文章编号:1004-0609(2013)S1-s0305-07

航空发动机用Alloy C+阻燃钛合金的抗点燃机理

弭光宝,黄 旭,曹京霞,王 宝,曹春晓

(北京航空材料研究院 先进钛合金航空科技重点实验室,北京 100095)

摘 要:采用摩擦点燃的方法,实验研究摩擦压力p和预混气流氧浓度xo对Alloy C+阻燃钛合金的抗点燃性能的影响,建立定量描述Alloy C+钛合金抗点燃性能的p—xo关系曲线,并结合SEM和XRD等手段分析Alloy C+钛合金的抗点燃机理。结果表明:Alloy C+钛合金的p-xo关系曲线符合抛物线规律,p在0.075~0.250 MPa变化时,着火对应的xo的变化范围约为20%;Alloy C+钛合金的抗点燃性能比TC4钛合金高40%以上;摩擦过程产生强烈的火花,着火首先发生在摩擦试样的中心孔内;摩擦表面由TiO2、V2O5和Cr2O3等氧化物融合物构成,厚度为2~5 μm,在摩擦过程中,该层融合物改善了接触表面的润滑条件,使摩擦区的温度大幅度降低,从而提高了阻燃钛合金的抗点燃性能。

关键词:航空发动机;阻燃钛合金;阻燃性能;抗点燃性能;氧化物融合物;机理;钛火

中图分类号:TG146.2 文献标志码:A

Ignition resistance mechanism of Alloy C+ fireproof titanium alloy for aero-engine

MI Guang-bao, HUANG Xu, CAO Jing-xia, WANG Bao, CAO Chun-xiao

(Aviation Key Laboratory of Science and Technology on Advanced Titanium Alloys, Beijing Institute of Aeronautical Materials, Beijing 100095, China)

Abstract: The effect of friction contact pressure p and oxygen concentration xo of mixed airflow on the ignition resistance of Alloy C+ titanium alloy was studied by frictional ignition test, the relationship p—xo quantitatively describing the ignition resistance performance of Alloy C+ was established and the ignition resistance mechanism of Alloy C+ was analyzed by SEM and XRD, etc. The results show that the relationship p—xo of Alloy C+ obeys parabolic rule. The varying range of xo corresponding ignition is about 20% while p varies within 0.075-0.250 MPa. The ignition resistance performance of Alloy C+ is 40% higher than that of TC4. The violent sparks appears during friction process, and the origin of ignition is in the center hole of frictional sample. The surface under friction is composed of the fusion of the oxides including TiO2, V2O5, Cr2O3, etc, whose thickness is 2-5 μm, and this fused layer improves the lubrication condition between the contact surfaces, resulting in a dramatically decreases temperature in the friction area, and thus improves ignition resistance of fireproof titanium alloys.

Key words: aero-engine; fireproof titanium alloy; fireproof performance; ignition resistance performance; fused oxides; mechanism; titanium fire

新一代先进航空发动机对推重比提高的要求与压气机中钛合金制件发生钛火倾向增大之间的矛盾,对耐更高温度和抗燃烧的新型高温钛合金材料提出了迫切需求[1]。Ti-V-Cr系阻燃钛合金(V元素质量分数为22%~40%,Cr元素质量分数为为13%~36%[2])应运而生,以优异的抗燃烧性能成为一种有广阔应用前景的发动机关键材料。其中,以美国开发的Alloy C(名义成分为Ti-35V-15Cr)阻燃钛合金最为典型,并于20世纪90年代大量服役于代表当今世界水平的美国第四代军用战机的F119发动机上(工作温度为540 ℃,用于制造发动机内环、静子叶片和喷口调节片以及加力燃烧室筒体等零件)[3-4],至今未见发生钛火的报道。我国在Alloy C钛合金基础上,通过合金成分优化,研制了Ti40(Ti-25V-15Cr-0.2Si)和Alloy C+(Ti-35V- 15Cr-xSi-yC)等Ti-V-Cr系阻燃钛合金[5-7],但目前仍处于试车考核阶段[7],未获得实际应用。主要是因为我国对Ti-V-Cr系阻燃钛合金点燃与不燃的边界即抗点燃性能以及抗点燃机理等基础实验和理论研究尚不充分。导致发动机设计部门对Ti-V-Cr系阻燃钛合金的选材信心不足,阻碍了钛合金在先进航空发动机上的应用研究和工程化进程。

发动机钛火并不是钛合金制件整体的热自燃,而是局部的点燃即强迫着火事故,叶片与机匣之间的高能摩擦或载荷冲击是主要的点火源,因而抗点燃性能是阻燃钛合金使用安全性的关键性能指标,也是合金结构功能性的重要特征。因此,本文作者采用摩擦点燃的方法,实验研究Alloy C+钛合金的抗点燃性能,进而揭示抗点燃机理。

1 实验方法

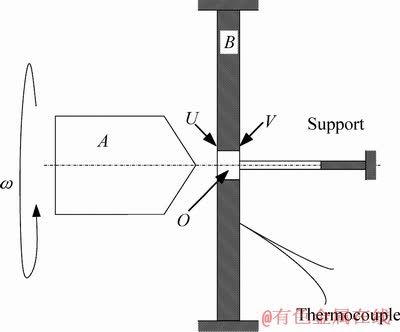

采用摩擦点燃实验方法进行Alloy C+(名义成分为Ti-35V-15Cr-xSi-yC)钛合金的抗点燃性能测试[8]。通过设计预混气流氧浓度xo和摩擦接触压力p等控制参数,对原俄罗斯引进摩擦实验设备的供气系统及数据采集系统进行了改造,装置原理图如图1所示。试样由旋转楔形试样A和带孔固定长条试样B组成。在实验过程中,首先将试样A和B分别固定于电机带动的旋转轴和夹具支座上,盖上移动保护盖,然后开启设备的电气系统和供气系统,在一定摩擦接触压力和预混气流条件下,高速旋转试样A与固定试样B形成一对摩擦副,因剧烈高速摩擦,试样局部温度急剧升高,直至点燃。根据点燃过程实时记录和实验后试样B的形貌判断试样是否点燃。试样A的转速为5 000 r/min,气流压力为0.1~0.2 MPa,试样A与B的初始温度恒定,通过调控参数p和xo,得到不同条件下点燃与不燃的实验点。将实验点进行数据处理,将获得的p—xo关系曲线作为表征Alloy C+钛合金抗点燃的性能指标。实验后,采用XRD、SEM和EDS等方法分析点燃与不燃试样的物相与形貌。

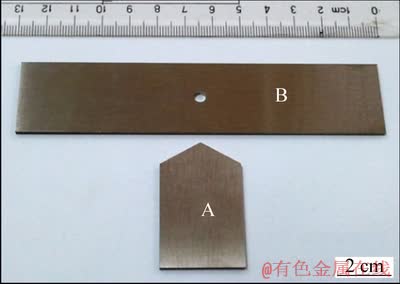

实验用Alloy C+钛合金取自吨级工业坯料,该坯料通过多次真空自耗熔炼、包套挤压开坯和改锻等工艺获得,对比实验用TC4钛合金取自模锻件。采用线切割、钻、铣和磨等加工方法,获得厚度为2 mm的抗点燃性能测试试样,且表面清洁、光亮,如图2所示。

图1 摩擦点燃实验装置原理图

Fig. 1 Schematic diagram of frictional ignition apparatus

图2 抗点燃性能测试试样实物图

Fig. 2 Test sample of ignition resistance

2 结果分析与讨论

2.1 Alloy C+钛合金点燃过程的原位观察

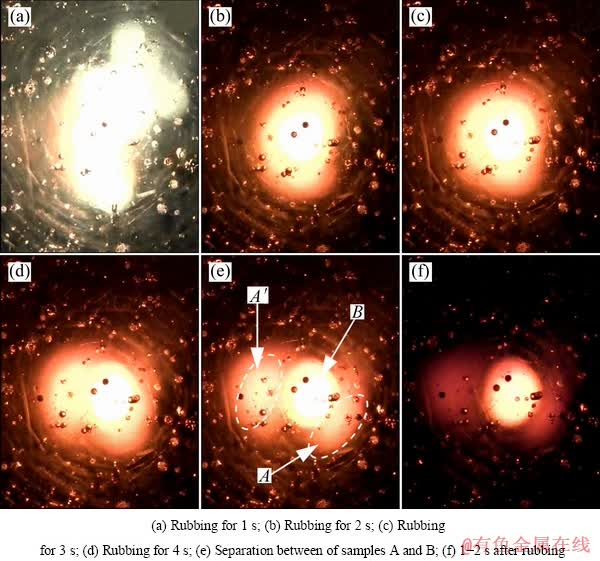

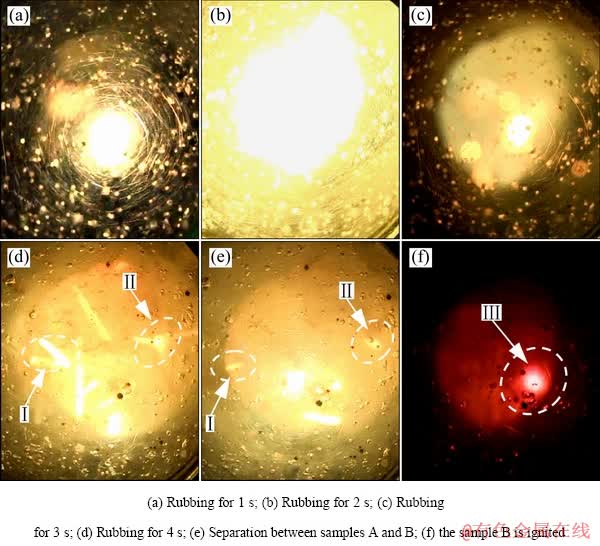

图3和4所示为不同条件下Alloy C+钛合金摩擦过程的实验记录。从图3可见:高速旋转的试样A与B接触后产生强烈的摩擦火花(图3(a));随着摩擦的持续进行,试样温度急剧升高呈炽热状态(图3(b));持续摩擦5 s后,试样A与B分离,摩擦表面温度由内而外呈明显的梯度分布(图3(c)),在分离过程中,试样A在B上明显形成镜像A′(图3(d)~(e));摩擦结束后1~2 s,试样炽热状态迅速减弱(图3(f)),整个过程没有发现着火的迹象。从图4可见:当试样A与B的中心孔接触后同样产生摩擦火花(图4(a));摩擦开始后,试样A与B的接触面积增大,摩擦火花更为剧烈(图4(b));随着摩擦的持续,试样温度急剧升高呈炽热状态(图4(c)),并伴随着摩擦碎片Ⅰ和Ⅱ的产生、爆燃和散落(图4(d)),下落碎片燃烧使整个空间布满了火焰(图4(e));摩擦持续5 s后,试样A与B分离,试样B的炽热状态更加显著且呈红色,此时,试样B点燃且进入扩展燃烧阶段(图4(f)),明显可见,试样B的燃烧位置Ⅲ。可见:当xo超过临界值时,试样B点燃并持续燃烧数十秒。这也说明Alloy C+钛合金一旦点燃,在一定条件下会迅速蔓延并扩展燃烧。

图3 在(0.225 MPa,77%)条件下Alloy C+钛合金的摩擦实验过程

Fig. 3 Friction test process of Alloy C+ under condition of (0.225 MPa, 77%)

图4 在(0.20 MPa,88%)条件下Alloy C+钛合金的摩擦实验过程

Fig. 4 Friction test process of Alloy C+ under condition of (0.20 MPa, 88%)

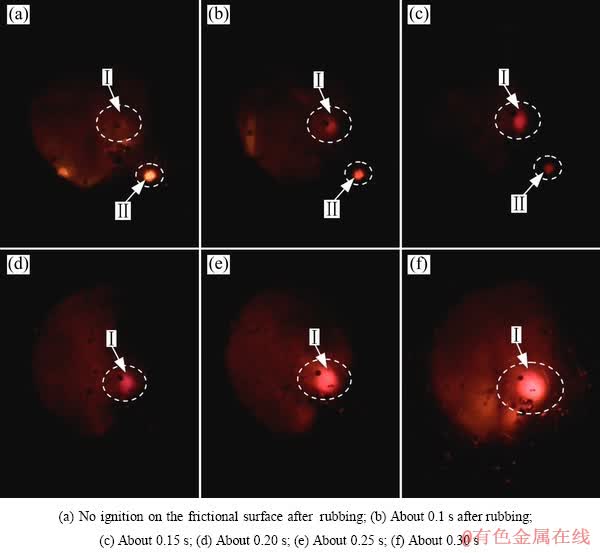

实际上,Alloy C+钛合金的点燃过程发生在图4(e)和(f)之间,通过原位观察可以描述该过程,并确定着火源的位置,如图5所示。从图5可见:试样A与B分离后,整个摩擦表面及中心孔Ⅰ均未见着火发生迹象(图5(a));经过约0.1 s后,在摩擦中心孔Ⅰ处观察到微弱的火焰(图5(b)),类似散落碎片Ⅱ燃烧的火焰;再经过约0.1 s,摩擦中心孔Ⅰ的火焰变得更加明亮(图5(c)~(f)),此时,碎片Ⅱ炽热状态消失,说明着火没有发生在试样B摩擦表面U上,而是在表面V的中心孔O附近发生(位置见图1标注)。需要说明的是,观察到的着火发生时间滞后于真实时间。根据上述观察,可以判断Alloy C+钛合金着火源所在的位置,即摩擦过程着火首先在试样B中心孔中。

图5 Alloy C+钛合金摩擦点燃过程的原位观察

Fig. 5 In-situ observation of frictional ignition process for Alloy C+ titanium alloy

2.2 Alloy C+钛合金的抗点燃性能

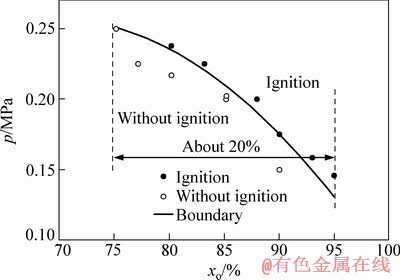

图6所示为不同条件下Alloy C+钛合金的摩擦点燃实验结果。图6中的红色实心圆点和黑色空心圆点分别为对应参数(p,xo)下Alloy C+钛合金点燃和不燃的实验测试结果。通过实验数据处理、差值迭代和非线性拟合发现,Alloy C+钛合金的p—xo关系曲线符合抛物线规律,即

p=-0.69+0.03xo-1.95×10-4xo2 (1)

式中:p为试样A与B的摩擦接触压力(MPa);xo为预混气流氧浓度(%)。

式(1)表示了Alloy C+钛合金点燃和不燃的边界(见图6中p—xo关系曲线)。从式(1)可见:随着xo的增大,p呈抛物线规律降低,表征了Alloy C+钛合金的抗点燃性能。

图6 Alloy C+钛合金摩擦点燃实验结果及p—xo关系曲线

Fig. 6 Test results and p—xo curve of frictional ignition of Alloy C+

从图6可以看出:当p在0.075~0.25 MPa变化时,着火对应的xo变化范围约为20%,说明Alloy C+钛合金的抗点燃性能对xo和p的敏感程度有所不同。当xo较低时,Alloy C+钛合金抗点燃性能对p较敏感,而随着xo增大,抗点燃性能对xo更加敏感。可以推测:在xo较低的空气环境中,Alloy C+钛合金的抗点燃性能主要由p控制。

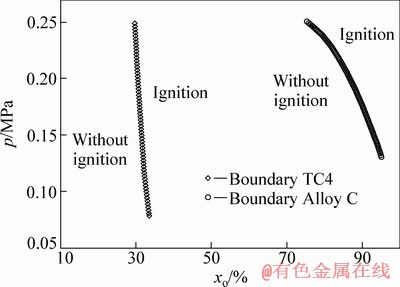

同理,根据不同(p,xo)条件下TC4钛合金点燃和不燃的实验点,通过数据处理,可以得到TC4钛合金的抗点燃性能,即

p=8.31-0.47xo+6.7×10-3xo2 (2)

可见:p在0.075~0.25 MPa变化时,着火对应的xo的变化范围约为4%,说明TC4钛合金的抗点燃性能对p不敏感,对xo更加敏感,即xo是控制TC4钛合金抗点燃性能的主导因素。

图7所示为Alloy C+和TC4钛合金的抗点燃性能比较。通过比较发现:在本实验条件下,Alloy C+钛合金的抗点燃性能远高于TC4的,点燃所对应的xo比TC4钛合金高40%以上。因而,图7也可作为本实验标准下两种钛合金的抗点燃评级图。

图7 Alloy C+钛合金的抗点燃评级图

Fig. 7 Rating chart of ignition resistance for Alloy C+

2.3 Alloy C+钛合金的抗点燃机理

在摩擦过程中,试样A与B的接触表面是粗糙的,存在着凹凸不平的微凸体(凸起或碎片),瞬间在微凸体上会出现极高的温度,可能会导致着火发生,所以,只要获得微凸体的温度即可以确定着火的临界温度。但是,微凸体的摩擦温升很难测量,只能通过理论计算或较大接触面积上的平均温度获得。通过上述分析可知,无论微凸体在试样B的中心孔边缘,还是在中心孔内部,微凸体的散热都很慢,均可以通过试样A与B的平均摩擦升温得到。假设Alloy C+钛合金的着火首先发生在金属原生表面的微凸体,由于摩擦做功加热升温为DT,故着火发生的临界温度(Tig)为

Tig=T0+DT (3)

式中:T0为微凸体的初始温度(K);DT为微凸体的温度变化(K),主要由摩擦生热产生。

摩擦过程中的能量状态采用下面方程描述[9](整个过程的热累积是摩擦热、氧化热、散热(传导、对流和辐射)以及变形能的速率函数):

(4)

(4)

式中: 为摩擦热;

为摩擦热; 为散热;

为散热; 为氧化热;

为氧化热; 为变形耗热。

为变形耗热。

通过积分处理得到合金在摩擦过程中的温度变化值,其中 ,得到

,得到

(5)

(5)

根据摩擦学基本知识,实验中的摩擦热可以近似为

(6)

(6)

式中:μ为摩擦因数;σs为材料的屈服强度;A为摩擦实际接触面积;ω为角速度;r为接触半径。

如果合金中的热累积足够使温度上升至使 ,着火发生,Glassman定义这个温度为临界温度[10],那么,综合式(3)~(6)得

,着火发生,Glassman定义这个温度为临界温度[10],那么,综合式(3)~(6)得

(7)

(7)

从式(7)可以看出:摩擦过程着火的临界温度主要影响因素有摩擦因数、材料的强度、接触面积以及比热容等。如果材料为Alloy C+钛合金,则根据摩擦过程中实验试样A的损失情况可知,摩擦5 s内,一方面,试样A与B的摩擦接触面积随接触压力增大而迅速增加,提高了试样B中心的热量;另一方面,随着试样A与B接触压力增大,微凸体的接触点不断增多,接触界面的间距不断减小,使微凸体接触点之间的相互热影响增大,即某个接触点的温升在相邻接触点上产生一个附加温升,所有微凸体的热累积效应将会使总的平均摩擦温升增大,即解释了试样A与B接触压力增大,摩擦温升增加的原因。考虑到实验过程中试样B接触面积的变化精确测量困难,所以,在固定摩擦接触面积条件下讨论摩擦升温。此时,摩擦因数对摩擦升温起到主要作用,因而必须结合摩擦磨损产物分析Alloy C+钛合金的抗点燃机理。

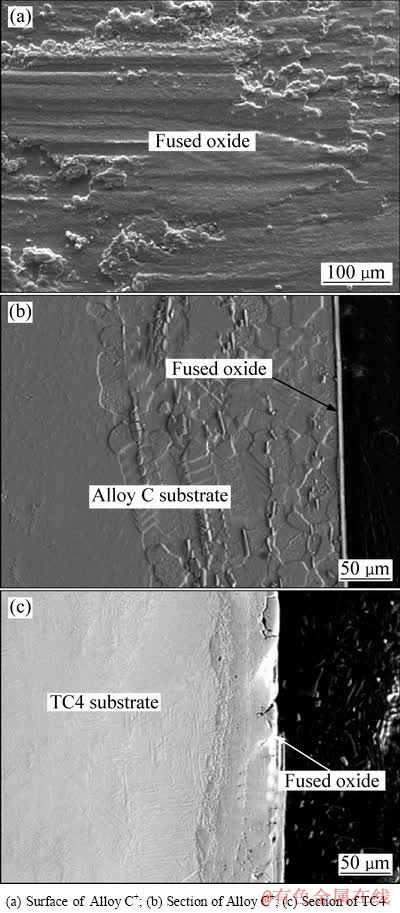

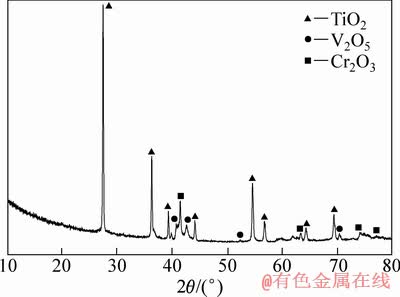

图8所示为Alloy C+钛合金摩擦不燃产物的SEM分析结果。从图8可以看到:磨损产物表面光滑呈黑色,存在明显的摩擦痕迹(图8(a));厚度为2~5 μm且与基体结合致密(图8(b));而常规TC4钛合金的磨损产物厚度为70~80 μm且不致密(图8(c))。通过XRD分析,磨损产物表面由V2O5、TiO2和Cr2O3 3种物相构成,如图9所示。由于V2O5为低熔点氧化物(熔点为675 ℃),所以,当摩擦升温超过V2O5的熔点时,摩擦接触面润滑条件迅速发生改变,液态“软化相”对摩擦副起到润滑作用,即摩擦因数突然减小(Alloy C+钛合金的摩擦因数测试实验结果给予支撑[11])。因此,根据式(7)知,摩擦作功为Alloy C+钛合金着火提供的热量大大降低。这主要是因为摩擦过程软质材料的实际接触面积较大,它降低了单位面积上的热量[12-13]。换句话说,摩擦过程试样的升温大大减小,从而大幅度降低了Alloy C+钛合金的着火危险。

图8 钛合金摩擦磨损产物SEM分析结果

Fig. 8 SEM results of frictional wear product

图9 Alloy C+钛合金摩擦磨损产物XRD分析结果

Fig. 9 XRD results of frictional wear products of Alloy C+

综上所述,Alloy C+钛合金的抗点燃机理可以解释为:高速摩擦作用使试样表面快速形成一层由V2O5、TiO2和Cr2O3构成的氧化物融合物,一方面最先形成的液态“软化相”V2O5弥合了“硬质相”TiO2和Cr2O3之间刚性连接产生的缺陷,极大地释放了表面氧化膜的内应力,使氧化膜的致密性及与基体的结合强度得到提高,减慢或阻止了氧的继续扩散,另一面使摩擦的润滑条件得到改善,试样表面的干摩擦转变为湿摩擦,摩擦因数大大减小,从而减少了摩擦生热,这种作用与潮湿火柴不容易点燃相类似。

3 结论

1) 建立了定量描述Alloy C+钛合金抗点燃性能的p-xo关系曲线,p随xo的增大呈抛物线规律下降,p在0.075~0.25 MPa变化时,xo的变化范围约为20%;Alloy C+钛合金摩擦过程产生强烈的火花,着火首先发生在摩擦试样的中心孔内。

2) Alloy C+钛合金的抗点燃性能比TC4钛合金高40%以上;当xo较低时,Alloy C+钛合金的抗点燃性能主要由p控制,随着xo增大,抗点燃性能对xo更加敏感,而xo是影响TC4钛合金抗点燃性能的主导因素。

3) Alloy C+钛合金的摩擦表面由TiO2、V2O5和Cr2O3等氧化物融合物构成,该层融合物的厚度为2~5 μm,这种融合物致密且具有良好的结合性,改善了摩擦的润滑条件,体现了“软化相”与“硬质相”之间的互补性作用,从而使摩擦区温度大大降低,起到抗点燃作用。

REFERENCES

[1] MI Guang-bao, HUANG Xiu-song, LI Pei-jie, CAO Jing-xia, HUANG Xu, CAO Chun-xiao. Non-isothermal oxidation and ignition prediction of titanium-chromium alloys[J]. Transaction of Nonferrous Metals Society of China, 2012, 22(10): 2409-2415.

[2] BERCZIK D M. Age hardenable beta titanium alloy: United States, 5176762[P]. 1993-01-05.

[3] 黄 旭, 曹春晓, 马济民, 王 宝, 高 扬. 航空发动机钛燃烧及阻燃钛合金[J]. 材料工程, 1997(8): 11-15.

HUANG Xu, CAO Chun-xiao, MA Ji-min, WANG Bao, GAO Yang. Titanium combustion in aeroengines and fire-resistant titanium alloys[J]. Journal of Materials Engineering, 1997(8): 11-15.

[4] 梁春华, 李晓欣. 先进材料在战斗机发动机上的应用与研究趋势[J]. 航空材料学报, 2012, 31(6): 32-36.

LIANG Chun-hua, LI Xiao-xin. Application and development trend of advanced materials for fighter engine[J]. Journal of Aeronautical Materials, 2012, 31(6): 32-36.

[5] ZHAO Y Q, ZHU K Y, QU H L, WU H, ZHOU L, ZHOU Y G, ZENG W D, YU H Q. Microstructures of a burn resistant highly stabilized β-titanium alloy[J]. Materials Science and Engineering A, 2000, 282: 153-157.

[6] SUN F S, LAVERNIA E J. Creep behavior of nonburning Ti-35V-15Cr-xC alloys[J]. Journal of Materials Engineering and Performance, 2005, 14(6): 784-787.

[7] 黄 旭, 朱知寿, 王红红. 先进航空钛合金材料与应用[M]. 北京: 国防工业出版社, 2012: 276-291.

HUANG Xu, ZHU Zhi-shu, WANG Hong-hong. Advanced aeronautical titanium alloys and applications[M]. China: National Defense Industry Press, 2012: 276-291.

[8] 弭光宝, 黄 旭, 曹京霞, 王 宝, 曹春晓. 一种表征航空发动机钛合金抗点燃性能的测试方法: 中国, 201218003649.0[P]. 2012-09-04.

MI Guang-bao, HUANG Xu, CAO Jing-xia, WANG Bao, CAO Chun-xiao. A test method characterizing the fireproof performance of titanium alloys for aero-engine: China, 201218003649.0[P]. 2012-09-04.

[9] GUNAJI M V, SIRCAR S, BEESON H D. Ignition and combustion of titanium and titanium alloys[C]//Flammability and Sensitivity of Materials in Oxygen-Enriched Atmospheres: 7th Volume, ASTM STF 1267. Philadelphia, USA, 1995: 81-85.

[10] GLASSMAN I, MELLOR A M, SULLIVAN H F, LAURENDEAU N M. A Review of metal ignition and flame models[C]//Conference Proceedings No. 52 NATO AGARD Annual Meeting. Paris, France, 1970: 11-30.

[11] 黄 旭. 钛合金阻燃机制研究[D]. 西安: 西北工业大学及北京航空材料研究院, 1998.

HUANG Xu. Fire-resistant mechanism of titanium alloy[D]. Xi’an: Northwestern Polytechnic University and Beijing Institute of Aeronautical Materials, 1998.

[12] BHUSHAN B. Magnetic head-media interface temperatures- part2: Application to magnetic tapes[J]. ASME J Trib, 1987, 109: 252-256.

[13] GULINO R, BAIR S, WINER W O, BHUSHAN B. Temperature measurement of microscopic areas within a simulated head/tape interface using infrared radiometric technique[J]. ASME J Trib, 1986, 108: 29-34.

(编辑 陈灿华)

基金项目:航空科学基金资助项目(20123021004);总装预研基金资助项目(51312030501)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:弭光宝,博士;电话:010-62946628;E-mail:miguangbao@163.com