>文章编号:1004-0609(2009)08-1473-07

含TiN中间层IrO2-Ta2O5涂层钛阳极的电催化性能

叶张军,甘永平,张文魁,黄 辉,陶新永

(浙江工业大学 化学工程与材料学院,杭州 310032)

摘 要:采用钛片在氮气中700 ℃退火的方法,在钛片表面原位生成TiN薄膜,并以此为基体采用热分解法制备IrO2-Ta2O5涂层钛阳极。研究含TiN中间层IrO2-Ta2O5涂层钛阳极及传统IrO2-Ta2O5涂层钛阳极的开路电位、析氧行为、循环伏安和电化学阻抗等性能。结果表明:含TiN中间层IrO2-Ta2O5涂层钛阳极具有非连续状裂纹结构,且表面生长出大量IrO2纳米晶体,其电催化析氧性能优于传统IrO2-Ta2O5涂层钛阳极的电催化析氧性能;涂层烧结温度越低,电化学性能越好;当烧结温度低于500 ℃时,TiN中间层可以显著延长IrO2-Ta2O5涂层钛阳极的工作寿命。

关键词:TiN薄膜;IrO2-Ta2O5涂层;钛阳极;电催化性能;热处理

中图分类号:TG 146.4 文献标识码: A

Electrocatalytic properties of

IrO2-Ta2O5/Ti coating anodes with TiN interlayer

YE Zhang-jun, GAN Yong-ping, ZHANG Wen-kui, HUANG Hui, TAO Xin-yong

(College of Chemical Engineering and Materials Science, Zhejiang University of Technology, Hangzhou 310032, China)

Abstract: TiN film was prepared by heating treatment of titanium plates under N2 flow at 700 ℃, and IrO2-Ta2O5 coating was formed on the as-prepared Ti/TiN substrate by thermal decomposition method. The electrocatalytic properties of the IrO2-Ta2O5 /Ti coating anodes with and without TiN interlayer, such as the open-circuit potential, oxygen evolution, cyclic voltammetry and electrochemical impedance spectroscopy were investigated. The results show that the IrO2-Ta2O5/TiN/Ti anodes have discontinuity crack and abundant IrO2 nanocrystals on the surface, which results in better electrocatalytic properties than the normal IrO2-Ta2O5/Ti anodes. The lower the sintering temperature for coating of IrO2-Ta2O5 layer is, the better electrochemical properties the IrO2-Ta2O5/TiN/Ti anodes have. The TiN film can increase the life time of coating anodes prepared at temperature lower than 500 ℃.

Key words: TiN film; IrO2-Ta2O5; coating; Ti anodes; electrocatalytic properties; heat treatment

钛基金属氧化物阳极具有高催化活性以及优良的耐腐蚀性,广泛应用于氯碱工业、电镀、废水处理、阴极保护和有机电合成等领域作为析氧或析氯电 极[1?5]。其中,IrO2-Ta2O5涂层钛阳极具有优良的电催化活性与电化学稳定性,尤其在强酸性溶液、高电流密度下能够长期稳定工作,是目前在酸性介质中替代铅、铅合金及二氧化铅电极的重要析氧电极[6]。IrO2-Ta2O5涂层钛阳极的失效是因为涂层与基体之间发生溶解,基体氧化生成绝缘性TiO2[7]。通过在基体与涂层间添加合适的中间层,延缓或阻止基体表面TiO2的产生,是改善电极使用寿命的有效方法之一[8?9]。

氮化钛具有一定的导电导热性,耐酸、碱腐蚀性,且与钛基体有良好的结合力,是中间层的理想选择。姜俊峰等[10]通过离子镀法制备了TiN薄膜,并以此为基体制备IrO2-Ta2O5涂层钛阳极,结果显示TiN可增加涂层电极的催化活性,延长使用寿命,但是离子镀法制备的TiN在工业上很难大规模推广,而且制得的TiN薄膜表面光滑,表面积小,氧化物负载较困难。将预处理后的钛片在氮气氛中高温退火可以在其表面得到一层TiN薄膜,该工艺简单、操作容易,不仅可发挥TiN薄膜的优点,而且处理后的钛片表面粗糙,增加了氧化物的负载量,能克服离子镀法的不足。本文作者对钛片进行喷砂及5%HF漂洗后,将其在氮气中高温退火制备了TiN薄膜,并以此为基体通过热分解法制备了含TiN中间层的新型IrO2-Ta2O5涂层钛阳极,探讨热分解温度、中间层制备工艺等对涂层电催化析氧性能与强化寿命的影响。

1 实验

1.1 Ti/TiN/IrO2-Ta2O5涂层电极的制备

工业纯钛片(10 mm×10 mm×2 mm)经过喷砂,5% HF漂洗10 s,去离子水清洗干净,在管式炉中高纯氮气氛下于700 ℃高温退火处理30 min,然后在氮气保护下自然冷却。采用0.5 mol/L NaOH溶液和去离子水分别清洗样品。混合定量的H2IrCl6?6H2O和乙醇钽溶液(含Ta 13.4%)于正丁醇中形成涂液,n(IrO2)? n(Ta2O5)=7?3。将涂液均匀涂敷在样品表面,于120 ℃烘干,然后在预定温度下烧结10 min,冷却后重复涂敷过程,最后一次烧结时间为1 h。用于比较的Ti/IrO2-Ta2O5涂层电极制备过程相似,钛片经喷砂处理后于95 ℃,10%(质量分数)草酸溶液中刻蚀2 h,取出清洗干净后按照上述过程直接涂敷。

1.2 结构测试

Ti/TiN中间层物相分析采用Thermo SCINTAG X″ TRA型X射线衍射仪(XRD)分析,Cu Kα辐射,Ni滤波,扫描速度为2(?)/min。IrO2-Ta2O5涂层钛阳极的表面形貌采用S?4700型扫描电子显微镜(SEM)分析。

1.3 电化学测试

电化学测试使用CHI650B型电化学工作站,测试在三电极电解池中进行。工作电极表观面积为2 cm2,辅助电极为铂电极,参比电极为饱和甘汞电极(SCE)。电解液为0.5 mol/L H2SO4溶液,温度为(25±0.5)℃。新制备电极在电解液中静置20 min后记录开路电位值。采用计时电流法测得析氧极化曲线,电极电位从平衡电位开始到1.5 V,每隔0.2 V取值。每个电位下稳定2 min,读取电流值。循环伏安测试范围为0.16~1.16 V,扫描速度为20 mV/s。电化学阻抗谱测试频率为100 kHz ~ 0.01 Hz,偏置电压为1.35 V,采用Zview软件对阻抗谱数据进行拟合。

1.4 强化寿命

强化寿命测试采用SK1760直流电源。电解液为1 mol/L H2SO4溶液,保持温度在(55±1)℃,铅作为阴极,阴阳极间距1 cm,钛阳极测试面积2 cm2,恒定电流密度2 A/cm2,记录槽电压随时间的变化,槽压急剧升高(约5 V)视为阳极失效。

2 结果与讨论

2.1 结构表征

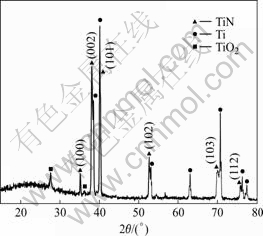

图1所示为钛片在氮气氛中热处理形成的Ti/TiN薄膜的XRD谱。从图1中可以辨别TiN、Ti及金红石相TiO2的特征峰。由图1可看出,Ti基体衍射峰很明显,少量TiO2峰的出现是由于高温下Ti与氮气氛中残留的微量氧发生了反应。TiN的特征衍射峰峰形尖锐,表明高温下金属钛可与氮气发生反应形成TiN薄膜。

图1 氮气氛中热处理形成的Ti/TiN薄膜XRD谱

Fig.1 XRD pattern of Ti/TiN film annealed in nitrogen

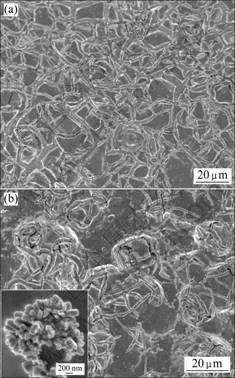

图2所示为470 ℃烧结温度下IrO2-Ta2O5涂层钛阳极的SEM像。由图2可看出,不含TiN中间层IrO2-Ta2O5表面为典型的泥裂结构,裂纹呈现连续状态(见图2(a));含TiN中间层的IrO2-Ta2O5涂层钛电极表面显微结构的区别较大,裂纹不连续,这可以增强钛阳极在电解过程中的稳定性(见图2(b))。值得注意的是,含TiN中间层的IrO2-Ta2O5涂层钛电极表面的泥裂间隙处析出大量呈棒状的纳米晶体,直径约为80~200 nm(见图2(b)插图),而不含TiN中间层的电极表面则没有观察到类似的纳米晶体。经能谱分析证实,析出的棒状晶粒为活性物质IrO2,表明TiN的存在明显增加了表面的催化活性物质。IrO2的大量析出可能与TiN中间层在电极制备过程中逐渐分解有关,具体的机理有待进一步研究。

图2 IrO2-Ta2O5涂层钛阳极的SEM像

Fig.2 SEM images of IrO2-Ta2O5 coating anodes: (a) Without TiN layer; (b) With TiN layer

2.2 电化学性能

2.2.1 循环伏安特性与伏安电量分析

图3所示为470 ℃烧结的IrO2-Ta2O5涂层钛阳极的循环伏安曲线。文献[4, 11]报道P2和P1峰对应于电极表面Ir的氧化还原电对(Ir(Ⅲ)/Ir(Ⅳ))。由图3可知,含TiN中间层IrO2-Ta2O5涂层钛阳极伏安曲线的面积要大于传统Ti/IrO2-Ta2O5涂层钛阳极的,电催化反应活性增加,这与其表面催化活性物质较多有关,但P2和P1峰位置不变,表明TiN中间层不影响铱钽钛涂层阳极表面电催化活性点的化学本性。

图3 470 ℃烧结温度下制备的IrO2-Ta2O5 涂层钛阳极的循环伏安曲线

Fig.3 Cyclic voltammograms of IrO2-Ta2O5/Ti coating anodes sintered at 470 ℃

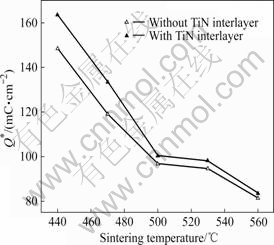

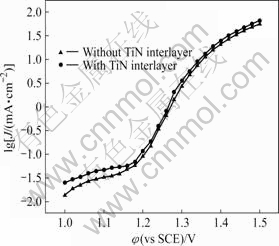

循环伏安电量(Q*)反映了涂层钛阳极表面催化活性点的数量[12],文献[13]常用电极在析气(O2, H2)电位间的循环伏安曲线上的积分电量来比较电极的催化活性。图4所示为循环伏安电量与制备温度的关系曲线。从图4可以看出,伏安电量随着烧结温度的升高迅速降低,烧结温度升得越高,涂层电催化活性降得越低。含有TiN中间层电极的伏安电量高于对应的Ti/IrO2-Ta2O5电极的,但随着烧结温度的升高,伏安电量均快速下降,当烧结温度为560 ℃时,两者基本接近,表明在烧结温度较低的情况下,TiN中间层可以增加IrO2-Ta2O5涂层钛阳极的催化活性点数量。在高温下,两者趋于一致可能是由于TiN逐渐分解所引起的。

图4 IrO2-Ta2O5涂层钛阳极循环伏安电量与烧结温度的 关系

Fig.4 Relationship between voltammetric charge capacity of IrO2-Ta2O5/Ti coating anodes and sintering temperature

2.2.2 开路电位

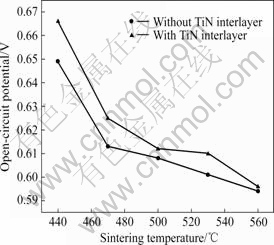

图5所示为新制备的IrO2-Ta2O5涂层钛阳极浸入0.5 mol/dm H2SO4溶液,静置20 min后测得的稳态开路电位值。从图5可以看出,开路电位随着烧结温度升高而降低,含TiN中间层的开路电位比传统Ti/IrO2- Ta2O5电极的略高。

图5 IrO2-Ta2O5 涂层钛阳极的开路电位与烧结温度的关系

Fig.5 Relationship between open-circuit potential and sintering temperature of IrO2-Ta2O5/Ti coating anodes

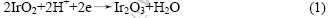

氧化物电极的开路电位是由电极表面发生的氧化还原电对所决定的,Ti/IrO2-Ta2O5涂层阳极表面电化学活性是由Ir(Ⅲ)/Ir(Ⅳ)电对所决定[14?15],化学反应式可以表示为:

在稳态开路电位下,IrO2-Ta2O5涂层钛阳极发生Ir3+→Ir4+的转化过程,由于IrO2/Ir2O3具有较高的转化活性,电极表面转化反应的交换电流密度远大于析氧反应的交换电流密度。电极开路电位有如下关系:

考虑到Ir3+/Ir4+氧化还原电对是可逆的,导入能斯特方程可以得到:

由式(3)可知,溶液pH值不变,开路电位(φoc)取决于电极表面Ir3+/Ir4+氧化还原电对的含量。图5表明,TiN中间层的存在增加了电极表面的催化活性点数量,从而增加IrO2-Ta2O5 涂层钛阳极的电催化活性。因此,在较低烧结温度下制备得到的含TiN中间层铱钽涂层具有更好的电催化活性。

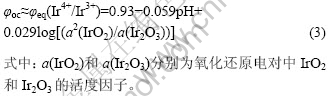

2.2.3 析氧性能

析氧极化曲线是评价IrO2-Ta2O5 涂层钛阳极电催化活性的重要方法。DASILVA等[16]常用一定电位下的析氧电流密度来比较不同阳极的电催化活性大小。图6所示为470 ℃制备的IrO2-Ta2O5 涂层钛阳极的析氧极化曲线。从图6可看出,含TiN中间层IrO2-Ta2O5 涂层钛阳极的电流密度要高于传统铱钽涂层钛阳极的电流密度。

图6 470 ℃制备的IrO2-Ta2O5钛阳极析氧极化曲线

Fig.6 Oxygen evolution polarization curves of IrO2-Ta2O5/Ti coating anodes sintered at 470 ℃

图7所示为φ=1.4 V下IrO2-Ta2O5涂层阳极的电流密度与其制备温度的关系。由图7可以看出,制备温度越低,所得的IrO2-Ta2O5涂层钛阳极的析氧电流密度越大。比较而言,含TiN中间层的IrO2-Ta2O5涂层钛阳极普遍具有较高的电流密度,但随着温度升高,电流密度趋向于一致。这进一步证实了伏安电量与开路电位的测试结果。

图7 电极电位为1.4 V时电流密度与烧结温度的关系

Fig.7 Relationship between current density and sintering temperature at φ=1.4 V

2.2.4 电化学阻抗

电化学阻抗谱可以用来研究IrO2-Ta2O5涂层钛阳极的电化学性能。图8所示为470 ℃所制备铱钽涂层钛阳极的典型阻抗谱复平面图。由图8可看出,不同制备温度下的阻抗谱形状相似。一般认为IrO2-Ta2O5涂层钛阳极的阻抗可使用等效电路Rs(RctQdl)(R1Q1)进行拟合[17?18]。其中Rs代表溶液电阻,Rct和Qdl分别代表电极/溶液界面上的电荷转移电阻和双电层电容,Q1代表涂层本身的常相位角元件,R1是涂层本身的电阻。从图8可以看出,两类IrO2-Ta2O5涂层钛阳极拟合所得曲线与实验结果符合得很好。

图8 470 ℃制备的IrO2-Ta2O5涂层钛阳极的阻抗复平面图

Fig.8 Nyquist diagram of IrO2-Ta2O5/Ti coating anodes prepared at 470 ℃: (a) Without Ti/TiN interlayer; (b) With Ti/TiN interlayer

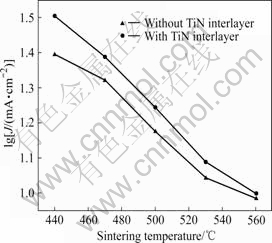

Qdl反映了活性电极/溶液界面双电层电容的 变化规律,可以用来表征钛阳极表面催化活性点的数量[17, 19]。Qdl值越大,表明电极表面的催化活性点越多。图9所示为Qdl和Rct与制备温度的关系曲线。从图9可以看出,制备温度越低,Qdl值越大,说明涂层表面的催化活性点越多,具有较高的多孔性。随着温度升高,催化活性点数量减少。在较低烧结温度下,含有TiN中间层的IrO2-Ta2O5涂层电极具有较多的催化活性点,这与扫描电镜中所观察到的结果相符合,表明TiN中间层的存在可以增加涂层钛电极的电催化活性。Rct也可以反映出IrO2-Ta2O5涂层钛阳极的析氧电催化活性[10]。Rct越大,表明析氧电催化活性越低。从图9还可看出,随着制备温度增加,Rct值快速增加,这与电极表面的反应活性点数量减少有关,表明制备温度的增加不利于析氧反应的进行。

图9 IrO2-Ta2O5涂层钛电极的Qdl和Rct与制备温度的关系

Fig.9 Relationship between Qdl and Rct at 1.35 V and sintering temperature for IrO2-Ta2O5/Ti coating anodes

2.3 强化寿命

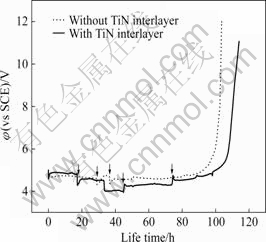

在强化寿命测试过程中,对电极铅在恒电流阴极极化下,表面状态不会发生较明显的变化,槽压的变化可以基本体现出阳极电位的变化趋势。胡吉明等[20]常用槽电压的突变来反应IrO2-Ta2O5涂层钛阳极的失效。图10所示为470 ℃制备温度下两类IrO2-Ta2O5涂层钛阳极的强化寿命。

图10 470 ℃制备的IrO2-Ta2O5涂层钛阳极的强化寿命

Fig.10 Accelerated life time of IrO2-Ta2O5/Ti coating anodes prepared at 470 ℃

箭头处槽电压的波动是由于强化电解过程中需要添加稀硫酸溶液以保持电解液合适的浓度与体积。在强化腐蚀过程中,IrO2-Ta2O5涂层钛阳极的槽电压基本保持稳定,最后在短时间内槽电压升高,电极失效。从图6中可以看出,即便在苛刻的电解条件下,增加TiN中间层也能提高强化寿命近10 h,这表明TiN中间层在电解过程中起到了延缓电解液对基体侵蚀的作用。当制备温度大于500 ℃时,含TiN中间层的涂层钛电极寿命大幅度地减小,这可能是因为TiN发生了分解或者部分分解。吴锋等[21]曾报道热处理形成的TiN在 400 ℃开始缓慢分解,在450 ℃显著分解,到550 ℃全部分解。分解后产生TiO2绝缘性物质,损害电极的使用寿命。因此,只有在合适的制备温度(低于500 ℃)下,添加TiN中间层才能提高电极的使用寿命。

3 结论

1) 利用高温退火法在Ti表面原位形成TiN薄膜,并以此为基体采用热分解法成功制备出了含TiN中间层的IrO2-Ta2O5涂层钛电极。该类电极具有非连续裂纹结构,且表面生长有大量IrO2纳米晶体,从而提高表面的催化活性点数量。与传统的涂层钛阳极相比,含TiN中间层的IrO2-Ta2O5涂层钛电极具有更高的电催化活性。

2) 通过含TiN中间IrO2-Ta2O5涂层钛阳极与传统铱钽阳极在电催化性能上的比较,发现随着烧结温度的增加,电催化活性趋向于一致。在高温时,随着TiN层的逐步分解,TiN层对涂层表面的影响显著降低;当温度大于500 ℃时,TiN快速分解,中间层对电极性能的影响逐渐消失。

3) TiN中间层具有良好的稳定性,与基体结合牢固,可以延长钛阳极的使用寿命。强化寿命测试表明制备温度低于500 ℃时, TiN中间层的存在可以明显地增加涂层钛阳极的使用寿命。

REFERENCES

[1] PILLA A S, COBO E O, DUARTE M M E, SALINAS D R. Evaluation of anode deactivation in chlor-alkali cells[J]. Journal of Applied Electrochemistry, 1997, 27(11): 1283?1289.

[2] MRAZ R, KRYSA J. Long service life IrO2/Ta2O5 electrodes for electroflotation[J]. Journal of Applied Electrochemistry, 1994, 24(12): 1262?1266.

[3] KIM K M, LEE E H, KIM J S, SHIN K H, JUNG B I. A study on performance improvement of Ir oxide-coated titanium electrode for organic destruction[J]. Electrochimica Acta, 2002, 47(15): 2525?2531.

[4] SCIALDONE O, RANDAZZO S, GALIA A, FILARDO G. Electrochemical oxidation of organics at metal oxide electrodes: The incineration of oxalic acid at IrO2-Ta2O5(DSA-O2) anode[J]. Electrochimica Acta, 2009, 54: 1210?1217.

[5] MILLER B, CHEN A C. Effect of concentration and temperature on electrochemical oscillations during sulfide oxidation on Ti/Ta2O5-IrO2 electrodes[J]. Electrochimica Acta, 2005, 50(11): 2203?2212.

[6] COMNINELLIS C H, VERCESI G P. Characterization of DSA-type oxygen evolving electrodes: choice of a coating[J]. Journal of Applied Electrochemistry, 1991, 21(4): 335-345.

[7] HU J M, MENG H M, ZHANG J Q, CAO C N. Degradation mechanism of long service life Ti/Ta2O5-IrO2 oxide anodes in sulphuric acid[J]. Corrosion Science, 2002, 44(8): 1655?1668.

[8] 姚书典, 沈嘉年, 孙 娟, 王国平, 李爱军, 饶英相. IrO2-Ta2O5系钛基改性涂层阳极和失效特点[J]. 稀有金属材料与工程, 2006, 35(12): 1916?1919.YAO Shu-dian, SHEN Jia-nian, SUN Juan, WANG Guo-ping, LI Ai-jun, RAO Ying-xiang. The surface modifications and failure mechanism for IrO2-Ta2O5 coated titanium anodes [J]. Rare Metal Materials and Engineering, 2006, 35(12): 1916?1919.

[9] 陶自春, 潘建跃, 罗启富. 铂中间层的制备及对铱钽涂层钛阳极性能的影响[J]. 材料科学与工程学报, 2004, 22(2): 240?244.TAO Zi-chun, PAN Jian-yue, LUO Qi-fu. Study on preparations of Pt inter-media and effects of the inter-media on the performances of Ti-substrate IrO2-Ta2O5 coating anodes[J]. Journal of Materials Science and Engineering, 2004, 22(2): 240?244.

[10] 姜俊峰, 徐海波, 王廷勇, 王 佳, 许立坤, 成 光. TiN基IrO2-Ta2O5涂层电催化性能研究[J]. 稀有金属材料与工程, 2007, 36(2): 344?348.JIANG Jun-feng, XU Hai-bo, WANG Ting-yong, WANG Jia, XU Li-kun, CHENG Guang. Study on electrocatalytical properties of TiN based IrO2-Ta2O5 coating anodes[J]. Rare Metal Materials and Engineering, 2007, 36(2): 344?348.

[11] WEN T C, HU C C. Hydrogen and oxygen evolutions on Ru-Ir binary oxides[J]. Journal of the Electrochemical Society, 1992, 139(8): 2158?2163.

[12] LI Y J, CHANG C C, WEN T C. A mixture design approach to thermally prepared Ir-Pt-Au ternary electrodes for oxygen reduction in alkaline solution [J]. Journal of Applied Electrochemistry, 1997, 27(2): 227?234.

[13] LI Bao-song, LIN An, GAN Fu-xing. Prepared and electrocatalytic properties of Ti/IrO2-Ta2O5 anodes for oxygen evolution[J]. Trans Nonferrous Met Soc China, 2006, 16(5): 1193?1199.

[14] HU J M, ZHANG J Q, MENG H M, CAO C N. Microstructure, electrochemical surface and electrocatalytic properties of IrO2-Ta2O5 oxide electrodes[J]. Journal of Materials Science, 2003, 38(4): 705?712.

[15] XU Li-kun, XIN Yong-lei, WANG Jun-tao. Acomparative study on IrO2-Ta2O5 coated titanium electrodes prepared with different methods[J]. Electrochimica Acta, 2009, 54: 1820?1825.

[16] DASILVA L A, ALVES V A, TRASATTI S, BOODTS J F C. Surface and electrocatalytic properties of ternary oxides Ir0.3Ti(0.7?x)PtxO2 Oxygen evolution from acidic solution[J]. Journal of Electroanalytical Chemistry, 1997, 427(1/2): 97?104.

[17] LASSALI T A F, BOODTS J F C, BULHOES L O S. Charging processes and electrocatalytic properties of IrO2/TiO2/SnO2 oxide films investigated by in situ AC impedance measurements [J]. Electrochimica Acta, 1999, 44(24): 4203?4216.

[18] 许立坤, 宋诗哲, 王廷勇, 陈光章. 金属氧化物阳极失效过程的电化学监测[J]. 电化学, 2003, 9(2): 177?183.XU Li-kun, SONG Shi-zhe, WANG Ting-yong, CHEN Guang-zhang. Electrochemical monitoring on the deactivation of a metallic oxide anode[J]. Electrochemistry, 2003, 9(2): 177?183.

[19] YE Zhi-guo, MENG Hui-min, SUN Dong-bai. Electrochemical impedance spectroscopic (EIS) investigation of the oxygen evolution reaction mechanism of Ti/IrO2-MnO2 electrodes in 0.5 M H2SO4 solution[J]. Journal of Electroanalytical Chemistry, 2008, 621: 49?54.

[20] 胡吉明, 吴继勋, 孟惠民, 张抒洁, 杨德钧. Ti基IrO2+Ta2O5涂层中氧化物附着量的XRF分析[J]. 材料保护, 2000, 33(4): 34?36.HU Ji-ming, WU Ji-xun, MENG Hui-ming, ZHANG Shu-jie, YANG De-jun. X-ray analysis of IrO2 and Ta2O5 loading in titanium based Ir/Ta mixed oxides coatings[J]. Materials Protection, 2000, 33(4): 34?36.

[21] 吴 锋, 李志坚, 陈俊红, 亓华涛. 碳热还原氮化合成TiN的研究[J]. 耐火材料, 2006, 40(2): 89?91.WU Feng, LI Zhi-jian, CHEN Jun-hong, QI Hua-tao. Research on synthesis of titanium nitride powder by carbo-thermal reduction nitrifying method[J]. Refractories, 2006, 40(2): 89?91.

基金项目:国家自然科学基金资助项目(20673100)

收稿日期:2008-12-25;修订日期:2009-03-08

通讯作者:张文魁,博士,教授;电话:0571-88320394;E-mail: msechem@zjut.edu.cn

(编辑 龙怀中)