文章编号:1004-0609(2007)08-1373-06

300 kA预焙铝电解槽温度和初晶温度的自适应模糊控制

任必军1, 2,李晋宏3,张廷安1

(1. 东北大学 材料与冶金学院,沈阳 110004;

2. 伊川电力集团总公司,伊川 471312;

3. 北方工业大学 计算机系,北京 100041)

摘 要:采用自适应模糊技术,设计了300kA预焙槽电解质温度和初晶温度的控制系统。该系统包括参数采集,参数网络传输和参数预处理,专家知识规则库、模糊逻辑决策,参数辨识、模糊规则自适应,人机界面和执行机构等模块。通过调整氟化铝添加量、出铝量和设定电压,以及氧化铝下料间隔的自修正,实现对电解槽温度、初晶温度、效应系数的控制。该系统在常规模糊控制基础上,通过变化在线辨识参数,得到系统自适应不同的电解槽。系统的输入参数除传统的电压、温度和分子比外,还采用初晶温度、过热度和阴极压降等作为系统的输入参数。控制系统在我国某厂300 kA铝电解槽上运行9个月,电流效率达94.3%,效应系数为0.08,每吨铝的直流电耗13 000 kW?h。

关键词:铝电解槽;模糊控制;初晶温度;自适应

中图分类号:TF335; TF821 文献标识码:A

Adaptive fuzzy control system of temperature and liquidus

of 300 kA aluminum production cells

REN Bi-jun1, 2, LI Jin-hong3, ZHANG Ting-an1

(1. School of Materials and Metallurgy, Northeast University, Shenyang 110004, China;

2. Yichuan Power Limited, Yichuan 471312, China;

3. Computer Depertment, North China University of Technology Beijing 100041, China)

Abstract: An adaptive fuzzy control system for 300kA prebake aluminum production cells was designed, which includes the sampling, transmission and pretreatment of the parameters, the database and fuzzy logical determination, the parameter recognition and adaptivity of the fuzzy rule and actor. The bath temperature, liquidus and anode effect were controlled by adjusting the AlF3 additions, aluminum tapping magnitude, cell voltage set-point and the alumina feeding interval. Based on the tradition fuzzy control, the system can automatically adapt different cells in different periods by online recognition. Besides the cell voltage, bath temperature and bath ratio, the inputs of the system also include the liquidus temperature, superheat extent and cathode voltage. The control system has been running nine months in some Aluminum Plant in Hennan Province of China, with current efficiency up to 94.3%, anode effect coefficient down to 0.08 and DC energy consumption to 13 000 kW?h per ton aluminum.

Key words: aluminum production cells; fuzzy control; liquidus; adaptivity

由于电流效率的实时监测还处于研究之中,电流效率作为铝电解过程控制系统的目标参数在工业上的

应用还有一段距离[1?2]。目前铝电解过程的控制采用最佳的工艺条件来进行,其中温度和摩尔比(或初晶温度)是最重要的技术指标,近年来受到广泛的关注[3?4]。国内外大量的生产和研究表明,大型铝电解槽的参数监测和控制技术对提高铝电解厂的经济效益具有重要意义[5?6]。温度对铝电解过程技术经济指标有重要影响,一般电解温度比电解质初晶温度高8~15 ℃以上,必须设法降低初晶温度,才能为低温度电解创造条件。

近年来,以低分子比、低温为主要特征的工艺技术条件被生产厂家广泛接受,对铝电解控制系统的控制精度提出更高的要求。现代控制理论和新的控制方法在氧化铝浓度的控制和电解槽诊断中得到了广泛应用[7?9]。俄罗斯学者认为分子比和温度对电解槽的运行起重要作用[10]。国内目前广泛使用模糊专家控制方法实施电解槽的控制,这些方法在不同时期不同程度上对推动电解槽的控制技术发展起重要作用。

分析和研究已有的控制方法发现,基于模型的控制必须要有很好的模型参数辨识算法;简单的基于槽电阻曲线跟踪的控制方法对电解槽生产运行的平稳性及相关条件均有较高要求,否则容易出现控制发散、需人工干预处理的现象。基于专家知识的模糊控制难以根据控制效果的反馈动态修正规则进行自调整。国内对氧化铝浓度的控制和辨识研究较多, 并且已开发了基于在线智能辨识的模糊专家控制方法[11],对其它工艺参数如温度、初晶温度和出铝量等研究较少。为此,本文作者提出一种基于系统在线智能辨识的自适应模糊专家控制方法,以实现对电解槽温度和初晶温度的控制。

1 实验

为了确定控制规则,为专家知识库提供依据,在不严重影响电解槽生产的前提下,进行了电压升降对电解槽温度和初晶温度的影响实验。影响电解槽温度的因素很多,几乎所有的工艺参数都对温度有一定的影响,而最主要的因素是槽工作电压、出铝量和氟化铝添加量。一般现场技术人员也是通过对这些参数的修正来达到控制电解槽温度的目的。

分子比由于分析比较困难,分析结果的滞后较长,对于实施控制意义不大,而初晶温度已被越来越多的技术人员接受。这里采用贺利氏设备[12]测量初晶温度和过热度,作为系统的参数。

1.1 电压对温度的影响

电压增加实验:通过抬高槽电压来改变输入能量的大小,确定槽电压对电解质温度、过热度的影响程度,从而确定槽电压的调整因子。

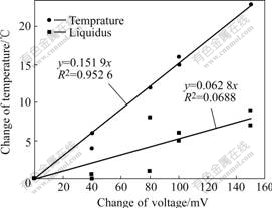

电压阶段响应实验中电压分别增加40、80、100和150 mV,以及电压分别降低40、80、100和120 mV, 由此形成8个方案。每2台槽用于1个方案跟踪24 h。电压增加或降低对温度和初晶温度的影响如图1和2所示。

图1 电压增加对温度和初晶温度的影响

Fig.1 Effect of voltage increase on temperature and liquidus

图2 电压减小对温度和初晶温度的影响

Fig.2 Effect of voltage decrease on temperature and liquidus

1.2 出铝量和氟化铝添加量对温度的影响

出铝量和氟化铝添加量对温度的影响是通过现场工艺参数的调整来进行的。通过分析温度的响应和多元自回归辨识,提取单因素的影响因子,分析单因数对温度的关系。图3所示204#槽出铝量对温度的影响,说明出铝量对温度影响较大,但没有定量关系。

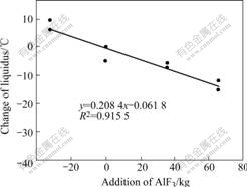

1.3 氟化铝添加量对初晶温度的影响

氟化铝添加量对初晶温度有直接的影响,但这种关系很复杂。图4所示为氟化铝添加量对初晶温度的影响。

图3 出铝量对温度的影响

Fig.3 Effect of Al-tap on temperature

图4 氟化铝加入量对初晶温度的影响

Fig.4 Effect of AlF3 addition on liquidus

2 控制模型

实验结果表明,电压变化对温度的影响比初晶温度大得多,说明初晶温度的变化除随电解质成分变化外,还会随槽帮的熔化/冷凝而动态变化。电压升高对提高电解槽温度产生很明显的影响,电压升高100 mV,在10 h内温度可提高10~15 ℃;电压降低对温度的影响也很明显,但反应速度稍慢些。在工业电解槽中所有的工艺参数都是相互影响的,不可能进行单因素实验,只能通过筛选主要因子,忽略次要因子,采用多元辨识方法,得到温度和初晶温度之间的半定量关系。现场测量数据分析表明,温度和初晶温度与工艺参数存在强相关性,但很难得到普遍适用的数学模型,实验结果对于确定输入与输出之间的半定量关系非常重要。

针对大型铝电解槽参数测量非线性、大滞后、精度不高以及下料器下料存在误差、出铝操作存在误差的特点,本研究采用自适应模糊控制方案。整个系统包括:参数的采集,参数的网络传输,参数预处理,模糊决策规则库,模糊逻辑决策,参数辨识,模糊规则自适应,人机界面和执行机构等模块。系统的功能主要是根据电解槽的运行历史数据决策下一步电解槽的管理,即氟化铝下料量、出铝量、设定电压和氧化铝加工间隔。将温度控制在948~958 ℃,初晶温度控制在936~948 ℃,效应系数控制在0.1以下。控制系统的结构图如图5所示。

2.1 参数预处理

鉴于电解槽测量参数的特点,人工测量数据和从局域网上采集的各种数据不能直接使用,为此,开发了铝电解槽模糊专家系统的数据预处理程序。首先对输入模型的参数进行处理,主要有:1) 电解温度,在铝电解模糊知识库中并不直接使用,而是使用电解温差(电解温度减去炉别基准)、五天温趋等变换后的数据;2) 平均每4天测一次分子比,其余时间要使用最近一次的分子比和最近几天氟化铝下料量等数据进行计算才能得到。另一方面,模糊专家系统推理出的数据大部分是差值,但在发布到网上或下发到槽控机时是实际值,这需要在输出前进行各种计算。参数预处理主要采用简单的数学方法,如加权平均、移动平均、一阶滤波和数学方程式计算。

图5 基于系统在线智能辨识的模糊控制系统结构图

Fig.5 Chart of fuzzy control system based on online intelligent recognition

2.2 专家规则库的建立

2.2.1 变量及其论域

该控制系统的输入变量主要有:温度、分子比、铝水平、平均电压、炉底压降、炉帮厚度,历史氟化铝添加量、历史氧化铝添加量。输出变量:出铝量和设定电压,氟化铝添加量和氧化铝添加量(下料间隔)。

将论域限制在当前实验所需要的范围内,定义温度的论域为[930,1 020]℃,分子比的论域为[2.0 2.9],铝水平的论域为[20,25]cm, 平均电压的论域为[3 900,4 500]mV。

出铝量为[1 800,2 800]kg,设定电压为[4 000,4 300]mV,氟化铝添加量为[0,120]kg,氧化铝添加量为[3 500,4 900]kg。

2.2.2 模糊语言变量的隶属度函数

为考虑控制效果和方便可行起见,对不同的语言变量采用不同的隶属度函数,模糊子集的数目根据需要确定,例如温度分13个子集,氟化铝添加量分个13子集,炉底压降只有2个子集。以温度为例,隶属度函数的数目取13个,采用C1到C13来分别表示温度变量从小到大的各语言值。隶属度函数的形状定义成三角形隶属函数。

2.2.3 模糊规则的建立

采用“IF X is A and Y is B,THEN Z is C”的模糊规则形式,其中A表示输入X的隶属函数,B表示输入Y的隶属函数,C表示输出Z的隶属函数。由于输入参数多,所有参数的各个模糊子集的全排列会导致规则库太庞大,运行效率低。本实验采用主元素分类来排列,在主元素满足推理条件时就能给出结论,不再考虑次元素。基于上述实验数据,根据电解槽运行一段时间的实际生产技术指标和现场技术人员的经验,建立该体系的一系列模糊规则,系统正常运行时的规则库共有860条规则。

2.3 模糊逻辑推理

近年来,人们已提出多种模糊推理算法[13],本实验采用“Product-Sum-Gravity”模糊推理算法。该模糊推理算法采用代数积(Algebraic product)规则定义模糊蕴涵表达的模糊关系,模糊关系的合成运算采用“求和”(Sum)运算。

由前面实验得到860条规则,对于每次输入分别求出每个规则中每个前件的隶属度,再求出该规则前件的隶属度,由此规则前件的隶属度求出该输入作用于这条规则的输出,取所有规则输出的集合作为该输入的输出。

图6 模糊控制器决策图

Fig.6 Chart of process for fuzzy control

2.4 模糊量的精确化

采用面积重心法计算精确量,找出所截隶属函数曲线与横坐标围成图形的重心,便可将输出模糊集合化成精确的输出值,即系统的决策量。具体算法与文献[14]相同。

3 模糊控制系统的自适应

电解槽控制系统为了适应槽龄的不同、季节的变化、系列电流大范围变动、工艺的改变以及原材料性质的不同,控制系统必须有自适应能力。本系统在传统的模糊控制技术上增加2个模块,即基于预测和反馈的直接自适应和基于在线智能辨识的间接自适应。

3.1 基于预测和反馈的直接自适应

系统通过决策量的自修正和非对称变论域技术模糊推理实现铝电解槽模糊专家系统的直接自适应。

1) 决策量的自修正模块

综合考虑前一阶段技术条件变化情况、当前槽况等,根据一周的决策量构造预测模型,预测出昨日决策量导致今日电解槽技术参数的变化,这个预测值与今日实际测量值比较,来修正今日各槽的设定电压、氟化铝添加量等,通过网络自动下发至槽控机,实现决策量的优化调整。设预测量和实际测量值偏差为E,偏差的变化为DE,规则的形式为:if E is L and DE is L, then决策修正量最大。

2) 非对称变论域技术模糊推理

随着生产的进行,系统的工艺特性也在变化,为了使同一套模糊专家系统规则对不同的槽或同一台槽的不同时期适用,采用变论域专家模糊推理机[15]。系统进行推理时,按照以下的映射关系对数据进行变换:

这样通过上述公式,就将传统的对称型模糊变论域算法改变为非对称型变论域算法,推理结束后,进行数据的反映射。a、b由系统辨识结果来在线修正,从而在不改变推理规则和系统结构、只改变论域的情况下实现了决策量的自适应。

3.2 基于在线智能辨识的间接自适应

综合考虑最近若干天的运行参数及技术指标,对电解槽的槽况进行诊断[16],如正常槽还是异常槽,是何种异常槽或有病槽的趋势,并通过对规则库的修正达到对出铝量、氟化铝量、设定电压进行调整,达到对槽况的调理与维护,诊断结果一方面以网上发布和报表形式提供给现场操作管理人员,另一方面供决策模块使用。

这一模块用于基于预测和反馈的直接自适应控制效果不好的情况下,辨识的结果作为规则库的输入,主要用于特殊槽的处理。其输出结果分为3种情况,即:主因素重置,某因素论域重置和模糊关系矩阵重置。针对这3种情况分别优化,并根据优化推理后的结果修改模糊专家系统规则库,达到自适应各槽的变化,从而达到同一系统可以适应同一台槽的不同时期。

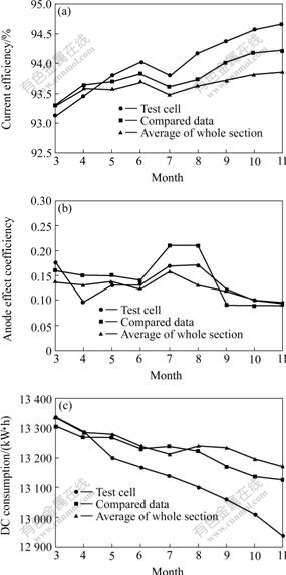

4 系统运行结果及讨论

温度和初晶温度的自适应模糊控制技术在300 kA电解槽上运行9个月,过热度达到6~12 ℃。从图7可以看出,6台实验槽运行9个月的平均电流效率达到94.3%,效应系数达到0.08,直流电耗为13 000 kW?h,炉底压降略有下降且槽况稳定。较工段43台相比,电流效率提高0.7%,直流电耗下降127 kW?h。在运行期间由于供电等原因,造成电解槽运行指标短期内波动,但不影响系统工作的总体效果。

控制和辨识是铝电解过程中的一对矛盾,铝电解过程需要稳定,波动尽可能小,控制器必须保证电解槽稳定;辨识要求过程在一定程度上波动,通过模糊推理分析被控对象对特定输入序列的“响应”,确定当前的特征曲线的平坦度和极值点位置,以及当前工作点在特征曲线上所处的位置。由于在正常控制的情况下,不允许大范围参数变动,解决矛盾的方法是,利用铝电解过程非正常作业机会,例如换阳极、出铝、限电、下料器故障等人工作业来分析参数变动对电解槽的影响。

图7 自适应模糊控制系统运行9个月的效果

Fig.7 Comparation of results of control system for 9 months:

(a) Current efficiency; (b) Anode effcet coefficiency; (c) DC consumption

需要指出的是,这种方法和原理具有通用性,但规则库和具体的自适应算法需要根据不同槽的实验和时间及实践经验来确定;系统中“基于在线智能辨识的间接自适应模块”由于缺乏大波动的辨识条件,电解槽也没有经历大范围变化的在线辨识需要,这个模块有待于今后更多的数据进一步的实践检验。

5 结论

1) 考察了电压、出铝量和氟化铝添加量对温度和初晶温度的影响,并结合专家经验设计了温度和初晶温度的控制规则及自适应模糊控制系统。

2) 将电解质初晶温度作为新的输入量和控制量,结合反馈和预测实施了对电解槽的闭环控制。

3) 该系统在300 kA电解槽上运行9个月,电流效率提高了0.7%,直流电耗每吨铝下降127 kW?h,效应系数达0.08。

REFERENCES

[1] ZENG Shui-ping, LIU Ye-xiang, MEI Chi. Mathematical Model for continuous detection of current efficiency in aluminum production[J]. Trans Nonferrous Met Soc China, 1998, 8(4): 683?687.

[2] 曾水平, 张秋萍. 预焙铝电解槽电流效率与阳极电流分布的数学模型[J]. 中国有色金属学报, 2004, 14(4): 681?685.

ZENG Shui-ping, ZHANG Qiu-ping. Mathematical model of current efficiency with anode current distribution in aluminum production[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(4): 681?685.

[3] 邱竹贤. 预焙槽炼铝(修订版)[M]. 北京: 冶金工业出版社, 2005: 6.

QIU Zhu-xian. Prebake aluminum metallurgy[M]. Beijing: Metallurgical Industrial Press, 2005: 6.

[4] Verstreken R P, Kobbeltvedt O. Liquidus temperature determination in molten salts[J]. TMS, Light Metals, 1998, 127: 359?365.

[5] 刘业翔, 陈湘涛, 张更容, 李 劼. 铝电解控制中灰关联规则挖掘算法的应用[J]. 中国有色金属学报, 2004, 14(3): 454?498.

LIU Ye-xiang, CHEN Xiang-tao, ZHANG Geng-rong, LI Jie. Application of mining algorithm based on gray association rule in aluminum electrolysis control[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(3): 454?498.

[6] Leonardo P, Jean Y, Roberta A C. Araujo-Jeronimo C. Bath ratio control improvements at alcoa pocos de caldas-brazi[J]. TMS, Light Metals, 2005, 134: 419?422.

[7] Meghlaoui A, Aljabri N. Aluminum fluoride control strategy improvement[J]. TMS, Light Metals, 2003, 132: 425?429.

[8] Yurkov V, Mann V. A simple dynamic realtime model for aluminum reduction cell control system[J]. TMS, Light Metals, 2005, 134: 423?428.

[9] Berezin A I, Poliakov P V, Rodnov O O, Mezhubovsky I V, et al. Neural network qualifier of noises of aluminium reduction cell[J]. TMS Light Metals, 2003, 132: 437?440.

[10] Yurkov V, Mann V, Piskazhova T, et al. Dynamic control of the cryolite ratio and the bath temperature of aluminium reduction cell[J]. TMS, Light Metals, 2002, 131: 383?388.

[11] 李 劼, 张文根, 丁凤其, 刘业翔. 基于在线智能辨识的模糊专家控制方法及其应用[J]. 中南大学学报: 自然科学版, 2004, 35(6):911?914.

LI Jie, ZHANG Wen-gen, DING Feng-qi, LIU Ye-xiang. Fuzzy expert control method based on on-lineintelligent identification and its application[J]. Journal of Central South University of Technology: Natural Science, 2004, 35(6):911?914.

[12] White P, Wai-Poi N, Rolofs B, Verstreken P, Kelchtermans R. Development and application of a novel sensor for combined measurement of bath temperature and cathode voltage drop in aluminium cells[J]. TMS, Light Metals, 2001, 130: 1179?1186.

[13] Mizumoto M. Product-sum-gravity method-fuzzy singleton-type reasoning method-simplified fuzzy reasoning method[C]//IEEE International Conference on Fuzzy Systems, Priscataway: IEEE, 1996, 3: 2098?2102.

[14] 曾水平, 吴连成. 铝电解槽温度的模糊模式识别[J]. 模式识别与人工智能, 2001, 14(4): 466?469.

ZENG Shui-ping, WU Lian-cheng. Fuzzy patter recognition of the temperature in aluminum reduction[J]. Patter Recognition and Artificial Intelligent, 2001, 14(4): 466?469.

[15] ZENG Shui-ping, LI Jin-hong. Adaptive fuzzy control system of 300 kA aluminum production cell[J]. TMS, Light Metals, 2007, 136: 559?563.

[16] ZENG Shui-ping, LI Jin-hong, DING Lei. Fault diagnosis system for 350ka pre-baked aluminum reduction cell based on bp neural network[J]. TMS, Light Metals, 2007, 136: 583?587.

收稿日期:2006-12-18;修订日期:2007-04-16

通讯作者:任必军,教授级高工,电话:0379-68315359;传真:0379-68316210;E-mail: renbijun@vip.sina.com

(编辑 龙怀中)