oxygen systems[J]. Hydrometallurgy, 2011, 105(3): 350.

[21] 廖亚龙, 黄斐荣, 周娟, 等. 低冰镍转炉渣中钴的氧压酸浸行为及其动力学[J]. 化工学报2015, 66(10): 3972-3978.

LIAO Yalong, HUANG Feurong, ZHOU Juan, et al. Kinetics and behavior of cobalt extraction from low nickel matte converter slag by pressure oxidative leaching with sulfuric acid[J]. CIESC Journal, 2015, 66(10): 3972-3978.

[22] BEHNAMFARD A, SALARIRAD M M, VEGLIO F. Process development for recovery of copper and precious metals from waste printed circuit boards with emphasize on palladium and gold leaching and precipitation[J]. Waste Management, 2013, 33(11): 2354-2363.

[23] 李洪桂. 冶金原理[M]. 北京:科学出版社, 2017: 291.

LI Honggui. Metallurgical principle[M]. Beijing: Science Press, 2017: 291.

[24] 黄金, 谢芳浩, 肖海建, 等. 盐酸磷酸络合浸出白钨矿的试验研究[J]. 稀有金属, 2014, 38(4): 703-710.

HUANG Jin, XIE Fanhao, XIAO Haijian, et al. Coordination leaching of scheelite ore by HCl-H3PO4[J]. Chinese Journal of Rare Metals, 2014, 38(4): 703-710.

[25] WANG Ruochao, ZHAI Yuchun, NING Zhiqiang, et al. Kinetics of SiO2 leaching from Al2O3 extracted slag of fly ash with sodium hydroxide solution[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(6): 1928.

[26] 贺山明. 高硅氧化铅锌矿加压酸浸工艺及理论研究[D]. 昆明: 昆明理工大学, 2012: 123-126.

HE Shanming. Study on the technology and theory of acid leaching of high silica lead-zinc ore[D]. Kunming: Kunming University of Science and Technology, 2012: 123-126.

(编辑 伍锦花)

收稿日期:2017-08-23;修回日期:2017-10-28

基金项目(Foundation item):国家自然科学基金资助项目(U1502271)(Project(U1502271) supported by the National Natural Science Foundation of China)

通信作者:刘大春,博士,教授,从事复杂二次资源综合利用研究;E-mail:794392138@qq.com