J. Cent. South Univ. Technol. (2009) 16: 0738-0742

DOI: 10.1007/s11771-009-0122-3

Deformation division of metal flow behavior during extrusion process of 7075 aluminum alloy

LI Feng(李 峰)1, CHU Guan-nan(初冠南)2, LIU Xiao-jing(刘晓晶)1

(1. College of Materials Science and Engineering, Harbin University of Science and Technology,

Harbin 150040, China;

2. College of Shipping, Harbin Institute of Technology at Weihai, Weihai 264209, China)

Abstract: To reduce defects caused by non-homogeneous metal flow in conventional extrusion, a die with guiding angle was designed to improve the metal flow behavior. The characteristic quantities such as the second invariant of the deviator stress J2 and Lode’s coefficient μ were employed for the division of deformation area. The results show that when the metal is extruded with the guiding angle, no metal flow interface forms at the container’s bottom, the dead zone completely disappears, the deformation types of the metal in the plastic deformation area change from three types to one type of tension, and the homogeneity of the deformation as well as metal flow are greatly improved. The non-homogeneous metal flow at the final stage of extrusion is improved, reducing the shrinkage hole at the axis end. The radial stress of the furthest point from the axis is transformed from tensile stress to compressive stress and the axial stress, and decreased from 70.8 to 34.8 MPa. Therefore, the surface cracks caused by additional stress are greatly reduced.

Key words: extrusion process; flow defect; deformation division

1 Introduction

The improvement of the metal flow during extrusion processes is an important means to increase the formability and eliminate defects [1]. Many factors may influence the metal flow, among which the die structure is closely related to the metal flow. Analysis of die pocket design parameters shows that different pocket angles and pocket offsets will influence the metal flow greatly, and the latter tends to cause the bending of extrusion products [2-4]. CHUNG et al [5] discovered that the inhomogeneity of the strain distribution and generation of dead zone during double shear extrusion could be decreased by applying a smaller taper. ULYSSE [6] found that if the die bearing was not corrected or tuned appropriately, the product might be twisted and warped. Finite element method can be used for the optimum design of the die [7], and the homogeneity of the metal flow can be controlled effectively; the metal can be extruded easily [8], and the extrusion force can be decreased greatly [9].

Many researches on the optimum design of the die have been done, but most of them are designed for avoiding a certain extrusion defect. It is complicated to optimize the die structure by employing the finite element method, and even difficult to apply it to practical production [10-12]. For the above shortcomings, an extrusion die with guiding angle was designed to improve the metal flow during extrusion process.

The guiding angle is different from the entry round corner of the conventional die [13]. Although a wider entry round corner can be employed to improve the product quality, it cannot basically improve the metal flow and avoid the defects; after the guiding angle is employed, the metal in the deforming area is extruded twice with a lower extrusion ratio, which greatly changes the metal flow at the die pocket and influences the extrusion defects. Therefore, in this work, numerical simulation of extruding with and without guiding angle was carried out to investigate the influence of guiding angle on metal flow, and comparison analysis between simulation and experiment results was also conducted.

2 Simulation conditions

2.1 Die structure

The direct hot extrusion was taken as example. The die structures with and without guiding angle are shown in Fig.1.

Guiding angle (θ) can change in a certain range, and θ=0? means without guiding angle.

2.2 Finite element model

DEFORMTM-2D was used to simulate the extrusion process. Because of the symmetrical characteristics, axisymmetric model was selected in the simulation, as shown in Fig.2. The radial constrain is superimposed on the symmetry plane to make the normal deformation zero.

Fig.1 Schematic drawings of die structure under conditions of without (a) and with (b) guiding angle (θ)

Fig.2 Finite element model of extrusion process under conditions of without (a) and with (b) guiding angle

Aluminum alloy 7075 billet was used in the experiments. The billet was 50 mm in diameter and 50 mm in height. The geometrical and material parameters were the same in both the simulation and experiment. In this work, the extrusion process was simulated by using rigid-plastic finite element model. The punch, container and die were considered as rigid bodies. The speed of the punch was 2 mm/s; the time increment was 0.1 s; the friction coefficient was 0.3; the isothermal extrusion temperature was 435 ℃, and the extrusion ratio was 9.8. Numerical simulation was carried out at θ=5?, 10?, 15?, 20? and 30?, respectively. The results showed that extrusion load was the minimum at θ=15? [14]. Therefore, the die with θ=15? was selected.

3 Simulation of metal flow

3.1 Steady stage

It can be seen from the deformation of the grids that, grids in this area mostly flow towards the die pocket in the form of parallelogram, which indicates that the deformation and flow of the metal are homogeneous. Therefore, it is easy for the metal to flow out the die pockets without the formation of dead zone.

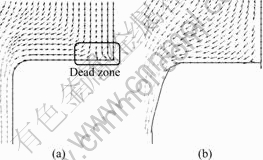

Fig.3 shows the velocity field with and without the guiding angle at the bottom of the die. It can be seen from Fig.3(a) that without employing the guiding angle, there is an obvious metal flow interface at the bottom of the die. A part of metal flows towards the die pocket, the other flows inward, and the dead zone is formed. After employing the guiding angle, as shown in Fig.3(b), the metal near the container flows towards the die pockets homogeneously, and no velocity interface is formed in the plastic deformation zone. The metal flows towards the die pockets radially without large angle turning, which will not only decrease the flow line turbulence, dead zone and overlap, but also improve the extrusion product quality.

Fig.3 Velocity field at bottom of die under conditions of without (a) and with (b) guiding angle

Comparison of the axial stress on the die exit section with and without the guiding angle is shown in Fig.4.

The stress states of the axis and surface are compressive stress and tensile stress respectively when the metal is extruded without the guiding angle. With the increase of the distance from axis, the axial stress transforms from compressive stress to tensile stress. The compressive stress and tensile stress are approximately equal, which will result in non-homogeneity of the microstructure and properties. The additional stress increases rapidly and leads to the surface cracks when the lubrication condition is not very good. After the guiding angle is employed, the axial tensile stress of the surface point decreases from 70.8 (P1) to 34.8 (P2) MPa, and the axial stress distribution along the radial direction changes a little (Fig.4(a)).

The radial stress distribution is shown in Fig.4(b), without employing guiding angle, the stress state of axial points is compressive stress and that of the surface points is tensile stress that increases with the distance from axis. After the guiding angle is employed, the radial stress at the die exit becomes compressive stress, and the radial stress and compressive stress are almost equal.

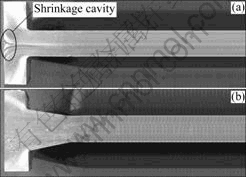

3.2 Final stage

When lower billet is extruded at the final stage of extrusion process, shrinkage cavity is a common defect. The comparison of the equivalent strain distribution at the feeding of the punch of 48 mm is shown in Fig.5.

Fig.4 Distribution of axial stress (a) and radial stress (b)

Fig.5 Equivalent strain distribution at final stage of extrusion under conditions of without (a) and with (b) guiding angle

The inhomogeneous deformation and flow are obvious during the extrusion without the guiding angle, as shown in Fig.5(a). Compared with the outside metal, the inner metal deforms and flows faster, which causes that the outside metal cannot fill in time and the shrinkage cavity forms at the last stage of extrusion. After the guiding angle is employed as shown in Fig.5(b), the mean strain difference between the metal near the axis and at the bottom of the die changes a little, and the metal flow in the deformation zone is homogeneous.

4 Deformation division

The stress distribution in the deformed grids can be obtained by the post-process module of the numerical simulation software, which is convenient for further analysis.

4.1 Method of deformation division

In extrusion, the metal in some regions of a billet cannot satisfy the plastic deformation condition and the plastic deformation cannot occur due to the friction. For the convenience, the von-Mises yield criterion can be described by [15]

(1)

(1)

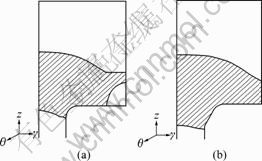

where J2 is the second invariant of the deviator stress, and σS is the flow stress of the work piece, which is a constant value. Using invariant J2, the division of stress field without or with the guiding angle can be shown in Fig.6. The regions marked with shadow represent the areas where the plastic deformation occurs.

Fig.6 Division of rigid and plastic regions under conditions of without (a) and with (b) guiding angle

Fig.6(a) shows that without the guiding angle, the region of the workpiece in the upper part of the container and in the lower corner of the container does not deform plastically. In the extrusion with the guiding angle, as shown in Fig.6(b), the plastic region is larger, and there is no dead zone. So it can be assumed that the guiding angle increases the area of plastic deformation of the metal at the bottom corner of the container.

4.2 Types of deformation

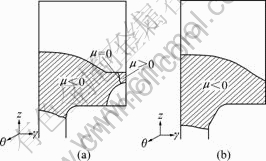

Lode’s parameter μ is used to represent the stress situation regularly since it can reflect the relative magnitude of the second principal stress, and it is also relative with the type of strain state. -1≤μ<0 represents tensile strain state, μ=0 represents plane strain state and 0≤μ<1 represents compressive strain state. That is, the type of strain state and the degree of complicacy can be determined by Lode’s coefficient. Through the analysis of Lode’s coefficient, some measures can be taken to change the stress situation, and then change the plastic deformation condition to improve the forming property of the billet.

Based on the rigid-plastic division, the strain of the material in the plastic area during extrusion process can be classified into different types using the visual display of Lode’s coefficient, as shown in Fig.7.

Fig.7 Division of Lode’s coefficient under conditions of without (a) and with (b) guiding angle

It can be seen from Fig.7(a) that without the guiding angle, Lode’s coefficient in most of the region near the die is negative, i.e. the strain in the material is tensile. The region where Lode’s coefficient equals zero belongs to plane strain; while at the corner of the container, Lode’s coefficient is positive, i.e. the strain is compressive. In the extrusion with active friction, the strain in the plastic region is everywhere tensile, as shown in Fig.7(b). So, compared with the extrusion without the guiding angle, the metal flow in the container is more homogeneous.

5 Experimental

Comparison of the metal flow line at the final stage of extrusion is shown in Fig.8.

Flow line in the container is inhomogeneous at the last stage of conventional extrusion. It bends more seriously at bottom die corner in the extrusion process, which indicates that the hard deforming area increases. Flow velocity near the container and axis is greatly different, and the metal at axis flows faster, which tends to cause the shrinkage cavity, as shown in Fig.8(a).

Fig.8 Metal flow line on section at final stage of extrusion under conditions of without (a) and with (b) guiding angle

It can be seen from the flow line shown in Fig.8(b) that at the last stage of extrusion with guiding angle, metal flow line on the section is homogeneous, and nearly parallel to the axis. The metal flow line at the die bottom is slightly bent. Compared with conventional extrusion, the metal flow in the container is more homogeneous. The shrinkage cavity is reduced and product quality is improved remarkably.

6 Conclusions

(1) When the guiding angle is used, axial stress state of the metal near the axis changes from tensile stress to compressive stress, and the shrinkage cavity caused by the higher flow velocity of the axial metal is reduced.

(2) The axial stress at the die exit is decreased by using the guiding angle, the inhomogeneity of flow velocity is reduced remarkably, and the twisting caused by the inhomogeneous metal flow is decreased. Therefore, the surface cracks caused by additional stress are avoided.

(3) The results indicate that when the metal extruded with the guiding angle by deformation division, the dead zone of metal completely disappears, the deformation type of the metal in the plastic deformation area changes from three types to a type of tension, and the homogeneity of the deformation as well as metal flow are greatly improved, which is helpful for extruding and promoting the quality of extrudates.

References

[1] PONALAGUSAMY R, NARAYANASAMY R, SRINIVASAN P. Design and development of streamlined extrusion dies: A Bezier curve approach [J]. Journal of Materials Processing Technology, 2005, 161(3): 375-380.

[2] DAMODARAN D, SHIVPURI R. Prediction and control of part distortion during the hot extrusion of titanium alloys [J]. Journal of Materials Processing Technology, 2004, 150(1/2): 70-75.

[3] DENG Xiao-min, SUN Hong-jian, LI Sheng-zhi, FANG Mu-yun, CAO Jie. Friction and friction coefficient for aluminium alloy extrusion [J]. The Chinese Journal of Nonferrous Metals, 2003, 13(3): 599-605. (in Chinese)

[4] HAMBLI R, BADIE L D. Damage and fracture simulation during the extrusion processes [J]. Computer Methods in Applied Mechanics and Engineering, 2000, 186(1): 109-120.

[5] CHUNG S W, KIM W J, HIGASHI K. The effect of die geometry on the double shear extrusion by parametric FVM simulation [J]. Scripta Materialia, 2004, 51(11): 1117-1122.

[6] ULYSSE P. Extrusion die design for flow balance using FE and optimization methods [J]. International Journal of Mechanical Sciences, 2002, 44(2): 319-341.

[7] HOSSEIN R D, MOSTAFA K. Simulation of “L” section extrusion using upper bound method [J]. Journal of Materials and Design, 2004, 25(6): 535-540.

[8] ZOU L, XIA J C, WANG X Y. Optimization of die profile for improving die life in the hot extrusion process [J]. Journal of Materials Processing Technology, 2003, 142(3): 659-664.

[9] FAZAL A, ARIF M. On the use of non-linear finite element analysis in deformation evaluation and development of design charts for extrusion processes [J]. Finite Elements in Analysis and Design, 2003, 39(10): 1007-1020.

[10] LI Q, SMITH C J, HARRIS C, JOLLY M R. Finite element investigations upon the influence of pocket die designs on metal flow in aluminium extrusion (Part I): Effect of pocket angle and volume on metal flow [J]. Journal of Materials Processing Technology, 2003, 135(2/3): 189-196.

[11] LI Q, SMITH C J, HARRIS C, JOLLY M R. Finite element modelling investigations upon the influence of pocket die designs on metal flow in aluminium extrusion (Part II): Effect of pocket geometry configurations on metal flow [J]. Journal of Materials Processing Technology, 2003, 135(2/3): 197-203.

[12] LEE D J, KIM D J, KIM B M. New processes to prevent a flow defect in the combined forward-backward cold extrusion of a piston-pin [J]. Journal of Materials Processing Technology, 2003, 139(1/3): 422-427.

[13] LI F,YUAN S J,HE Z B. Effect of guiding angle on metal flow and defects in extrusion deformation [J]. Journal of Materials Science and Technology, 2007, 15(1): 15-18. (in Chinese)

[14] ZOU Liang. Study on the function of impeding angle in extrusion die [J]. Journal of Plastic Engineering, 2006, 13(2): 67-69. (in Chinese)

[15] HU W L, HE Z B, FANG Y. Uniform principle on stress, strain and yield locus for analyzing metal forming processes [J]. Journal of Materials Processing Technology, 2004, 151(1/3): 27-32.

(Edited by CHEN Wei-ping)

Foundation item: Project(RC2010QN017008) supported by the Excellent Young Teachers Program of Harbin City, China

Received date: 2008-12-03; Accepted date: 2009-03-05

Corresponding author: LI Feng, PhD; Tel: +86-451-86392510; E-mail: hitlif@126.com