DOI: 10.11817/j.issn.1672-7207.2016.05.029

全尾砂浆最佳絮凝沉降参数

王新民,赵建文

(中南大学 资源与安全工程学院,湖南 长沙,410083)

摘要:为了得到最佳的絮凝沉降参数,研究使用BP神经网络进行优化选择。通过对比分析,将输入因子简化为絮凝剂单耗和尾砂质量分数2个因子,输出因子简化为沉降速度1个因子;通过正交试验,建立网络学习、训练样本,优选出最佳网络模型。扩大正交试验,增加输入因子水平,组合优选样本,搜索最佳絮凝沉降参数。以司家营铁矿全尾砂絮凝沉降为例,优选出絮凝剂单耗为10 g/t,尾砂质量分数为18%,预测沉降速度为1.38 m/h,满足生产要求,比原生产所需絮凝剂单耗节省50%。应用结果表明:该研究成果效果显著,为絮凝沉降参数优选提供一种新思路。

关键词:絮凝剂单耗;尾砂;絮凝沉降;网络模型

中图分类号:TD853 文献标志码:A 文章编号:1672-7207(2016)05-1675-07

Optimal flocculating sedimentation parameters of unclassified tailings slurry

WANG Xinmin, ZHAO Jianwen

(School of Resources and Safety Engineering, Central South University, Changsha 410083, China)

Abstract: Back-Propagation neural network was occupied in order to obtain the optimization of the flocculating sedimentation parameters. By practising comparison analysis, input data were simplified as the flocculating agent consumption and tailings concentration, and the sedimentation speed as the synthesized output data. By performing the numbered orthogonal tests, some learning and training samples were established so as to get the best network mode. Then, the best parameters were acquired using the selected network by expanding the orthogonal tests, increasing the levels of the parameters, optimizing the samples and exploring the optimization of the flocculating sedimentation parameters. BP neural network mode was applied in Sijiayin Iron Mine. The results show that the flocculating agent consumption and tailings mass fraction are 10 g/t, 18% respectively, and the sedimentation speed is 1.38 m/h, which meet the production requirements and save 50% compared to the original production. The application indicates that this mode makes significant effect, providing a novel method to obtain the optimization of the flocculating sedimentation parameters.

Key words: flocculating agent consumption; tailings; flocculating sedimentation; network mode

全尾砂由于其来源广泛、成本低廉常作为主要的充填骨料。尾砂来源于选矿后排出的全尾砂浆,其质量分数一般仅为10%~20%,无法直接制备高质量分数的充填料浆。低质量分数的充填料浆充入井下,会带来脱水量大、充填质量低、封堵难等一系列问题。为此在生产中,高质量分数充填成为了一种趋势。高质量分数充填一般指充填料浆的质量分数达到75%~ 80%,在输送过程中不发生离析、脱水、分层现象,完成充填作业的过程[1]。高质量分数充填料浆制备过程中,最关键的因素就是全尾砂浆的浓缩沉降。传统的全尾砂充填中,全尾砂在立式砂仓中依靠自然沉降浓缩成质量分数为60%~70%的全尾砂浆。由于立式砂仓的断面较小,低质量分数的全尾砂浆进入立式砂仓后,其自然沉降速度慢,沉降路径较短,导致溢流水含固量量高,跑浑现象严重。为加快全尾砂的沉降速度,实践生产中主要通过添加絮凝剂来实现全尾砂的快速沉降。提高全尾砂浆的浓缩沉降,一些学者针对不同矿山的全尾砂进行了大量的室内试验。张钦礼 等[2]选择絮凝剂单耗及质量分数、尾砂质量分数作为变量,进行了全尾砂的浓缩沉降试验,并利用spss软件进行回归分析。王洪武等[3]研究了五道岭钼矿全尾砂浆在不同因素影响条件下的絮凝沉降特性。史秀志等[4]针对不同质量分数的全尾砂浆液选用不同分子量的阴离子聚丙烯酰胺,并配以一定量的氯化铁,进行了全尾砂絮凝沉降试验。以上学者对全尾砂絮凝沉降参数的选取,均是在有限的室内试验基础上进行的。但仅仅通过实验室有限的试验来选择最佳的絮凝沉降参数,往往具有一定的局限性。BP神经网络具有较强的容错、联系、学习、抗干扰、非线性动态处理能力,可实现输入因子和输出因子之间的非线性映射关系,能灵活方便地对少数据、贫信息等问题的建模。石灵芝等[5]在根据长沙火车站监测点全年气象参数平均数据的基础上,建立了BP神经网路对长沙火车站的大气污染物PM10小时质量分数的预测模型;蒋建平等[6]在仅选取4个常规物理参数作为主要影响因素的条件下,利用BP神经网络对土压缩系数进行了预测;姜安龙[7]利用BP神经网路建立了回采巷道围岩稳固性的知识表达系统,解决了山东兖州煤矿巷道稳定性判别困难的问题。本文作者研究通过对比分析,简化输入、输出因子,进行正交试验,建立网络学习、训练样本,优选出最佳网络模型;扩大正交试验,增加输入因子水平,组合优选样本,搜索最佳絮凝沉降参数。

1 BP神经网络预测、优选模型

1.1 输入、输出因子

全尾砂在立式砂仓中的浓缩沉降是一个多因素影响的过程,主要影响因素有:尾砂的物理、化学性质,全尾砂浆的质量分数以及絮凝剂的性质和用量。在高质量分数全尾砂充填过程中,尾砂的来源是固定的,其物理化学性质是一定的;对于金属矿山全尾砂浆浓缩使用的絮凝剂大多为聚丙烯酰胺。在尾砂性质和絮凝剂性质一定的情况下,影响全尾砂絮凝沉降效果的主要因素为全尾砂浆质量分数和絮凝剂的用量。

1) 全尾砂浆质量分数较低时,尾砂颗粒间的相互作用力较小,絮凝剂可以较好地作用于尾砂颗粒,形成较大的絮凝团,在重力作用下加速沉降,但其沉降质量分数较低,无法满足放砂质量分数的要求;当全尾砂质量分数较高时,虽然可以形成较高的沉降质量分数,但由于尾砂颗粒间的相互作用较大,沉降速度慢。

2) 为满足立式砂仓动态放砂的要求,需要增加絮凝剂的用量来加速全尾砂的沉降速度,但如果絮凝剂添加过量,则不仅会造成药剂的浪费,成本的增加,而且会造成溢流水中絮凝剂含量增高,造成二次污染[8-9]。

因此,确定絮凝剂沉降参数优选模型的输入因子为全尾砂浆质量分数和絮凝剂单耗。

全尾砂絮凝沉降的目的在于高效率地制备高质量分数的全尾砂浆,评价全尾砂絮凝沉降效果的指标有沉降速度、沉降质量分数、溢流水含固量等。

1) 沉降速度。为实现立式砂仓动态放砂,需保证放砂速度等于沉砂速度。在室内试验中,沉砂速度即为固液面下沉的速度,通过测定固液面随时间的变化来计算。

2) 沉砂质量分数。全尾砂进入立式砂仓完成絮凝沉降后,在立式砂仓底部的浆体质量分数,也称放砂质量分数。为配置质量分数较高的浆体,放砂质量分数越高越好。在室内试验中通过测定沉降结束后固液面下浆体的质量来计算。

3) 溢流水含固量。全尾砂进入立式砂仓后,大部分尾砂颗粒在自重或絮凝作用下下沉,少部分尾砂颗粒还没来得及下沉就随着上层溢流水流出砂仓。溢流水含固量的高低直接影响溢流水的回收处理费用。

质量分数一定的全尾砂浆进入立式砂仓后,浆体的总质量不变,尾砂固体颗粒的总质量不变,则溢流水中固体含量与放砂质量分数是相对立的,放砂质量分数越大,溢流水固体越低,反之亦然。当絮凝剂单耗确定后,全尾砂的沉降速度、沉砂质量分数也就相应确定。沉降速度和沉砂质量分数同时存在,是反映沉降效果问题的2个方面,不应重复考核。本次研究选择沉降速度作为评价絮凝沉降效果的指标。

因此,确定絮凝剂沉降参数优选模型的输出因子为沉降速度。

1.2 学习样本和训练样本确定

通过上述分析,简化了BP神经网络预测输入、输出因子。在此基础上,根据矿山的具体情况,为输入因子(絮凝剂单耗、尾砂质量分数)选择若干个合理的水平,建立正交试验表,进行有限次的正交试验,经统计求得输出因子—沉降速度;并最终得到BP神经网络的学习样本和训练样本。

但是,正交试验所进行的组合是有限的,而且往往没有包含最优水平组合。因此,必须进一步细化输入因子水平,增加其水平组合情况,形成参数预测、优选的样本集,以此来得到最佳的絮凝沉降参数。

1.3 BP神经网络模型

本次研究所建立的BP网络模型的输入因子是絮凝剂用量和全尾砂浆质量分数,输出因子为沉降速度。模型建立过程中,最重要的是隐含层节点数的选择:

<

< (1)

(1)

<

< (2)

(2)

(3)

(3)

式中:n为输入因子数;m为输出因子数;a为0~10之间的常数。根据上式,本次研究所建立模型隐含层的合理节点数应该为5~12,建立模型后,通过对不同隐含层数目情况进行收敛速度和预测误差的比较,从而选出最佳的隐含层数,确定隐含层节点数[10]。

对样本集中的数据进行归一化处理,以避免不同指标间出现量级差别,归一化采用的函数为x’=(x-min(x))/(max(x)-min(x))。数据归一化处理后的都处于[0,1]内,此时模型隐含层的神经元传递函数可以采用S型正切函数tansig,其输出层的传递函数可以采用对数函数logsig。预测后对输出结果进行反归一化处理,即x = x′(max(x)-min(x))+min(x)。

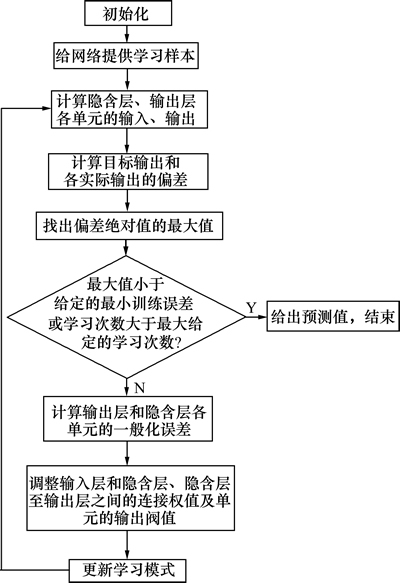

全尾砂絮凝沉降参数的BP神经网络预测模型的算法流程如图1所示。

2 应用实例

以司家营铁矿为例,用BP神经网络进行絮凝沉降参数预测、优选。司家营铁矿超大能力超细全尾砂充填系统,使用立式砂仓全尾砂高质量分数充填,立式砂仓直径为11 m,系统充填能力为200 m3/h。全尾砂快速沉降是实现高质量分数连续充填的关键,而全尾砂进入立式砂仓后絮凝沉降参数选择的优劣是能否实现全尾砂快速沉降的最重要因素[11-12]。本次研究针对司家营铁矿超细全尾砂的性能,选取合理的絮凝剂,进行正交试验从而得到BP神经网络的其学习、训练的样本。

图1 神经网络算法

Fig. 1 Arithmetic in neural network

2.1 全尾砂物理性质

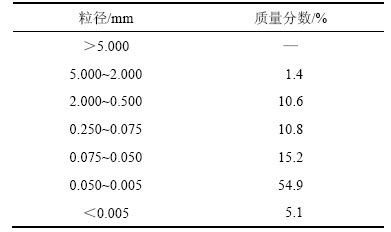

所取司家营铁矿全尾砂粒级组成见表1,主要物理力学性能测定结果见表2。由表1可知:全尾砂粒度非常细,中值粒径仅为0.034 mm,粒径小于74 μm颗粒的质量分数高达75.2%,粒度过细,其表面积较大,在水中形成的结合水膜丰富,导致其在水中的自然沉降速度非常小[13-15],仅靠自然沉降远远不能满足动态放砂的要求,必须采用絮凝沉降。

表1 全尾砂不同粒径颗粒质量分数

Table 1 Particle size composition of unclassified tailings

表2 全尾砂物理和力学性能

Table 2 Physical and mechanical properties of unclassified tailings

为实现全尾砂在立式砂仓中动态放砂,其沉降速度应大于等于放砂速度。沉降速度等于放砂能力与沉降面积的比值,立式砂仓断面为94.99 m2,放砂能力不小于100 m3/h,则其沉降速度应≥1.05 m/h。

2.2 正交试验

根据司家营铁矿全尾砂的性质,选择3种比较典型的絮凝剂单耗q(g/t)和尾砂质量分数w (%)组合进行正交试验,从而选用可安排二因素、三水平试验的正交试验表,试验水平如表3所示。表4所示为参数优选试验结果(训练样本集)。

表3 试验因素与水平

Table 3 Factors and levels in test

按照试验设计,在实验室通过量筒试验测定沉降速度,即为学习样品本输出向量。试验过程中通过测定不同时间和沉降界面的高度来计算沉降速度。

表4 参数优选试验结果(训练样本集)

Table 4 Optimization test result (samples of training)

2.3 预测及优选

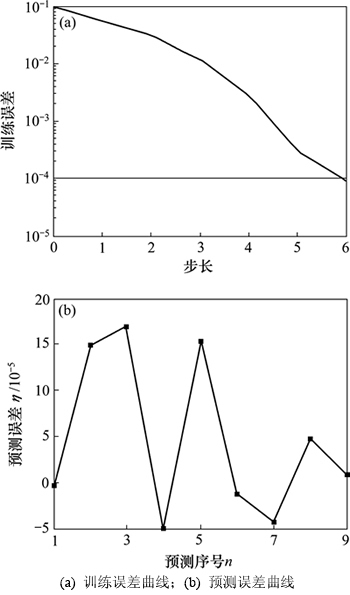

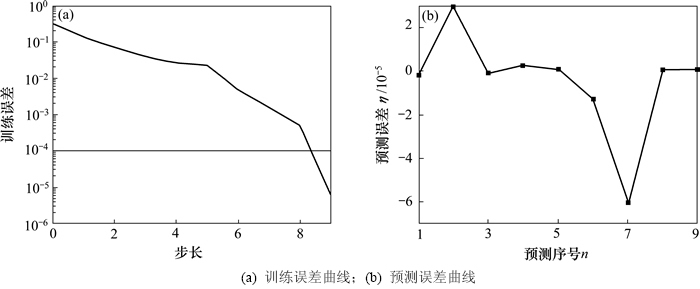

建立BP神经网络时,首先对网络进行调试,确定最佳隐含层节点数[16-17],分别取5,9和12这3种情况,并以表3提供的9组数据为训练样本,分别检查网络性能,得出网络训练误差和预测误差曲线,结果如图3~5所示。由图3~5可见:当隐含层节点数为5时,经过6步运算达到要求,其最大预测误差为0.017;当节点数为9时,需经过9步计算,最大预测误差为0.006;当节点数为12时,需经过6步计算,最大预测误差为0.025。因此,最近的隐含层接点数为9,此时所建模型的收敛速度快,最大预测误差小。

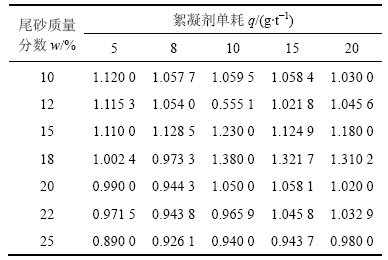

为了搜索出最优的絮凝沉降参数,将絮凝剂单耗进一步划分为5,8,10,15和20共5个水平,尾砂质量分数进一步划分为10,12,15,18,20,22和25共7个水平,总计35种组合,以此为预测、优选样本进行搜索,结果见表5。

絮凝沉降参数预测优化结果表明:

1) 通过对比预测模型的收敛速度和最大预测误差,选择最佳的隐含层接点数,是保证模型预测准确的首要条件[18-19]。

图2 BP神经网络性能曲线(隐单元数为5)

Fig. 2 Capability curve of BP neural network (concealed cell is 5)

图3 BP神经网络性能曲线(隐单元数为9)

Fig. 3 Capability curve of BP neural network (concealed cell is 9)

图4 BP神经网络性能曲线(隐单元数为12)

Fig. 4 Capability curve of BP neural network (concealed cell is 12)

表5 絮凝沉降参数搜索结果

Table 5 Search result of flocculating sedimentation parameter

2) 本次研究建立的BP神经网路预测模型具有较强的预测能力,通过输入絮凝剂单耗、全尾砂浆质量分数可以较精确地预测出全尾砂的沉降速度。预测模型建立过程中,学习样本的建立以室内正交试验数据为依据,对多个水平的输入因子组合进行搜索,得出了更为详细的输出因子值,输入因子的选取依托于矿山实际情况,其水平选择合理,预测结果满足要求。

3) 由表5可以看出:全尾砂的沉降速度与絮凝剂单耗、尾砂质量分数并不呈线性关系,在絮凝剂单耗较小时,沉降速度随质量分数的增大而减小。在尾砂质量分数较高时,沉降速度随着絮凝剂用量的增大而增大。其主要原因在于过量的絮凝剂无法与全部尾砂颗粒发生反应,絮凝剂本身形成絮凝团,由于其密度小,在水中的沉降速度慢。因此,合理的絮凝剂单耗与尾砂质量分数两者密切相关,单一地增加絮凝剂单耗、降低尾砂质量分数,并不能达到增加沉降速度的要求。

综合以上原因,司家营铁矿絮凝沉降最佳参数预测结果:絮凝剂单耗为10 g/t,尾砂质量分数为18%,此时全尾砂在立式砂仓中的沉降速度最快(1.38 m/h),沉降效果最好,且大于1.05 m/h,满足动态放砂需要。而目前司家营铁矿采用的絮凝沉降参数参考于同类矿山,絮凝剂单耗为20 g/t,尾砂质量分数15%,其沉降速度为1.18 m/h,虽也满足动态放砂的要求,可絮凝剂的单耗增加1倍。通过司家营铁矿的生产实践,验证了本次研究内容的实用性,该研究成果有效地降低了全尾砂絮凝沉降成本,提高了絮凝沉降效果。

3 结论

1) 利用BP神经网路建立全尾砂浆絮凝沉降参数优选预测模型。模型建立过程中,首选通过对比分析,确定输入因子为絮凝剂单耗和全尾砂质量分数,输出因子为沉降速度,大大简化了神经网路体系,从而提高了网路模型的学习及训练速度,降低了预测误差。

2) 全尾砂的沉降速度与絮凝剂单耗和尾砂质量分数并不呈线性关系,并非单耗越高,质量分数越低,沉降速度越快。通过设计正交试验,产生样本集,选取合理的隐含层节点数;通过扩大正交试验,进行输入因子多水平组合,得出预测和优选样本,并使用BP神经网络实现最优絮凝沉降参数搜索。

3) 运用BP神经网络模型对司家营铁矿絮凝沉降参数进行预测优化,避免传统全尾砂絮凝沉降参数选择的盲目性,减少室内大量试验的工作量,降低了生产成本。同时,也为其他矿山全尾砂絮凝沉降参数优化研究提供了一种新的思路。

参考文献:

[1] 王洪江, 吴爱祥, 肖卫国, 等. 粗粒级膏体充填的技术进展及存在的问题[J]. 金属矿山, 2009, 401(11): 1-5.

WANG Hongjiang, WU Aixiang, XIAO Weiguo, et al. The progresses of coarse paste fill technology and its existing problem[J]. Metal Mine, 2009, 401(11): 1-5.

[2] 张钦礼, 周登辉, 王新民, 等. 超细全尾砂絮凝沉降试验研究[J]. 广西大学学报(自然科学版), 2013, 38(2): 451-455.

ZHANG Qinli, ZHOU Denghui, WANG Xinmin, et al. Experimental study on flocculating sedimentation of ultra-fine unclassified tailings[J]. Journal of Guangxi University (Nat Sci Ed), 2013, 38(2): 451-455.

[3] 王洪武, 吴爱祥, 刘超, 等. 五道岭钼矿全尾砂絮凝沉降试验研究[J]. 昆明理工大学学报, 2010, 35(2): 1-4.

WANG Hongwu, WU Aixiang, LIU Chao, et al. Experimental study on unclassified tailings flocculation and settlement in Wudaoling Molybdenum Mine[J]. Journal of Kuming University of Science and Technology, 2010, 35(2): 1-4.

[4] 史秀志, 胡海燕, 杜向红, 等. 立式砂仓尾砂浆液絮凝沉降试验研究[J]. 矿冶工程, 2010, 30(3): 1-3.

SHI Xiuzhi, HU Haiye, DU Xianghong, et al. Experimental study on flocculating sedimentation of tailings slurry in a vertical sand tank[J]. Mining and Metallurgical Engineering, 2010, 30(3): 1-3.

[5] 石灵芝, 邓启红, 路婵, 等. 基于BP人工神经网络的大气颗粒物PM10质量浓度预测[J]. 中南大学学报(自然科学版), 2012, 43(5): 1969-1974.

SHI Lingzhi, DENG Qihong, LU Chan, et al. Prediction of PM10 mass concentrations based on BP artificial neural network[J]. Journal of Central South University (Science and Technology), 2012, 43(5): 1969-1974.

[6] 蒋建平, 章杨松, 阎长虹, 等. BP神经网络在地基土压缩指数预测中的应用[J]. 中南大学学报(自然科学版), 2010, 41(2): 722-724.

JIANG Jianping, ZHANG Yangsong, YAN Changhong, et al. Application of BP neural network in prediction of compression index of soil[J]. Journal of Central South University (Science and Technology), 2010, 41(2): 722-724.

[7] 姜安龙, 戚玉亮. 粗糙集-BP神经网络组合方法及其应用[J]. 中南大学学报(自然科学版), 2011, 42(10): 3190-3193.

JIANG Anlong, QI Yuliang. Method of rough sets-back propagation neural network and its application to identification of surrounding rock stability[J]. Journal of Central South University (Science and Technology), 2011, 42(10): 3190-3193.

[8] HU Huiping, ZHANG Kunyu, ZHANG Lijuan, et al. Behaviour of polyacrylamidomethyltrimethyl ammonium chloride in red mud separation process[J]. Journal of Central South University, 2008, 6(15): 808-810.

[9] YUAN Yining, CHAI Liyuan, YANG Zhihui. Application of polymeric aluminum salts in remediation of soil contaminated by Pb, Cd, Cu, and Zn[J]. Journal of Central South University, 2013, 20(6): 1638-1640.

[10] 赵彬, 王新民, 史良贵, 等. 基于BP神经网络的爆破参数优选[J]. 矿冶工程, 2009, 29(4): 24-27.

ZHAO Bin, WANG Xinmin, SHI Lianggui, et al. Optimization of blasting parameters based on back-propagation neural network[J]. Mining and Metallurgical Engineering, 2009, 29(4): 24-27.

[11] 李小斌, 赵东峰, 章宣, 等. 赤泥主要物相的表面性质对其沉降性能的影响[J]. 中国有色金属学报, 2012, 22(1): 281-286.

LI Xiaobin, ZHAO Dongfeng, ZHANG Xuan, et al. Effect of surface property of main minerals in red mud on their sedimentation ability[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(1): 281-286.

[12] 张钦礼, 谢盛青, 郑晶晶, 等. 充填料浆沉降规律研究及输送可行性分析[J]. 重庆大学学报, 2011, 34(1): 105-107.

ZHANG Qinli, XIE Shengqin, XIAO Weiguo, et al. Sedimentation law research and transportation feasibility study of backfilling slurry[J]. Journal of Chongqing University, 2011, 34(1): 105-107.

[13] 刘凯, 黄德镛, 张明旭, 等. 大红山铜矿全尾砂絮凝沉降的试验研究[J]. 中国矿业, 2008, 17(12): 60-63.

LIU Kai, HUANG Deyong, ZHANG Mingxu, et al. Experimental study on all tailings flocculation settling in Dahongshan cooper mine[J]. China Mining Magazine, 2008, 17(12): 60-63.

[14] 王星, 瞿圆媛, 胡伟伟, 等. 尾矿浆絮凝沉降影响因素的试验研究[J]. 金属矿山, 2008, 383(5): 149-151.

WANG Xing, QU Yuanyuan, HU Weiwei, et al. Experiment research on factors influencing tailing pulp flocculation settling[J]. Metal Mine, 2008, 383(5): 149-151.

[15] ZHAO Ru, ZHANG Zheng, SHI Jiangbo. Characterization of stress corrosion crack growth of 304 stainless steel by electrochemical noise and scanning Kelvin probe[J]. Journal of Central South University, 2010, 17(1): 13-18.

[16] 喻寿益, 王吉林, 彭晓波. 基于神经网络的铜闪速熔炼过程工艺参数预测模型[J]. 中南大学学报(自然科学版), 2007, 38(3): 153-157.

YU Shouyi, WANG Jilin, PENG Xiaobo. Prediction model of craft parameters based on neural network during the process of copper flash smelting[J]. Journal of Central South University (Science and Technology), 2007, 38(3): 153-157.

[17] 姜安龙, 戚玉亮. 粗糙集-BP神经网络组合方法及其应用[J].中南大学学报(自然科学版), 2011, 42(10): 3189-3191.

JIANG Anlong, QI Yuliang. Method of rough sets-back propagation neural network and its application to identification of surrounding rock stability[J]. Journal of Central South University (Science and Technology), 2011, 42(10): 3189-3191.

[18] WANG W Y, LEU Y G, LEA T T. Robust adaptive fuzzy-neural control of nonlinear dynamical systems using generalized projection update law and variable structure controller[J]. IEEE Trans Syst Man Cybern-Part B: Cybernetics, 2001, 30(1): 140-147.

[19] 葛哲学, 孙志强. 神经网络理论与MATLAB R2007实现[M]. 北京: 电子工业出版社, 2007: 13-21.

GE Zhexue, SUN Zhiqiang. Neural network theory and the application of MATLAB R2007[M]. Beijing: Publishing House of Electronics Industry, 2007: 13-21.

(编辑 陈爱华)

收稿日期:2015-07-08;修回日期:2015-09-09

基金项目(Foundation item):科技部“十一五”科技支撑计划项目(2008BAB32B03) (Project(2008BAB32B03) supported by the National Science and Technology Pillar Program during the 11th “Five-year” Plan Period)

通信作者:王新民,教授,博士,博士生导师,从事采矿与充填技术研究;E-mail: zhaojianwen0607@qq.com