文章编号: 1004-0609(2006)10-1765-06

316L不锈钢扩散焊接头的微观结构和力学性能

安子良, 轩福贞, 涂善东

(华东理工大学 机械与动力工程学院, 200237)

摘 要: 针对不同焊接参数的含镍中间层316L不锈钢扩散焊接头, 进行室温和550℃高温拉伸实验, 采用SEM、 XRD和金相显微镜分析接头区域的微观结构和相分布。 结果表明: 接头的室温力学性能随焊接温度的提高而降低, 而高温力学性能随温度的提高而提高。 XRD分析表明, 焊接过程中产生的Fe0.64Ni0.36 导致接头区域的相组成不均一; 在高温拉伸实验时, DB2和DB3接头中的Fe0.64Ni0.36发生相变, 强度和塑性更好的FeNi3是接头高温强度提高的原因。

关键词: 镍中间层; 316L不锈钢; 扩散焊; 高温强度

中图分类号: TG453·9 文献标识码: A

Microstructure and mechanical properties of

diffusion bonding joints of 316L stainless steel

AN Zi-liang, XUAN Fu-zhen, TU Shan-dong

(School of Mechanical and Powder Engineering,

East China University of Science and Technology, Shanghai 200237, China)

Abstract: For diffusion bonding joints of 316L stainless steel with Ni interlayer bonded at different process parameters, tensile tests were performed to evaluate the strength of joints at room temperature and elevated temperature of 550℃. The microstructure and phase structure were identified by scanning electronic microscopy, optical microscopy and X-ray diffractometry, respectively. The results indicate that as the bonding temperature increases, the strength of joints decreases at room temperature, whereas increases at elevated temperature. The XRD analysis reveals that Fe0.64Ni0.36 produced in the diffusion bonding process results in the inhomogeneity at the bonded zone of the joints. At elevated temperature tensile tests, Fe0.64Ni0.36 of the DB2 and DB3 joints is transformed to FeNi3 with higher plasticity and strength, it is the reason for the improvement in the strength of these joints.

Key words: Ni interlayer; 316L stainless steel; diffusion bonding; high temperature strength

微化工机械多为薄板复合结构, 板与板间的连接工艺要求加工精度高, 几何变形小[1]。 熔焊构件变形大, 不满足微机械设备的焊接要求。 最近的研究结果表明, 钎焊接头在高温受载时是焊接结构中最脆弱的部位[2]。 近年来, 扩散焊作为一种高效、 成熟和应用广泛的材料连接技术, 不仅在金属、 异种金属和异种材料的焊接中得以完美体现, 而且是微化工机械主要的加工方法[3-7]。 Takeda等[8]对利用扩散焊技术制备的微型紧凑式中间换热器进行了密封性和力学性能等方面的测试。 Little等[9]在比较了多种材料连接方法后, 选用扩散焊技术加工的微型换热器已经批量生产。 YU等[10]研制的甲醇重整制氢微型反应器已经达到实验室级水平。

熔焊的经验表明, 高温环境下, 焊接构件的早期失效多发生在焊缝或者接头附近的热影响区[11]。 很明显, 工作在高温环境中的扩散焊接头也面临同样的风险。 但到目前为止很少有文献报道关于扩散焊接头的高温性能和接头高温强度设计准则[12, 13]。 本文作者在研究316L不锈钢直接扩散焊接头常温和高温机械性能时发现[14], 焊接界面由于母材线膨胀系数大而容易产生宏观塑性变形, 导致焊缝区域微观组织恶化、 焊合率低。 因此, 在考虑满足焊接结构精度和强度的前提下, 可将镍片作为中间层添加到母材中间, 通过合理调整工艺参数制备微观组织和机械性能俱佳的接头。

本文作者着重研究焊接工艺参数和镍中间层对316L不锈钢扩散焊接头的常温、 高温短时拉伸性能的影响, 探讨镍中间层对同种材料焊接的作用。

1 实验

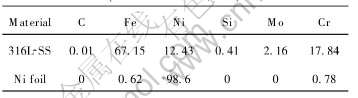

采用316L不锈钢圆棒做母材, 厚度为20μm的镍片作为中间层填充在母材中间。 其化学成分列于表1。

表1 母材和中间层材料的化学成分

Table 1 Chemical composition of base and interlayer materials

(mass fraction, %)

实验采用d70mm×50mm的对接圆棒, 被焊表面的粗糙度在磨床上加工到1.6μm, 焊前酸洗316L不锈钢和镍片后用丙酮脱脂。 以镍片作为中间层, 分别在850、 950和1050℃ 3个温度水平和10MPa的焊接压力下进行焊接实验, 试样分别命名为DB1、 DB2和DB3。 焊接过程中, 炉腔的真空度保持在1.33×10-3 Pa。

在配备了温控高温炉的材料试验机上进行20℃、 550℃短时拉伸实验, 拉伸试样标距d5mm×30mm, 实验结果取3次测试的平均值。 从接头区域取10mm×5mm×5mm的样品, 在金相显微镜下观察接头区域的组织结构, 并对焊接区域做标记。 对标记过的金相样品分别采用X射线衍射仪和显微硬度仪测定接头区域中新相的物相结构和焊接界面区域的显微硬度。 垂直于焊缝做线扫描(EDS)以确定元素在焊接界面扩散的情况。 拉断的试样经丙酮清洗后, 在扫描电镜下观察断口形貌, 研究测试温度对接头断裂方式的影响。

2 结果和讨论

2.1 接头微观结构

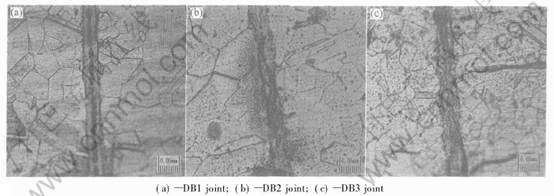

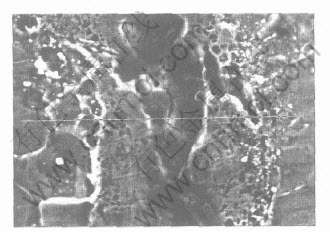

接头区域微观组织显示(图1), 接头的焊合率随着焊接温度的提高而逐渐下降。 且相对于316L不锈钢直接扩散接头, 加入镍中间层后的接头焊合率显著提高。 这是因为随着焊接温度的提高, 母材屈服强度下降, 线膨胀系数提高。 在10MPa的焊接压力和高温的共同作用下, 母材变形加大, 被焊表面变得越来越粗糙, 因此焊合率随着焊接温度的上升而有所下降。 从接触条件看, 被焊表面的凸起处与镍中间层形成了物理接触, 凹陷处被镍片所填充。 因此被焊界面物理接触情况主要取决于中间层的蠕变速度, 而不再是母材界面的蠕变速度。 焊接

图1 接头区域的微观组织

Fig.1 Microstructures of joints with Ni interlayer bonded at different temperatures

实验时, 较大的母材塑性变形阻止了镍中间层的变形发展。 由此可知, 镍中间层的引入降低了焊接界面区域的蠕变速度, 缓解了母材膨胀系数过大而引起的宏观塑性变形, 改善了界面的微观形貌。

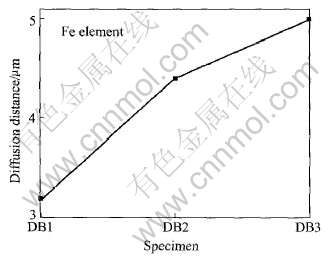

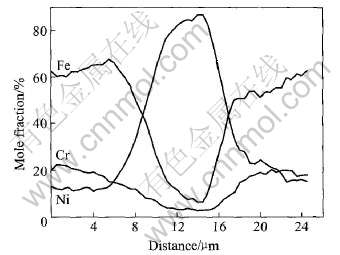

对含镍中间层接头EDS线扫描结果表明, 铁原子扩散到镍中间层的深度随着焊接温度的提高而增加(图2)。 由公式(1)可知, 随着焊接温度的提高, 元素的扩散系数逐渐提高, 但由于焊接时间较短, 中间层过厚而没有完全焊透(图3), 且铬元素的在镍片中的扩散远远小于铁元素。 因此, 接头中的合金化反应主要集中在铁、 镍元素之间。 对接头XRD分析可知, 接头区域发生了固溶反应生成了新相Fe0.64Ni0.36。 加入镍中间层后, 在接头焊缝区域形成了固溶合金/镍/固溶合金类似于“三明治”的结构, 导致母材、 镍中间层和其界面的化学成分与组织结构的不均匀。 图3和图4所示为元素分布曲线和DB3接头界面的EDS图, 在图4中靠近界面处可以观察到柯肯达尔效应。 根据经典扩散理论, 熔点高、 原子半径小的元素容易向熔点低、 原子半径大的元素扩散。 铁和镍的原子半径分别为1.27和1.24, 因此, 镍元素在铁中的扩散速度要大于铁在镍中的扩散速度, 这就导致了界面处柯肯达尔孔洞的形成。

式中 D为扩散系数; D0为扩散常数; R为气体常数; Q为扩散激活能; T为温度。

2.2 接头常温力学性能

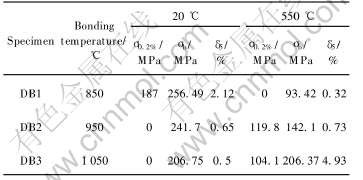

由表2可知, 含镍中间层接头常温抗拉强度和延伸率随着焊接温度的提高而逐渐下降。 仅在850℃焊接的DB1接头发生了屈服现象, 而在较高焊接温度制备的DB2、 DB3接头在弹性阶段就发生了

表2 316L不锈钢扩散焊接头力学性能

Table 2 Mechanical properties of 316L-SS diffusion bonding joints at different temperatures

图2 铁元素在接头界面处扩散的距离

Fig.2 Diffusion distance of Fe element in interface of joints with Ni interlayer bonded at different temperatures

图3 DB3接头界面处元素分布曲线

Fig.3 Element distribution curves in interface of DB3 joint

图4 DB3接头界面处EDS线扫描图

Fig.4 EDS line scan micrograph in interface of DB3 joint

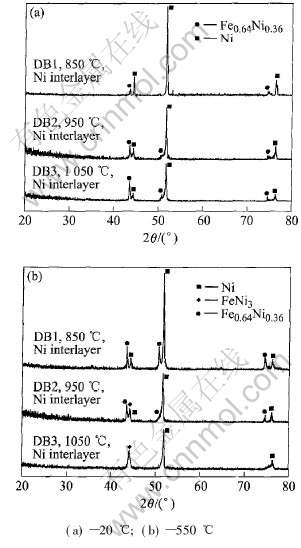

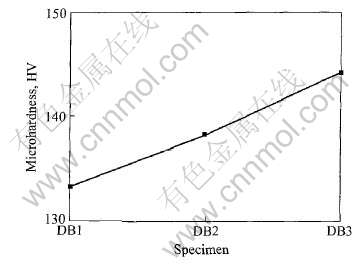

断裂。 中间层的引入导致扩散焊接头常温性能恶化, 主要是因为母材和镍中间层中互扩散的铁、 镍元素发生了固溶合金反应形成脆硬的Fe0.64Ni0.36造成的。 由图5(a)可见, 新相Fe0.64Ni0.36的衍射峰强随着焊接温度的提高而逐渐增加, 镍元素的衍射峰强显著降低, 说明焊缝中的固溶合金含量随着焊接温度的提高而增加。 由图6可知, 随着焊接温度的提高, 接头界面上的显微硬度随着焊接温度的提高而提高。 显微硬度的变化趋势也在一定程度上证实了上述XRD的分析结果。

镍中间层的引入, 使得焊缝区域的化学成分和组织结构与母材不一致。 在拉伸过程中, 未反应的软质镍中间层进入塑性状态时, 母材和界面固溶合金仍然处于弹性状态, 因此镍层的塑性变形受到两侧高强材料的拘束作用, 使镍层处于三向受拉状态, 从而被强化。 因此, 中间层的“接触强化效应”使得接头强度下降幅度不大[15, 16]。

图5 接头区域XRD衍射谱

Fig.5 XRD patterns of diffusion bonding joints with Ni interlayer bonded at different temperatures

图6 接头界面区域显微硬度

Fig.6 Microhardness of interface of joints with Ni interlayer bonded at different temperatures

2.3 接头高温力学性能

高温下的接头表现出与常温性能迥异的特点, 接头高温抗拉强度和延伸率随着焊接温度的上升而提高。 但在850℃焊接的DB1试样高温性能急剧下降, 接头高温抗拉强度只有常温的36.4%, 延伸率仅为常温的15.1%。 在高温拉伸过程中, DB2、 DB3样品都出现了非常明显的屈服现象, 接头高温性能比常温有了大幅度的提高。 在1050℃焊接的DB3接头的高温抗拉强度等于其常温强度, 高温延伸率是其常温延伸率的9.86倍。 虽然DB3接头的高温短时拉伸性能良好, 但柯肯达尔孔洞在高温环境中, 有可能成为蠕变裂纹扩展的发源地, 因此镍中间层对316L不锈钢扩散焊接头的作用需要进一步的高温蠕变实验来检验。

对经过与高温拉伸实验相同条件处理的金相试样XRD分析表明(图5(b)), 接头焊缝的Fe0.64-Ni0.36发生了相变。 对比图5(a)和5(b)可知, 在进行高温拉伸实验时, DB1试样继续发生铁、 镍固溶合金反应, 大量Fe0.64Ni0.36合金生成导致DB1接头脆性增加、 高温强度显著下降。 而DB2样品的Fe0.64Ni0.36的衍射峰强减弱, 出现了宽而矮的FeNi3衍射峰。 由此可知, DB2接头中部分的Fe0.64-Ni0.36合金发生了相变生成了FeNi3。 DB3样品的Fe0.64Ni0.36的衍射峰消失, 完全转变为尖而窄的结晶良好的FeNi3衍射峰。 由于铁镍固溶合金的强度和韧性随着镍含量的提高而增强, 所以在高温短时拉伸时, 相变生成韧性更好的FeNi3合金是接头高温性能提高的根本原因。

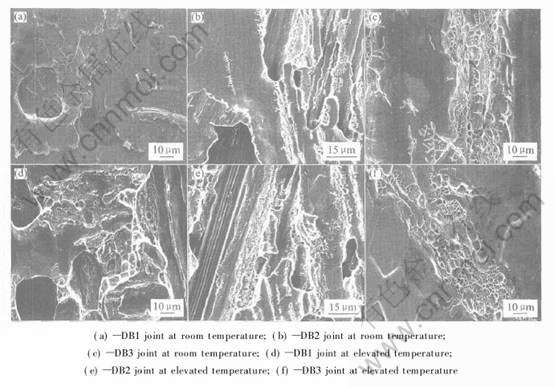

2.4 断口形貌分析

室温时, 扩散焊接头为脆性断裂占主导作用的脆性和韧性混合断裂模式, 接头断裂的位置不同。 850℃ 焊接的DB1接头室温拉伸断口呈现出层叠状的解理台阶, 属于脆性断裂, 且接头断裂位置位于镍中间层内, 但是其良好的焊合率和中间层的“接触强化作用”保证了较高的常温抗拉强度。 由DB2接头常温拉伸试件断口SEM像(图7(b))可知, 断面的未焊合区, 具有与磨削加工痕迹吻合的条纹, 焊合区的形貌呈现典型的脆断, 个别区域出现韧窝, 韧窝尺寸小且分布不均匀, 断裂发生在母材与中间层界面处。 而DB3断口SEM像(图7(c))显示, 中间层和母材接触的部位为韧性断裂, 凹陷处被镍中间层填充且为脆性断裂。 对接头断面XRD分析发现, 断口表面为Fe0.64Ni0.36, 没有镍的衍射峰存在, 可见断裂发生在镍中间层和固溶合金Fe0.64Ni0.36的界面处。

对高温拉伸试件断口电镜分析表明, 850℃ 焊接的DB1接头呈现出了少量韧窝, 偶尔也可见切削的痕迹, 其断裂方式接近于DB2常温的断裂方式(图7(d))。 DB2接头高温微观形貌和其常温断口形貌相比, 出现韧窝的面积稍稍增加, 沿晶脆断面积减少(图7(b)、 7(e))。 DB3高温试样断口为等轴韧窝和板片状解理层片组成的具有撕裂特征的混合形貌, 从韧窝包围处可以看出, 沿晶粒生长边界断裂的圆滑一次晶特征, 韧窝大而均匀。 相变产生的FeNi3固溶合金韧性和强度都要比Fe0.64Ni0.36高, 需要更大的载荷才能使之断裂, 因而提高了接头高温延伸率和强度。

3 结论

1) 含镍中间层316L扩散焊接头的常温强度和延伸率随着焊接温度的提高而下降, 但高温时反而随着焊接温度的提高而增加。

2) 镍中间层的引入提高了焊合率, 改善了接头的高温韧性, 使接头在不同的测试温度下表现出了不同的力学性能。

3) 含镍中间层316L不锈钢扩散焊接头常温为脆性断裂占主导作用的脆性和韧性混合断裂模式; 高温时, 接头的断裂为韧性断裂占主导作用的脆性和韧性混合断裂模式。

图7 接头拉伸断口扫描电镜像

Fig.7 SEM fractographies of diffusion bonding joints with Ni interlayer

REFERENCES

[1]Tu S T. New Need of Structural integrity technology for high temperature applications[A]. FM 2004: Environmental Effect on Fracture and Damage[C]. Hangzhou: Zhejiang University Press, 2004: 43-57.

[2]Shi J, Zhang X L, Tu S T. Design of high temperature brazed joints against creep failure[J]. J Pres Equipment and Sys, 2004, 2: 38-43.

[3]He P, Feng J C, Zhang B G, et al. Microstructure and strength of diffusion-bonded joints of TiAl base alloy to steel[J]. Materials Characterization, 2002, 48: 401-406.

[4]He P, Zhang J H, Zhou R, et al. Diffusion bonding technology of a titanium alloy to a stainless steel web with an Ni interlayer[J]. Materials Characterization, 1999, 43: 287-292.

[5]Jujur I N, Hanada S. Tensile properties of W/ NiAl composites at elevated temperatures[J]. Mater Sci Eng A, 1995, A192/193: 848-855.

[6]秦斌, 盛光敏, 周波, 等. 钛合金和不锈钢的扩散焊接[J]. 中国有色金属学报, 2004, 14(9): 1545-1550.

QIN Bin, SHENG Guang-min, ZHOU Bo, et al. Diffusion welding of titanium alloy and stainless steel[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(9): 1545-1550.

[7]郭立伟, 于彦东, 谷丰, 等. 形状记忆合金CuZnAl 的扩散焊接头组织性能[J]. 中国有色金属学报, 2003, 13(2): 404-408.

GUO Li-wei, YU Yan-dong, GU Feng, et al. Weldability of CuZnAl alloy in diffusion bonding[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 404-408.

[8]Takeda T, Kunitomi K, Horie T, et al. Feasibility study on the applicability of a diffusion-welded compact intermediate heat exchanger to next-generation high temperature gas-cooled reactor[J]. Nuclear Engineering and Design, 1997, 168: 11-21.

[9]Little W A. Microminiature refrigenrator for Joule-Thomson cooling of electronic chips and devices[J]. Advances Cry Eng, 1990, 35: 1305-1333.

[10]Yu X H, Tu S T, Wang Z D. On-bond production of hydrogen for fuel cells over Cu/ZnO/Al2O3 catalyst coating in micro-chemical reactor[J]. J of Power Sources, 2005, 150: 57-66.

[11]Tu S T, Segle P, Gong J M. Creep damage and fracture of weldments at high temperature[J]. Int J Pres Ves and Piping, 2004, 81(2): 199-209.

[12]Nishi H, Araki T, Eto M. Diffusion bonding of alumina dispersion-strengthened copper to 316L stainless steel with interlayer metals[J]. Fusion Engineering and Design, 1998, 39-40: 505-511.

[13]Nishi H, Araki T. Low cycle fatigue strength of diffusion bonded joints of alumina dispersion-strengthened copper to stainless steel[J]. Journal of Nuclear Materials, 2000, 283/287: 1234-1237.

[14]AN Zi-liang, XUAN Fu-zhen, TU Shan-tung et al. High temperature performance of 316L-SS joint produced by diffusion bonding[J]. Key Engineering Materials, 2005, 297/300: 2795-2799.

[15]孙荣禄, 李慕勤, 张九海, 等. 中间过渡金属对钛合金与不锈钢扩散焊接头强度的影响[J]. 焊接学报, 1996, 17(4): 212-218.

SUN Rong-lu, LI Mu-qing, ZHANG Jiu-hai, et al. Influence of different transition metals on properties of diffusion bonding joint of Ti alloy to stainless steel[J]. Transactions of the China Welding Institution, 1996, 17(4): 212-218.

[16]孙荣禄, 杨文杰, 于斌. 钛合金与不锈钢扩散焊中间金属的选择[J]. 宇航材料工艺, 1997, 4: 15-20.

SUN Rong-lu, YANG Wen-jie, YU Bin. Selection of medium metal in diffusion welding of titanium alloy and stainless steel[J]. Aerospace Materials and Technology, 1997, 4: 15-20.

(编辑李向群)

基金项目: 国家自然科学基金资助项目(50225517, 50475068)

收稿日期: 2006-01-09; 修订日期: 2006-07-25

通讯作者: 涂善东, 教授; 电话: 021-64253425; E-mail: sttu@ecust.edu.cn