一种新型晶粒长大抑制剂对YG10硬质合金烧结行为的影响

曹顺华,林信平,李炯义,蔡志勇,谢 湛

(中南大学 粉末冶金国家重点实验室,湖南 长沙,410083)

摘要: 研究了一种新型晶粒长大抑制剂对机械合金化制备的纳米晶WC-10Co复合粉末真空烧结行为的影响,探讨了其影响机理。研究结果表明:新型晶粒长大抑制剂有利于烧结致密化;在传统的过渡族元素碳化物基础上添加新型晶粒长大抑制剂,能明显提高复合抑制剂抑制晶粒长大效果,使WC晶粒在烧结过程中明显发生定向生长,抑制盘状WC晶粒的形成;含0.1%新型晶粒长大抑制剂的 WC-10Co-0.8VC/Cr3C2纳米晶复合粉末压坯在1375 ℃烧结30 min后密度为14.48 g/cm3,WC晶粒尺寸为160 nm,显微硬度为2.150 GPa。

关键词: 纳米硬质合金; 晶粒长大抑制剂; 真空烧结; 致密化

中图分类号:TG135.5 文献标识码:A 文章编号: 1672-7207(2005)04-0533-06

Effects of a new type of grain growth inhibitor onsintering behavior of YG10 cemented carbide

CAO Shun-hua, LIN Xin-ping, LI Jiong-yi, CAI Zhi-yong, XIE Zhan

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083,China )

Abstract: The effects of a new type of grain growth inhibitor on vacuum sintering behavior of nanograined WC-10Co powders produced by mechanical alloying as well as its affecting mechanism were investigated. The results show that the new grain growth inhibitor can promote sintering densification process. Adding the new inhibitor to traditional transitional group element carbides, composite inhibitors become much more effective, obviously induce oriented WC grain growth and evidently encumber plate-like WC grain formation during sintering. For WC-10Co-0.8VC/Cr3C2 powders with 0.1% of the new additive, the density of 14.48 g/cm3 can be achieved after sintering at 1375 ℃ for 30 min, corresponding to the grain size of 160 nm and the micro-hardness of 2.150 GPa.

Key words: nano-grained cemented carbide; grain growth inhibitor; vacuum sintering; densification

纳米晶硬质合金的强度和硬度高[1,2],其制备过程有2个关键技术:其一是纳米(晶)粉末的制备[3,4];其二是烧结时抑制WC晶粒的长大,以获得纳米级的微观结构,从而制得高性能的纳米硬质合金。随着纳米(晶)WC-Co粉末制备技术的日趋成熟,控制烧结过程中的晶粒长大成为纳米硬质合金研究领域的难点。为了抑制WC晶粒长大,可以采[CM(22] 用特殊的烧结方法,如热等静压[5]、热压烧结[6]、场 辅助烧结 [7]、微波烧结[8]等技术,通过压力和温度以及各种外加电磁场的综合作用来实现晶粒尺寸的控制,但是,这些烧结方法由于其特殊性而难以用于批量生产。控制晶粒长大的另一重要途径是往粉末中添加晶粒长大抑制剂,如VC,Cr3C2,TaC等传统的过渡族元素碳化物[9],以降低WC在液相中的溶解度,从而有效地控制以溶解—析出为主导的WC晶粒长大机制。过渡族元素碳化物抑制晶粒长大效果较明显,但它们对烧结致密化产生不利的影响,降低硬质合金的力学性能[10]。研究结果表明,以过渡族碳化物为晶粒长大抑制剂的纳米(晶)粉末压坯经过低压烧结技术,最后得到的烧结WC晶粒尺寸可控制在200 nm左右[11],但到目前为止,还未见晶粒度小于100 nm硬质合金的报道。此外,作为硬质合金的常用添加剂之一,稀土元素可抑制硬质合金烧结过程的晶粒长大,并改善组织分布,净化晶界,对硬质合金起有效的强韧化作用[12]。同时,稀土元素还具有降低硬质合金烧结温度的作用[13],较好地解决了控制晶粒长大和烧结致密化之间的矛盾。另外,添加B和P等非金属元素可明显降低WC-Co出现液相的温度,实现硬质合金的低温活化烧结,较好地保持WC的细晶结构,所以,B和P等元素也是纳米硬质合金潜在的添加剂[14]。

黄石等[15]通过研究发现,添加少量Cu对WC-13Fe/Co/Ni硬质合金具有细化和球化WC晶粒的作用。这主要是Cu在烧结过程中溶入Fe/Co/Ni粘结相中,降低WC在粘结相中的溶解度,因而降低溶解—再析出过程晶粒长大的速率。但添加Cu会明显降低硬质合金的硬度,同样降低硬质合金的高温性能,所以,Cu也不是纳米硬质合金的理想添加剂。目前,对硬质合金晶粒长大抑制剂的研究主要局限于对过渡族碳化物的优化工艺研究,在此,作者研究一种性能优异的新型晶粒长大抑制剂对纳米硬质合金烧结行为的影响。

1 实验过程与方法

本实验采用的原料粉末有:WC粉,Co粉,VC粉,Cr3C2粉以及一种新型晶粒长大抑制剂A。将原料粉末按照WC-10Co-0.8VC/Cr3C2-xA配置成3种成分体系,其中新型抑制剂的含量x分别为0,0.1%和0.2 %。3种不同混合粉末在混料器中混合2 h,接着在以硬质合金球为研磨体的高能球磨机中球磨80 h。最后所得的粉末颗粒粒径约为0.5 μm,WC晶粒尺寸为20~40 nm。

球磨后,在粉末中掺入1.5%的石蜡。粉末经干燥后在内径为10 mm的模具内压制,压制压力为200 MPa,压坯质量为(5±0.2) g。用游标卡尺测量压坯的径向尺寸。

压坯在普通的SL63-6B真空电阻炉中烧结,保持真空度为0.1 Pa。烧结温度为1275,1300,1325,1350和1375 ℃;在每个温度点考察不同烧结时间的影响,烧结时间分别为5,10,15,20和30 min。

压坯经过烧结后测量其密度和径向尺寸,烧结密度在精度为1/10000 g的AEL-200电子分析天平上用排水法测量。

最后,对烧结坯在MEF3A万能金相显微镜上进行显微硬度测量,实验载荷为1.96 N。为了减小实验中的测量误差,对每个样品的硬度测量3次,取平均值。

2 实验结果与讨论

2.1 新型抑制剂对烧结致密化的影响

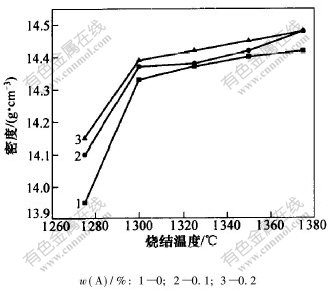

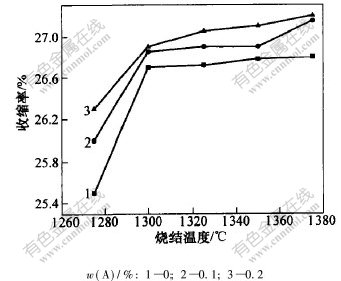

图1和图2所示分别为不同新型抑制剂含量的样品烧结密度和收缩率随烧结温度的变化曲线,烧结时间为30 min。可见,在较低烧结温度下,含有抑制剂A的样品具有较高的密度,均高于不含抑制剂A的样品密度,说明添加新型抑制剂A促进了烧结致密化,这对于纳米硬质合金块体材料的制备是相当有利的。在1375 ℃时含有A的试样烧结密度达到14.48 g/cm3,而不含A的试样密度只有14.42 g/cm3。实验中,添加A提高了样品的致密化程度,这主要是由于A是一种惰性物质,既不会与WC形成固溶体,也不会溶解在Co中。但Co对纳米A颗粒具有良好的润湿性。通过机械合金化后,A能够均匀地分布在晶界上,减小了粉末颗粒在升温阶段的纳米WC间的接触程度,阻碍了晶粒长大,有利于在烧结过程中保持纳米结构,一方面降低了烧结体系出现液相的温度,另一方面便于纳米WC晶粒局部调整位置,降低液相烧结时的颗粒重排阻力。此外,适量增加A的含量(从0.1%增加到0.2%)有利于致密化。

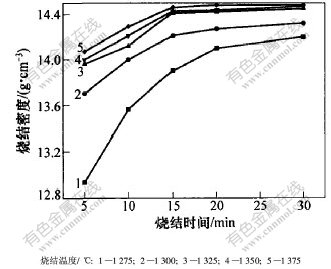

含有新型晶粒长大抑制剂A的复合粉末烧结密度随烧结温度和时间的变化规律如图3所示。可以看出,各个温度点对应的烧结密度基本上随着烧结时间的提高而增加;当烧结时间超过15 min后,曲线变得较平缓,尤其对于1300,1325,1350和1375 ℃时的曲线,表现得更加明显。这说明纳米晶粉末活性高,在1300 ℃/15 min左右基本完成致密化,此时,相对密度超过了98%,这与文献[16]报道的结果相吻合(该文献认为,含有抑制剂VC的纳米晶WC-Co复合粉末在液相出现的温度下烧结15 min才可致密)。样品在1375 ℃烧结30 min,烧结密度可达14.48 g/cm3。由图3还可看出,在1300 ℃以上的温度曲线所对应的密度均明显高于1275 ℃的温度曲线所对应的密度,这说明在温度高于1300 ℃时,液相大量出现,这有利于溶解—析出和颗粒重排,提高致密度。可见,晶粒细化引起的合金共晶点降低效果较明显(普通硬质合金共晶点为1320 ℃[17])。

图 1 不同样品的烧结密度随烧结温度变化曲线

Fig. 1 Change curves in sintering density with ncreasing sintering temperaturefor different parts

图 2 不同样品的烧结收缩率随烧结温度变化曲线

Fig. 2 Change curves in sintering shrinkage with increasing sintering temperature for different parts

图 3 烧结温度和时间对含0.2%新型抑制剂样品烧结密度的影响

Fig. 3 Effects of sintering temperature and sintering time on sintered density for powders with 0.2% mass content of new grain growth inhibitor

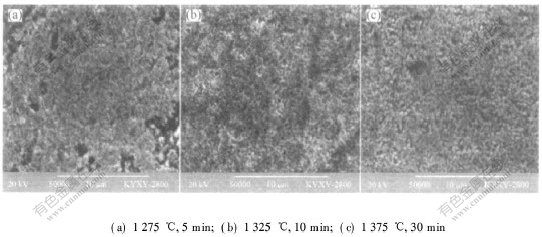

图4所示是烧结温度为1275,1325和1375 ℃,烧结时间为30 min烧结条件下得到的含0.2%抑制剂A样品的扫描电镜照片。可以看出密度随烧结温度、时间的变化规律:1275 ℃烧结的样品存在大量的孔隙,而1325 ℃和1375 ℃烧结的样品已经基本致密。

2.2 新型抑制剂对烧结显微硬度和显微组织的影响

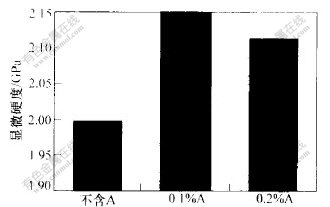

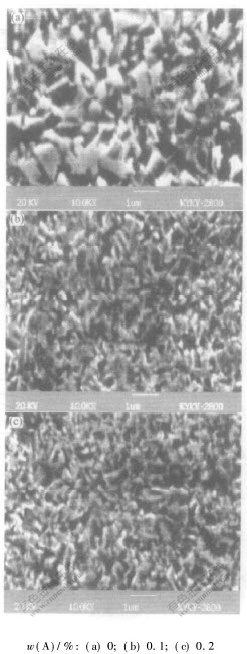

图5所示为不同样品在1375 ℃/30 min烧结后的显微硬度。可以看出,含0.1%A的样品硬度最高,达到2.150 GPa;含0.2%A的样品,硬度为2.114 GPa;不含A的样品硬度最低,为1.998 GPa。这主要是由于不含A样品的烧结晶粒粗大,而且VC和Cr3C2复合抑制剂不利于烧结致密化,密度仅为14.42 g/cm3;而添加了新型晶粒长大抑制剂A的样品,其晶粒尺寸小,分别为160 nm和180 nm,复合抑制剂抑制效果明显;同时,A还可以促进烧结致密化,密度均达到14.48 g/cm3。不同样品在1375 ℃,30 min烧结条件下所得的扫描电镜照片如图6所示。可见,增加A含量(从0.1%增加到0.2%)使烧结WC晶粒由160 nm长大到180 nm。这主要是由于A含量较大时,在固相升温阶段抑制晶粒长大更加明显,因细化晶粒引起的共晶点降低亦更加显著,在烧结温度时液相增多,溶解—析出造成的WC晶粒长大作用增强。所以,A的添加量必须控制在一定范围内。此外,值得注意的是,添加A[CM(22] 使WC晶粒在烧结时明显定向生长,抑制了盘状WC晶粒的形成,这有利于硬质合金性能的提高,使材料兼具纤维增强效果和纳米特性。

图 4 含0.2%新型抑制剂的样品在不同烧结温度、烧结时间下的扫描电镜照片

Fig. 4 SEM images of powders with 0.2% mass fraction of inhibitor A at

different sintering temperatures and times

图 5 不同样品在1375 ℃,30 min烧结后的显微硬度

Fig. 5 Micro-hardness of different parts after sintering at 1375 ℃ for 30 min

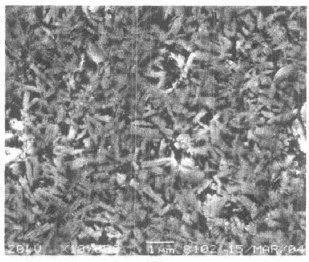

为了进一步考察该纳米晶粉末的热稳定性,即在高温下晶粒是否快速长大,将含0.2%A的粉末压坯于1400 ℃烧结30 min,其扫描电镜形貌如图7所示。可见,WC晶须长大约1 μm,径向尺寸为200~250 nm,比图6(c)所示的显微结构尺寸大50 nm。这说明粉末具有很高的热稳定性,不同于仅含过渡族碳化物抑制剂的情况。复合抑制剂具有优异的晶粒长大抑制效果。

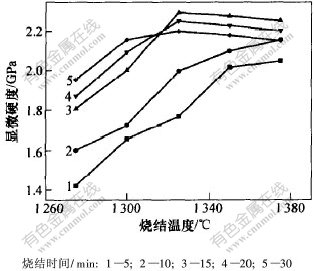

含有新型晶粒长大抑制剂A的复合粉末烧结显微硬度随烧结温度和时间的变化规律如图8所示。可以看出,当烧结时间为5 min和10 min时,硬度随着烧结温度的升高而不断增加。这是由于在液相烧结条件下至少烧结15 min才能使溶解—析出及颗粒重排充分进行[16],获得致密体;而当烧结[CM(22] 时间小于15 min时,烧结温度升高,烧结密度不断

图 6 不同样品在1375 ℃,30 min烧结条件下的扫描电镜照片

Fig. 6 SEM images of different parts after sintering at 1375 ℃ for 30 min

图 7 于1400 ℃烧结30 min的样品显微形貌

Fig. 7 SEM image of sintered part with 0.2%A at 1400 ℃ for 30 min

增加,最终硬度提高;而当烧结时间为15,20和30 min时,在1325℃时烧结温度时硬度最大。这是由于在1325 ℃时出现了足够的液相,使烧结致密化充分进行,若温度偏低,则就不能保证充分致密化,所以,硬度偏低;若温度偏高,过多的液相将促使晶粒长大,则硬度下降。另外,从图8还可发现,当烧结时间为15,20和30 min时的3条曲线出现了交叉现象,在较低温度(1275~1300 ℃)时,烧结时间越长,烧结致密化程度越高,烧结样品硬度越高;而在较高温度(1325~1375 ℃)下,硬度随时间变化呈现相反的规律,这主要是由于增加烧结时间促进了晶粒长大。样品在1325 ℃,15 min获得最高的硬度,为2.295 GPa。

图 8 烧结温度和烧结时间对含0.1%新型抑制剂样品显微硬度的影响

Fig. 8 Effects of sintering temperature and time on micro-hardness of powders with 0.1% of inhibitor A

新型晶长大抑制剂A的成功开发为纳米结构硬质合金研究提供了新思路。A对晶粒长大具有明显的抑制效果(见图6),因晶粒细化引起的共晶点降低效果明显,有利于烧结致密化(见图1和图2),含有A的纳米晶粉末在1300 ℃,15 min烧结条件下具有相当高的密度(见图3)。可见,采用抑制剂A较好地解决了致密化和控制晶粒长大之间的矛盾。若在此基础上引入低压烧结等特殊烧结工艺,进一步降低烧结温度,减少烧结时间,提高烧结密度,可制备出全致密的纳米结构硬质合金。

A对硬质合金烧结过程中的WC晶粒作用机制(如抑制晶粒长大、促使晶粒发生定向生长)有待于进一步研究。

3 结 论

a. 新型晶粒长大抑制剂可以有效地抑制WC晶粒长大,降低烧结温度,促进烧结致密化;含有该种抑制剂的纳米(晶)粉末在1300 ℃烧结15 min后,其相对密度超过了98%,在1375 ℃烧结30 min后,密度达到14.48 g/cm3。

b. 在传统的过渡族元素碳化物基础上添加新型晶粒长大抑制剂,使复合抑制剂抑制晶粒长大效果明显提高,使纳米(晶)复合粉末具有更高的热稳定性。 对于WC-10Co-0.8VC/Cr3C2 -0.1A粉末,当烧结条件为1375 ℃,30 min时,WC晶粒尺寸约为160 nm,显微硬度为2.150 GPa;对于WC-10Co-0.8VC/Cr3C2-0.2A粉末,晶粒尺寸、显微硬度分别为180 nm和2.114 GPa。

c. 新型抑制剂明显使WC晶粒在烧结时定向生长,抑制盘状WC晶粒的形成。

参考文献:

[1]Tracey V A. Nickel in hardmetals [J]. International Journal of Refractory Metals and Hard Materials, 1992, 11(1): 1-37.

[2]王辉平. 纳米技术与硬质合金[J].中国钨业, 2001, 16(2):105-114.

WANG Hui-ping. Nanotechnology and cemented carbides[J]. China Tungsten Industry, 2001,16(2): 105-114.

[3]Kear B H, Strutt P R. Chemical processing and applications for nanostructured materials[J]. Nanostructured Materials, 1995, 14(6): 227-236.

[4]马学鸣, 赵凌, 董远达. 机械合金化制备纳米硬质合金[J]. 上海大学学报, 1998, 4(2):156-159.

MA Xue-ming, ZHAO Ling, DONG Yuan-da. The fabrication of nano-grained cemented carbides through mechanical alloying[J]. Journal of Shanghai University, 1998, 14(6): 227-236.

[5]Azcona I,Ordonez A M,Sanchez J M. Hot isostatic pressing of ultrafine tungsten carbide-cobalt hardmetals[J]. Journal of Materials Science, 2002, 37(19): 4189-4195.

[6]Sun J, Zhang F, Shen J. Characterizations of ball-milled nanocrystalline WC-Co composite powders and subsequently rapid hot pressing sintered cermets[J]. Materials Letters, 2003, 57(21): 3140-3148.

[7]Wang S W, Chen L D, Hirai T. Densification of Al2O3 powder using spark plasma sintering[J]. Journal of Material Research, 2000, 15(4):982-987.

[8]周健,程吉平,袁润章,等. 微波烧结WC-Co细晶硬质合金工艺与性能[J].中国有色金属学报,1999,9(3):465-468.

ZHOU Jian, CHENG Ji-ping, YUAN Run-zhang, et al. Property and technology of WC-Co fine grain cemented carbide in microwave sintering[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(3): 465-468.

[9]Sadangi R K, McCandlish L E, Kear B H, et al. Grains growth inhibition in liquid phase sintered nanophase WC/Co alloys[J]. Powder Metallurgy International, 1999, 35(1):27-33.

[10]王社权. 影响硬质合金性能的几个因素[J].硬质合金, 2000,17(1):9-12.

WANG She-quan. Effects on the properties of cemented carbide[J]. Cemented Carbide, 2000, 17(1): 9-12.

[11]张立. WC纳米棒强化的硬质合金—PCB微钻的材料与工艺设计[J]. 硬质合金, 2001, 18(4): 194.

ZHANG Li. WC nanorod reinforced cemented carbide-material and technology design for PCB microdrill[J]. Cemented Carbide, 2001,18(4):194.

[12]魏庆丰,孙景,李昌青. 稀土添加剂在硬质合金中的应用研究[J]. 稀有金属与硬质合金, 2002, 30(2): 33-36.

WEI Qing-feng, SUN Jing, LI Chang-qing. Research on the application of RE additive in the cemented carbide[J]. Rare Metals and Cemented Carbides, 2002, 30(2): 33-36.

[13]雍志华,汪仕元,王振宁,等. Y2O3对WC-8Ni硬质合金性能和烧结温度的影响[J]. 稀有金属与硬质合金, 1997, 26(1):21-25.

YONG Zhi-hua, WANG Shi-yuan, WANG Zhen-ning, et al. Effects of Y2O3 on the properties and sintering temperature of WC-8Ni cemented carbide[J]. Rare Metals and Cemented Carbides, 1997, 26(1):21-25.

[14]马保松,张祖培,刘宝昌. 热压法制造金刚石-硬质合金复合柱齿的研究[J]. 粉末冶金技术, 2000, 18(1):28-31.

MA Bao-song, ZHANG Zhu-pei, LIU Bao-chang. Research on hot-pressing method for fabrication of diamond and tungsten carbide composite button[J]. Powder Metallurgy Technology, 2000, 18(1):28-31.

[15]黄石,杨金辉,赖为华. 添加Cu对WC-13%Fe/Co/Ni硬质合金性能与组织的影响[J]. 粉末冶金技术, 1995, 13(3):174-180.

HUANG Shi, YANG Jin-hui, LAI Wei-hua. Influence of Cu addition on properties and structure of WC-13%Fe/Co/Ni cemented carbide[J]. Powder Metallurgy technology, 1995, 13(3): 174-180.

[16]Fang Z, Eason J W. Study of nanostructured WC-Co composites[J]. International Journal of Refractory Metals and Hard Materials, 1995, 13(5): 297-303.

[17]Porat R, Berger S, Rosen A. Dilatomertric study of the sintering mechanism of nanocrystalline cemented carbides[J]. Nanostructured Materials, 1996,7(4):429-436.

收稿日期:2004 -11 -20

基金项目:国家自然科学基金资助项目(50474049)

作者简介:曹顺华(1965-),男,湖南祁阳人,教授,从事钨基和铁基粉末冶金新技术研究

论文联系人: 曹顺华,男,教授;电话:0731-8830724(O);E-mail:shuacao@163.com