Trans. Nonferrous Met. Soc. China 23(2013) 1674-1680

Tribological properties of sulfur-containing high-speed steels at elevated temperature

Ru-tie LIU, Xiang XIONG

State Key Laboratory for Powder Metallurgy, Central South University, Changsha 410083, China

Received 25 September 2012; accepted 11 January 2013

Abstract: Tribological properties of ferrous-based alloys can be effectively improved by introducing an appropriate amount of elemental sulfur into the alloys. A few samples of sulfur-containing high-speed steels were prepared by powder metallurgy techniques. High temperature friction properties of the samples mating with different counter materials, i.e., self-dual and GT35 steel bonded carbide were studied on a pin-on-disk tribo-meter. Worn surfaces were analyzed using SEM, EDS and XPS, and the friction mechanism was discussed. It is found that for both cases of self-dual and GT35 counter mates, the friction factors gradually decrease and the wear rates increase with rising the temperature. The friction coefficient curves become more stable at 400 °C and 700 °C than at room temperature, and the better friction performance is observed for the GT35. Below 400 °C, friction coefficients drop with rising the temperature, due to sulfide softening. Above 400 °C, friction coefficients drop mainly due to the formation of oxides on the worn surfaces.

Key words: high-speed steel; sulfur; steel bonded carbide; elevated temperature; sliding friction; wear

1 Introduction

Some studies have shown that the tribological properties of ferrous-based alloys (and also nickel-based super alloys) can be effectively improved by introducing an appropriate amount of elemental sulfur into the alloys [1-3]. It is believed that sulfur in the alloys can react with certain elements to form some sorts of solid lubricants that can be used at higher temperatures than MoS2, either during alloy fabrication or during the process of friction, which provides a promising solution to lubrication problems in many high-temperature engineering fields, such as aerospace, power machinery and metal processing. In this study, we examine and compare the high-temperature friction performance of sulfur-containing high-speed steels mating with two different counter materials. High-speed steel fabricated by powder metallurgy (P/M) techniques will be used as the matrix alloy because of its many advantages including fine grain size, fine carbide particle size, good hot workability, good grinding performance, good mechanical property combination (toughness and high temperature hardness), low tendency to component segregation, and as well its resistance to shape-distortion during heat treatment. As a fact, ferrous alloys developed on the basis of P/M high-speed steels have shown enormous potential in addressing friction, wear and lubrication problems faced by many military and civil industries [4,5]. It is also recently noticed that selection of different mate materials can produce considerable variation in the tribological performance of materials [6,7]. Both friction performance and anti-friction mechanism of sulfur-containing high-speed steel with different mate materials at elevated temperatures will be further discussed, which is of great significance to the research and development of new, improved ferrous- based friction materials [8,9].

2 Experimental

2.1 Fabricating process

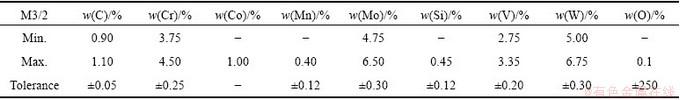

Raw materials used in the present study were M3/2 high-speed steel powders of less than 150 μm in size made by  and MoS2 powders of less than 55 μm in size. The chemical composition of high-speed steel powders is provided in Table 1. M3/2 is a fully pre-alloyed powder that was annealed after water atomization. 97.5% M3/2 and 2.5% MoS2 were mixed and blended in a V-shape blender for 120 min, and then pressed and sealed in a steel mould under a pressure of 700 MPa. The canned powders were sintered at 1250 °C in a DL-VF-30 vacuum furnace for 60 min and then cooled down to room temperature by furnace cooling.

and MoS2 powders of less than 55 μm in size. The chemical composition of high-speed steel powders is provided in Table 1. M3/2 is a fully pre-alloyed powder that was annealed after water atomization. 97.5% M3/2 and 2.5% MoS2 were mixed and blended in a V-shape blender for 120 min, and then pressed and sealed in a steel mould under a pressure of 700 MPa. The canned powders were sintered at 1250 °C in a DL-VF-30 vacuum furnace for 60 min and then cooled down to room temperature by furnace cooling.

Table 1 Chemical composition of M3/2 high-speed steel

2.2 Test and analysis

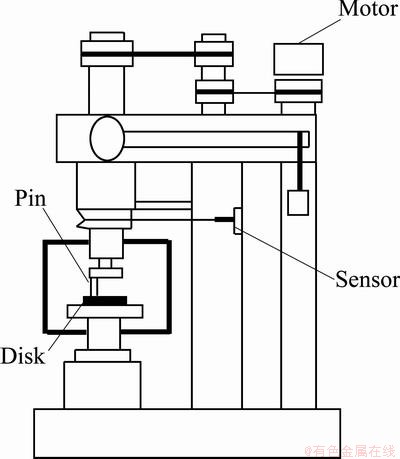

Hardness was measured with Rockwell hardness tester. Friction coefficient was determined using a MMU-10G high-temperature tribo-meter made by Ji’nan Yihua company, which performs pin-on-disk friction testing with a fixed disk in contact with a rotating pin (Fig. 1). Sizes of the pin and the disc were measured as d4 mm×18 mm and d50 mm×4 mm, respectively, and the rotating radius was 12 mm. Self-dual (a high-speed steel containing 2.5% MoS2 in mass fraction) and GT35 (a steel-bonded carbide containing (0.6-0.8)% C, 3.0% Cr, 3.0% Mo, 35% TiC and Fe the remainder) were chosen to be the mate materials under tests. The bend strength and the hardness of the self-dual material were measured to be 1380 MPa and HRC37, respectively. The bend strength and the hardness of GT35 were measured to be 1560 MPa and HRC48, respectively. Samples’ surfaces were polished with No. 500 sand paper, and after being degreased and cleaned, the samples were presented for friction and wear testing under conditions of a load of 100 N, a rotational speed of 400 r/min, a time period of 30 min, and a variety of temperatures (room temperature, 400, 550, and 700 °C). The data were collected and recorded, and the average friction coefficient was calculated in a fully automatic way. The samples were cleaned with alcohol after each test. The wear mass loss was weighed by a precision of 0.1 mg. Wear rate was determined by mass loss, load and sliding distance by considering the mass increase because of the effects of high temperature oxidation on samples’ non-worn surfaces. Crystalline phases were identified on a Japan D/max-γ X-ray diffractometer. Worn surfaces were also examined under a JSM-6360LV scanning electron microscope (SEM) with energy dispersive spectroscopy (EDS) and a K-alpha 1063 X-ray photoelectron spectroscope (XPS).

Fig. 1 High-temperature face wear tester (MMU-10G)

3 Results and discussion

3.1 Microstructure

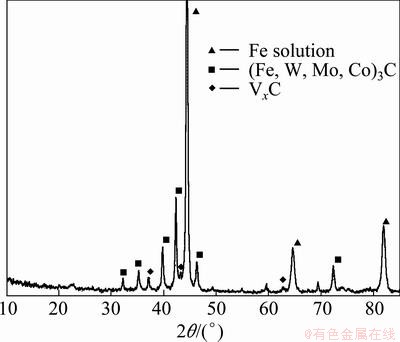

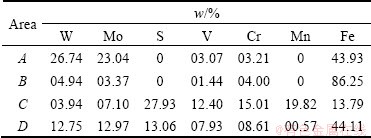

Three major phases, vanadium carbide, ferrous solid solution and (Fe,W,Mo,Co)3C, were identified using an X-ray diffractometer (Fig. 2). The crystalline phase of MoS2 was not detected in the XRD pattern which was expected due to its decomposition as a result of sintering at temperatures up to 1250 °C. Further metallographic and EDS analyses (Fig. 3 and Table 2) revealed that at least other four different phases exist in the alloy: at area A (a dispersed particle) or B (the iron-based matrix), the chemical composition is dominated by Fe. The contributions of W, Mo, Cr and V are also detected, while sulfur is not present. Area C is enriched in S, followed by Mn, Cr, Fe and V. The composition in area D is somewhat similar as that in area A, but with the presence of 13% S. It is suggested for areas C and D that sulfur has been decomposed from MoS2 and might have formed some sorts of sulfides with the alloying elements. The presence of a large number of fine dispersed carbide phases in the iron-based matrix is favorable to improve the high temperature performance of the material.

Fig. 2 XRD pattern of material made from 97.5% M3/2 and 2.5% MoS2

Fig. 3 SEM images (a, b) and EDS results (c, d, e, f) of materials made from 97.5% M3/2 and 2.5% MoS2

Table 2 Element distribution in different areas

3.2 Friction coefficient and wear rate

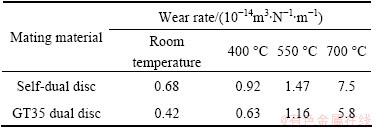

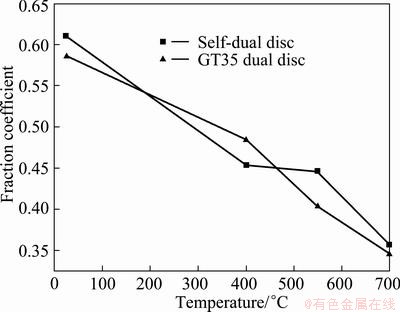

Friction coefficient and wear rate of the material sensitively depend on the ambient temperature and the nature of the mating material. To investigate this influence, we compared the average friction coefficients measured for the self-dual disc and the GT35 dual disc in Fig. 4, and the average measurement of wear rates in Table 3. A general trend was observed for both cases: the highest average coefficient of friction was obtained as about 0.60 at room temperature. As the temperature rose, the friction coefficient decreased rapidly. At 700 °C, the average coefficient was reduced about in half, to ~0.35. Although there is no significant difference between the performances of the two different dual discs, it is still worthy to note that the average friction coefficient with GT35 dual disc is slightly lower than that with self-dual disc, for temperature above ~450 °C. It is seen in Table 3 that the wear rate with the same mating materials increases with rising the temperature and is even ten times higher at 700 °C than at room temperature, and that the wear rate with GT35 dual disc is lower than that with self-dual disc.

Table 3 Wear rates for different mates

Fig. 4 Curves of friction coefficient vs temperature for different mates

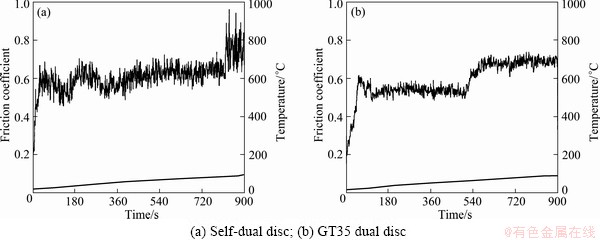

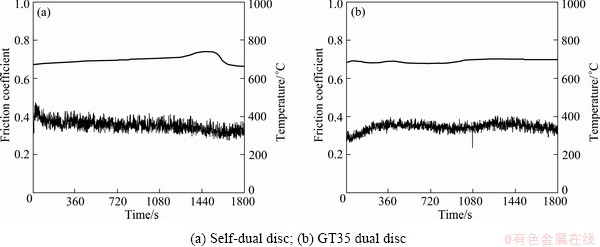

Fig. 5 Curves of friction coefficient and temperature vs time at room temperature (Zigzag curves refer to friction coefficient and smooth curves refer to temperature in same figure)

Fig. 6 Curves of friction coefficient and temperature vs time at 400 °C (Zigzag curves refer to friction coefficient and smooth curves refer to temperature in same figure)

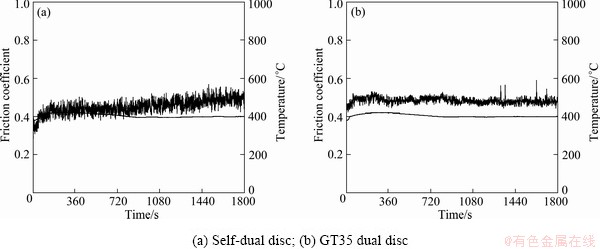

Figures 5-7 show the curves of the friction coefficients and testing temperatures varying with time measured for the two different matches, at room temperature, 400 °C and 700 °C, respectively. It is noticed that at room temperature, the friction coefficients for both matches were high, and also rather volatile over time, while at 400 °C and 700 °C, the friction coefficients were largely reduced, but also somewhat stabilized with the increasing time. The friction coefficient of the material with the GT35 dual disc was more stable than that with the self-dual disc.

3.3 Friction mechanism analysis

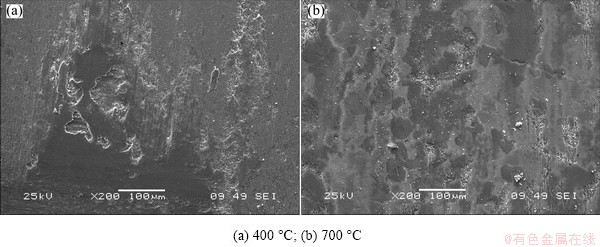

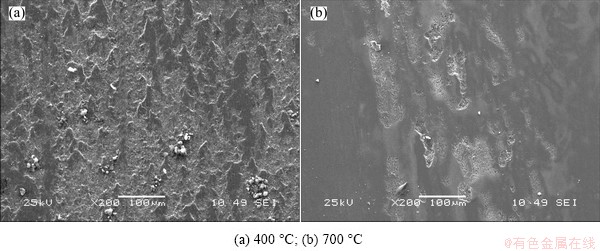

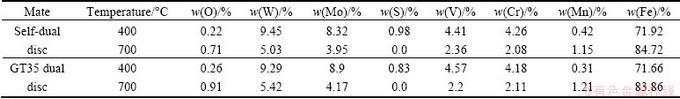

Figures 8 and 9 show the SEM secondary electron images of the worn surfaces after the friction and wear tests at 400 °C and 700 °C. The corresponding EDS results are further compared in Table 4.

It is evident from Table 4 that there exists a small concentration of sulfur on the worn surfaces of the material, with the self-dual disc and as well the GT35 dual disc, at 400 °C, which is a sign of solid lubrication effects due to sulfides’ softening and easiness to disperse out on the surface at high temperatures according to earlier research results [10-12]. As the temperature rose, the sulfides began to decompose while oxides began to form on the worn surfaces. At 700 °C, sulfides have been reduced to a nearly undetectable level, and instead, more oxides have been produced. The increasing amount of the oxide should be responsible for the further reduced friction coefficients at high temperatures [13-18]. Oxidation wear on worn surfaces is also evident, also as revealed in the figures.

Fig. 7 Curves of friction coefficient and temperature vs time at 700 °C (Zigzag curves refer to friction coefficient and smooth curves refer to temperature in same figure)

Fig. 8 SEM images of worn surface with self-dual disc at different temperatures

Fig. 9 SEM images of worn surface with GT35 at different temperatures

Table 4 EDS results of worn surface at different temperatures

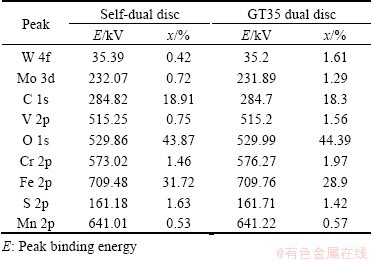

The XPS spectra analyses of the worn surfaces after wear test at 700 °C were performed to further identify the precise details, as shown in Fig. 10. The surface elemental chemistry differs little from each other, suggesting that the responsible friction mechanisms were basically the same. The atomic concentration of sulfur at 700 °C still exists, which is not detected in EDS because of the differences for these two analysis manners. Though sulfides may start to decompose and oxidation can occur on the surface above a certain high temperature, yet they provide self-lubrication of the material and also help to reduce and stabilize the friction coefficient even at 700 °C. From Table 5, the formation of oxides of W, Mo, V, Cr, Mn and Fe on the worn surfaces is also evident at 700 °C. However, it should be notified that GT35 contains a lot of hard TiC particles and hence has high temperature hardness higher than the self-dual disc, which can better support solid lubricant film on the worn surfaces. It could be the reason for its smoother and more stable friction coefficients over time as observed in Fig. 7.

Fig. 10 XPS spectra of worn surface with different mates at 700 °C

Table 5 XPS results of worn surface with different mates at 700 °C

4 Conclusions

1) The average friction coefficients and wear rates of the material with the self-dual disc and the GT35 dual disc follow a common general trend of decreasing and increasing respectively with rising the temperature. The wear rate with GT35 dual disc is lower than that with self-dual disc at the same testing temperature.

2) Friction coefficients are volatile at room temperature, and become more stable at higher temperatures. The comprehensive high-temperature friction performance of the material can be improved when mated with the GT35 dual disc.

3) Below around 400 °C, the friction coefficient of the material drops as the temperature rises, mainly due to sulfide softening. At higher temperatures up to 700 °C, though sulfur has still some effects on tribological performance, and friction coefficient decreases mainly due to the formation of oxides on the worn surfaces, where tribo-oxidation wear becomes the major wear mechanism.

References

[1] ZHANG Si-wei. Recent advances in tribology [J]. Tribology, 1994, 14(1): 84-87. (in Chinese)

[2] BEGG A R. Metal matrix composites by powder metallurgy [J]. Powder Metallurgy, 1993, 36(2): 107-110.

[3] LI J L, XIONG D S. Tribological properties of nickel-based self-lubricating composite at elevated temperature and counter face material selection [J]. Wear, 2008, 265(3-4): 533-539.

[4] WANG Qing-nian, SUI Zhong-xiang, ZHANG Ming-pin. Research and development on the metal matrix self-lubricating composites overseas [J]. Tribology, 1997, 17(1): 89-96. (in Chinese)

[5] XUE Qun-ji, LU Ji-jun. Research status and developing trend of solid lubrication at high temperatures [J]. Tribology, 1999, 19(1): 91-96. (in Chinese)

[6] MA W, LU J, WANG B. Sliding friction and wear of Cu–graphite against 2024, AZ91D and Ti6Al4V at different speeds [J]. Wear, 2009, 266(11-12): 1072-1081.

[7] TANNO Y, AZUSHIMA A. Effect of counter materials on coefficients of friction of TiN coatings with preferred grain orientations [J]. Wear, 2009, 266(11-12): 1178-1184.

[8] LIU Jin-zhu, GAO Jin-tang, LIU Wei-min. Selection of friction mates for a high temperature self-lubricating nickel-based alloy containing sulfur [J]. Material for Mechanical Engineering, 1998, 22(1): 30-33. (in Chinese)

[9] HAN Jie-sheng, LIU Wei-min, LIU Ji-jun, WANG Jing-bao. Tribological properties of Fe-Mo-(MoS2/PbO)high temperature self-lubricating material [J]. Journal of Materials Science & Engineering, 2008, 26(1): 118-120. (in Chinese)

[10] PETERSON M B, CALABRESE S T. Friction of alloys at high temperature [J]. Journal of Material Science & Technology, 1994, 10(3): 313-320.

[11] LIU Ru-tie, LI Xi-bin, XIONG Dang-shen, CHENG Shi-he. Study on the tribological characteristics of a high-temperature self-lubricating nickel-base material [J]. Journal of Central South University of Technology, 2000, 31(3): 260-263. (in Chinese)

[12] XIONG D S. Lubrication behavior of Ni-Cr based alloys containing MoS2 at high temperature [J]. Wear, 2001, 251(11-12): 1094-1099.

[13] LI Yu-feng, OUYANG Jia-hu, ZHOU Yu. Research and development status of high temperature solid lubricant materials [J]. Heat Treatment Technology, 2007, 28(6): 2-5. (in Chinese)

[14] DELLA CORTE C. The effect of counter face on the tribological performance of a high temperature solid lubricant composite from 25 to 650 °C [J]. Surface & Coatings Technology, 1996, 86(2): 486-492.

[15] LIU Jin-zhu, GAO Jin-tang, OUYANG Jin-lin. Microstructure and phase structure analysis of a self-lubrication Ni-base alloy [J]. Tribology, 1996, 16(3): 208-212. (in Chinese)

[16] LANCASTER J K. Transfer lubrication for high temperature: A review [J]. Journal of Tribology, 1985, 107(10): 437-442.

[17] WANG Ying, WANG Jin-bao, WANG Jun-an. Study on the nickel alloy containing sulfide and its tribological properties at high temperature [J]. Tribology, 1996, 16(4): 289-297. (in Chinese)

[18] PETERSON M B, LI S Z, MURRAY S F. Wear-resisting oxide films for 900 °C [J]. Journal of Material Science &Technology, 1997, 13(2): 99-106.

含硫高速钢的高温摩擦性能

刘如铁,熊 翔

中南大学 粉末冶金国家重点实验室,长沙 410083

摘 要:引入适量的硫可以明显改善铁基材料的摩擦学性能。采用粉末冶金技术制备了含硫高速钢样品材料,采用销盘高温摩擦试验机研究了该样品材料与不同配副(自对偶和GT35钢结硬质合金)摩擦时的高温摩擦性能,通过SEM、EDS和XPS检测了摩擦面,并分析了其摩擦机理。结果表明:与自对偶盘和GT35盘这2种对偶材料摩擦时,摩擦因数的变化趋势是随着温度的升高而逐渐降低的,磨损率则是随着温度的升高而逐渐变大的;在400 °C和700 °C时的摩擦因数曲线比室温时更加平稳,与GT35摩擦时样品材料的综合高温摩擦性能最佳;在400 °C以下时,由于样品材料中硫化物的软化会使得材料的摩擦因数随着温度的升高而降低,在400 °C以上时样品材料摩擦因数的降低主要是由于摩擦面的氧化物作用而引起的。

关键词:高速钢;硫;钢结硬质合金;高温;滑动摩擦;磨损

(Edited by Hua YANG)

Foundation item: Project (331101109) supported by State Key Laboratory Innovation Funding for Powder Metallurgy of Central South University, China

Corresponding author: Ru-tie LIU; Tel: +86-731-88876566; E-mail: LLRRTT@csu.edu.cn

DOI: 10.1016/S1003-6326(13)62647-3