Effects of electromagnetic stirring on microstructure and mechanical properties of super light Mg-Li-Al-Zn alloy

YAO Lei(姚 磊), HAO Hai(郝 海), GU Song-wei(谷松伟), DONG Han-wei(董汉伟), ZHANG Xing-guo(张兴国)

School of Materials Science and Engineering, Dalian University of Technology, Dalian 116024, China

Received 23 September 2009; accepted 30 January 2010

Abstract: Effects of electromagnetic stirring on the microstructure and mechanical properties of the magnesium-lithium-aluminum alloy were studied. The results reveal that, the morphology of the α phase changes from the long block to globular structure and β phase distributes more widely in the periphery of α phase when the electromagnetic stirring voltage is higher than 110 V. The mechanical properties are increased significantly with the increasing electromagnetic stirring. The tensile strength is improved from 172 to 195 MPa, and the elongation is increased from 10.65% to 25.75%.

Key words: Mg-Li-Al-Zn alloys; electromagnetic stirring; microstructure; mechanical properties

1 Introduction

With the energy shortage of the world and rising concern on environmental awareness, the lightweight materials have drawn much attention. Mg-Li alloys known as the lightest structural metallic alloys have a great potential for wide applications in aerospace and aircraft structures and in structural components of ultra-lightweight communication systems[1].

Because of its hexagonal close-packed (HCP) structure and less slip-systems[2], magnesium alloy has poor ductility. Adding lithium with a density of 0.534 g/cm3 into magnesium can further decrease the density of the alloy and improve the processing characteristics[3]. With Li content between 5.7% and 10.3% (mass fraction), BCC structured β phase of Li solid solution coexists with the HCP α phase of Mg solid solution[4]. Lithium content of 9% is chosen in this study because the alloy with 9% Li shows ideal mechanical properties and good deformation ability at room temperature. In order to strengthen Mg-Li alloys, Al and Zn are usually used as alloying element. However, the deformability of Mg-Li alloys will decrease sharply when Al content is more than 6%[5-6]. The alloy density increases significantly with increasing Zn content. In this work, Mg-9Li-5Al- 1Zn alloy is selected as the experimental material.

The electromagnetic stirring is an effective method to refine grains and obtain homogenous refining structure [7-9]. Electromagnetic stirring has been applied to the production of aluminum alloys[10-11], but the application for Mg-Li alloys is still in its initial stage. In the present work, we use electromagnetic stirring during solidification of the Mg-9Li-5Al-1Zn alloy and study the effect of electromagnetic field on its structure.

2 Experimental

Mg-9Li-5Al-1Zn alloys were prepared using ingots of pure magnesium (99.9%), pure lithium (99.9%), pure aluminum (99.9%), and pure zinc (99.9%). Melting was conducted in a steel crucible (the ratio of height to diameter is 3:1) in an electric resistance furnace under an argon atmosphere. The melt was covered with a molten flux of 75% LiCl+25% LiF (mass fraction). The melt was poured into stainless steel mould (d 55 mm×150 mm) at a preheated temperature of 200 ?C in self-made electromagnetic stirring equipment at a frequency of 50 Hz. The electromagnetic stirring voltages selected were 50, 80, 110, and 140 V, respectively.

Microstructure characterization was examined using optical microscopy. The test specimens were etched by picral solution. Chemical element distribution was measured by electron probe microanalysis. Ultimate tensile strength and elongation were tested on tensile tester at a crosshead rate of 1 mm/min. Fracture surface was analyzed using scanning electron microscopy.

3 Results and discussion

3.1 Microstructure

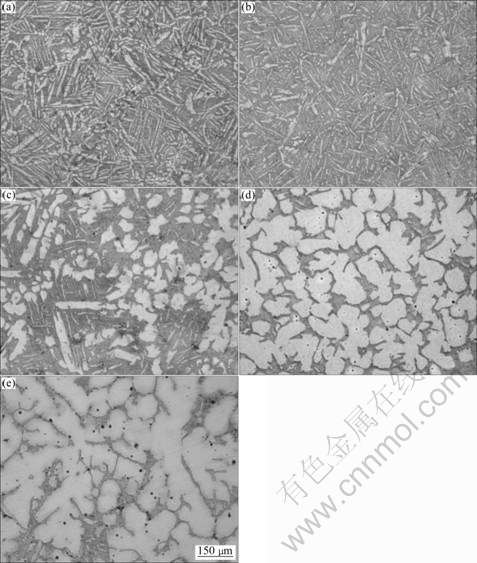

The microstructures of Mg-9Li-5Al-Zn alloys with different electromagnetic stirring voltages are illustrated in Fig.1. With electromagnetic stirring, the movement of the alloy melt is strengthened, and the heat transfer and element diffusion are accelerated[12-13]. The temperature in various parts is uniform. Fragmentation of the solidification front is the most probable mechanism for the promotion of the morphology of phase transition with high velocity flows. The microstructure of Mg-9Li- 5Al-Zn alloy changes obviously with the application of electromagnetic stirring, compared with the alloy without electromagnetic stirring treatment.

The morphology of the α phase is found to change from the long block to a globular structure. The α phase is coarse long blocky structure in normal casting, and distributes in β phase. When the electromagnetic stirring voltage is 50 V, α phase exhibits small long blocky phases under a very low level stirring, but the morphology of α phase has no great difference from that of the normal casting. When the electromagnetic stirring voltage is 80 V, α phase is segmented into pieces, and coarse long blocky structure is changed into globular one. There are some small globular structures and a small quantity of residual long blocky phases in the alloys. When the electromagnetic stirring voltage is 110 V, almost all the α phases become globular structure. When the electromagnetic stirring voltage is 140 V, coarse globular structures are obtained. β phase also changes remarkably and distributes more widely in the periphery of α phase when the electromagnetic stirring voltage is higher than 110 V.

3.2 Chemical element distribution

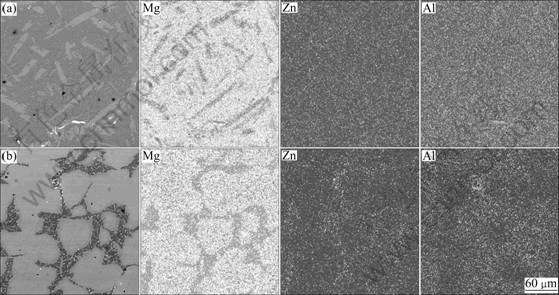

Fig.2 shows the chemical element distribution in Mg-9Li-5Al-Zn alloys with and without electromagnetic

Fig.1 Microstructure of Mg-Li-Al-Zn alloy with different electromagnetic stirring voltages: (a) 0 V; (b) 50 V; (c) 80 V; (d) 110 V; (e) 140 V

Fig.2 EPMA area analysis of Mg-Li-Al-Zn alloy: (a) 0 V; (b) 110 V

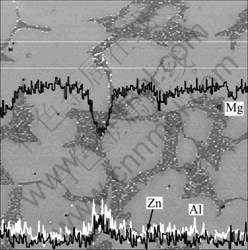

stirring. The gray long blocky part (α phase) is rich in magnesium, and the black phase (β phase) is rich in lithium. There are some little white particles at the boundaries between α and β phase, many of which are observed inside the β phase, and a little bit more in Fig.2(b). However, the distributions of Al and Zn are more uniform and dispersive in Fig.2(a) than in Fig.2(b). In Fig.2(b), Zn is highly enriched in β phase, Al is enriched in the phase boundary and β phase. Perhaps the electromagnetic stirring affects the distribution of elements. According to phase diagrams and Fig.3, it can be concluded that the white particles at the boundaries are Mg17Al12[14]. Because of the impact of electro- magnetic stirring, Zn is widely distributed in β phase, and

Fig.3 EPMA line analysis of Mg-Li-Al-Zn alloy

metastable phase MgLi2Zn and equilibrium phase MgLiZn can be precipitated in Mg-Li-Zn alloy[15]. The little white particles inside the β phase are MgLi2Zn and/or MgLiZn, and there may be still LiMgAl2 and/or AlLi[14]. Naturally, the little particles in the β phase lead to the dispersion strengthening effect.

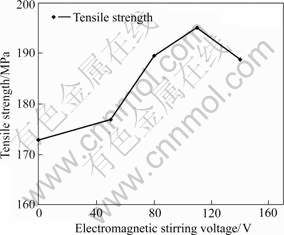

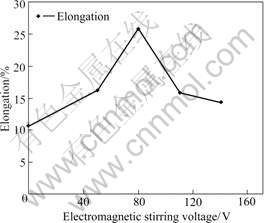

3.3 Mechanical properties

The mechanical properties of Mg-9Li-5Al-Zn alloys with different electromagnetic stirring intensity are shown in Figs.4 and 5. It is found that the electromagnetic stirring can enhance both tensile strength and ductility values of Mg-9Li-5Al-Zn alloy. It is seen that tensile strength is improved from 172 MPa (without electro-

Fig.4 Effects of electromagnetic stirring on tensile strength of Mg-9Li-5Al-Zn alloy

Fig.5 Effects of electromagnetic stirring on elongation of Mg-9Li-5Al-Zn alloy

magnetic stirring) to 195 MPa (with 110 V electro- magnetic stirring), and the elongation is raised from 10.65% to 25.75%.

There is a close relationship between the mechanical properties and the microstructure. When the electromagnetic stirring voltage is 50 V, α phase changes little because of low intensity stirring. When the electromagnetic stirring voltage is 80 V, some small globular structures begin to emerge and β phase is still the matrix phase. The tensile strength and elongation increase simultaneously to a large extend. When the voltage is 110 V, the tensile strength keeps rising with the increase of globular structures, but the elongation decreases. The β phase has more independent slip systems because of the BCC lattice structure. If a relatively large stress concentration occurs in some area during a tensile test, the deformation may be transferred and accommodated by the β phase[16]. The morphology of β phase which has great impact on the deformation changes into dendritic structure and leads to a decrease of elongation. When the voltage is 140V, the tensile strength and elongation further reduced as the structure becomes coarse.

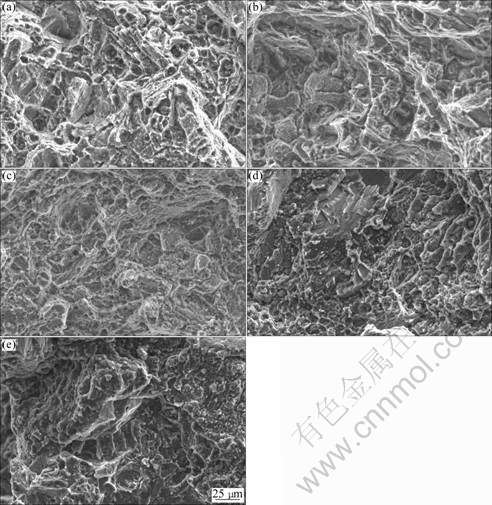

The scanning electron micrographs of the fracture surfaces of the tensile specimens are shown in Fig.6. Plastic fracture consisting of dimples of all the specimens is observed. Especially, when the electromagnetic stirring is 80 V (Fig.6(c)), the image shows typical plastic fracture. Numerous little isometric dimples are

Fig.6 SEM images of tensile fracture surfaces of Mg-9Li-5Al-Zn alloy with different stirring voltages: (a) 0 V; (b) 50 V; (c) 80 V; (d) 110 V; (e) 140 V

observed on the fracture surface. However, brittle fracture regions are partially present on the fracture surfaces in other images. For example, cleavage fracture with river pattern also appears when the stirring voltages are 0 and 50 V.

4 Conclusions

1) The microstructure changes considerably under the electromagnetic stirring. The morphology of the α phase is found to change from the long blocky structure to a globular structure. β phase distributes more widely in the periphery of α phase when the electromagnetic stirring voltage is higher than 110 V.

2) There are more little white particles in the β phase with the electromagnetic stirring; and they may be MgLi2Zn and/or MgLiZn. The little particles in the β phase lead to the dispersion strengthening effect.

3) The electromagnetic stirring enhances both tensile strength and ductility values of Mg-9Li-5Al-Zn alloy. The tensile strength is improved from 172 to 195 MPa, and the elongation is raised from 10.65% to 25.75%.

References

[1] SANSCHAGRIN A, TREMBLAY R, ANGERS R, DUBE D. Mechanical properties and microstructure of new magnesium-lithium base alloys [J]. Materials Science and Engineering A, 1996, 220(1/2): 69-77.

[2] AL-SAMMAN T. Comparative study of the deformation behavior of hexagonal magnesium lithium alloys and a conventional magnesium AZ31 alloy [J]. Acta Materialia, 2009, 57(7): 2229-2242.

[3] MA Chun-jiang, ZHANG Di, QIN Ji-ning, HU Wen-bin, SHI Zhong-liang. Aging behavior of Mg-Li-Al alloys [J]. Transactions of Nonferrous Metals Society of China, 1999, 9(4): 772-777.

[4] CHANG Tien-chan, WANG Jian-yih, CHU Chun-len, LEE S. Mechanical properties and microstructures of various Mg-Li alloys [J]. Materials Letters, 2006, 60(27): 3272-3276.

[5] YU Hua-shun, MIN Guang-hui, CHEN Xi-chen. Effect of alloying elements on Mg-Li base alloys [J]. Rare Metal Materials and Engineering, 1996, 25(2): 1-5. (in Chinese)

[6] CHEN Bin, FENG Lin-ping, ZHONG Hao, ZHOU Tie-tao, LIU Pei-ying. Microstructures and properties of a Mg-Li-Al-Zn wrought alloy [J]. Journal of Beijing University of Aeronautics and Astronautics, 2004, 30(10): 976-979.

[7] LI M, TAMURA T, MIWA K. Controlling microstructures of AZ31 magnesium alloys by an electromagnetic vibration technique during solidification: From experimental observation to theoretical understanding [J]. Acta Materialia, 2007, 55(14): 4635-4643.

[8] LIU S F, LIU L Y, KANG L G. Refinement role of electromagnetic stirring and strontium in AZ91 magnesium alloy [J]. Journal of Alloys and Compounds, 2008, 450(1/2): 546-550.

[9] KIM W, LEE H, PARK J, KIM M, YOON U. Forging of Mg-3Al-1Zn-1Ca alloy prepared by high-frequency electromagnetic casting [J]. Materials and Design, 2009, 30(10): 4120-4125.

[10] LU De-hong, JIANG Ye-hua, GUAN Gui-sheng, ZHOU Rong-feng, LI Zhen-hua, ZHOU Rong. Refinement of primary Si in hypereutectic Al-Si alloy by electromagnetic stirring [J]. Journal of Materials Processing Technology, 2007, 189(1/3): 13-18.

[11] CAO Zhi-qiang, JIA Fei, ZHANG Xing-guo, HAO Hai, JIN Jun-ze. Microstructures and mechanical characteristics of electromagnetic casting and direct-chill casting 2024 aluminum alloys [J]. Materials Science and Engineering A, 2002, 327(2): 133-137.

[12] ZHANG Qi, JIN Jun-ze, WANG Tong-min, LI Ting-ju, GUO Qing-tao. Analysis of molten metal flow in rotating magnetic field [J]. The Chinese Journal of Nonferrous Metals, 2007, 17(1): 98-103. (in Chinese)

[13] ZHANG Shi-bin, DENG Kang, LI Wei-xuan, WANG Ye-shuang, FANG Zhong-xue, REN Zhong-ming, XU He. Effect of electromagnetically continuous casting on structure and mechanical properties of magnesium alloy AZ31 [J]. The Chinese Journal of Nonferrous Metals, 2007, 17(1): 106-110. (in Chinese)

[14] WU Rui-zhi, ZHANG Mi-lin, LIU Bin. Influences of misch metal on microstructure and mechanical properties of Mg-10Li-4Al alloy [J]. Journal of Rare Earths, 2007, 25(s1): 547-549.

[15] LI Jin-feng, ZHENG Zi-qiao, LI Shi-chen. Effect of heat treatment on mechanical properties of Mg-10.02Li-3.86Zn-2.54Al-1.76Cu alloy [J]. Rare Metal Materials and Engineering, 2005, 34(11): 1770-1773. (in Chinese)

[16] LIU T, ZHANG W, WU S D, JIANG C B, LI S X, XU Y B. Mechanical properties of a two-phase alloy Mg-8%Li-1%Al processed by equal channel angular pressing [J]. Materials Science and Engineering A, 2003, 360(1/2): 345-349.

(Edited by FANG Jing-hua)

Foundation item: Project(2009AA03Z525) supported by the National High-tech Research and Development Program of China; Project(NCET-08-0080) supported by the Program of New Century Excellent Talents of the Ministry of Education of China; Project(20082172) supported by the Natural Science Foundation of Liaoning Province, China

Corresponding author: HAO Hai; Tel/Fax: +86-411-84709458; E-mail: haohai@dlut.edu.cn