钒钛磁铁精矿冷固球团催化还原机理

来源期刊:中南大学学报(自然科学版)2000年第3期

论文作者:朱德庆 郭宇峰 邱冠周 姜涛

文章页码:208 - 211

关键词:钒钛磁铁精矿;冷固球团;直接还原;催化还原;铁晶粒;综合利用

Key words:vanadium-bearing titanomagnetite; cold-bound pellets; direct reduction; catalyzing reduction; metal iron crystal; comprehensive utilization

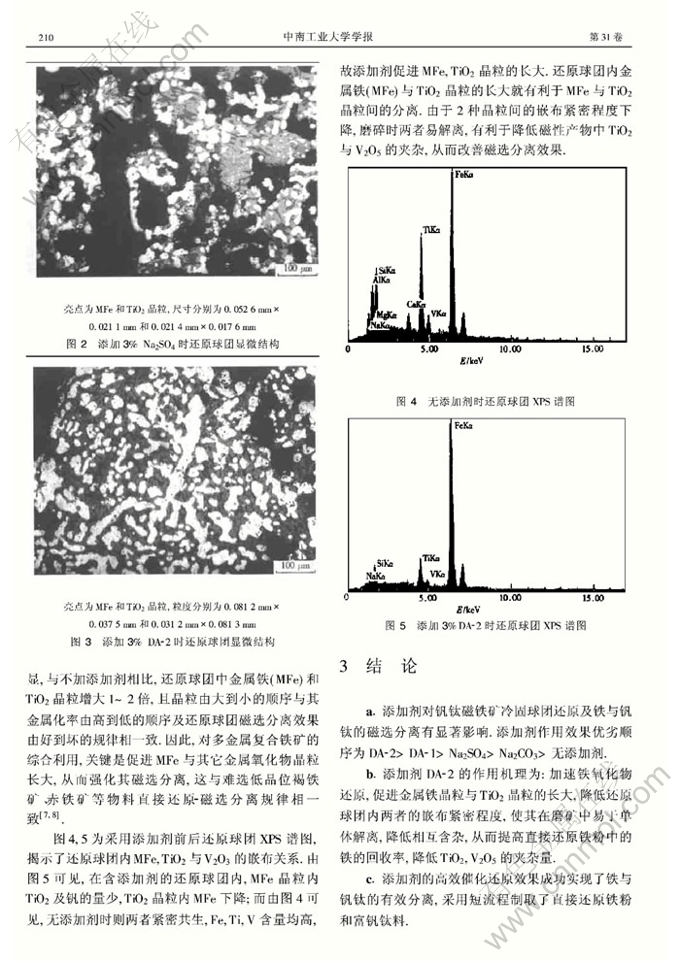

摘 要:对添加剂催化钒钛磁铁精矿冷固球团直接还原行为进行了详细的研究,包括添加剂种类和用量及催化剂催化还原机理.研究结果表明:在1 050~1 100℃,m(C)∶m(Fe)为0.5~0.6,还原时间3 h的条件下,添加DA-2催化剂与常规的Na2SO4或Na2CO3相比,钒钛磁铁精矿冷固球团煤基直接还原所得产品的金属化率提高3.1%~4.6%;该金属化球团经磨矿磁选进行铁和钒钛分离时,所得磁性产品(直接还原铁粉)中铁的品位提高5.30%~5.43%,非磁性物中TiO2,V2O5的品位分别提高2.76%~3.87%和0.27%~0.45%,TiO2,V2O5的回收率分别提高14.68%~13.08%和4.13%~6.97%.SEM及XPS等微观测试结果表明:添加剂DA-2的作用机理为加速铁氧化物还原,促进铁晶粒的长大,降低还原球团中MFe与TiO2晶粒嵌布的紧密程度,从而强化了铁与钒钛的磁选分离.

Abstract: The catalyzing effect of additives on the direct reduction of cold-bound pellets from titanomagnetite concentrate was studied in detail, which covered the dosage of four kinds of additives and the corresponding catalyzing mechanism. It is shown that the percent metallization of reduced pellets is improved by 3.1%~4.6% when DA-2 is added, compared with addition of Na2SO4 or Na2CO3 and under the conditions of reduction temperature 1 080℃,m(C)∶m(Fe) 0.58 and reduction duration 3 h. The separation of iron fromvanadium and titanium was carried out successfully through magnetic concentration of finely ground metallized pellets, and the results have been achieved as follows: the grade of iron in magnetic concentrate is increased by 5.30%~5.43%, the grade of vanadium and titanium increased by 2.76% ~3.87% and 0.27%~0.45%, and the recovery increased by 14.68%~13.08% and 4.13%~6.97% in the nonmagnetic tailings, respectively. The results of SEM and XPS determination have proved that the function of additive DA2 lies in accelerating iron oxide reduction and enhancing the growth of metal iron crystal, the tightness of paragenesis among metal iron, vanadium and titaniumoxide being loosened, and the separation of iron from vanadiumand titaniumbeing improved.