DOI: 10.11817/j.issn.1672-7207.2015.07.010

基于无打滑现象钢球研磨的动力学分析

张京军1,李国广2,高瑞贞2,闫宾2,薛会民2

(1. 河北工程大学 土木工程学院,河北 邯郸,056038;

2. 河北工程大学 机电工程学院,河北 邯郸,056038)

摘要:基于卧式研球机在研磨时钢球与研磨盘之间不发生打滑现象,建立钢球的研磨运动方程,并通过MATLAB软件求解揭示其运动规律。为使钢球在转动盘牵引力的作用下不发生打滑,从垂直沟槽面和沿沟槽面分别对其进行动力学分析,推导出研磨压力及研磨盘转速的取值范围。以研磨盘材料HT300和钢球材料GCr15为例,给出摩擦因数和钢球大小对研磨曲线的影响,并说明沟槽偏置时α与β的选择原则,为改善钢球的表面质量提供参考。研究结果表明:通过增大盘径来减小迹线间距的差值,进而使钢球表面的迹线分布更加均匀化。

关键词:研磨;无打滑;动力学;沟槽;MATLAB软件

中图分类号:TH133 文献标志码:A 文章编号:1672-7207(2015)07-2452-07

Dynamic analysis of grinding balls based on no slipping

ZHANG Jingjun1, LI Guoguang2, GAO Ruizhen2, YAN Bin2, XUE Huimin2

(1. College of Civil Engineering, Hebei University of Engineering, Handan 056038, China;

2. College of Mechanical and Electrical Engineering, Hebei University of Engineering, Handan 056038, China)

Abstract: Based on no-slip cases between steel balls and lapping discs when a horizontal grinding machine works, the motion equations of the ball lapping were established and the law of the motion was revealed by the MATLAB software. In order to prevent balls from slipping when rotary disc drived them to rotate, the ranges of the lapping pressure and lapping disc speed were deduced by using the dynamics analysis considering from the vertical trench surface and along the groove surface, respectively. The material HT300 of lapping discs and the material GCr15 of steel balls were taken as an example to analyze the effect of friction and sizes of balls on the lapping curves, and the selection principles of alpha and beta were explained when the trench had some bias, which can provide reference for improving the quality of the steel balls surface. The results show that the difference of the trace spacing is reduced by increasing the disc diameter, which can make the trace distribution of the steel ball surface more uniform.

Key words: grinding; no slipping; dynamics; groove; MATLAB software

轴承是当代机械设备中一种举足轻重的零部件。它的主要功能是支撑机械旋转体,降低设备在传动过程中的载荷摩擦因数。而钢球作为球轴承的重要组成部分,其加工具有独特的专业化特征,且加工的质量将在很大程度上影响球轴承的使用寿命和可靠性[1-5]。研磨是钢球加工的最后1道工序。在此期间,研磨盘、磨粒对球坯进行挤压和刮擦,去除其表面的加工余量,从而提高钢球的球度和降低表面的粗糙度[6-8]。球度是钢球的主要技术指标之一,对轴承的性能(如精度、噪声、振动等)影响很大[9-13]。关于研磨,传统的看法是钢球在转动盘牵引力的作用下绕圆盘轴线公转,球面与沟槽接触弧线的线速度差形成钢球自转,公转与自转的共同作用使钢球完成研磨[14]。但这种解释较为简单,因为在研磨过程中,公转速度远大于自转速度,钢球势必会形成椭圆体。朱晨[15]提出在同轴两盘的研磨方式下, 研磨盘通过与钢球的接触点沿球面的3个圆进行重复性磨削,进而证明了单个钢球在运动中的研磨轨迹是绕过球心某一轴线的迹线圆。本文作者针对钢球的研磨,建立无打滑研磨运动方程,并利用MATLAB软件计算其自转、公转及偏转角。分析钢球表面的迹线分布,通过减小2个迹线圆间距的差值,使钢球表面的研磨更加均匀化。为避免钢球在各个方向上发生打滑,从沟槽的2个面分别对其进行动力学分析,确定研磨压力及研磨盘转速的取值范围。最后,以选取的研磨盘材料HT300和钢球材料GCr15为例,得到研磨压力与研磨盘最大允许转速之间的关系曲线,并说明沟槽偏置时为使迹线均匀分布 与

与 应满足的选择原则。

应满足的选择原则。

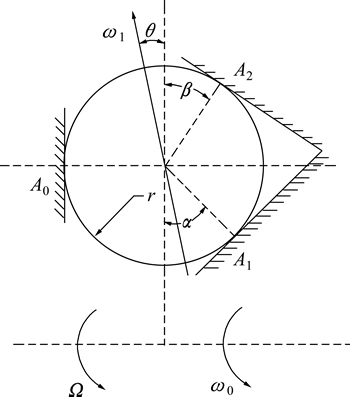

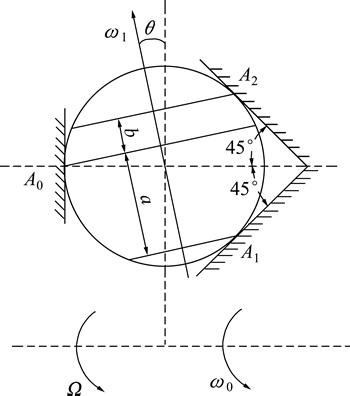

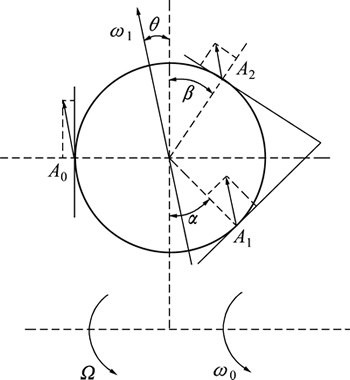

1 钢球研磨的运动规律

1.1 研磨运动方程

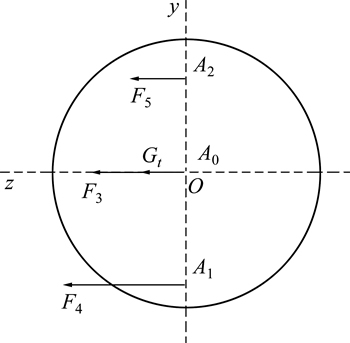

研究卧式研球机钢球的研磨运动时,将钢球和研磨盘都视为刚体,这时两者之间为理想化点接触。图1所示为钢球运动分析图。如图1所示,设钢球与转动盘、固定盘的3个接触点分别是A0,A1和A2,其公转半径为R0,R1和R2。钢球在沟槽内的转动,可分为绕转动盘中心公转的角速度ω0及绕自身球心自转的角速度ω1,一般情况下,自转又可分为枢转转动和滚转转动[16-17]。不考虑接触变形,应用刚体普遍原理,在三接触点处的钢球无打滑研磨运动方程为

(1)

(1)

其中:Ω为转动盘的转速;θ为偏转角;r为钢球半径。

解出3个研磨参数分别为

(2)

(2)

图1 钢球运动分析图

Fig. 1 Motion analysis of a steel ball

其中: ;

; 。

。

由式(2)可得钢球无打滑研磨运动的规律:当钢球在沟槽中的位置及转动盘转速确定时,θ,ω0和ω1有唯一解,即运动可以被唯一确定,且ω0和ω1均正比于Ω。由于θ一般不为0,ω1在三接触处就存在法向和切向2个分量,其中,法向分量对应的运动主要起磨削作用,切向分量对应的运动主要起碾压作用,两者相辅相成,共同完成对钢球的研磨。

1.2 研磨盘结构优化

取常选择的沟槽截形 =45°,保持夹角

=45°,保持夹角 不变。在钢球研磨的同一循环不同自转圈中,研磨迹线为3个绕自转轴的圆,正是对迹线圆的重复性研磨完成了对钢球的最终加工。

不变。在钢球研磨的同一循环不同自转圈中,研磨迹线为3个绕自转轴的圆,正是对迹线圆的重复性研磨完成了对钢球的最终加工。

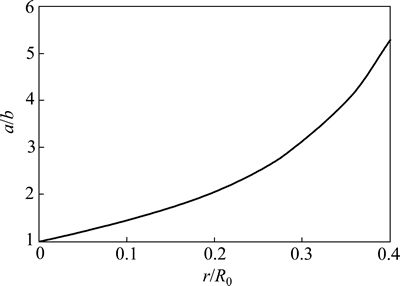

图2所示为研磨迹线分布图。从图2可见:3条迹线之间的距离为a和b,有

(3)

(3)

由式(3)可得

(4)

(4)

位于钢球表面3个迹线圆,经过点A0的圆居中,经过点A1和A2的圆分列2侧。由式(4)可以看出:迹线圆间距的比值仅与r/R0有关,其关系曲线如图3所示。试验表明:a/b影响钢球研磨的质量和效率,当a/b接近于1时,将有利于钢球表面精度的提高[18-19]。

图2 研磨迹线分布图

Fig. 2 Trace distribution of grinding

图3 r/R0-a/b曲线

Fig. 3 Curve of r/R0-a/b

当纵坐标为1时,横坐标无限趋近于0,即公转半径远大于钢球半径。即若加工的钢球规格一定,则可通过增大研磨盘的直径来减小外沟槽对应的横坐标,进而提高钢球表面的研磨质量。但是,加大外径也存在一些问题,若研磨盘内外沟槽的公转半径相差过大,势必会造成线速度有较大的差值,这样将无法使所有的钢球同时顺利地进出沟槽,造成钢球表面的破坏。所以,选取r/R0时需综合考虑前面的2个方面。

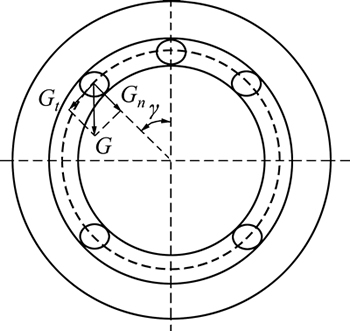

2 钢球研磨的动力学分析

对于卧式研球机,图4所示为钢球在研磨盘上同一沟槽中的分布。设单个钢球的重力为G,则其在4个象限中的分量分别为:

图4 钢球重力分解

Fig. 4 Gravity decomposition of steel balls

,

, ,

,

,

,

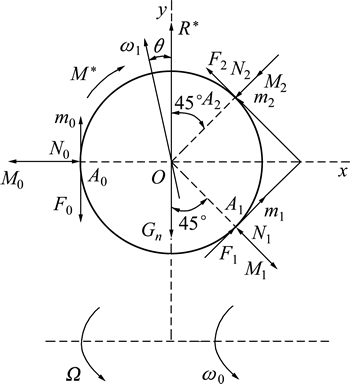

2.1 垂直沟槽面的动力学方程

不计钢球间的相互作用及研磨液对钢球的影响,取单个作无打滑研磨运动的钢球为研究对象。为避免钢球在各个方向上发生打滑,选取垂直沟槽和沿沟槽2个面分别进行分析,图5所示为垂直沟槽面受力分析图,图6所示为沿沟槽面受力分析图。

图5 垂直沟槽面受力分析

Fig. 5 Stress analysis of vertical trench surface

从图5可知:钢球若要在V形槽中不发生绕z轴方向的打滑,需满足的动力学方程为

,

, ,

, (5)

(5)

即

图6 沿沟槽面受力分析

Fig. 6 Stress analysis along groove surface

(6)

(6)

式中:N0,N1和N2为三接触点处所受的压力;F0,F1和F2为三接触点处的滑动摩擦力;R*为钢球受到的惯性力;M*为钢球受到的惯性力偶矩。

设三接触点处的临界压力为[N0],[N1]和[N2],临界滑动摩擦力为[F0],[F1]和[F2],则有如下关系式:

[F0]=f [N0],[F1]=f [N1],[F2]=f [N2] (7)

其中:f为滑动摩擦因数。由式(6)和式(7)联立可得:

(8)

(8)

对于临界压力,每1项都包含R*,Gn和M*。在一般情况下,R*,Gn和M*/r三者具有相同的数量级,滑动摩擦因数f比较小。所以,式(8)可以近似表示为

(9)

(9)

对于运动中的钢球,转动惯量J和惯性力偶矩M*分别为

,

, (10)

(10)

为使钢球不发生打滑,临界压力需小于三接触点处的实际研磨压力,其关系式为

[N0]<N0,[N1]<N1,[N2]<N2 (11)

根据式(9)~(11),可以得出N0的下限不等式为

>

> (12)

(12)

2.2 沿沟槽面的动力学方程

从图6可知:钢球若要不发生绕x轴和y轴方向的打滑,需满足的动力学方程为

,

, ,

, (13)

(13)

即

(14)

(14)

式中:F3,F4和F5为三接触点处的滑动摩擦力;M0,M1和M2为三接触点处的枢转摩擦力矩;m0,m1和m2为三接触点处的滚转摩擦力矩;mx和my为枢转摩擦力矩和滚转摩擦力矩在x轴和y轴上投影的代数和。

其中:mx和my的表达式分别为:

在三接触点处,滚转摩擦力矩远小于枢转摩擦力矩。不妨略去滚转摩擦力矩,只考虑枢转摩擦力矩在轴上的投影,则表达式可化简为:

(15)

(15)

(16)

(16)

联立式(14)~(16)可得

(17)

(17)

设钢球﹑研磨盘的弹性模量和泊松比分别为Eg和Ey;υg和υy。按弹性接触理论,三接触点处的枢转摩擦力矩分别为[20]

(18)

(18)

分析钢球在沟槽中的静态受力,发现静态时研磨压力的比值近似等于动态临界压力的比值。所以,有理由认为实际研磨压力的相对关系为

(19)

(19)

联立式(18)~(19)可将式(17)化简得

(20)

(20)

在研磨过程中,转动盘需克服三接触点处的枢转摩擦力矩和滚转摩擦力矩,带动钢球转动。若要使钢球在转动时不发生打滑,需满足的条件为

|F3|<N0 f,|F4|<N1 f,|F5|<N2 f (21)

比较式(20)中滑动摩擦力,F4大于F3和F5。选取F4为代表式,将式(20)代入式(21)化简可得:

<

< (22)

(22)

2.3 压力及转速的选取

由式(18)中可得,M0正比于N04/3。将式(18)代入式(22),存在使N0小于某个特定的值,这里记为B。同理,对式(21)的第1和第3个不等式化简求解,可得出N0分别小于特定值A和C。

所以,为使钢球在研磨过程中各个方向都不发生打滑,需满足如下关系式:

<

< <

< (23)

(23)

把式(2)代入式(23)可知,下限表达式正比于Ω2。由于A,B和C均是与转动盘转速无关的常数,可推出Ω<D,即D为转动盘转速允许的最大值。

3 影响参数

3.1 工艺参数

钢球在沟槽中作无打滑研磨运动时,公转半径的不同会影响研磨压力及最大允许转速的取值范围。选取研磨盘的材料为HT300,钢球的材料为GCr15,公转半径R0为315 mm。

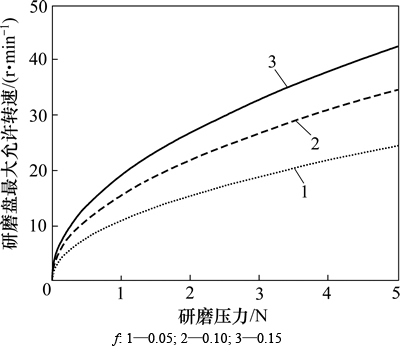

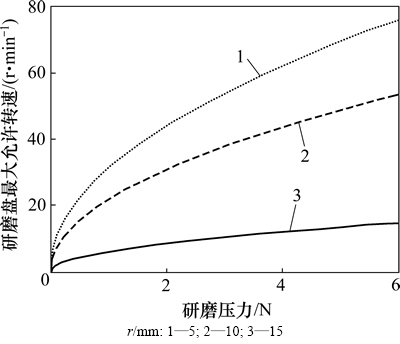

图7所示为r=10 mm时研磨盘最大允许转速与研磨压力之间的关系曲线。从图7可见:随研磨压力的增加,最大允许转速呈现上升趋势。摩擦因数越大,研磨盘允许达到的转速越大,进而钢球将变得越不容易发生打滑。图8所示为钢球半径对研磨曲线的影响。从图8可知:在滑动摩擦因素f=0.05时随钢球半径的增大,研磨盘的最大允许转速减小,说明钢球将变得容易发生打滑,此时应加大研磨压力、降低研磨盘转速。

图7 滑动摩擦因数f对研磨曲线的影响

Fig. 7 Influence of sliding friction factor on grinding curve

图8 钢球半径对研磨曲线的影响

Fig. 8 Influence of radius of balls on grinding curves

3.2 沟槽偏置

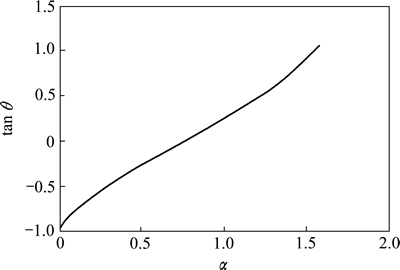

在研磨过程中,影响钢球表面质量的因素很多,如沟槽形状、机床精度和研磨盘力学性能等。沟槽的形状容易控制和改变,可通过变化参数α和β来实现。图9所示为接触点处的相对转动。从图9可知:三接触点处转速的法向和切向分量分别为

(24)

(24)

通过分析发现接触点处的法向分量和切向分量呈反向关系,接触点间的研磨情况存在差异。图10所示为 与

与 的关系曲线。从图10可以看出:

的关系曲线。从图10可以看出: 在π/4附近时,

在π/4附近时, 有零值存在,此时三接触点间的研磨相差较小。所以,沟槽偏置时

有零值存在,此时三接触点间的研磨相差较小。所以,沟槽偏置时 和

和 的选择应符合一定的原则:两者宜不相等且相差不大,相加之和在π/2附近,这样可使迹线圆在钢球表面能有较好的分布,同时提高钢球的研磨效率。

的选择应符合一定的原则:两者宜不相等且相差不大,相加之和在π/2附近,这样可使迹线圆在钢球表面能有较好的分布,同时提高钢球的研磨效率。

图9 接触点处的相对转动

Fig. 9 Relative rotation of contact points

图10 α与tan θ关系曲线

Fig. 10 Relationship between of α and tan θ

4 结论

1) 当钢球作无打滑研磨运动时,其运动规律可以被唯一确定,且钢球的公转角速度与自转角速度均正比于转动盘转速。

2) 卧式研球机对钢球进行研磨时,若要使钢球不发生打滑现象,则研磨压力必须限制在一定的范围内,转动盘转速也不得大于其允许的最大值。

3) 增大研磨压力或滑动摩擦因数,都可以降低钢球发生打滑的可能;研磨大钢球比研磨小钢球更容易发生打滑,此时可以加大研磨压力和降低研磨盘转速。

4) 当 和

和 相差不大,且相加之和在π/2附近时,钢球表面的迹线圆有较好分布。

相差不大,且相加之和在π/2附近时,钢球表面的迹线圆有较好分布。

参考文献:

[1] 张永乾, 吴朝阳. 我国钢球加工工艺设备的现状及发展趋势[J]. 轴承, 2011(4): 59-62.

ZHANG Yongqian, WU Zhaoyang. The status quo and development trend of China steel balls processing equipment[J]. Bearing, 2011(4): 59-62.

[2] 苗璞, 郑多, 王宇石. 钢球对轴承性能的影响[J]. 哈尔滨轴承, 2008(2): 38-40.

MIAO Pu, ZHENG Duo, WANG Yushi. Effect of steel balls on bearing performance[J]. Journal of Harbin Bearing, 2008(2): 38-40.

[3] 于彩娜. 钢球研磨工艺的优化设计与研究[D]. 无锡: 江南大学机械工程学院, 2009: 10-15.

YU Caina. Optimized design and research of balls milling process[D]. Wuxi: Jiangnan University. School of Mechanical Engineering, 2009: 10-15.

[4] 周井玲, 陈建春, 吴国庆, 等. 试验机结构参数对被试球接触应力影响[J]. 工程力学, 2011, 28(6): 226-230.

ZHOU Jingling, CHEN Jianchun, WU Guoqing, et al. Effect of test rig structure parameters on contact stress of specimen[J]. Engineering Mechanics, 2011, 28(6): 226-230.

[5] Childs T H C, Mahmood S, Yoon H J. Magnetic fluid grinding of ceramic balls[J]. Tribology International, 1995, 28(6): 341-348.

[6] 刘秀莲. 钢球精研及其精研液[J]. 哈尔滨轴承, 2006(1): 32-33.

LIU Xiulian. Super grinding of steel ball and whet liquid[J]. Journal of Harbin Bearing, 2006(1): 32-33.

[7] 梁华, 赵学军, 仇亚军. 轴承钢球在生产过程中表面剥落原因分析[J]. 轴承, 2008(8): 26-27.

LIANG Hua, ZHAO Xuejun, QIU Yajun. Analysis of the flaking of bearing steel balls in the production process[J]. Bearing, 2008(8): 26-27.

[8] 丁东辉, 戴勇, 何瑞江. 轴承球研磨运动特性及其影响因素分析[J]. 轻工机械, 2012, 30(3): 77-80.

DING Donghui, DAI Yong, HE Ruijiang. Analysis on motion characteristics of bearing balls grinding and their influence factors[J]. Light Industry Machinery, 2012, 30(3): 77-80.

[9] Ohta H, Kobayashi K. Vibrations of hybrid ceramic ball bearings[J]. Journal of Sound and Vibration, 1996, 192(2): 481-493.

[10] HU Huiqing. Grinding of double disc grinding machine[J]. Chinese Journal of Mechanical Engineering, 2005, 1(8): 1-4.

[11] 孙立明, 赵滨海, 杨进周. 深沟球轴承振动和噪声控制及相关技术探讨[J]. 轴承, 2002(6): 25-28.

SUN Liming, ZHAO Binhai, YANG Jinzhou. Vibration of deep balls bearing, noise control and discussion of related technologies[J]. Bearing, 2002(6): 25-28.

[12] Huang B W, Kung H K. Variations of instability in a rotating spindle system with various bearings[J]. International Journal of Mechanical Sciences, 2003, 45(2): 57-72.

[13] Momono T, Noda B. Sound and vibration in rolling bearings[J]. Motion & Control, 1999, 6(5): 29-37.

[14] 聂兰芳, 赵学军. 钢球加工成圆条件及其影响因素探讨[J]. 轴承, 2001(1): 16-18.

NIE Lanfang, ZHAO Xuejun. The conditions that process into round balls and explore the influencing factors[J]. Bearing, 2001(1): 16-18.

[15] 朱晨.两种钢球研磨方式的力学分析[J]. 轴承, 2000(9): 11-13.

ZHU Chen. Mechanical analysis of two kinds of ball grinding method[J]. Bearing, 2000(9): 11-13.

[16] 薛喆, 傅蔡安, 张韬. 钢球磨削的微观机理[J]. 江南大学学报, 2009, 8(4): 439-444.

XUE Zhe, FU Caian, ZHANG Tao. Research on mechanism of grinding balls[J]. Journal of Jiangnan University, 2009, 8(4): 439-444.

[17] 傅蔡安, 张韬, 薛喆. 钢球磨削机理研究[J]. 机械设计与制造, 2010, 8(6): 163-165.

FU Caian, ZHANG Tao, XUE Zhe. Research of mechanism of grinding balls[J]. Machinery Design & Manufacture, 2010, 8(6): 163-165.

[18] 夏新涛, 马伟, 颉谭成. 滚动轴承制造工艺学[M]. 北京: 机械工业出版社, 2007: 55-60.

XIA Xintao, MA Wei, XIE Tancheng. Manufacturing technology of rolling bearing[M]. Beijing: China Machine Press, 2007: 55-60.

[19] Yuan J L, Wang Z W, Lü B H. Simulation study on the developed eccentric V-grooves lapping mode for precise ball[J]. Key Engineering Materials, 2006, 304: 300-304.

[20] 朱晨. 钢球研磨力学原理[M]. 郑州: 河南科学技术出版社, 1995: 75-78.

ZHU Chen. The mechanics principle of grinding balls[M]. Zhengzhou: Henan Science and Technology Press, 1995: 75-78.

(编辑 罗金花)

收稿日期:2014-10-23;修回日期:2014-12-30

基金项目(Foundation item):河北省科技厅科技支撑计划项目(12212110D) (Project(12212110D) supported by the Technology Support Projects of the Department of Science and Technology in Hebei Province)

通信作者:张京军,博士,教授,从事机床设计及动力学研究;E-mail: santt88@163.com