采用混合元素法制备多孔Ni3Al材料

何晓宇,刘 咏,李 为,刘 彬

(中南大学 粉末冶金国家重点实验室,湖南 长沙,410083)

摘 要:利用NaCl颗粒为造孔剂,通过粉末冶金方法制备多孔结构的Ni3Al合金,并采用控制升温速度和保温时间的烧结工艺,添加不同质量分数的NaCl制备Ni3Al。研究造孔剂NaCl的添加量与Ni3Al合金的孔隙度、孔隙结构之间的关系。并研究采用元素粉末法制备多孔Ni3Al合金的反应过程与孔隙形成过程。结果表明,Ni3Al的多孔结构是由真空状态下材料中添加的NaCl挥发后所形成的,添加NaCl的量对材料孔隙度和孔隙结构有显著的影响,通过调节NaCl颗粒的大小可以直接控制材料中孔隙的大小,孔隙形状与NaCl颗粒的形状一致。孔隙度随NaCl添加量的提高而提高,材料密度随NaCl添加量的提高而降低,基本呈线性关系。当采用NaCl的质量分数为50%时,得到孔隙分布均匀、孔隙无聚集的多孔Ni3Al材料。

关键词:Ni3Al;密度;NaCl

中图分类号:TF124.31;TF124.5+3 文献标识码:A 文章编号:1672-7207(2009)02-0357-05

Preparation of porous Ni3Al material by blend element

HE Xiao-yu, LIU Yong, LI Wei, LIU Bin

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The porous Ni3Al alloy was prepared by using powder metallurgy method and employing NaCl particle with a defined particle size as pore-forming material. Meanwhile, the sintering parameters including the temperature rising rate and the holding time were controlled as well as different additional amounts of NaCl as pore-forming to fabricate Ni3Al. Moreover, the relationships between the additional amount of NaCl and porosity and structure were investigated. The mechanism of reaction using powder metallurgy method to prepare porous Ni3Al alloy was presented. The results indicate the porous structure of Ni3Al forms due to the volatilization of added NaCl in vacuum; the additional amount of NaCl has an important effect on material porosity and porous structure; the size of pore could be controlled by NaCl particle size directly, and the shape of pore correspondences with the shape of NaCl particle. This specimen porosity increases as the additional amount of NaCl increases while the density decreases and the relationship between them is nearly a line. When the additional amount of NaCl reaches 50%, the Ni3Al alloy with homogeneous distributed pore and without gathered pores can be obtained.

Key words: Ni3Al; density; NaCl

从1957年Westbrook[1]发现Ni3Al的强度随着温度的升高而提高的反常现象以来,引起了科学研究工作者的广泛关注。Ni3Al作为高温Ni基材料中的强化相,由于其具有良好的正温度性能,且在其熔点1 395 ℃之前具有良好的强度与韧性[2-4]。近些年,多孔反应器作为结构紧凑且高效的氢气生产系统引起了研究人员的高度重视,该系统使用酒精或碳氢化合物作为原料,因为比起传统反应器来,这种反应器有高的表面积-体积比,高的热导率和高的质量迁移[3-12]。在许多情况下,不锈钢和硅基材料被用作结构板,同时要把活化催化剂以及多孔支撑材料通过复杂的化学过程镀在结构板上[3-9]。但是,不锈钢的隔热性能不好,而硅基材料的成型性和机械强度不高,这些缺点限制了以上材料在微管反应器中的应用。因此,开发既具有优良隔热性能又具有良好成型性和机械强度的材料是十分必要的。Ni3Al基合金有许多优良的性能[13],如具有熔点高、密度小、比强度高、抗氧化性能好的优点,而在一定温度下,屈服强度还随温度的上升而提 高[14]。多孔Ni3Al既具有Ni3Al基合金的熔点高、抗氧化性能好的优点,又具有较好的隔热性能,与其他常用的不锈钢多孔材料、硅基多孔材料相比较作为多孔反应器具有较好的综合性能。

目前,Chun等[15]对多孔Ni/Ni3Al作为燃料电池阳极的高温蠕变性能进行了相关的研究,Hiranou等[16]研究了Ni3Al制成蜂窝结构作为甲醇的分解催化剂制氢的性能。但上述研究中多孔Ni3Al材料中存在孔隙大小不可控、孔隙分布不均匀的问题。本文作者拟采用一定大小NaCl颗粒作为造孔剂制备多孔的Ni3Al合金,并对孔隙控制进行研究。

1 实 验

本实验采用纯度为99.9%的还原Ni粉,气雾化Al粉,纯NaCl 经研磨后过孔径为75 μm筛,将Ni粉与Al粉按摩尔比3?1混合,在V型混料机中混合2 h,然后分别添加不同质量分数的NaCl,再混合2 h。在直径为12 mm的模具中压制成型,压制压力为600 MPa,在真空烧结炉中,600 ℃保温3 h,900 ℃保温1 h,1 000 ℃保温1 h,后随炉冷却。通过X射线衍射仪(XRD)、扫描电子显微镜(SEM)分析所制备样品的显微组织和成分,并对样品采用排水法进行密度与孔隙度的测试。

2 实验结果

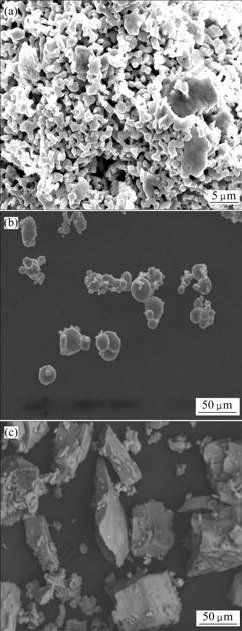

图1(a)所示为Ni粉的形貌。可见主要呈树枝状,存在少量的团聚现象。图1(b)所示为Al粉的形貌,可以看出采用气雾化制备的Al粉呈圆球状,存在少量的卫星颗粒。

图1(c)所示为NaCl的原始形貌。可以看出NaCl粉末形状不规则,呈现多边形岩石状。其颗粒的大小介于50~100 μm。激光粒度测试后,Al粉的平均粒度为10 μm,Ni粉的平均粒度为3 μm。

(a) 镍粉; (b) 铝粉; (c) NaCl粉

图1 原料粉末的形貌

Fig.1 Morphologies of raw powders

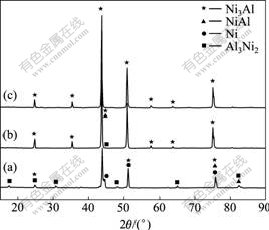

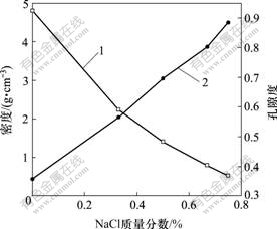

图2所示为Ni和Al元素粉末在不同条件下烧结后的XRD谱。可见,在600 ℃烧结2 h后,存在Ni3Al,NiAl,Ni和Ni2Al3相,不存在Al相。在1 000 ℃烧结1 h后烧结坯中仅存在Ni3Al相,表明反应已完全。在添加NaCl的材料中经烧结后没有NaCl相的存在,表明其已经完全挥发了。图3所示为添加NaCl的质量分数与材料密度及孔隙度之间的关系。从图中可以看出随着造孔剂含量的增加,材料的密度呈降低的趋势,材料孔隙率呈上升的趋势。材料孔隙度与造孔剂的添加量两者之间呈近线性关系。

(a) 600 ℃; (b) 1 000 ℃; (c) 添加NaCl,1 000 ℃

图2 不同烧结条件下样品的XRD谱

Fig.2 XRD patterns of specimen at different sintering conditions

1—合金密度;2—孔隙度

图3 Ni3Al合金密度、孔隙度与造孔剂添加量的关系

Fig.3 Relationships between density, porous of Ni3Al alloy and addition amount of pore-forming material

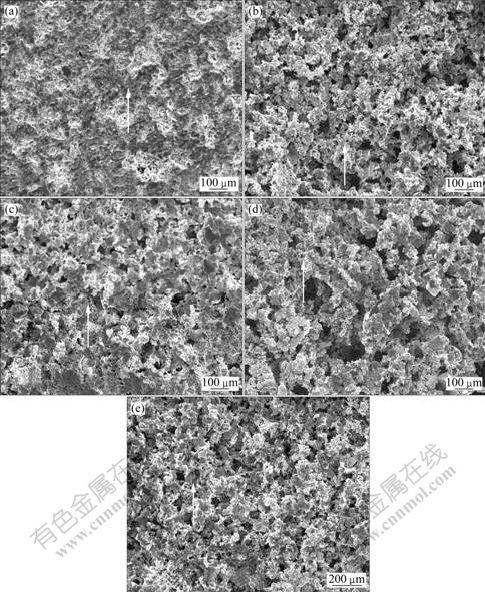

图4所示为不同NaCl添加量时Ni粉与Al粉烧结后的显微组织。从图中可以看出烧结后的坯体无较大的孔隙,添加NaCl烧结后的坯体,存在大的孔隙。随着NaCl含量的增加,孔隙的数量也增多,当NaCl的含量小于或等于50%时,孔隙大小只介于50~100 μm,不存在大于100 μm的孔隙。但当NaCl的含量大于50%时,孔隙开始出现聚集的现象,出现大于100 μm的孔隙。随着NaCl含量的继续增加,原来那些大小介于50~100 μm的孔隙数量减少,大于100 μm的孔隙数量逐渐增多。但未添加NaCl与添加NaCl烧结后的烧结坯中都存在细小的孔隙,如白色箭头处所示。

(a) 0; (b) 33%; (c) 50%; (d) 67%; (e) 75%

图4 添加不同质量分数NaCl的Ni3Al坯体的显微组织

Fig.4 Microstructures of Ni3Al specimen with different amounts of NaCl

3 分析与讨论

Ni-Al体系中,Al的熔点是660 ℃。X射线衍射分析结果表明,在600 ℃反应2 h后就没有Al相存在,表明此时Al已经完全扩散到Ni中去了。由于烧结温度低于Al的熔点,故本实验在烧结过程中没有液态Al的出现,此时反应过程主要是由扩散反应控制。在图4中几乎没有观察到任何的NaCl相,表明反应烧结后无NaCl残留,这也与图2中X射线衍射分析结果相符合。在经过600 ℃保温3 h后再在900 ℃时保温1 h,液态的NaCl在真空下挥发,此时NiAl,Ni2Al3与Ni继续发生反应,生成Ni3Al。由于Al原子在Ni中扩散的浓度梯度降低了,故反应速度较慢,反应也进行得不够完全,所以此时依然还有残留的Ni和NiAl等。在1 000 ℃时两者继续反应,Ni与NiAl继续反应生成Ni3Al,同时产生粉末颗粒的烧结,使粉末之间的空隙减少,XRD谱表明1 000 ℃保温1 h后完全生成Ni3Al。

在本实验中使Ni与Al 先在600 ℃时保温3 h,使两者充分发生扩散反应。在此温度下Ni与Al之间产生较慢的扩散,主要生成NiAl和Ni2Al3,另外还有一些未完全反应的Ni。在900 ℃时保温1 h,由于NaCl的熔点为801 ℃,此温度超过了材料中NaCl的熔点而呈液态,在此温度下通过真空挥发的方法可以去除多余的NaCl。根据式(1)[17]:

。 (1)

。 (1)

式中:p为物质的饱和蒸汽压;A,B,C和D为系数;T为温度。在900 ℃时熔融的NaCl的饱和蒸汽压为245 Pa[17]。在抽真空的情况下,此时的气压仅为0.1 Pa,远小于NaCl的饱和蒸汽压。此时NaCl从液态直接变成气态,于水冷套的水冷处凝结析出。在此温度下,NaCl从材料中挥发出来,原来NaCl所占据的位置成为孔隙,孔隙大小与NaCl的颗粒大小相同,这与材料烧结后显微组织中的孔隙大小情况一致。

Ni粉、Al粉反应烧结后在材料中存在的细小微孔隙,主要由两种类型的孔隙组成。一种是粉末压坯中粉末颗粒之间的孔隙经烧结后的残留。这种孔隙的存在是因为粉末冶金压坯中颗粒之间存在孔隙,经烧结后,在原子的迁移扩散、蒸发凝聚等机制的共同作用下,孔隙仍未完全闭合所残留下来的。另一种是偏扩散产生的孔隙。这种孔隙是由于在烧结扩散过程中原子的扩散速率不同所导致的结果,在反应过程中Al在Ni中的扩散速度大于Ni在Al中的扩散速度[18],这样Al向Ni中扩散,Al扩散到Ni的原子晶格后,原来Al的位置所残留的孔隙,这样就产生了由于两种不同原子的扩散速率不同而造成的偏扩散微孔。在这两类孔隙中,较大的细小孔隙是粉末压制过程中存在的孔隙在烧结后的残留,较小的孔隙是由于偏扩散所产生的。

添加NaCl的量,对多孔材料性能有重要的影响。添加NaCl的量过少,孔隙太少,不利于气体液体的通过。添加NaCl的量过多,又会导致材料的力学性能下降而不具备足够的强度,同时也会由于孔隙的聚集而产生孔隙大小不能控制的现象。当添加的量小于或等于50%时,此时材料的孔隙主要介于50~100 μm之间,这时NaCl造成的孔隙在材料中分布均匀,当大于50%时,NaCl造成的孔隙在材料中分布不均匀,开始出现孔隙大于100 μm的孔隙,产生上述现象的原因可能由以下2种因素造成:一是在混合过程中由于NaCl含量过多导致的混合不均匀而出现的NaCl颗粒的聚集,二是由于在烧结过程中出现液相的NaCl,由于NaCl含量较多而出现液相的NaCl在表面张力作用下相互聚集而形成熔盐池,熔盐池在真空挥发后形成较大的孔隙。

4 结 论

a. Ni3Al的多孔结构主要是依赖于在900 ℃时,作为造孔剂的NaCl在真空状态下从材料中挥发后而形成的。

b. 采用NaCl为造孔剂制备出多孔的Ni3Al,当NaCl的质量分数不大于50%时,通过NaCl颗粒的大小可控制材料中孔隙的大小,所得孔隙形状与NaCl颗粒的形状一致。

c. 孔隙度随NaCl添加量的提高而提高,即材料密度随NaCl添加量的提高而降低,基本呈线性关系。当NaCl的质量分数为50%时,得到孔隙分布均匀、孔隙无聚集的多孔Ni3Al材料。

参考文献:

[1] Westbrook J H. Grain boundary segregation and the grain size dependence of strength of nickel-sulfur alloys[J]. Trans AIME J Met, 1957, 6(3): 895-898.

[2] Liu C T, Kumar K S. Ordered intermetallic alloys. Part Ⅰ: Nickel and ion aluminides[J]. JOM, 1993, 45(5): 38-44.

[3] Yang J M, Kao W H, Liu C T. Development of nickel aluminum matrix composites[J]. Materials Science and Engineering A, 1989, 107(1): 81-91.

[4] Janicke M T, Kestenbaum H, Hagendorf U, et al. Newly applied two-dimensional solid-state NMR correlation techniques for the characterization of organically modified silicates[J]. Journal of Catalysis, 2000, 191(2): 282-286.

[5] Yu X, Tu S T, Wang Z, et al. Development of a microchannel reactor concerning steam reforming of methanol[J]. Chemical Engineering Journal, 2006, 116(2): 123-132.

[6] Won J Y, Jun H K, Jeon M K, et al. Performance of microchannel reactor combined with combustor for methanol steam reforming[J]. Catalysis Today, 2006, 111(3/4): 158-163.

[7] 刘 咏, 黄伯云, 贺跃辉, 等. 热压反应合成 TiAl 合金的密度及孔隙分布[J]. 中南大学学报: 自然科学版, 1998, 29(5): 446-449.

LIU Yong, HUANG Bai-yun, HE Yue-hui, et al. Distribute of density and porosity of TiAl alloy compound by hot-pressing[J]. Journal of Central South University: Science and Technology, 1998, 29(5): 446-449.

[8] Kawamura Y, Ogura N, Yamamoto T, et al. A miniaturized methanol reformer with Si-based microreactor for a small PEMFC[J]. Chemical Engineering Science, 2006, 61(4): 1092-1101.

[9] 郭建亭. 金属间化和物NiAl的研究进展[J]. 中南大学学报: 自然科学版, 2007, 38(6): 1013-1027.

GUO Jian-ting. Research progress of intermetallic NiAl alloys[J]. Journal of Central South University: Science and Technology, 2007, 38(6): 1013-1027.

[10] Bodke A S, Bharadwaj S S, Schmidt L D, et al. Carbon formation on and deactivation of nickel-based/zirconia anodes in solid oxide fuel cells running on methane[J]. Catalysis Today, 1998, 46(2/3): 137-145.

[11] Aartun I, Venvik H J, Holmen A. Temperature profiles and residence time effects during catalytic partial oxidation and oxidative steam reforming of propane in metallic microchannel reactors[J]. Catalysis Today, 2005, 110(1/2): 98-107.

[12] Wanat E C, Suman B, Schmidt L D. Partial oxidation of alcohols to produce hydrogen and chemicals in millisecond-contact time reactors[J]. Journal of Catalysis, 2005, 235(1): 18-27.

[13] Devis C, Skka V K. Nickel and ion aluminides-an view on properties, processing and application[J]. Intermetallics, 1996, 4(5): 357-375.

[14] 张永刚, 韩雅芳, 陈国良. 金属间化合物结构材料[M]. 北京: 国防工业出版, 2001: 552-630.

ZHANG Yong-gang, HAN Ya-fang, CHENG Guo-liang. Structural material of intermetallics[M]. Beijing: National Defense Industry Press, 2001: 552-630.

[15] Kim Y S, Lee K Y, Chun H S. Creep characteristics of porous Ni/Ni3Al anodes for molten carbonate fuel cells[J]. Journal of Power Sources, 2001, 99(1/2): 26-33.

[16] Dong H C, Ya X, Hirano T. Spontaneous catalytic activation of Ni3Al thin foils in methanol decomposition[J]. Journal of Catalysis, 2006, 243(1): 99-107.

[17] 梁英教, 车荫昌. 无机物理化学数据手册[M]. 沈阳: 东北大学出版社, 1993: 520-521.

LIANG Ying-jiao, CHE Yin-chang. Data book of inorganic physical chemistry[M]. Shenyang: North East University Press, 1993: 520-521.

[18] 索进平, 胡定安, 冯 涤, 等. Ni3Al复合材料生产工艺[J]. 材料生产工艺, 2000, 8(1): 93-100.

SUO Jing-ping, HU Ding-an, FENG Di, et al. Production technology of Ni3Al compound material[J]. Material Production Technology, 2000, 8(1): 93-100.

收稿日期:2008-05-14;修回日期:2008-08-20

基金项目:国家自然科学重点基金资助项目(50634060);国家自然科学基金面上资助项目(50704037)

通信作者:刘 咏(1973-),男,江西萍乡人,教授,从事先进粉末冶金材料研究;电话:0731-8830406;E-mail: yonliu@mai.csu.edu.cn