文章编号:1004-0609(2011)01-0118-07

Co替代Ni对快淬Mg2Ni型合金结构及电化学贮氢性能的影响

张羊换1, 2, 马志鸿1, 3, 赵栋梁1, 张 胤2, 郭世海1, 王新林1

(1. 钢铁研究总院 功能材料研究所,北京 100081; 2. 内蒙古科技大学 材料与冶金学院,包头 014010;

3.包头稀土研究院 科技处,包头 014010)

摘 要:为了改善Mg2Ni型贮氢合金的电化学贮氢性能,以Co部分替代合金中的Ni,用快淬工艺制备Mg2Ni型Mg2Ni1-xCox (x = 0, 0.1, 0.2, 0.3, 0.4)合金, 获得长度连续、厚度约为30 μm、宽度约为25 mm的快淬合金薄带。并用XRD、SEM、HRTEM分析快淬态合金薄带的微观结构;用DSC研究快淬薄带的热稳定性;用程控电池测试仪测定合金薄带的电化学贮氢性能;探索Co替代Ni对快淬Mg2Ni型合金结构及电化学贮氢性能的影响。结果表明:在快淬无Co合金中没有发现非晶相,但快淬含Co合金中存在明显的非晶结构,证明Co替代Ni提高了Mg2Ni型合金的非晶形成能力。Co替代Ni使快淬态合金的热稳定性略有提高,显著地改善了合金的电化学贮氢性能,包括放电容量、电化学循环稳定性以及高倍率放电性能,这主要归因于Co替代Ni导致结构的变化以及非晶形成能力的提高。

关键词:Mg2Ni型合金;快淬;Co替代Ni;电化学贮氢

Influences of substituting Ni with Co on structure and electrochemical hydrogen storage characteristics of melt spun Mg2Ni-type alloys

ZHANG Yang-huan1, 2, MA Zhi-hong1, 3, ZHAO Dong-liang1,

ZHANG Yin2, GUO Shi-hai1, WANG Xin-lin1

(1. Department of Functional Materials Research, Central Iron and Steel Research Institute, Beijing 100081, China;

2. School of Materials and Metallurgy, Inner Mongolia University of Science and Technology, Baotou 014010, China;

3. Department of Science and Technology, Baotou Research Institute of Rare Earths, Baotou 014010, China)

Abstract: In order to improve the electrochemical hydrogen storage characteristics of the Mg2Ni-type alloy, Ni in the alloy was partially substituted by element Co. The Mg2Ni-type Mg2Ni1-xCox (x = 0, 0.1, 0.2, 0.3, 0.4) alloys were prepared by melt-spinning technology. The spun ribbons with a continuous length, a thickness of about 30 μm and a width of about 25 mm were obtained. The microstructures of the spun alloy ribbons were analyzed by XRD, SEM and HRTEM. The thermal stability of the as-spun alloys was investigated by DSC. The electrochemical hydrogen storage performances of the spun alloy ribbons were tested by an automatic galvanostatic system. The influences of substituting Ni with Co on the structure and electrochemical hydrogen storage characteristics of melt spun Mg2Ni-type alloy were investigated. The results show that no amorphous phase is detected in the as-spun Co-free alloy, but the as-spun alloys containing Co display an evident percent of amorphous phase, suggesting that the substitution of Co for Ni significantly heightens the glass forming ability of the Mg2Ni-type alloy. The substitution of Co for Ni causes a slight increase in the thermal stability of the as-spun alloy, and significantly improves the electrochemical hydrogen storage performances of the alloys, involving the discharge capacity and the cycle stability as well as the high rate discharge (HRD) capability, for which the increased glass forming ability by Co substitution is mainly responsible.

Key words: Mg2Ni-type alloy; melt-spinning; substituting Ni with Co; electrochemical hydrogen storage

近30年来,金属氢化物贮氢引起高度重视,特别是Mg及Mg基氢化物由于其储量丰富、密度低、吸氢容量大而被广泛地研究。比如MgH2、Mg2NiH4、Mg2CoH5和Mg2FeH6的吸氢量(质量分数)分别为7.6%、3.6%、4.5%和5.4%。这些氢化物极有望用作燃料电池的贮氢材料或Ni-MH电池的负极材料[1]。然而,上述氢化物具有极强的热稳定性,因此,其吸放氢动力学性能极差。各种方法被用来降低氢化物的热稳定性,包括机械合金化[2]、GPa氢压合成法[3]、快淬法[4]、重力铸造法[5]、氢化燃烧合成法[6]、表面改性 法[7]、多元合金化法[8]和催化剂法[9]等。

高能球磨法是一种制备纳米晶/非晶Mg及Mg基合金非常有效的方法,特别是在MgH2或Mg2NiH4氢化物中添加高熔点元素时,这种方法尤为有效。然而,球磨Mg及Mg基合金的吸放氢循环稳定性很差,主要是由于球磨形成的亚稳态结构在多次吸放氢循环过程中逐渐消失[10]。与球磨法相比,熔体快淬技术能克服上述缺点,并有效地防止Mg及Mg基合金吸放氢循环特性的明显衰退[11]。此外,熔体快淬是获得纳米晶/非晶结构的有效方法,并非常适合于批量化制备纳米晶/非晶Mg基合金。SPASSOV和K?STER[12]用熔体快淬技术制备Mg2(Ni, Y)型Mg63Ni30Y7贮氢合金,合金的最大吸氢量约为3.0%,且合金的吸放氢动力学性能优于多晶Mg2Ni合金的吸放氢动力学性能,与用球磨法制备的Mg2Ni合金的吸氢性能相当。HUANG等[13]用快淬技术制备了非晶(Mg60Ni25)90Nd10合金,其放电容量高达580 mA?h/g。国内外研究者对Mg2Ni型合金的电化学性能进行了深入的研究,取得了重要的研究成果[14-16]。

为了改善Mg2Ni合金的电化学贮氢性能,本文作者以Co部分替代合金中的Ni,用快淬技术制备纳米晶/非晶Mg2Ni1-xCox(x=0~0.4)三元合金,并深入研究Co含量对合金结构及电化学贮氢性能的影响。

1 实验

1.1 合金的制备

试验合金的成分为Mg2Ni1-xCox(x = 0,0.1,0.2,0.3,0.4),对应于Co含量x,合金编号分别为Co0、Co1、Co2、Co3和Co4。试验合金用9.8 N真空中频感应电炉熔炼。为了防止Mg在冶炼过程中挥发,用压力为0.04 MPa的氦气保护。熔炼后的合金经铜模浇铸获得母合金锭;将母合金重熔后,进行单辊快淬处理,获得不同淬速下的快淬态合金。淬速以铜辊表面线速度表示,本试验的淬速为15、20、25和30 m/s。

1.2 微观结构分析

用XRD (D/max/2400)分析合金的相结构,射线源为Cu Kα1。将快淬合金薄带用离子减薄法制成薄膜样品,用高分辨透射电子显微镜(HRTEM, JEM-2100F)观察其形貌,并用电子衍射(ED)分析合金的晶态。

1.3 热稳定性分析

用DSC设备(STA449C)研究快淬态合金的热稳定性及晶化过程,加热温度为600 ℃,加热速率为 10 ℃/min。

1.4 电化学贮氢性能测试

铸态及快淬态合金经机械破碎后过孔径为0.063 mm筛,将合金粉与镍粉以1:4(摩尔比)的比例充分混合,在35 MPa下制成直径为15 mm的试验用电极片,质量约为1 g。干燥4 h后,放入 6 mol/L KOH溶液中浸泡24 h后,用程控电池测试仪测试其电化学性能。合金电极片作为试验电池的负极,正极为Ni(OH)2/NiOOH,参比电极为Hg/HgO,电解液为6 mol/L KOH水溶液,负极和参比电极之间的电压为放电电压。合金电极以20 mA/g的电流密度充电,10 min后,以相同的电流密度放电至截止电压为-0.500 V。测试环境温度保持在30 ℃。

合金被完全活化后,在50%放电深度DOD时,用综合电化学测试仪(PARSTAT 2273)测试合金的电化学阻抗谱(EIS),频率扫描范围为10 kHz~5.0 mHz,电位扰动幅度为5 mV。

2 结果与讨论

2.1 微观结构

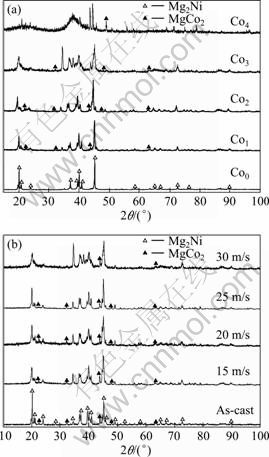

图1所示为铸态及快淬态合金的XRD谱。从图1可以看出,快淬态Co0合金中没有发现非晶相,但Co4合金中显示有非晶相存在,且合金的非晶化程度随Co含量的增加而增加。这表明,Co替代Ni能提高Mg2Ni型合金的非晶形成能力。Co替代Ni提高合金非晶形成能力主要归因于Co的原子半径大于Ni的原子半径。合金的非晶形成能力与原子半径差密切相关,原子半径差越大,非晶形成能力越强[10]。Co替代Ni没有改变铸态合金的主相Mg2Ni,但在合金中形成了第二相MgCo2,并且MgCo2相的量随Co含量的增加而增加。采用软件Jade 6.0分析合金的XRD数据,计算铸态及快淬合金的晶格常数、晶胞体积以及主衍射峰半高宽值(FWHM),其结果见表1和2。由表1和2可以看出,主衍射峰半高宽值随Co含量的增加而增大,Co替代Ni使晶格常数及晶胞体积增大,这归因于Co的原子半径大于Ni的原子半径。比较图1(a)和(b)可知,快淬使合金的衍射峰显著宽化,这是由于快淬使晶粒细化和应变能增加。

图1 铸态及快淬态合金的XRD谱

Fig.1 XRD patterns of as-cast and spun alloys: (a) As-spun (30 m/s); (b) Co3 alloy

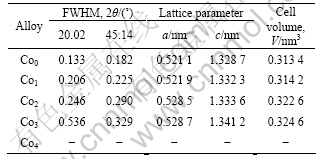

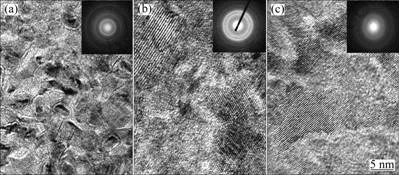

表1 快淬(30 m/s)合金的主衍射峰半高宽值、晶胞体积及晶格常数

Table 1 FWHM values, lattice parameters and cell volumes of diffraction peaks of as-spun (30 m/s) alloys

表2 铸态及快淬态Co3合金的主衍射峰半高宽值、晶格常数、晶胞体积

Table 1 FWHM values lattice parameters, cell volumes and of diffraction peaks of as-cast and spun Co3 alloy

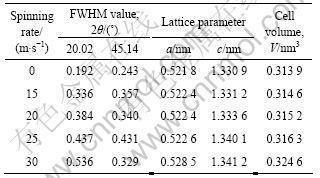

用HRTEM观察快淬态(30 m/s)合金的形貌,结果如图2所示。从图2可以看出,Co0合金为纳米晶结构,晶粒大小约为10 nm。而快淬Co2和Co4合金为纳米晶粒镶嵌在非晶基体中的结构,且非晶相的量随Co含量的增加而显著增多,这表明Co替代Ni可以提高Mg2Ni型合金的非晶形成能力。电子衍射谱也显示相同的结果,这与XRD分析结果完全一致。

图2 快淬态(30 m/s)合金的TEM像及电子衍射谱

Fig.2 TEM images and ED patterns of as-spun (30 m/s) alloys: (a) Co0 alloy; (b) Co2 alloy; (c) Co4 alloy

2.2 热稳定性

用DSC分析了快淬(30 m/s)合金的晶化过程及热稳定性,其结果如图3所示。由图3可以看出,在加热过程中,合金发生完全晶化。晶化过程分两步完成:第一步晶化反应发生在215~232 ℃,对应图3中大的放热峰;第二步晶化反应对应小的放热峰,发生在约418 ℃。晶化的第一步反应显然是非晶Mg2Ni的晶化反应[17]。可以看出,晶化温度随Co含量的增加明显升高,说明Co替代Ni增加了非晶Mg2Ni合金的热稳定性。值得注意的是,当Co含量x=0.4时,合金的热稳定性略有降低,这可能与Co替代Ni形成第二相MgCo2有关。

图3 快淬(30 m/s)合金的DSC曲线

Fig.3 DSC profiles of as-spun (30 m/s) alloys

2.3 电化学贮氢性能

2.3.1 活化性能及放电容量

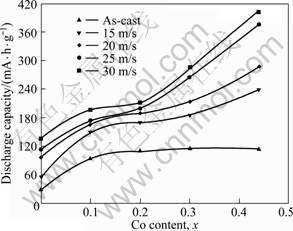

图4所示为在电流密度为20 mA/g充放电时铸态及快淬态合金的放电容量与循环次数之间的关系。由图4可知,所有的合金均具有良好的活化性能,在第1次循环时均可以达到最大放电容量。从图4 (a)可以看出,快淬态合金的放电容量随Co含量的增加而增加。当Co含量x从0增加到0.4时,快淬态(30 m/s)合金的放电容量从135.5 mA?h/g增加到402.5 mA?h/g。Co替代Ni导致放电容量增加归因于Co能提高合金的非晶形成能力,因此,非晶Mg2Ni合金表现出较高的放电容量。图4 (b)表明,快淬能显著提高合金的放电容量。当淬速从0 (铸态,定义其淬速为0)增加到30 m/s时,Co3合金的放电容量从115.4 mA?h/g增加到284.2 mA?h/g。由快淬形成的纳米晶和非晶对提高氢的扩散能力和氢的固溶度是非常有利的,因此,合金的放电容量随淬速的增加而增加。为了更清楚地反映Co含量对放电容量的影响,获得了放电容量与Co含量的关系曲线,如图5所示。显然,Co替代对快淬态合金的放电容量具有更加显著的作用,这主要归因

图4 铸态及快淬态合金放电容量与循环次数的关系

Fig.4 Relationship between discharge capacity of as-cast and spun alloys and cycle number: (a) As-spun (30 m/s); (b) Co3 alloy

图5 合金放电容量与Co含量的关系

Fig.5 Relationship between maximum discharge capacity of alloys and Co content (x)

于快淬形成的纳米晶/非晶结构,因为当纳米晶/非晶以一个合适的比例共存时,Mg基合金具有良好的吸放氢动力学和较高的电化学贮氢容量。

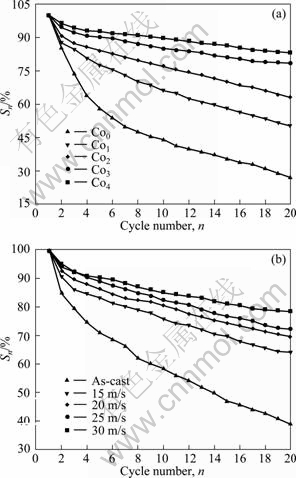

2.3.2 循环稳定性

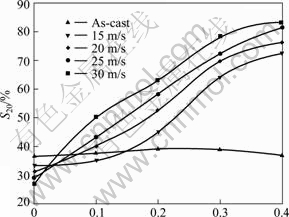

用容量保持率来评价合金的循环稳定性。容量保持率的定义为:Sn= Cn/Cmax×100%。其中,Cmax为最大放电容量,Cn为第n次循环时的放电容量。铸态及快淬态合金的容量保持率与循环次数的关系如图6所示。从图6(a)可以看出,合金的容量保持率随Co含量的增加而增加,这主要归因于Co替代Ni提高了合金的非晶形成能力。从图6(b)可知,快淬显著提高了Co3合金的循环稳定性,合金的容量保持率随淬速的增 加而增加。为了更清楚地反映淬速对循环稳定性的影响,给出了第20次循环的容量保持率与Co含量的关系,如图7所示。由图7可以看出,合金的容量保持率均随Co含量的增加而增加,但Co替代对快淬态合金的循环稳定性具有更加显著的影响。当Co含量x从0增加到0.4时,铸态合金的容量保持率从36.7%

图6 铸态及快淬态合金容量保持率与循环次数的关系

Fig.6 Relationship between capacity retaining rate of alloys and cycle number: (a) As-spun (30 m/s); (b) Co3 alloy

图7 第20次循环的容量保持率与Co含量的关系

Fig.7 Relationship between capacity retaining rate at the 20th cycle and Co content

增加到37.0%,而30 m/s快淬态合金从27.1%增加到83.4%。Co替代能大幅提高快淬态合金的电化学循环稳定性主要归因于Co替代Ni提高了合金的非晶形成能力。这是因为非晶相不但能提高合金的抗粉化能力,而且能大幅度提高合金的抗氧化和抗腐蚀能力[18]。由上述实验结果可知,改善Mg基贮氢合金电化学循环稳定性的有效途径是提高其在腐蚀性电解液中的抗腐蚀与抗氧化性能。

2.3.3 高倍率放电性能(ηHRD)

高倍率放电(ηHRD)能力是合金的动力学性能,用下述公式计算:ηHRD = Ci/C20×100%。其中,Ci和C20分别为放电电流为Ii和20 mA/g时合金的最大放电容量。铸态及快淬态合金的ηHRD性能曲线如图8所示。由图8(a)可看出,对于给定的淬速(15 m/s),合金的ηHRD随Co含量的增加而增加。当Co含量从0增加到0.4时,对于放电电流Ii=120 mA/g,ηHRD值从53.3%增加到80.1%。图8(b)表明,Co3合金的ηHRD值随淬速的增加而先升高后降低。当淬速为20 m/s时,Co3合金的ηHRD具有极大值。需要指出的是,所有快淬态合金的ηHRD均远远高于铸态合金的ηHRD,表明快淬可以提高Mg2Ni型合金的高倍率放电性能。

图9所示为铸态及快淬态合金电极的电化学阻抗谱(EIS)。由图9可以看出,阻抗谱由两段半圆弧和一段斜线组成。根据KURIYAMA等的模型[19],高频区的半圆弧反映合金与集流体之间的接触电阻;低频区的半圆弧反映合金电极表面的电化学反应,主要与合金表面的电化学活性及氢的扩散相关。从图9(a)可以看出,高频区的圆弧半径基本不变,低频区的圆弧半

图8 铸态及快淬态合金的高倍率放电能力(ηHRD)

Fig.8 High rate discharge capability (ηHRD) of as-cast and spun alloys: (a) As-spun (15 m/s); (b) Co3 alloy

径随Co含量的增加而减小。由图9(b)可看出,Co3合金阻抗曲线在低频区的圆弧半径随淬速的增加先减小而后增加。其总的趋势与图8结果基本一致,这说明合金的结构特性是合金电极表面电化学反应阻抗的决定因素。Co替代Ni对合金高倍率放电性能的作用归结于两个方面的原因:一是Co替代Ni能降低氢化物的稳定性,使放氢反应更加容易进行[20];二是由于Co替代形成的第二相MgCo2对放氢反应具有一定的催化作用,从而改善合金的高倍率放电性能[10]。快淬对合金高倍率放电性能的作用归因于晶粒细化,由于大量的界面和晶界为氢原子扩散提供有利通道,从而改善了合金的放氢性能[21]。值得注意的是,当淬速进一步增大(≥25 m/s)时,Co3合金的高倍率放电性能略有下降,这主要是由于合金中出现了部分非晶相。众所周知,氢原子在非晶相中的扩散系数比在晶界的扩散系数要小得多,因此,不难理解,更高淬速使高倍率下合金的放电能力降低。

图9 铸态及快淬态合金的电化学阻抗谱(EIS)

Fig.9 Electrochemical impedance spectra of as-cast and spun alloy electrodes: (a) As-spun (15 m/s); (b) Co3 alloy

3 结论

1) 用快淬技术制备了Mg2Ni型Mg2Ni1-xCox (x=0, 0.1, 0.2, 0.3, 0.4)合金薄带。结构分析表明,Co替代Ni不改变合金的主相,但形成第二相MgCo2。快淬Co0合金具有完全的纳米晶结构,而快淬Co2和Co4具有纳米晶镶嵌在非晶基体中的结构,这表明Co替代Ni能显著地提高合金的非晶形成能力。

2) Co替代Ni能显著地改善合金的电化学贮氢性能,包括放电容量、循环稳定性以及高倍率放电能力,这主要归因于Co替代Ni能提高合金的非晶形成能力、降低氢化物的热稳定性以及增加晶格常数与晶胞体积。

3) 快淬能显著地提高含Co合金的放电容量和循环稳定性。合金的高倍率放电能力(HRD)随淬速的增加先增加后减小,这主要归因于快淬形成了纳米晶和非晶结构。

References

[1] ROSS D K. The major technological barrier to the development of hydrogen fuel cell cars[J]. Vacuum, 2006, 80: 1084-1089.

[2] EBRAHIMI-PURKANI A, KASHANI-BOZORG S F. Nanocrystalline Mg2Ni-based powders produced by high-energy ball milling and subsequent annealing[J]. J Alloys Comp, 2008, 456: 211-215.

[3] KYOI D, SAKAI T, KITAMURA N, UEDA A, TANASE S. Synthesis of FCC Mg-Ta hydrides using GPa hydrogen pressure method and their hydrogen-desorption properties[J]. J Alloys Comp, 2008, 463: 306-310.

[4] PALADE P, SARTORI S, MADDALENA A, PRINCIPI G, LO RUSSO S, LAZARESCU M, SCHINTEIE G, KUNCSER V, FILOTI G. Hydrogen storage in Mg-Ni-Fe compounds prepared by melt spinning and ball milling[J]. J Alloys Comp, 2006, 415: 170-176.

[5] SONG M Y, YIM C D, BAE J S, MUMM D R, HONG S H. Preparation by gravity casting and hydrogen-storage properties of Mg-23.5%Ni-(5, 10 and 15%)La[J]. J Alloys Comp, 2008, 463: 143-147.

[6] LIU F J, SUDA S. Properties and characteristics of fluorinated hydriding alloys[J]. J Alloys Comp, 1995, 231: 742-750.

[7] CZUJKO T, VARIN R A, CHIU C, WRONSKI Z. Investigation of the hydrogen desorption properties of Mg+10%X (X=V, Y, Zr) submicrocrystalline composites[J]. J Alloys Comp, 2006, 414: 240-247.

[8] LIU Y N, ZHANG X J. Effect of lanthanum additions on electrode properties of Mg2Ni[J]. J Alloys Comp, 1998, 276: 231-234.

[9] SAKINTUNA B, LAMARI-DARKRIM F, HIRSCHER M. Metal hydride materials for solid hydrogen storage: A review[J]. Int J Hydrogen Energy, 2007, 32: 1121-1240.

[10] SONG M Y, KWON S N, BAE J S, HONG S H. Hydrogen-storage properties of Mg-23.5Ni-(0 and 5)Cu prepared by melt spinning and crystallization heat treatment[J]. Int J Hydrogen Energy, 2008, 33: 1711-1718.

[11] SAVYAK M, HIRNYJ S, BAURE H D, UHLEMANN M, ECKERT J, SCHULTZ L, GEBERT A. Electrochemical hydrogenation of Mg65Cu25Y10 metallic glass[J]. J Alloys Comp, 2004, 364: 229-237.

[12] SPASSOV T, K?STER U. Thermal stability and hydriding properties of nanocrystalline melt-spun Mg63Ni30Y7 alloy[J]. J Alloys Comp, 1998, 279: 279-286.

[13] HUANG L J, LIANG G Y, SUN Z B, WU D C. Electrode properties of melt-spun Mg-Ni-Nd amorphous alloys[J]. J Power Sources, 2006, 160: 684-687.

[14] JIANG J J, GASIK M. An electrochemical investigation of mechanical alloying of MgNi-based hydrogen storage alloys[J]. J Power Sources, 2000, 89: 117-124.

[15] MOKBLI S, ABDELLAOUI M, ZARROUK H, LATROCHE M, PERCHERON A, GU?GAN. Hydriding and electrochemical properties of amorphous rich MgxNi100-x nanomaterial obtained by mechanical alloying starting from Mg2Ni and MgNi2[J]. J Alloys Comp, 2008, 460: 432-439.

[16] SIMI?I? M V, ZDUJI? M, DIMITRIJEVI? R, NIKOLI?-BUJANOVI? LJ, POPOVI? N H. Hydrogen absorption and electrochemical properties of Mg2Ni-type alloys synthesized by mechanical alloying[J]. J Power Sources, 2006, 158: 730-734.

[17] SPASSOV T, SOLSONA P, SURI?ACH S, BAR? M D. Optimization of the ball-milling and heat treatment parameters for synthesis of amorphous and nanocrystalline Mg2Ni-based alloys[J]. J Alloys Comp, 2003, 349: 242-254.

[18] ZHANG Y H, LI B W, REN H P, CAI Y, DONG X P, WANG X L. Investigation on structures and electrochemical performances of the as-cast and -quenched La0.7Mg0.3Co0.45Ni2.55-xFex (x=0-0.4) electrode alloys[J]. Int J Hydrogen Energy, 2007, 32: 4627-4634.

[19] KURIYAMA N, SAKAI T, MIYAMURA H. Electrochemical impedance and deterioration behavior of metal hydride electrodes[J]. J Alloys Comp, 1993, 202(1/2): 183-197.

[20] WOO J H, LEE K S. Electrode characteristics of nanostructured Mg2Ni-type alloys prepared by mechanical alloying[J]. J Electrochem Soc, 1999, 146: 819-823.

[21] WU Y, HAN W, ZHOU S X, LOTOTSKY M V, SOLBERG J K, YARTYS V A. Microstructure and hydrogenation behavior of ball-milled and melt-spun Mg-10Ni-2Mn alloys[J]. J Alloys Comp, 2008, 466: 176-181.

(编辑 陈卫萍)

基金项目:国家高技术研究发展计划资助项目(2006AA05Z132); 国家自然科学基金资助项目(50871050;50961001);内蒙古自然科学基金重点资助项目(200711020703); 内蒙古高等教育科学研究资助项目(NJzy08071)

收稿日期:2010-01-28;修订日期:2010-06-16

通信作者:张羊换,教授,博士;电话:010-62187570;E-mail: zyh59@yahoo.com.cn