文章编号:1004-0609(2011)06-1258-07

颗粒增强铝基梯度复合材料的摩擦磨损性能

陈聪聪,陈 刚,严红革,苏 斌

(湖南大学 材料科学与工程学院,长沙 410082)

摘 要:采用新型喷射沉积技术制备SiC体积分数呈连续分布(0~30%)的Al-Si基梯度复合材料,利用MG-2000型销-盘磨擦磨损试验机,研究不同滑动转速和载荷对该梯度复合材料摩擦磨损性能的影响。采用SEM和MHV-2000型维氏硬度计研究该梯度复合材料的显微组织、硬度及其耐磨性的梯度分布规律。结果表明:随着滑动转速和载荷的增大,梯度材料的摩擦因数逐渐降低;材料的磨损率随载荷的增加而增大,随滑动转速的提高先增大后减小,在转速500 r/min时达到最大;对比研究沉积态与热压态材料的摩擦磨损行为,喷射沉积态由于孔隙等缺陷的存在,其磨损形式主要是磨粒磨损和剥层磨损;热压后,梯度材料的磨损形式以磨粒磨损和粘着磨损为主;随基体中SiC含量的逐渐增加,锭坯各部分硬度和耐磨性也随之提高。

关键词:Al-Si梯度复合材料;颗粒增强;耐磨性;磨损机制

中图分类号:TG 146.2+1; TB 333 文献标志码:A

Friction and wear properties of particle reinforced graded aluminum matrix composites

CHEN Cong-cong, CHEN Gang, YAN Hong-ge, SU Bin

(College of Materials Science and Engineering, Hunan University, Changsha 410082, China)

Abstract: The Al-17Si functionally graded material (FGM) with SiC volume fraction of 0-30% continuously were synthesized using new spray deposition technique. Furthermore, the microstructure, hardness and wear ability of this functionally graded material were studied with SEM, MHV-2000 Hervey hardness tester and MG-2000 pin-on-disc friction and wear testing machine. The results show that the friction coefficient decreases with increasing the applied load and sliding speed. The wear rate rises with the increase of applied load and it reaches the maximum at speed of 500r/min firstly, and then falls with increasing the sliding speed. Because of the existence of defects, such as the hole, the mainly wear way of the deposition is abrasive and delamination, while the composites after hot pressing is mainly abrasive and adhesive. The hardness and wear resistance of every part of materials increase with increasing the SiC content in the deposition billet.

Keywords: Al-Si graded composite material; particle reinforcement; wear resistance; wear mechanism

颗粒增强铝基复合材料具有比强度和比刚度 高、弹性模量高、导热性和耐磨性能优良等,在交通车辆、航空航天、国防军工等领域有着极其广泛的应用,而事实上在很多的场合,材料的摩擦性能体现出了重要意义[1],如飞机的液压制动器缸体、风扇出口导流叶片、车辆部件的刹车系统、汽车发动机活塞和缸套缸盖等,这些零件对材料的摩擦磨损性能都有较严格的要求。因此,针对铝基复合材料的摩擦学性能和磨损机理已有不少的研究[2-4],但所制备和研究的对象皆为陶瓷颗粒在基体中均匀分布的复合材料,这种“均质”复合材料在实际应用中存在一些局限性,如采用陶瓷颗粒增强铝基复合材料制造的轻量化制动部件虽然表面耐磨和耐蚀等性能优异,但材料的整体塑性偏低、韧性也不高,在应用过程中耐疲劳性能不足。

梯度复合材料是基于一种全新的材料设计概念而开发的新型功能材料,由于材料构成要素(成分、组织结构等)在几何空间上连续变化,从而得到性能在几何空间上也是连续变化的非均质材料[5]。梯度复合材料的制备研究比较多的是离心铸造法,但是其梯度沉积层厚度及增强相的分布均匀性难以控制[6-7]。传统喷射沉积技术对沉积物的冷凝固速度有一定限制,喷射沉积坯尺寸精度不高,且难以实现增强相的梯度分布。

鉴于目前广泛使用的耐磨部件要求轻量化、表面高耐磨,耐腐蚀,而整体要求高强度、高韧性和疲劳性能[8-9],本文作者以Al-17Si合金系为基体,采用自行发明的新型喷射沉积技术[10],通过一个自动控制系统,根据沉积坯高度调节SiC颗粒输送量,制备了SiC体积分数为0~30%连续梯度分布的颗粒增强铝基复合材料。研究该梯度复合材料的组织、硬度的分布规律及其摩擦学性能,为研究和拓展颗粒增强铝基复合材料的应用提供参考。

1 实验

采用新型喷射沉积装置制备陶瓷颗粒增强铝基梯度复合材料的沉积态锭坯,SiC颗粒沿锭坯轴向呈梯度分布;为了进一步改善材料的性能,沉积态材料在540 ℃下进行热模压以实现致密化。

分别从沉积态和热压态材料上沿锭坯轴向切取d 6 mm×12 mm 3个不同SiC含量的试样。采用MG-2000型销-盘试验机进行室温摩擦磨损测试。对偶盘为45#钢,尺寸d 70 mm×10 mm,有效直径30 mm。试样经金相砂纸打磨平后再磨合10~20 min至约90%面积接触。测试时保持转速为300 r/min,取载荷分别为10、20、30、40和50 N;保持载荷为20 N时,取转速分别为300、400、500、700和900 r/min。实验进行的总转数为6 000转,通过测量质量损耗计算磨损率,磨损量的测量在感量为±0.1 mg的电子分析天平上进行,磨损率(W)由式(1)计算[11]:

(1)

(1)

式中:?m为梯度材料实验前后的质量损失,mg;R为有效回转半径,m;t为摩擦时间,min;v为盘试样的转速,r/min;?为平均摩擦因数;F为施加在销试样上的法向压力,N。

采用MM-6型卧式金相显微镜分别观察沉积态和热压态中SiC颗粒的梯度分布;采用MHV-2000型显微硬度计测定梯度材料的硬度分布。采用FEI- Quanta 200型扫描电子显微镜对试样的磨损表面形貌进行分析。

2 结果与分析

2.1 梯度复合材料的组织与性能

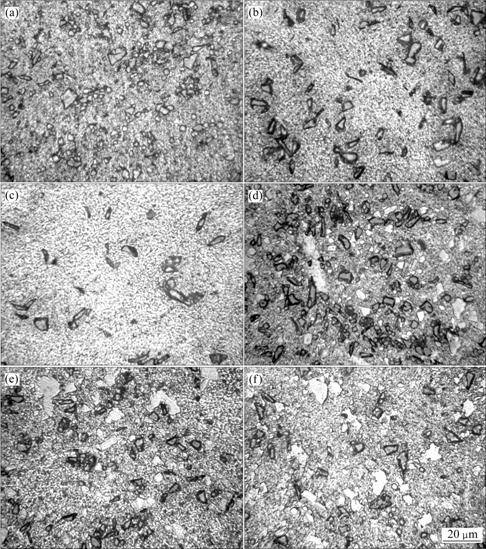

图1所示为沉积态与热压态试样沿轴向方向的SiC颗粒分布金相照片。由图1可见,实验所制备的复合材料锭坯SiC颗粒轴向方向含量变化明显(试样1、2、3的取样点分别距离锭坯顶部为12、24和36 mm),实现了梯度分布。且SiC颗粒分布较均匀,基体中孔隙非常少,克服了传统喷射沉积材料含有较多孔隙的不足[12];坯件经过热压后出现了一定量的初晶硅,致密度进一步提高,从而进一步改善材料的耐磨性。

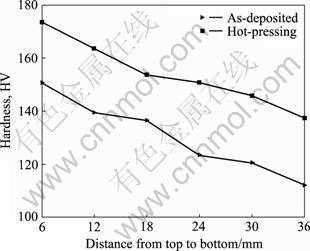

图2所示为沉积态和热压态锭坯沿轴向方向的硬度分布。由图2可知,随着取样点离锭坯顶部距离的增加,SiC颗粒的含量逐渐减少,沉积态与热压态的硬度也逐渐降低,同时热压后材料的硬度明显比沉积态高,这主要是由于材料经过热压后消除了沉积态材料中的孔隙,并使基体与增强相的结合强度更高。SiC颗粒的分布对材料的影响可以由硬度体现出来,而材料的硬度决定了接触材料表面的真实接触面积[13],因此与其耐磨性能有着密切联系。

2.2 梯度材料的磨损性能

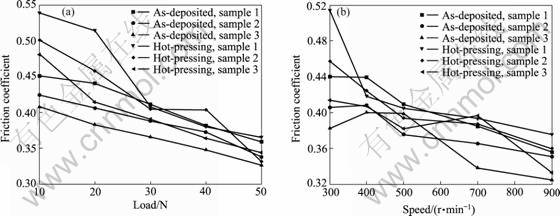

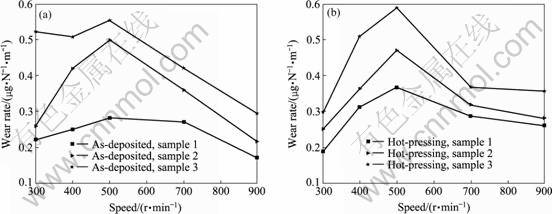

图3所示为沉积态与热压态试样1、2、3在不同载荷和转速下的摩擦因数。从图3可以看出,沉积态与热压态的摩擦因数总体上都随转速和压力的增大而降低。保持转速在300 r/min时,随着载荷的逐渐增 大,摩擦因数降低,变化趋势呈一定的线性关系,沉积态摩擦因数最低为0.326 7,热压态摩擦因数最低为0.331 7;而在载荷一定时,当转速逐渐增加,摩擦因数曲线波动都较大,沉积态摩擦因数最低为0.325 1,热压态摩擦因数最低为0.333 4;同一梯度下,热压态比沉积态的摩擦因数都高,热压态材料的摩擦因数最高达到0.539,而沉积态摩擦因数最高为0.451。

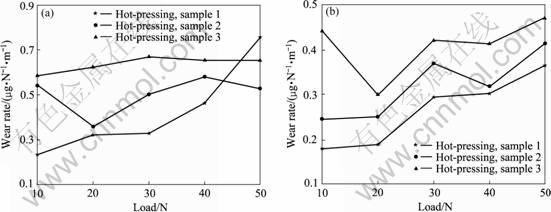

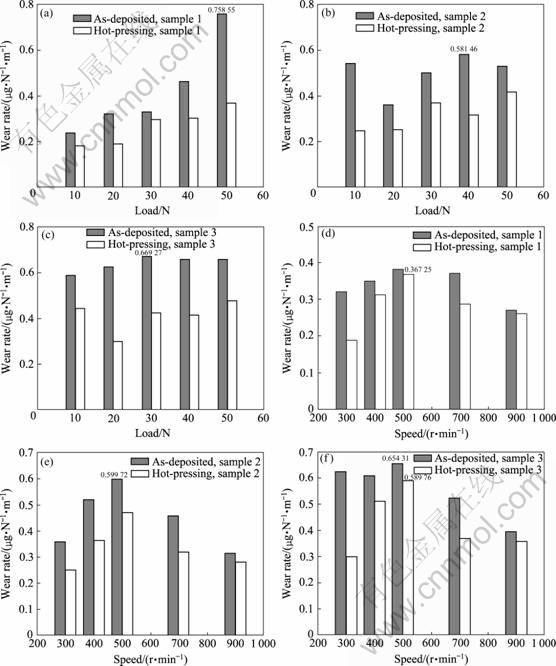

图4所示为在转速300 r/min时SiCp/Al-17Si梯度复合材料在不同载荷条件下,沉积态与热压态的不同梯度对应的磨损率变化曲线。由图4的磨损率—载荷曲线图可知,沉积态与热压态的磨损率基本都随载荷的增加而增大,在同一载荷情况下,两种材料的磨损率都是沿轴向方向由上至下逐渐增大,与梯度复合材料的硬度分布规律一致。图4(a)中沉积态试样1在载荷40 N以下时,磨损率的增加比较缓慢;40 N以上时,试样的磨损率突然大幅度增加,此时试样发生了严重磨损。图4(a)沉积态试样2和图4(b)热压态试样3的磨损率在20 N时都突然降低,之后又继续增大,分析认为,沉积态试样2与热压态试样3在20 N时试样的摩擦表面形成了一层机械混合层(Mechanical mixture layer, MML),这种MML能够保护基体,从而降低磨损率,随着载荷的增加,较脆的MML会慢慢断裂,以较大的片状剥落形式从基体脱落,使磨损逐渐加重[14-15];热压态3种梯度复合材料的磨损率由上至下逐渐增大,明显呈梯度变化,且由于材料经过热压后,增强颗粒与基体的结合界面加强,所以磨损率没有出现明显的变化。

图1 沉积态与热压态试样金相图

Fig.1 Metallographs of SiCp/Al-17Si gradient composites: (a) As-deposited, sample 1; (b) As-deposited, sample 2; (c) As-deposited, sample 3; (d) Hot-pressing, sample 1; (e) Hot-pressing, sample 2; (f) Hot-pressing, sample 3

图2 SiCp/Al-17Si梯度复合材料硬度分布

Fig.2 Hardness distribution of SiCp/Al-17Si FGM

图5所示为在载荷20 N时SiCp/Al-17Si梯度复合材料在不同转速条件下,沉积态与热压态的不同梯度对应的磨损率变化曲线。

由图5可知,沉积态与热压态试样的磨损率都随转速的增加先增大后减小。在同一转速下,两种材料的磨损率沿轴向方向由上至下逐渐增大,与梯度复合材料的硬度及SiC颗粒的分布规律一致。在转速500 r/min以下,沉积态与热压态梯度复合材料的磨损率先增加,并在500 r/min时达到峰值,随后磨损率随着转速的增大逐渐降低。分析认为,增加对磨速度可使材料的应变速率增加,引起加工硬化从而提高材料的表面硬度,所以磨损率降低。沉积态最小磨损率为0.270 53 μg/(N·m),最大磨损率为0.654 31 μg/(N·m);热压态最小磨损率为0.189 08 μg/(N·m),最大磨损率为0.589 76 μg/(N·m)。

图3 SiCp/Al-17Si梯度材料不同载荷与转速的摩擦因数曲线

Fig.3 Friction coefficient of SiCp/Al-17Si gradient composites at different loads and speeds: (a) 300 r/min; (b) 20 N

图4 转速300 r/min时SiCp/Al-17Si梯度复合材料的磨损率—载荷曲线

Fig.4 Change of wear rate—load curves of SiCp/Al-17Si gradient composites at speed of 300 r/min: (a) As-deposited; (b) Hot-pressing

图5 载荷20 N时SiCp/Al-17Si梯度复合材料的磨损率—转速曲线

Fig.5 Wear rate—speed curves of SiCp/Al-17Si gradient composites at load of 20 N: (a) As-deposited; (b) Hot-pressing

图6所示为沉积态与热压态同一梯度材料在不同载荷和转速下磨损率的对比。

由图6可看出,对同一梯度不同材料状态的磨损率进行比较发现,在不同转速和载荷下,热压态的磨损率都比沉积态小,沉积态磨损率最高,达到0.758 55 μg/(N·m),热压态最高磨损率为0.589 76 μg/(N·m),这说明经过热压致密化后,由于增强颗粒与基体的结合界面强度提高,消除沉积态材料内部的空隙,从而提高了材料的耐磨性,同时热压态材料中大量的初晶硅颗粒也起到耐磨和支撑载荷的作用,它能保护基体免受对偶微凸体的划伤,减少基体材料的磨损。

图6 不同载荷与转速下同一梯度材料的磨损率

Fig.6 Wear rate as function of different loads and speeds for same gradient composites

3 磨损表面形貌分析

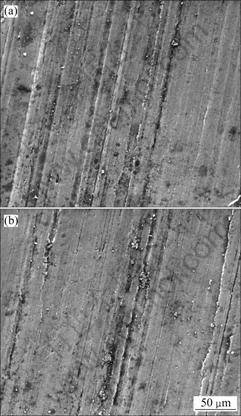

图7所示为SiCp/Al-17Si梯度复合材料沉积态与热压态在低速低载荷时磨损表面形貌。

图7 SiCp/Al-17Si梯度复合材料低速低载荷时的磨损表面形貌

Fig.7 Worn surface morphologies of SiCp/Al-17Si gradient composites at lower speed and load: (a) As-deposited; (b) Hot- pressing

由图7可见,沉积态与热压态的磨损表面都出现了犁沟,沉积态表面的犁沟较深,而热压态的表面犁沟较浅且数量少,相对平整,这也能从磨损率上体现出来。硬质颗粒增强复合材料的耐磨性还取决于基体与增强相的界面结合强度[16],当SiC颗粒与基体结合较弱时,随着磨损的进行,SiC颗粒在基体中发生晃动,从而松动,进而会被整个拔出基体或是颗粒发生断裂,断裂前半部分脱离基体,后半部分留在基体内,这些脱离基体的SiC颗粒夹在摩擦副之间形成典型的三体磨粒磨损,由于SiC颗粒的硬度远远大于基体材料的,随着滑动的进行,对材料产生微切削作用,因此沿摩擦滑动方向在表面形成了犁沟,从形貌上判断两种材料均为磨粒磨损。

图8所示为SiCp/Al-17Si梯度复合材料沉积态与热压态在高速高载荷时磨损的表面形貌。

图8 SiCp/Al-17Si梯度复合材料高速高载荷时的磨损表面形貌

Fig.8 Worn surface morphologies of SiCp/Al-17Si alloy gradient composites at higher speed and load: (a) As-deposited; (b) Hot-pressing

从图8中看出,热压态的磨损表面局部出现了一些粘着坑,而沉积态的磨损表面出现严重的剥层磨 损。当所施加的载荷超过SiC颗粒的承受极限时,SiC增强颗粒就不足以起到支撑载荷的作用,部分SiC颗粒破碎,使得复合材料基体与配副钢材料直接接 触,由于基体较软,从而在表面产生塑性流变,硬度越低,塑性变形越严重[17]。沉积态与热压态材料的表面都形成了一层MML,沉积态材料中由于存在孔隙,在摩擦实验过程中,这些空隙就相当于一个裂纹源,裂纹很容易在这些地方形成;且由于SiC颗粒与基体的结合强度不高,裂纹也容易在界面处产生。因此随着接触应力的持续作用,次表层上的的空穴增多并聚集,当裂纹扩展到一定尺寸后,就会使裂纹上下的材料脱离,形成剥层磨削,使材料发生剥层磨损。而热压态材料虽然在SiC颗粒与基体的结合界面处也会有裂纹的形成,但是经过热压致密化后,提高了材料的硬度,形成的MML比较致密,变形程度减小,只有局部的MML发生粘着剥落,对应的磨损率也降低。

4 结论

1) 采用新型喷射沉积技术制备了SiCp/Al-17Si梯度复合材料,且随着SiC含量的逐渐增加,材料的硬度和耐磨性都呈梯度变化。

2) 喷射沉积材料经过热压致密化后,消除了材料中的孔隙,从而提高了材料的硬度,热压态材料的耐磨性较沉积态明显的提高。

3) 沉积态梯度复合材料的磨损形式主要为磨粒磨损和剥层磨损,热压态材料的磨损形式以磨粒磨损和粘着磨损为主。

REFERENCES

[1] 吴洁君, 王殿斌, 桂满昌, 袁广江. 颗粒增强铝基复合材料干滑动摩擦性能述评[J]. 稀有金属, 1999, 23(3): 214-219.

WU Jie-jun, WANG Dian-bin, GUI Man-chang, YUAN Guang-jiang. Dry sliding wear of particle reinforced aluminum composites: Review and discussion[J]. Chinese Journal of Rare Metals, 1999, 23(3): 214-219.

[2] RAO R N, DAS S, MONDAL D P, DIXIT G. Dry sliding wear behaviour of cast high strength aluminium alloy (Al-Zn-Mg) and hard particle composites[J]. Wear, 2009, 267: 1688-1695.

[3] NATARAJAN N, VIJAYARANGAN S, RAJENDRAN. Wear behaviour of A356/25SiCp aluminium matrix composites sliding against automobile friction material[J]. Wear, 2006, 261: 812-822.

[4] 江润莲, 赵玉涛, 戴起勋, 程晓农, 陈 刚. Al-Zr-O体系反应合成原位复合材料的微结构与磨损特性[J]. 中国有色金属学报, 2005, 15(12): 1986-1991.

JIANG Run-lian, ZHAO Yu-tao, DAI Qi-xun, CHENG Xiao-nong, CHEN Gang. Microstructures and wear properties of in situ composite synthesized by direct melt reaction in Al-Zr-O system[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(12): 1986-1991.

[5] 吕广庶. 功能梯度材料及其应用[J]. 国防技术基础, 2002, 4: 19-20.

L? Guang-shu. Functional gradient materials and its application[J]. Technology Foundation of the National Defence, 2002, 4: 19-20.

[6] VELHINHO A, BOTAS J D, ARIZA E, GOMES J R, ROCHA L A. Tribocorrosion studies in centrifugally cast Al-matrix SiCp-reinforced functionally graded composites[J]. Materials Science Forum, 2004, 871: 455-456.

[7] VIEIRA A C, SEQUEIRA P D, GOMES J R, ROCHA L A. Dry sliding wear of alloy/SiCp functionally graded composites: Influence of processing conditions[J]. Wear, 2009, 267: 585-592.

[8] 刘 政, 刘小梅, 周彼德. 铝基复合材料在汽车中的应用[J]. 铝加工, 1994, 17(4): 49-52.

LIU Zhen, LIU Xiao-mei, ZHOU Bi-de. The application of the aluminum matrix composites in the automotive industry[J]. Aluminium Fabrication, 1994, 17(4): 49-52.

[9] 田治宇. 颗粒增强金属基复合材料的研究及应用[J]. 金属材料与冶金工程, 2008, 36(1): 5-7.

TIAN Zhi-yu. Research and application of particle reinforced metal matrix composite material[J]. Metal Materials and Metallurgy Engineering, 2008, 36(1): 5-7.

[10] 严红革, 陈 刚, 陈吉华, 苏 斌, 张福全. 陶瓷颗粒增强铝基梯度复合材料及其制备方法和用于制备该材料的喷射沉积装置: 中国, 2010101220763[P]. 2010-05-19.

YAN Hong-ge, CHEN Gang, CHEN Ji-hua, SU Bin, ZHANG Fu-quan. Preparation methods for ceramic particles reinforced graded aluminum matrix composites and the spray deposition device: CN 2010101220763[P]. 2010-05-19.

[11] 陈 跃, 邢建东, 张永振, 沈百令, 倪 锋. 增强颗粒对铝基复合材料摩擦学性能的影响[J]. 摩擦学学报, 2001, 21(4): 251-255.

CHEN Yue, XING Jian-dong, ZHANG Yong-zhen, SHEN Bai-ling, NI Feng. The tribological behavior of aluminum-matrix composites reinforced with ceramic particulates in dry sliding against a semi-metallic frictional material[J]. Tribology, 2001, 21(4): 251-255.

[12] BINDUMADHAVAN P N, CHIA T K, CHANDRASEKARAN M, WAH H K, LAM L N, PRABHAKAR O. Effect of particle-porosity clusters on tribological behavior of cast aluminum alloy A356-SiCp metal matrix composites[J]. Materials Science and Engineering A, 2001, 315: 217-226.

[13] ZHANG Song-li, ZHAO Yu-tao, CHEN Gang, CHENG Xiao-nong, HUO Xiao-yang. Fabrication and dry sliding wear behavior of in situ Al-K2ZrF6-KBF4 composites reinforced by Al3Zr and ZrB2 particles[J]. Journal of Alloys and Compounds, 2008, 450(1/2): 185-192.

[14] ZHANG L, HE X B, QU X H, DUAN B H, LU X, QIN M L. Dry sliding wear properties of high volume fraction SiCp/Cu composites produced by pressureless infiltration[J]. Wear, 2008, 265: 1848-1856.

[15] VENKATARAMAN B, SUNDARARAJAN G. Correlation between the characterisetics of the mechanically mixed layer and wear behaviour of aluminium Al-7075 alloy and Al-MMCs[J]. Wear, 2000, 245: 22-38.

[16] ACILAR M, GUL F. Effect of the applied load sliding distance and oxidation on the wear behaviour of Al-10Si/SiCp composites produced by vacuum infiltration technique[J]. Materials and Design, 2004, 25: 209-217.

[17] DAOUD A, ABOU M T. Wear and friction behavior of sand cast brake rotor made of A359-20vol% SiC particle composites sliding against automobile friction material [J]. Tribology International, 2010, 43: 544-553.

(编辑 李艳红)

基金项目:国家高技术研究发展计划资助项目(2009AA03Z111)

收稿日期:2010-06-28;修订日期:2010-10-02

通信作者:陈 刚,教授,博士;电话:13873120655;E-mail: chengang811@163.com