Insensitivity on tensile properties of forged Mg-13Li-X alloy to hot-rolling deformation

LI Li(栗 丽)1, LI Huan-xi(李焕喜)1, ZHOU Tie-tao(周铁涛)1, CHEN Chang-qi(陈昌麒)1,

WU Qiu-lin(邬秋林)2, ZHANG Qing-quan(章清泉)2, FU Zu-ming(傅祖明)2

1. School of Materials Science and Engineering, Beijing University of

Aeronautics & Astronautics, Beijing 100083, China;

2. Shougang Metallurgical Research Institute, Beijing 100088, China

Received 20 April 2006; accepted 30 June 2006

Abstract: In order to examine the dependences of tensile properties of a forged Mg-13Li-X alloy on hot-rolling deformation and the underlying mechanisms tensile tests, residual stress measurements and texture analyses were conducted in the present study. It is found that after a hot-rolling deformation of 50% at 200 ℃, no much changes in tensile properties, nature and magnitude of residual stresses, and texture type and intensity can be identified for the alloy investigated. The insensitivity of tensile properties of the Mg-Li-X alloy to hot-rolling deformation is attributed at least partially to the insensitivity of residual stress and texture to hot-rolling.

Key words: Mg-13Li-X alloy; residual stress; fracture observation; texture analysis

1 Introduction

The research on magnesium alloys in recent years has experienced a renaissance due to increased interests in their applications to transportation industries for the improved fuel efficiency through vehicle mass reduction[1-3]. One problem that inhibits widespread applications of traditional magnesium alloys is their limited ductility and, in particular, poor formability. Most of the studies have been on Mg-Zn-Zr and Mg-Al-Zn alloys with fine-grained microstructure[4], but the performance has not been obviously improved because the dominant slip plane is only basal in hcp Mg alloys at room temperature. There is a great demand for better ductility of magnesium alloys and lithium addition is considered to be an effective way in improving the ambient deformation ability of the alloys, thereby Mg-Li-X alloys are regarded as a promising wrought alloy series[5]. It has been already well understood that the ductility will increase with the increase of lithium amount in alloys. Especially, when the plastic b phase with bcc structure is introduced in the matrix[5-7].

In the present investigation, to get a wider and deeper understanding of its processing-property relationships, the effect of hot-rolling deformation on tensile properties of a laboratory Mg-13Li-X alloy and the associated mechanisms were studied.

2 Experimental

A new Mg-13Li-X alloy was developed in our laboratory. Cast ingot of this alloy after a suitable homogenization treatment was forged to a 10 mm thick plate at 100 ℃, and then the plate was rolled to a 5 mm thick sheet at 200 ℃. Optical microstructures of the alloy in as-forged and as-rolled conditions were observed by a NEOPHOT-2 optical microscope . Tensile specimens with a gauge length of 200 mm and a width of 20 mm were machined according to GB/T228-2002, tensile tests were carried out on a ZD10/90 machine, and fracture surfaces of broken specimens were characterized by a SEM-S530 microscope.

Residual stresses of the as-forged and as-rolled samples were measured with a X-Ray stress detector according to GB7704—87 standards, based on the theory of X-ray diffraction[8, 9]

2dsin θ=nλ (n=1, 2, 3, …) (1)

where λ is the wavelength of the incident X-ray, θ is the diffraction angle of the polycrystalline matrix, and d is the diffraction identity distance. By measuring the changes of θ and d, the magnitude and nature of residual stress within the surface of metal sheet can be determined.

To do the texture analyses, incomplete pole figures of the as-forged and rolled samples were conducted using a reflection method, with a Japanese 3 kW Rigaku-3014 X-ray diffraction instrument equipped with a four-circle goniometer[8]. The X-ray source has a 2 mm point collimator and the detector is preceded by Soller slits. Pole figures were obtained from {110} and {200} Bragg peaks. Complete orientation distribution functions were calculated from the experimental pole figure data using the WIMV method of the Preferred Orientation Package of Los Alamos (POPLA).

3 Results and discussion

3.1 Optical microstructure

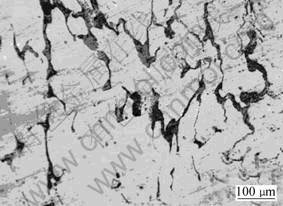

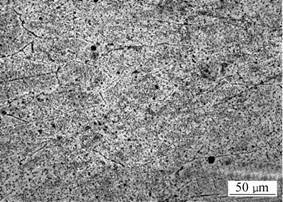

Optical microstructures of alloy in as-forged and as-rolled conditions are shown in Figs.1 and 2 . After forged, the coarse grains have been broken because of large deformation and the grains have stretched along deformation direction. After rolled, the grains have got further refining.

3.2 Tensile property

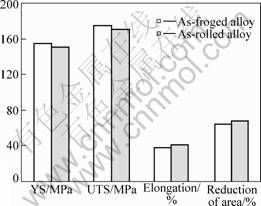

Tensile properties of alloys are shown in Fig.3. It can be found that no much difference can be identified for the properties tested, and only as-rolled alloy has better plasticity than as-forged alloy. It is important that two states of alloy have good plasticity and the residual stress values should be not large.

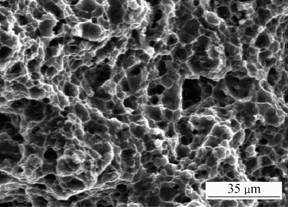

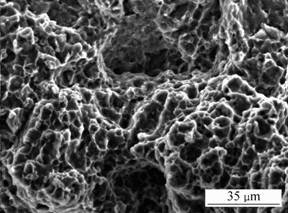

Figs.4 and 5 show the fractures of as-forged and as-rolled alloys. It can be observed that the dimples exist in fractures because of good plasticity and it is typical

Fig.1 Optical microstructure of as-forged sample

gliding fracture model.

3.3 Residual stress analysis

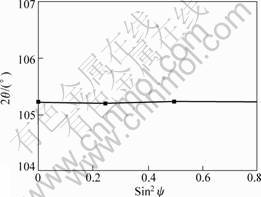

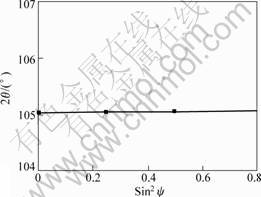

Figs.6-9 show the results of residual stress by cross-correlation method. For the isotropy polycrystal material, according to Bragg’s law and elastic theory and under the condition of plane stress state, it can be conducted that the stress σ has a direct ratio with the slope M[8-12].

σ=KM (M=d2θ/dsin2ψ)

Fig.2 Optical microstructure of as-rolled sample

Fig.3 Tensile properties of alloy at room temperature

Fig.4 SEM image of as-forged fracture

Fig.5 SEM image of as-rolled fracture

where K is the stress constant, M is the slope between 2θ and sin2ψ. The slope M can be calculated by least squares techniques from angle ψ′ peak 2θ and sin2ψ.

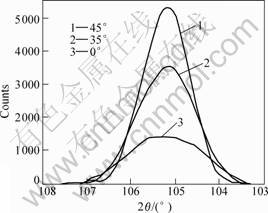

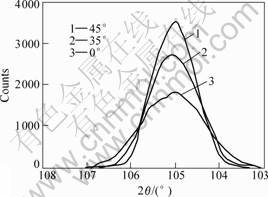

In this experiment, X-ray data were gathered using a well aligned X-350A X-ray diffraction system by GB7704-87 standard. The diffractometer was fitted with a fine-focus chromium tube operating at 25 kV and 7 mA. X-ray residual stress calculations were undertaken (using cross-correlation method) on the surface of two states alloys. The diameter of collimator is 2 mm, the index of diffraction crystallographic plane is {211}, and slope angles measure 0?, 35?, 45?. The stress constant K and 2θ angle have been obtained by repeating experiments.

The residual stress and tensile strength of as-forged alloy are -15.7 MPa and 175 MPa respectively(Fig.6). The residual stress and tensile strength of as-rolled alloy are -4.2 MPa and 170 MPa respectively(Fig.7). So the two conditions of alloys have slightly compressive stress with the shape of peaks sharp and the compressive stress values are much lower than the tensile strength in accordance with tensile tests.

2θ and sin2ψ have a linear relation theoretically, but

Fig.6 Cross-correlation function distribution curves of as-forged sample

Fig.7 Cross-correlation function distribution curves of as-rolled sample

between the points measured and the line they fitted there always exist some errors. The stress error Δσ reflects the fitting residual[8-10].

Δσ=KΔM

where ΔM is the error of slope.

There are two conditions[8, 9]. Firstly, if the material does not have any texture, Δσ is aroused by some of random reasons. It is the symbol of measurement accuracy. Secondly, if the materials do have obvious texture, the relation between 2θ and sin2ψ is nonlinear. So Δσ may mainly be impacted by texture besides the measuring error.

From Fig.8 and Fig.9, it can be calculated Δσ of as-forged alloy is ±4.2MPa of residual stress -15.7 MPa and that of as-rolled alloy is ±1.4 MPa of residual stress -4.2 MPa. The value of Δσ is much lower than residual stress that suggests the results of test have high degree of belief.

From the two fitting curves(Figs.8 and 9), the relation between 2θ and sin2ψ is approximately linear and it is suggested that the material may have weak texture.

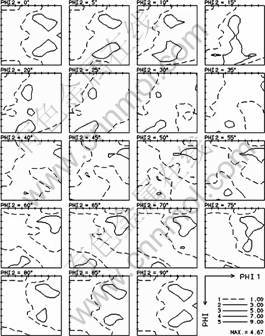

3.4 Texture analysis

Fig.8 Δσ of as-forged sample

Fig.9 Δσ of as-rolled sample

Pole densities were then used to calculate the grain orientation distribution function (ODF) of the sample. No sample symmetry was imposed. Complete pole figures for both structural phases and all {HKL} of interest were recalculated from the ODF to facilitate the discussion of the observed orientation changes. Such pole figures are internally consistent with the ODF[13]. Based on texture test, the ODF can be recalculated (Fig.10 and Fig.11). It can be easily found that, the deformation textures of as-forged and as-rolled alloys both are characterized by the α fiber texture with components of {001}<110>, {112}<110> and {111}<110>, the textures of <100> orientation and γ fiber texture {111}<112>. The results are conformity with the deformation mechanism of bcc structure metal[7, 14, 15]. And the textures of two states are weak (please notice the difference measuring scales between Fig.10

Fig.10 ODF of as-forged sample

and Fig.11) in accordance with residual stress tests.

Fig.11 ODF of as-rolled sample

4 Conclusions

Tensile tests show good plasticity and intensity of as-forged and as-rolled Mg-Li-X alloys, and by fracture observations, two states alloys both are gliding fracture. The two states alloys have slightly compressive stress and low Δσ by residual stress tests that suggest the alloys have good ductility; and by the texture tests, the two states alloys have weak texture. On the above basis, the insensitivity of tensile properties of the Mg-Li-X alloy to hot-rolling deformation is attributed at least partially to the insensitivity of residual stress and texture to hot rolling.

References

[1] BARNETT M R, NAVE M D, BETTLES C J. Deformation microstructures and textures of some cold rolled Mg alloys[J]. Materials Science and Engineering A, 2004, A386: 205-211.

[2] CHEN Zhen-hua, YAN Hong-ge, CHEN Ji-hua, QUAN Ya-jie, WANG Hui-min, CHEN Ding. Magnesium Alloys[M]. Beijing: Chemical Industry Press, 2004: 35-49.(in Chinese)

[3] CLAUDIO M. Magnesium die casting, history, principles and state of the art[J]. Magnesium Industry, 2001(2): 21-25.

[4] FROES F H, ELIEZER D, AGHION E. How to increase the use of magnesium in aerospace applications[A]. Magnesium 2000 : 2nd International Conference on Magnesium Science & Technology[C]. Beer-sheva: Magnesium Research Institute, 2000: 22-24.

[5] ZHANG Jin, ZHANG Tong-he. Magnesium Alloys and Applications[M]. Beijing: Chemical Industry Press, 2004: 21-35.(in Chinese)

[6] EDGAR R L. Global overview on damand and applications for magnesium alloy[A]. Kainer K V. Magnesium Alloys and Their Applications[C]. Munich: DGM, 2000: 3-5.

[7] FENG Lin-ping. Deformation behavior and microstructure of Mg-13Li-X Alloy[D]. Beijing: Beijing University of Aeronautics and Astronautics, 2005. (in Chinese)

[8] NOYAN I C, COHEN J B. Residual Stress Measurement by Diffraction and Interpretation[M]. New York: Springer-Verlag World Publishing Corporation, 1987.

[9] RENDLER N J, VIGNESS I. Hole-drilling strain-gage method of measuring residual stress[J]. Exp Mech, 1966, 6(12): 77-86.

[10] ALBERTINI G, BRUNO G. Comparative neutron and X-ray residual stress measurements on Al-2219 welded plate[J]. Materials Science and Engineering A, 1997, A224: 157-165.

[11] HADIAN S E, GABE D R. Residual stresses in electrodeposits of nickel and nickel–iron alloys[J]. Surface and Coatings Technology, 1999, 122(2-3): 118-135.

[12] REYNIER B, CHAPPUIS G, SPRAUEL J M. X-ray diffraction study of the fatigue behavior of a shot-peened lithium alloy[J]. Exp Mech, 1995, 35(2): 112-123.

[13] BUNGE H J, ESLING C. Quantitative Texture Analysis[M]. Munich: DGM-Information gesellschaft, 1982.

[14] WENK H R, LONARDELLI I, WILLIAMS D. Texture changes in the hcp-bcc-hcp transformation of zirconium studied in situ by neutron diffraction[J]. Acta Materialia, 2004, 52(7): 1899-1907.

[15] GUAN Xiao-jun, ZHOU Jia-juan, HU Xiao-jun, WU Qiu-lin. Effects of cold rolling on the texture of an extra low-carbon and high strength bake hardening sheet steel treated by Nb and Ti[J]. Journal of Shandong University of Technology, 1998, 28(2): 160-165. (in Chinese)

(Edited by ZHAO Jun)

Foundation item: Project(2003AA305071) supported by the National High-Tech and Development Program of China

Corresponding author: LI Li, Tel: +86-13381329912; Fax: +86-10-82338200; E-mail: lily@mse.buaa.edu.cn