Microstructure, mechanical properties and age-hardening of Mg-Li alloy sheets

LI Hong-bin(李红斌), YAO Guang-chun(姚广春), GUO Zhi-qiang(郭志强),

LIU Yi-han(刘宜汉), JI Hai-bin(吉海宾)

School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China

Received 28 July 2006; accepted 15 September 2006

Abstract: Mg-(5-22)(mass fraction, %)Li alloys with Zn addition were produced and studied. The density of studied alloys is 1.19- 1.62 g/cm3. It is found that the alloy has excellent cold-workability and can be rolled to thin sheets at room temperature. The tensile tests were carried out at various tensile temperatures and strain rates. It is remarkable that the superplasticity occurs during uniaxial tensions at 150℃. In addition, the sheet is very sensitive to strain-rate even at room temperature. The age-hardening of the sheets at room temperature and 50℃ was investigated. The hardening may be caused by the precipitation of MgLi2Zn phase, and overaging occurs owing to the phase transformation from MgLi2Zn to MgLiZn observed by X-ray diffractometry.

Key words: magnesium-lithium alloy; mechanical properties; aging-hardening

1 Introduction

Magnesium-lithium alloy is the lightest alloy at present. It is as light as engineering plastics but it has the properties of a metal such as high specific rigidity, impact ductility, good electrical and thermal conductivities, machining, electromagnetic shielding, and shockproof[1-3]. It is well known that the addition of lithium to magnesium can get workable and body-centered cubic alloys. Magnesium-lithium alloys exhibit two phase structures with Li(mass fraction) contents between 5.7% and 10.3%, consisting of α(hcp) magnesium-rich and β(bcc) lithium-rich phases at room temperature. The β single phase structure exists when Li content is greater than 10.3%. Due to their ultra-low density, magnesium-lithium (Mg-Li) alloys are attracting much attention, not only in aerospace applications, but also for use in automobiles and electric appliances.

Although people has studied Mg-Li alloys for long time[1-11], few studies have systematically discussed the microstructure, mechanical properties and aging properties of Mg-Li alloys from a practical point of view.

In this paper Mg-Li-Zn alloy was studied systematically. Firstly, the thin sheets of the Mg-(5-22)Li-2Zn alloys with thickness of 0.5-2 mm were produced at room temperature. Secondly, the microstructures were observed and tensile properties were examined by tensile tests for various strain rates and tensile temperature. Finally, the aging hardening of Mg-Li-Zn alloy was studied.

2 Experimental

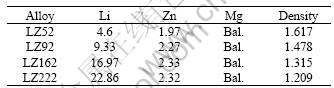

The materials used in this study consisted of pure Mg, Li and Zn. They were melted and cast in a low carbon steel crucible under an argon atmosphere and the molten flux of 75%LiCl+25% LiF. The Mg-(5-22)Li- 2Zn alloys were made and the compositions of the alloys are listed in Table 1.

The alloys were homogenized at 250 ℃ for 24 h firstly. For the loss of lithium on the surfaces of the alloys during homogenization, every surface of the specimens was milled by 2-3 mm. Then the alloys were rolled by 5% reduction every pass during rolling at room temperature. The billets with thickness of 15 mm could be successfully rolled to sheets with thickness of 0.5-2 mm by the annealing.

The total reduction was 86.67%-96.67%. The work hardening and the reduced limits of thickness during rolling were investigated. The hardness of the specimens was got by measuring the Vickers hardness (HV) at load of 9.8 N for 15 s.

The microstructures of the alloys were observed by the optical microscopy and the phase analysis was by X-ray diffractometry(XRD). The specimens for optical microscopy were prepared by etching. The etching reagent was a solution with 5 g picric acid, 100 mL ethanol and 0.7 mL phosphoric acid.

Table 1 Mass fraction of alloys(%) and density (g/cm3)

The tensile tests were carried out for the sheets at a constant cross-head velocity between 0.5 and 250 mm/min and the tensile temperatures from 25 to 150 ℃. Three samples were involved in tensile tests under each condition. The gauge length and width of the tensile specimens were 50 and 12.5 mm, respectively.

3 Results and discussion

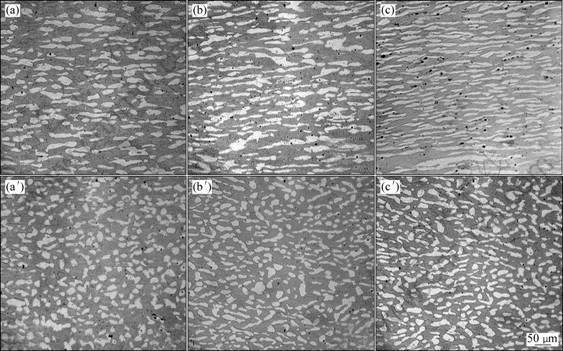

Fig.1 shows the microstructures of the sheets of Mg-9Li-2Zn alloy with the thickness from 0.5 to 2 mm. It is found that the microstructures of the different thickness sheets are similar. In the rolling direction the α phases take on the shape of the long and slim fibre, but perpendicular to the rolling direction the ‘fibre’ are very short. So the microstructures are anisotropic, which decides the tensile properties’ anisotropy in the rolling plane.

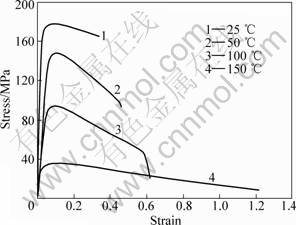

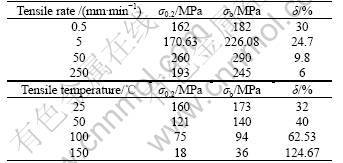

Fig.2 shows the strain—stress curves of the tensile tests of the sheets from 25 to 150 ℃. The values of the tensile properties of the sheets under different conditions are listed in Table 2.

It shows that the elongation which is remarkably large increases dramatically with rising tensile temperature, and it is especially remarkable that the superplasticity can be got for the uniaxial tension at 150 ℃. The values of the tensile properties obtained by the tensile tests for the various strain rates in the rolling direction are listed in Table 2. The sheet of the Mg-9Li-2Zn alloy has sufficiently high formability. At comparatively low strain rates, the elongation can exceed 30%. It is notable that such large elongations are attained in the specimens of the cold-rolling sheets and they also have high strength at the same time. A more remarkable feature of the sheet is that not only the elongation, but also the strength depends on the strain rate even at room temperature. The strength increases notably with rising strain rate, while the elongation decreases. The results obtained from the tensile tests in the other directions are the same as the above.

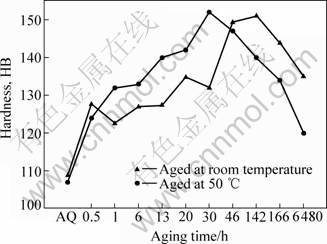

Fig.3 shows the curves of the age-hardening of the Mg-9Li-2Zn alloy sheet at room temperature and 50 ℃. The specimens are quenched in water at 25 ℃ after isothermal holding at 350 ℃ for 1 h. It shows that the hardness of the specimens rises sharply within short time, and it rises slowly with time prolonging. When aging for 142 h at room temperature, the hardness of the specimens gets to the highest value, then it starts to decrease rapidly. But the highest hardness of the specimens aged at 50 ℃ can be reached earlier.

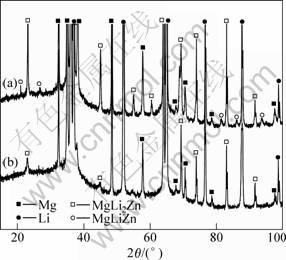

Fig.4 shows the results of X-ray analysis of the Mg-9Li-2Zn alloy sheet aged at room temperature. It shows that much MgLi2Zn compound occurs when the hardness of the specimen gets to the largest value after aging for 142 h. And the MgLiZn compound appears when overaging occurs after aging for 6 480 h. So it may be concluded that the hardening is caused mainly by the precipitation of the compound of MgLi2Zn, and the hardness of the alloy decreases because MgLi2Zn is decomposed to the soft and stable compound of MgLiZn.

Fig.1 Microstructures of Mg-9Li-2Zn alloy sheets under various conditions: (a), (a′) 0.5 mm; (b), (b′) 1 mm; (c), (c′) 2 mm; (a), (b), (c) Along rolling direction; (a′), (b′), (c′) Perpendicular to rolling direction

Fig.2 Strain—stress curves of Mg-9Li-2Zn alloy sheets at various tensile temperatures

Table 2 Tensile properties of Mg-9Li-2Zn alloy sheets under different tensile conditions

Fig.3 Aging curves of sheets of Mg-9Li-2Zn alloy quenched after isothermal holding at 350 ℃for 1 h

Fig.4 XRD patterns of sheets of Mg-9Li-2Zn alloy quenched after isothermal holding at 350 ℃ for 1 h with natural aging: (a) Aging for 6 480 h; (b) Aging for 142 h

References

[1] LE Qi-chi, CUI Jian-zhong. The past, now and the future of Mg-Li alloy[J]. Material Technics For Space Navigation, 1997, 27 (2): 1-6.

[2] WATANABLE H, TSUTSUI H. Deformation mechanisms in a coarse-grained Mg-Al-Zn alloy at elevated temperatures[J]. Int J Plasticity, 2001(17): 387-397.

[3] LI Hong-bin, YAO Guang-chun, LIU Yi-han. Microstructure and properties of superlight Mg-Li-Al wrought alloys as cold-rolling and annealing states[J]. Journal of Functional Materials, 2005, 36(4): 525-528.(in Chinese)

[4] JACKSON J H, FROST P D, LOONAM A C. Magnesium-lithium base alloys preparation, fabrication, and general characteristics[J]. Trans AIME, 1949, 185(149): 168-172.

[5] BUSK R S, LEMAN D L, CASEY J J. The properties of some Mg-Li alloys containing aluminum and zinc[J]. Trans AIME, 1950, 198(7): 945-951.

[6] FROST P D. The effect of sodium contamination on Mg-Li base alloys[J]. Trans AIME, 1950, 188: 1171-1172.

[7] TAKUDA H, KIKUCHI S, TSUKADA T, KUBOTA K, HATTA N. Effect of strain rate on deformation behaviour of a Mg-8.5Li-1Zn alloy sheet at room temperature[J]. Mater Sci Eng A, 1999, 271: 251-256.

[8] LI Hong-bin, YAO Guang-chun, JI Hai-bin, LIU Yi-han. Microstructrues and properties of superlight Mg-Li-Zn wrought alloys in cold-rolling and annealing states[J]. The Chinese Journal of Process Engineering, 2005, 5(5): 563-567.(in Chinese)

[9] HAFERKAMP H, NIEMEYER M, BOEHM R. Development processing and application range of Mg-Li alloy[J]. Master Sci Forum, 2000, 350(3): 31-41.

[10] KAMADO S, ASHIE T, OHSHIMA Y. Tensile properties and formability of Mg-Li alloy grain refined ECA process[J]. Master Sci Forum, 2000, 350(3): 55-62.

[11] ZHANG Jin, ZHANG Zhong-he. Magnesium Alloys and Application [M]. Beijing: Chemical Industry Press, 2004: 61.

(Edited by LONG Huai-zhong)

Foundation item: Project (2001AA335010) supported by the Hi-tech Research and Development Program of China

Corresponding author: LIU Yi-han; Tel: +86-24-83686462; E-mail: yihanliu689@163.com