文章编号:1004-0609(2009)12-2167-06

高线性超弹性多孔NiTi合金的压缩力学行为

张宇鹏1, 2,赵四勇2,马 骁1,张新平1

(1. 华南理工大学 材料科学与工程学院,广州 510640;

2. 广州有色金属研究院 焊接材料研究所,广州 510651)

摘 要:采用造孔技术结合粉末冶金烧结工艺制备多孔NiTi合金,并利用精密万能力学性能试验机对孔隙率为22.4%~60.6%的多孔NiTi合金样品进行循环压缩实验,以表征其压缩力学性能及超弹性。结果表明:所制备的合金经若干个应力─应变循环“训练”后其输入、输出能量可达平衡,应变水平高达4%,线性超弹性可靠,弹性模量稳定;循环加载条件下,残余应变量随孔隙率的增加而增大,但随循环数的增加而减小;残余变形与其影响因素之间可用双曲线函数关系描述。

关键词:多孔NiTi合金;超弹性;残余应变;弹性模量

中图分类号:TG 113.25 文献标识码: A

Compression mechanical behavior of porous NiTi alloys exhibiting high linear superelasticity

ZHANG Yu-peng1, 2, ZHAO Si-yong2, MA Xiao1, ZHANG Xin-ping1

(1. School of Materials Science and Engineering, South China University of Technology, Guangzhou 510640, China;

2. Group of Welding and Soldering Technologies, Guangzhou Research Institute of Non-ferrous Metals,

Guangzhou 510651, China)

Abstract: Porous NiTi alloys were fabricated by pore-forming technique and powder metallurgy sintering process, the compressive mechanical properties and superelasticity of the porous NiTi alloys with porosity ranging in 22.4%-60.6% were characterized by cyclic compression test using a versatile mechanical testing machine. The results show that the energy input balances against the energy output during cyclic loading of the porous NiTi alloy after performing several compression cycles as ‘training’, and the porous NiTi alloys exhibit reliable lineaing superelasticity and stable elastic modulus, with strain as high as 4%. The residual strain (εr) increases with increasing porosity whereas decreases with increasing number of compression cycles. The correlation between εr and other influential factors largely follows a hyperbolic trend.

Key words: porous NiTi alloys; superelasticity; residual strain; elastic modulus

多孔NiTi合金可在生物医学应用中作为硬组织修复和替换材料,还可有望作为轻型减震高强度阻尼材料应用。这些应用均需要材料具有良好的承载能力,而其中以承受压缩载荷最为常见,所以,对多孔NiTi合金压缩力学行为的研究显得尤为重要[1-3]。对于多孔NiTi合金,弹性模量和超弹性是影响其功能实现和使用寿命的关键指标。因此,合理调控多孔NiTi合金的弹性模量并获得足够的超弹性对合金的实际应用非常关键。

研究表明,多孔NiTi合金的超弹性一般在2%到6%之间[4-6],且其超弹性能力与结构特点密切相关。具有不同孔隙特征的多孔NiTi合金之间的超弹性能力差异很大,并与合金的孔隙率直接相关[6-9]。此外,多孔NiTi合金的超弹性变形行为也与致密NiTi合金有明显区别,前者的应力─应变(σ─ε)曲线中一般无应力诱发马氏体相变平台,而后者则通常存在明显的应力诱发相变平台[6-7]。近年来的研究[10-11]认为,这是由于孔洞的不规则分布使多孔NiTi合金内部受力不均匀进而引起相变不同步所致。受力时应力相对集中在孔壁上,造成部分基体先期发生马氏体相变或微塑性变形,而远离孔洞且具有较低应力集中的基体相变相对滞后。因此,合金中各部分相变不同步且在受力变形过程中应力诱发相变和微塑性变形交替发生,所以σ─ε曲线上未呈现明显的相变平台。

虽然对多孔NiTi合金的超弹性行为已有不少研究[4-7, 10],但对多孔NiTi合金超弹性、残余变形及其与孔隙特征相关性的定量研究尚不多见,尤其缺乏关于多孔NiTi合金超弹性过程能量分析和残余变形产生机理方面的研究。本文作者将对采用造孔工艺烧结制备的多孔NiTi合金的压缩性能、残余变形和超弹性行为进行研究,揭示多孔NiTi合金超弹性、弹性模量、残余变形机理及它们与样品自身孔隙特征的关系,并阐明残余变形与超弹性之间的相互影响规律。

1 实验

采用造孔工艺结合常规烧结法制备多孔NiTi合金样品[12]所用原料和工艺及参数列于表1。其工艺过程分为常温混料后冷压制坯、预处理去除造孔剂和高温粉末烧结这3个阶段。实验用原料粉末为高纯(99.9%)Ni粉(61 μm)、Ti粉(50 μm)和NH4HCO3粉(200 μm)。样品坯压制成型后置入通高纯氩气保护的管式烧结炉中,在543 K预处理去除造孔剂,然后加热至 1 323 K烧结3 h。烧结所得的4种多孔NiTi合金样品N1、N2、N3和N4(加入造孔剂的质量分数分别为0、10%、20%和30%)的孔隙率分别为22.4%、34.1%、43.1%和60.6%。

表1 样品的压制和烧结参数

Table 1 Press and sintering parameters used for green sample

将制得的样品清洗、风干后,切割成直径6 mm、高度12 mm的圆柱形标准压缩试样;利用材料力学性能试验机(Instron 5567)在应变量控制模式下对各试样分别进行循环压缩测试,加载时最大应变量为4%,应变率为3×10-3 s-1。此外,还切割出质量为10~20 mg的小试样,使用差示扫描量热分析仪(DSC2910,TA)分析其相变特性,测试温度范围为233~393 K (-40~120 ℃),升降温速率均为5 K/min。

2 结果与分析

2.1 多孔NiTi合金的线性超弹性

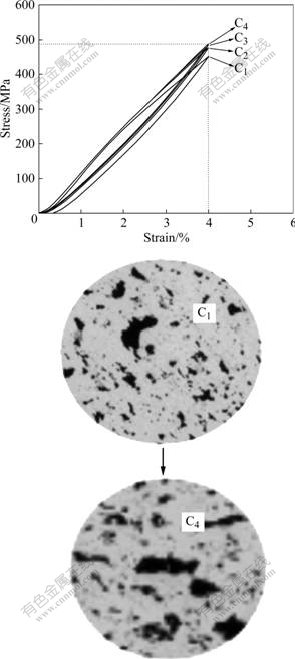

图1所示为样品N1在压缩应变量为4%时的σ─ε曲线。由图1可知,曲线总体上呈线性,经4个压缩循环后,σ─ε曲线斜率上升,应变量为4%时下样品N1的承载应力达487 MPa,明显高于文献[13]中孔隙率相近而烧结温度为1 223 K的样品的承载应力。样品在经过第1个压缩循环后,应变未能够完全恢复,残余应变量(εr)为0.3%左右,即形变恢复率(ηs)为92.5% (ηs=1-εr/ε,其中ε为总应变量);经过第2个压缩循环后,εr降为0.1%左右(ηs = 97.5%);而经过第3和第4个压缩循环后,εr趋向于0,即呈现完全线性超弹性。对经历4个压缩循环后的N1样品进行检测后发现,其内部发生了一定的塑性变形,这是残余应变的来源之一。

2.2 应力─应变循环过程中的能量分析和合金功能稳定性

由图1可见,样品N1各循环的σ─ε曲线形状相似,无明显转折点和应力平台。第1循环曲线与其它循环曲线的差异较明显,具体如下:1) 曲线所围面积最大;2) 曲线斜率最低。σ─ε曲线所围面积(Si)代表单个循环中输入样品的能量(Wi),曲线斜率(ki)反映样品的弹性模量(Ei)。对多孔NiTi合金,若发生残余变形,Wi将转变为塑性变形能(Q1)、储存的弹性能(Q2)和应力诱发马氏体相变能量消耗(Q3),此外,由于合金中存在大量孔隙,有部分能量转化为孔隙(主要是闭孔)中气体内能(Q4)。随σ─ε循环次数的增加,合金发生变形强化效应,导致 Q1减小,而Q2、Q3和Q4均

图1 多孔NiTi合金样品N1经历4个压缩循环的σ─ε曲线(其中C1-C4代表循环数)

Fig.1 σ─ε curves of porous NiTi sample N1 in first four cycles (Ci is cycle number, where i=1-4 )

呈增加趋势。可用式(1)和(2)描述该过程中能量传输 关系:

第1个循环时,

W1=Q1+Q2+Q3+Q4 (1)

循环数增加时,

Wi↓=Q1↓+Q2↑+Q3↑+Q4↑ (2)

式(2)表明,循环数增加时,Wi中塑性变形能(Q1)减小(对应残余变形减小),Q2、Q3和Q4相应增加。Wi随循环数增加而逐渐减小并最终趋于稳定。这说明随循环数增加样品对外加能量的耗散能力也逐渐减弱并趋于稳定,而每个循环过程中能量耗散量?W可以用下式(3)来表示:

(3)

(3)

式中 ?Qi(i=1-4)为每个循环中各部分能量的变化量。?W反映样品在重载荷下对能量的吸收能力。Wi最终趋于稳定,说明在高载荷作用下的多孔NiTi合金内耗值不高,合金超弹性起到维持合金力学性能稳定的 重要作用。压缩循环下的残余变形意味着多孔NiTi合金样品内部的薄弱部分(如孔间薄壁等)发生微塑性变形[14-15],使合金强化。在随后的超弹性变形情况下,Q1、Q2、Q3和Q4均趋于稳定(即输入和输出能量相等)。

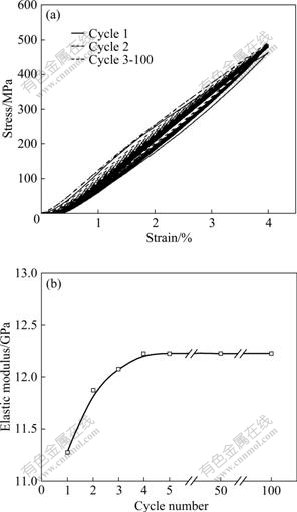

图2所示为样品N1在应变量为4%时连续加载100个循环时的σ─ε曲线(见图2(a))和弹性模量变化曲线(见图2(b))。显然,经过压缩循环“训练”后,样品σ─ε循环曲线和超弹性均保持稳定。样品的弹性模量在最初4个压缩循环中不断增加后趋于稳定,说明N1具有功能可靠性(超弹性)和抗疲劳稳定性(力学 性能)。

图2 应变4%时样品N1经历100个压缩循环后超弹性的变化

Fig.2 Superelasticity change of sample N1 after compression cycles of 100 at strain of 4%: (a) σ─ε curves; (b) Change of elastic modulus

2.3 合金压缩力学性能和残余应变

此外,具有4种不同孔隙率的多孔NiTi合金样品的压缩循环σ─ε曲线特性及超弹性的对比结果如图3所示。由图3可看出,各样品测试条件相同,均经历了应变水平为ε=4%的4个压缩循环。显然,样品孔隙率增加时其力学性能从488 MPa (N1)下降到83

图3 不同孔隙率多孔NiTi合金样品的压缩σ─ε曲线

Fig.3 Compression σ─ε curves of porous NiTi alloy samples with different porosities (C1 to C4 denotes 1st to 4th cycles respectively)

MPa (N4);随压缩循环数增加和孔隙率的减小,各样品的εr不断减小。各样品σ─ε曲线的共同特点是均无明显相变平台的出现,且随循环次数的增加,最终均表现出一定的超弹性。样品的εr随压缩循环数和孔隙率变化的结果如图4所示,各曲线可由式(4)进行数值拟合而描述:

(4)

(4)

式中n为循环次数;A、B和C是与样品结构和孔隙特征有关的系数。对多孔NiTi合金样品N1、N2、N3和N4进行拟合,结果分别如下式(5)至(8)所示:

对于N1合金:

(5)

(5)

对于N2合金:

(6)

(6)

对于N3合金:

(7)

(7)

对于N4合金:

(8)

(8)

计算表明,各数据点与按式(4)拟合曲线的置信水平(Confidence level)均在99.5%以上,说明各样品的残余应变εr均随循环数呈双曲线函数变化的关系是可靠的。值得注意的是,上面各式中右边第一项分式的分子值(对应于式(4)的A值)与孔隙率(P)的数值及变化趋势非常相近,所以,A可能在一定程度上反映了孔隙率对εr的影响规律。

根据式(5)~(8),可分别计算出各样品的残余应变为0(εr=0)时所需的压缩循环数n值(取整数),分别为6、8、11和7。这些数据基本上反映理论上各样品经多少个循环后具有完全超弹性。从前3个数据可见,样品孔隙率增加时则需要更多循环的“训练”使样品具有完全超弹性。但孔隙率为60.6%的样品n值为7,显然是不准确的;因为该样品(N4)各个循环的残余变形量都高于其它样品的,不可能在其它样品之前具有完全超弹性。对样品N4进行σ─ε循环实验,发现该样品在第8个循环上发生了断裂破坏。

图4 不同孔隙率多孔NiTi合金的εr随压缩循环的变化及拟合曲线

Fig.4 Change of εr with number of cycles and regression curves for porous NiTi alloy samples with different porosities

通过上述对压缩循环下εr随孔隙率和循环数n变化结果的分析,可以初步判定在σ─ε循环条件下样品是否具有超弹性和能否具有完全超弹性;也可以通过计算初步预测使样品拥有完全超弹性所需要的“训练”循环数。这对设计具有完全超弹性能力的多孔NiTi合金很有意义。

2.4 合金的残余变形分析

已有研究[7]表明,残余变形的来源可分为两类:一是孔洞自身变形,它与孔洞自身的形状、大小以及是否有尖角和微裂纹的存在有关;二是孔壁等合金基体的塑性变形。本研究所用的多孔NiTi合金的压缩试验均是在常温下(297 K)进行,且由图5所示的DSC谱可以看出,各样品的Af点均在313 K左右,所以合金在常温下除了强度较高的奥氏体相NiTi外,也有少量易变形的马氏体相存在。在受压缩时,马氏体NiTi在应力作用下生成马氏体变体,进而发生塑性变形。所以,马氏体NiTi的存在是残余应变εr的另一重要来源。

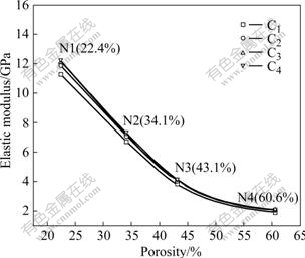

图6所示为具有不同孔隙率的样品N1、N2、N3和N4在各压缩循环下弹性模量的变化结果。由图6可以看出,孔隙率增加时,样品的弹性模量由约12.5GPa减小到2.5 GPa左右。此外,各样品的弹性模量均随σ─ε循环数增加而有所上升。计算发现,经历4个压缩循环后,样品N1的弹性模量值的上升率(ΔE/E)由第1个循环的5.5%减小到第4个循环的0.8%,而样品N4的弹性模量上升率则从第1个循环的6.5%减小到了第4个循环的1.2%。

图5 多孔NiTi合金样品的DSC曲线

Fig.5 DSC curves of porous NiTi: (a) Cooling; (b) Heating

图6 不同循环压缩条件下弹性模量随孔隙率的变化曲线

Fig.6 Changing curves of elastic modulus with porosity at different compression cycles

统计分析表明,上述4种孔隙率的多孔NiTi合金样品在经历4个压缩循环后的弹性模量总上升率均在8%~9%之间(平均为8.8%),并未发现弹性模量上升率与孔隙率的明显对应关系,这说明在一定的压缩循环应变量范围内(4%),多孔NiTi合金弹性模量的变化率并不受到孔隙率的直接影响,而是与样品材质属性有关(如成分变化和微观结构变化等)。这是因为压缩循环强化过程与位错的运动等材料本身微观构造在外力作用下的变化直接相关;而循环压缩过程中,位错的增殖运动和应力的重新分配会造成样品中力学性能薄弱部分的强化,从而使多孔样品内各部分力学性能趋于一致。这对于样品内部的应力和结构上的不均匀性均有一定改善。各样品孔隙率虽然不同,但材料成分和位错增殖特点完全一样,所以强化效果趋于一致。

3 结论

1) 所制备的多孔NiTi合金具有高达4%的线性超弹性,且其在压缩循环载荷条件下输入和输出的能量随循环数增加而趋于稳定,表现为可完全在材料中存储和释放的弹性能。

2) 制备的多孔NiTi合金经压缩“训练”后均具良好的线性超弹性;孔隙率增加时,样品呈现完全超弹性所需“训练“循环数也相应增加;合金弹性模量随循环数的增加和孔隙率的减小而提高,但其增加率稳定,与孔隙率无明显相关性。

3) 压缩循环下多孔NiTi合金残余应变量εr 与循环数之间的变化关系遵循双曲函数关系,该式反映孔隙率对残余变形的影响及样品完全超弹性所需压缩循环数。

REFERENCES

[1] ZHAO Y, TAYA M, KANG Y S, KAWASAKI A. Compression behavior of porous NiTi shape memory alloy[J]. Acta Materialia, 2005, 53: 337-343.

[2] ENTCHEV P B, LAGOUDAS D C. Modeling porous shape memory alloys using micromechanical averaging techniques[J]. Mechanics of Materials, 2002, 34: 1-24.

[3] ZHU S L, YANG X J, FU D H, ZHANG L Y, LI C Y, CU Z D. Stress-strain behavior of porous NiTi alloys prepared by powders sintering[J]. Mater Sci Eng A, 2005, 408: 264-268.

[4] NEMAT-NASSER S, SU Y, GUO W G. Experimental characterization and micromechanical modeling of superelastic response of a porous NiTi shape-memory alloy[J]. Journal of the Mechanics and Physics of solids, 2005, 53: 2320-2346.

[5] GRUMMON D S, SHAW J A, FOLTZ J. Fabrication of cellular shape memory alloy materials by reactive eutectic brazing using niobium[J]. Mater Sci Eng A, 2006, 438/440: 1113-1118.

[6] 李丙运, 戎利建. 多孔Ti-Ni合金的微观结构和超弹性[J]. 中国科学E辑, 1999, 29: 11-15.

LI Bing-yun, RONG Li-jian. Microstructure and superelasticity of porous Ti-Ni alloys[J]. Science in China Series E, 1999, 29: 11-15.

[7] ZHANG, X P, LIU H Y, YUAN B, ZHANG Y P. Superelasticity decay of porous NiTi shape memory alloys under cyclic strain-controlled fatigue conditions[J]. Mater Sci Eng A, 2008, 481/482: 170-173.

[8] SEHITOGLU H, KARAMAN I, ANDERSON R, ZHANG X, Gall K, MAIER H J, CHUMLYAKOV Y. Compressive response of NiTi single crystals[J]. Acta Materialia, 2000, 48: 3311-3326.

[9] WADA K, LIU Y. Factors affecting the generation of stress-assisted two-way memory effect in NiTi shape memory alloy[J]. Journal of Alloys and Compounds, 2005, 400: 163-170.

[10] 张宇鹏, 张新平, 钟志源. 梯度孔隙率与大孔隙尺寸NiTi形状记忆合金制备及其相变和超弹性行为[J]. 金属学报, 2007, 43(11): 1221-1227.

ZHANG Yu-peng, ZHANG Xin-ping, CHUNG Chi-yuen. Fabrication, transformation and superelasticity behavior of NiTi memory alloy with large pore-size and gradient porosity[J]. Acta Metallurgica Sinica, 2007, 43(11): 1221-1227.

[11] YUAN B, CHUNG C Y, ZHANG X P, ZENG M Q, ZHU M. Control of porosity and superelasticity of porous NiTi shape memory alloys prepared by hot isostatic pressing[J]. Smart Materials and Structures, 2005, 14: S201-S206.

[12] 张宇鹏. 低温分解造孔剂法烧结制备NiTi合金及其超弹性和阻尼性能研究[D]. 广州: 华南理工大学, 2008.

ZHANG Yu-peng. Superelasticity and damping property of porous NiTi alloys fabricated by use of low-temperature decomposable space-holder and sintering method, PhD Dissertation[D]. Guangzhou: South China University of Technology, 2008.

[13] ZHANG Y P, LI D S, ZHANG X P. Gradient porosity and large pore size NiTi shape memory alloys[J]. Scripta Materialia, 2007, 57: 1020-1023.

[14] NIKANOROV S P, BURENKOV Y A, VOLKOV M P, CURIN V N, DERKACHENK L I, KARDASHEV B K, REGEL L L, WILCOX W R. Elastic and microplastic properties of Al-Si/Ge alloys obtained from levitated melts[J]. Mater Sci Eng A, 2006, 442: 449-453.

[15] GASSER S, PAUN F, RIFFARD L, BRECHET Y. Microplastic yield condition for a periodic stacking of hollow spheres[J]. Scripta Materialia, 2004, 50: 401-405.

基金项目:国家自然科学基金资助项目(50671037; 50471038)

收稿日期:2009-02-16;修订日期:2009-05-26

通信作者:张新平,教授,博士;电话:020-22236396;传真:020-87111317;E-mail: mexzhang@scut.edu.cn

(编辑 龙怀中)