文章编号:1004-0609(2013)12-3341-07

氧化锌铝陶瓷(AZO)靶材的制备及其电阻性能的测定

王志勇,彭超群,王日初,王小锋,刘 兵

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:采用二步烧结技术制备AZO陶瓷靶材,并采用XRD、SEM和EDS对AZO陶瓷靶材进行表征,研究AZO靶材的电阻性能。结果表明:当Al的掺杂量w(Al2O3)为0.5%时,AZO靶材出现第二相ZnAl2O4;随Al掺杂浓度增加,ZnAl2O4的衍射峰强度逐渐增强,ZnO晶粒尺寸逐渐减小;随着第二步烧结温度θnd的升高,AZO靶材的晶粒尺寸逐渐增大,相对密度也随之增加。靶材的电阻率随θnd增加而降低,且随掺杂浓度升高而增加;在第一步烧结温度θst=1 400 ℃,升温速率vst=10 ℃/min,第二步烧结温度θnd=1 350 ℃和tnd=16 h烧结条件下,AZO陶瓷靶材(w(Al2O3)=1.5%)的电阻率仅为2.9×10-2 Ω·cm。

关键词:AZO靶材;二步烧结;保温温度;相对密度;电阻率

中图分类号:TB43 文献标志码:A

Precipitation of Al-doped-ZnO(AZO) ceramic targets and determination of its resistance properties

WANG Zhi-yong, PENG Chao-qun, WANG Ri-chu, WANG Xiao-feng, LIU Bing

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: AZO(Al-doped ZnO) target materials were prepared by two-step sintering techniques. The AZO ceramic targets were characterized with XRD, SEM and EDS. And the resistance properties of AZO targets were analyzed. The results show that the second phase ZnAl2O4 is detected when Al2O3 doping concentration is 0.5% (mass fraction). ZnAl2O4 diffraction peaks are enhanced and the grain sizes of AZO target are reduced with increasing the doping concentrations. With increasing the second-sintering temperature θnd, the grain sizes of AZO targets and the relative density increase. The electrical resistivity reduces with increasing the second-sintering temperature θnd, while increases with increasing the doping concentration. The electrical resistivity is 2.9×10-2 Ω·cm at the frist-sintering temperature of 1 400 ℃, the heating rate of 10 ℃/min, the second-sintering of 1 350 ℃ and holding time of 16h.

Key words: AZO targets; two steps-sintering; holding temperature; relative density; electrical resistivity

氧化锌铝(AZO)透明导电薄膜具有电阻率低、可见光区域的透射率高、红外区反射率高以及紫外吸收率高等优点,可广泛应用于太阳能电池电极、液晶显示器及等离子体显示器等光电子器件领域[1-3]。同时,由于其性能优良、原料丰富和价格低廉而成为国内外研究的热点,有望成为ITO薄膜的替代品[4]。

磁控溅射是制备AZO薄膜的主要方法之一[5]。而作为溅射薄膜的陶瓷靶材,其性能在很大程度上影响沉积薄膜的性能。研究表明:靶材的密度、纯度、微观组织、表面电阻、成分与结构的均匀性对溅射成膜的质量有重要的影响,获得高性能的靶材已成溅射薄膜的关键。

张静等[6]以均匀沉淀法制备的AZO粉末为原料,在高温常压条件下烧结干压成型的坯体,获得导电性能良好的AZO靶材。许积文等[7]以纳米级的ZnO和Al2O3粉体为起始原料,常压固相烧结AZO陶瓷,最后制备出致密度为95%、电阻率为1×10-2 Ω·cm的陶瓷靶材;但靶材的表面或内部偶尔出现黑点,它们不仅破坏靶材的致密度,还导致靶材成分上的不均匀,增强载流子的散射,最后影响沉积薄膜的性能。范锦鹏等[8]利用与ZnO粒径相同或相近的Al2O3的粉体作为原料,无压烧结出的靶材内部存在着大量的孔隙;而将Al2O3粒径降至纳米级时,采用相同的烧结工艺,可以获得致密度为99.8%以上的高致密靶材。龙涛等[9]采用热等静压方法烧结ZnO和γ-Al2O3的复合粉体,其中Al的掺杂量为2.5%(质量分数),1 050 ℃下烧结的AZO靶材晶粒呈现生长良好的六边形,该方法在很大程度上降低了烧结温度。SHIROUZU等[10]研究发现Al在ZnO陶瓷中的固溶度仅为0.3%(摩尔浓度),随着Al掺杂浓度的增大,在ZnO的晶界和晶体内部均有ZnAl2O4相析出。WANG等[11]采用热压方法低温烧结制备AZO靶材,与传统烧结方法相比,该法制备的AZO靶材中ZnAl2O4的含量较低,提高了靶材溅射出薄膜的性能。ZHANG等[12]在θst为1 050 ℃和θnd为800 ℃的二步烧结下,制备出高致密化的ZnO陶瓷,但Al2O3掺杂后AZO陶瓷的相对密度仅为80%左右,可见,Al的掺杂严重阻碍ZnO陶瓷的致密化进程。目前,大多数研究者多采用先进的烧结技术或气氛烧结方法来提高靶材的致密度。

而本文作者以ZnO和Al2O3粉为原料,采用凝胶注模成型,在常压下二步烧结来实现AZO靶材的致密化,研究了靶材的物相组成、掺杂浓度和第二步烧结温度对靶材相对密度及电阻率的影响。

1 实验

1.1 实验原料

实验原料为氧化锌(ZnO,分析纯)、氧化铝(Al2O3,分析纯)、丙烯酰胺(AM,分析纯)、N,N′-亚甲基双丙烯酰胺(MBAM,分析纯)、过硫酸铵(APS,(NH4)2S2O8,分析纯)和去离子水(实验室自制),其中氧化锌和氧化铝为主要实验原料,丙烯酰胺为网络有机单体,N,N'-亚甲基双丙烯酰胺为网络交联剂,过硫酸铵为聚合反应引发剂,去离子水为溶剂。

1.2 氧化锌铝陶瓷靶材的制备

采用电子天平分别秤量一定质量的ZnO和Al2O3(w(Al2O3)为0%、0.5%、1.0%、1.5%,2.0%和2.5%)粉体,制成混合浆料,再将浆料置于球磨罐中,以Al2O3球为球磨介质,在行星球磨机上球磨24 h,采用凝胶注模成型方法[13]制成AZO陶瓷靶材的素坯。然后将制成的素坯在一定温度下干燥,排胶和二步烧结。第一步烧结温度θst为1 500和1 400 ℃,升温速率vst为10℃/min,第二步烧结温度θnd为1 100、1 200、1 300和1 350 ℃,保温时间tnd为16 h。

1.3 性能检测

采用阿基米德方法测量试样的体积密度,运用日本理学D/Max2550VB+型X衍射仪定性的研究靶材的物相组成,采用扫描电子显微镜(Sirion200)对靶材进行显微结构(SEM)和成分分析(EDS),利用四探针测量仪来测量AZO靶材的电阻率。

2 结果与分析

2.1 掺杂浓度对AZO靶材显微结构的影响

2.1.1 AZO靶材的XRD谱

图1所示为θst=1 400 ℃、vst=10 ℃/min、θnd=1 350 ℃和tnd=16 h条件下烧结不同Al2O3掺杂浓度的AZO靶材的XRD谱。表1所列为不同Al2O3掺杂浓度的AZO靶材的晶格常数。从图1可见,AZO陶瓷靶材的XRD图谱与标准PDF卡片(JCPDS36-1451)基本一致,为纤锌矿结构。此外,Al2O3掺杂后的试样还出现ZnAl2O4物相的衍射峰,且随着掺杂浓度的增加,ZnAl2O4相的含量增多,ZnAl2O4的晶面衍射峰强度逐渐增强。这表明Al2O3掺杂浓度过高,超过Al在ZnO中的固溶度,生成第二相ZnAl2O4[14]。此外,AZO陶瓷靶材晶面衍射峰的宽化,也表明随Al2O3的掺杂溶度增加,试样的晶粒尺寸逐渐减小。CAI等[15]和CHEN等[16]也研究发现Al2O3在ZnO的固溶度有限,当掺杂浓度过大,为2%~4%(摩尔分数)时,过剩的Al与ZnO生成新相ZnAl2O4。从图1(b)还可知,Al2O3的掺杂改变了ZnO的晶面衍射角和晶格常数,晶面衍射角随Al2O3掺杂浓度的增加呈现先减小后增大的趋势,而晶格常数a、c均呈现出先增大后减小的趋势(见表1)。这主要是由于当Al2O3掺杂浓度较低时,Al3+或者被Al3+取代的Zn2+以间隙的形式进入ZnO的晶格中,引起晶格畸变,致使晶格常数偏大;当Al2O3掺杂浓度过大时,生成ZnAl2O4相的几率增大,导致Al3+在ZnO晶格中的掺杂浓度降低,晶格常数则出现相应的减小。

2.1.2 AZO靶材的SEM像

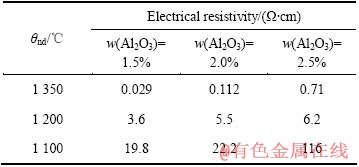

图2所示为不同掺杂浓度的AZO靶材在第二步烧结温度θnd为1 300 ℃条件下进行烧结后的显微组织。由图2可知,不同掺杂浓度试样晶粒轮廓和晶界都比较清晰,大致都呈现出六边形。当Al2O3的掺杂浓度为0时,AZO靶材的晶粒尺寸较大,且随着掺杂浓度的增加,晶粒尺寸逐渐趋于变小,这表明Al的掺杂能起到细化晶粒的作用。TASAKI等[17]的研究也认为 Al2O3在ZnO的晶界处引起钉扎效应,阻碍晶粒的生长和致密化过程。从图2(c)和(d)还可以看出,有少量的大晶粒存在,这主要是由于Al2O3掺杂到ZnO粉体中,掺杂量浓度较低时(w(Al2O3)为1.5%和2.5%),经过球磨后,Al2O3不可能完全均匀地分散在ZnO颗粒的周围,因此,经过成型后的坯体在烧结的过程中,富Al2O3区域的ZnO晶粒生长较快,而缺Al2O3区域的ZnO晶粒生长较慢,故出现少量的大尺寸晶粒。从图2可以看出,掺杂后的AZO靶材表面或晶界处存在一些白色物相,而且还有很多颜色较深的小颗粒镶嵌在ZnO的晶粒内或聚集于ZnO的晶界处。

图1 不同Al2O3掺杂溶度的AZO靶材的XRD谱

Fig. 1 XRD patterns of AZO targets with different concentrations

表1 不同Al2O3掺杂量的ZnO靶材的晶格参数

Table 1 Lattice constants of ZnO targets with different Al2O3 doping concentrations

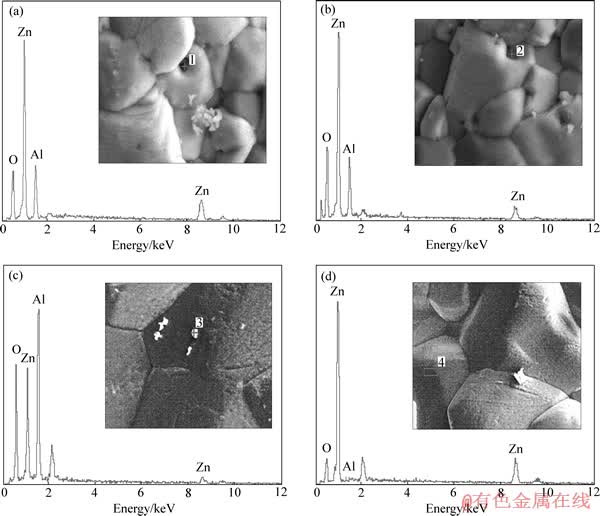

2.1.3 AZO靶材的EDS谱

图3所示为AZO靶材的EDS谱。其中,图3 (a)和(b)所示为θst=1 400 ℃、vst=10 ℃/min、θnd=1 200 ℃和tnd=16 h烧结工艺条件下,AZO陶瓷(w(Al2O3)=0.5%)的EDS谱,图3(c)和(d)所示为θst=1 500 ℃、vst= 10 ℃/min、θnd=1 400 ℃和tnd=16 h烧结工艺条件下AZO陶瓷(w(Al2O3)=1.0%)的EDS谱。1点和2点区域Zn、Al和O的摩尔比与ZnAl2O4成分的原子相差较大,这主要是由于基体中Zn元素的影响[18],而3点区域成分与ZnAl2O4较为相近。同时,通过EDS分析(如4点)发现,少量的Al存在于ZnO的基体中(见表2),说明Al掺杂在ZnO的晶格中,这与上述XRD的分析结果相符(见图1)。此外,这也与TAGA等[19]在Al掺杂ZnO陶瓷的晶界和晶内发现ZnAl2O4相相一致。

2.2 第二步烧结温度对靶材性能的影响

2.2.1 第二步烧结温度对靶材的相对密度影响

两步烧结的第一步烧结可以实现陶瓷中气孔的亚临界不稳定状态,为后续的低温烧结提供重要的基础条件。经过θst烧结后,坯体能够达到一定程度的致密,大尺寸的气孔逐渐消失,颗粒之间形成连续骨架,而这些骨架可作为试样下一步烧结的扩散通道,再通过第二步的晶界扩散作用便可达到致密,因此,两步烧结法中第二步烧结温度θnd是影响陶瓷密度和性能的一个重要的工艺参数。

图4所示为AZO靶材的相对密度与第二步烧结温度θnd的关系。当w(Al2O3)=0时,ZnO靶材在θnd为1 200 ℃的烧结温度下可获得较高的相对致密,为96.6%。随θnd的升高,ZnO靶材的密度反而呈现减小的趋势,这主要是由于在高温保温过程中,ZnO挥发较为严重,导致靶材的致密化程度降低;而θnd过低时(如θnd为1 100 ℃),晶界扩散的活化能较低,在一定的保温时间内难以实现致密化。较AZO靶材(w(Al2O3)=0)试样比较,掺杂后(w(Al2O3)=0.5%)的致密度较高。一方面,当Al2O3的掺杂浓度较低时,Al3+固溶在ZnO的晶格中,由于离子半径的差异,ZnO晶格发生畸变,晶格周围产生应力场,具有较高的能量,可促使质点的扩散迁移,加速烧结致密化的进程。另一方面,Al2O3在900 ℃左右获得足够的能量扩散至ZnO主晶相中,对Zn2+进行晶格取代或进入ZnO晶格的间隙中,产生晶格缺陷(如空位),这些晶格缺陷促进晶格或晶界扩散,加速烧结进程。从图4还可以看出,随着Al2O3掺杂浓度的增加,试样的相对密度呈现降低的趋势。过剩的Al2O3与ZnO在晶界上生成第二相ZnAl2O4(见XRD谱),降低烧结的驱动力,增加晶界扩散所需的活化能,阻碍晶界扩散,且ZnAl2O4的含量随掺杂浓度的提高而增加,故掺杂后试样的致密度逐渐降低。

图2 不同Al掺杂溶度AZO靶材的SEM像

Fig. 2 SEM images of AZO targets with different Al2O3 concentrations

图3 AZO靶材的EDS谱

Fig. 3 EDS energy spectra of AZO targets

表2 AZO陶瓷中Zn、Al和O元素含量

Table 2 Elements Zn, Al and O concentrations of AZO ceramic body

图4 在θst=1 400 ℃、vst=10 ℃/min、tnd=16 h的条件下ZAO靶材相对密度与θnd的关系

Fig. 4 Relationship between θnd and relative density of AZO targets at θst=1 400 ℃, vst=10 ℃/min and tnd=16 h

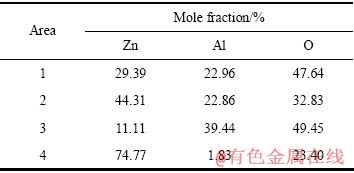

图5所示为θst=1 400 ℃、vst=10 ℃/min和tnd=16 h时不同第二步烧结θnd条件下AZO陶瓷(w(Al2O3)= 1.5%)的SEM像。从图5中可以看出,六方纤锌矿结构的ZnO晶粒的形貌基本为六边行,同时,在ZnO晶粒表面都能观察到析出的白色物相(ZnAl2O4相)。随着θnd提高,ZnO的晶粒尺寸也明显得到长大。当θnd升高至1 350 ℃时,ZnAl2O4相多数聚集于晶界上和三叉晶界口(见图2 (a))。而当保温温度降至1 100 ℃时,有明显的孔洞集中于晶界或三叉晶界口处(见图2(d)),阻碍了晶粒的生长,影响AZO陶瓷靶材相对密度。

2.2.2 第二步烧结温度对靶材的电阻率的影响

理想晶体在绝对零度的条件下,电子和空穴的迁移不受阻力,迁移率为无限大。但因为晶格的热振动、杂质引入、裂纹等破坏了晶格振动的周期性,自由载流子的迁移在这些因素作用下运动受阻,可能发生突然转向或丢失能量,这种现象称为载流子的散射。晶体缺陷的散射增强,电阻率上升,材料的导电性能降低。而对ZnO进行适当浓度的Al掺杂,能增加自由载流子的浓度,增强其导电性能[20]。

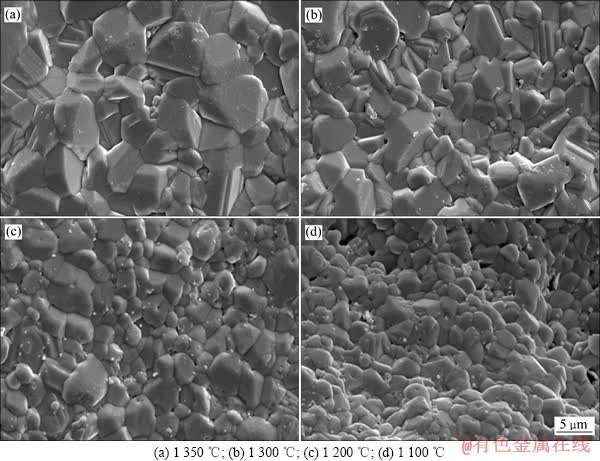

表3所列为AZO靶材在θst=1 400 ℃(vst=10 ℃/min)不同θnd下保温16 h后的电阻率。由表3可见,随着保温温度θnd的降低,不同掺杂浓度AZO靶材的电阻率的变化趋势都是逐渐增加。当θnd为1 350 ℃时,AZO(w(Al2O3)=1.5%)靶材电阻率为2.9×10-2 Ω·cm;而当θnd降至1 100 ℃时,试样的电阻率增加至19.8 Ω·cm。由图4可知,在AZO靶材的二步烧结过程中,第二步烧结温度θnd对靶材的相对密度有着重要的影响。θnd温度过低,靶材试样的致密化程度较低,试样中的气孔数量也较多,晶体中自由载流子的散射几率增大,材料的导电性能降低。同时,Al的掺杂会导致靶材内部微观结构不均匀,如晶格畸变、晶界和杂质等,载流子在电场作用下迁移至这些微观结构缺陷处受阻而积聚,形成空间电荷积聚效应,降低自由载流子的浓度,导致靶材的电阻率升高。COLDER等[21]研究也发现掺杂适当浓度的Ni原子进入ZnO的晶格中,能改变ZnO的能带结构,增加杂质能级,提高ZnO陶瓷的载流子浓度和导电性。此外,随着第二步烧结温度θnd的提高,靶材的结晶程度也趋于完整,晶体内部的缺陷浓度也在一定程度上降低,晶粒尺寸得到增大,晶界的数量就相应的减少,故自由载流子散射的几率降低,靶材试样的电阻率降低,导电性能增强。HAN等[22]在Mn掺杂ZnO的电学性能的研究中也发现同样的现象,随掺杂浓度和烧结温度增加,晶体的本征缺陷浓度增大,致使载流子的浓度增加,陶瓷材料的导电性能逐渐增强。比较图4和表3可知,当θnd为1 350 ℃时,w(Al2O3)掺杂量为2.0%和2.5%的靶材试样相对密度基本相同,而这两种试样的电阻率则相差较大。其主要原因是如下:1) 随着掺杂浓度的增加,晶粒生长受阻,晶粒尺寸偏小,电阻率偏大;2) Al的掺杂已超过Al在ZnO中的固溶度,Al2O3与ZnO生成ZnAl2O4的含量增加,这些新生成的第二相ZnAl2O4对ZnO的电导起着“杂质”的作用,增加自由载流子的散射;3) 增加的ZnAl2O4相破坏原有晶格振动的周期性,阻碍自由载流子的迁移,影响靶材的导电性能。

图5 在θst=1 400 ℃、vst=10 ℃/min和tnd=16 h不同θnd时AZO(w(Al2O3)=1.5%)靶材的SEM像

Fig. 5 SEM images of AZO (w(Al2O3)=15%) targets prepared in two steps-sintering at θst=1 400 ℃, vst=10 ℃/min, tnd=16 h and different θnd

表3 不同θnd时AZO靶材的电阻率

Table 3 Electrical resistivity of AZO at different second- sintering temperatures (θnd)

3 结论

1) AZO靶材的衍射峰与ZnO晶体的标准衍射峰相一致,为纤锌矿结构;随掺杂Al2O3掺杂浓度增加,XRD谱中出现锌铝尖晶石相(ZnAl2O4)的衍射峰,晶格常数a和c呈现先增大后减小的趋势。

2) 在θst=1 400 ℃、vst=10 ℃/min、θnd=1 200 ℃、tnd=16 h的烧结条件下,w(Al2O3)掺杂量为0的靶材的致密较高,为96.56%。随着θnd的提高,AZO靶材相对密度逐渐增加。

3) 靶材电阻率随烧结温度θnd的升高而降低,在θst=1 400 ℃、vst=10 ℃/min、θnd=1 350 ℃、tnd=16 h的烧结工艺下,AZO(w(Al2O3)=1.5%)靶材的电阻率仅为0.029 Ω·cm。

REFERENCES

[1] JIANG L N, JIANG D M, KIM K H, SHIM K B. Influence of texture on electrical properties of ZnO ceramic prepared by extrusion and spark plasma sintering[J]. Ceramics International, 2007, 33(1): 107-114.

[2] YAMAGUCHI H, CHONAN Y, ODA M, KOMIYAMA T, AOYAMA T, SUGIYAMA S. Thermoelectric properties of ZnO ceramics Co-doped with Al and transition metals[J]. Journal of Electronic Materials, 2011, 40(5): 723-727.

[3] NOMOTO J C, KONAGAI M, OKADA K, ITO T, MIYATA T, MINAMI T. Comparative study of resistivity characteristic between transparent conductive AZO and GZO thin films for use at high temperatures[J]. Thin Solid Films, 2010, 518(11): 2937-2940.

[4] SENGUPTA J, SAHOO R K, MUKHERJEE C D. Effect of annealing on the structural, topographical and optical properties of sol-gel derived ZnO and AZO thin films[J]. Materials Letters, 2012, 83(15): 84-87.

[5] JEONG S H, BOO J H. Influence of target-to-substrate distance on the properties of AZO films grown by RF magnetron sputtering[J]. Thin solid films, 2004, 447/448(30): 105-110.

[6] 张 静, 张维佳, 赵而敬, 沈燕龙, 杨东杰, 林 军. 掺铝氧化锌粉末及其陶瓷靶的制备及性能分析[C]// 第七届中国功能材料及其应用学术论文. 重庆: 功能材料, 2010: 39-41.

ZHANG Jing, ZHANG Wei-jia, ZHAO Er-jing, SHEN Yan-long, YANG Dong-jie, LIN Jun. Preparation and properties of AZO powder and ceramic target[C]// Seventh China Functional Materials and Applications Conference. Chongqing: Journal of the Functional Materials, 2010: 39-41.

[7] 许积文, 王 华, 任明放, 杨 玲. 高密度与低电阻率ZnO:Al靶材的制备及缺陷分析[J]. 功能材料, 2007, 38(9): 1457-1459.

XU Ji-wen, WANG Hua, REN Ming-fang, YANG Ling. Preparation of higher dense and low resistive ZnO:Al target and analysis of defect[J]. Journal of Functional Materials, 2007, 38(9): 1457-1459.

[8] 范锦鹏, 赵大庆, 吴敏生, 董民超. 用纳米Al2O3制备超高致密度ZAO靶材[J]. 粉末冶金技术, 2005, 23(1): 44-47.

FAN Jin-peng, ZHAO Da-qing, WU Ming-sheng, DONG Min-chao. Preparing super-dense ZAO target by doping Al2O3 nanopowder[J]. Powder Metallurgy Technology, 2005, 23(1): 44-47.

[9] 龙 涛, 朱德贵, 王良辉. 高导电性 ZAO 陶瓷靶材及薄膜的制备[J]. 电子元件与材料, 2004, 23(2): 31-34.

LONG Tao, ZHU De-gui, WANG Liang-hui. Highly conductive ZAO ceramic target and thin films preparation[J]. Electronic Components & Materials, 2004, 23(2): 31-34.

[10] SHIROUZU K, OHKUSA T, HOTTA M, ENOMOTO N, HOJO J. Distribution and solubility limit of Al in Al2O3-doped ZnO sintered boby[J]. Journal of the Ceramic Society of Japan, 2007, 115(4): 254-258.

[11] WANG Xing-ming, BAI Xue, DUAN Hua-ying, SHI Zhi-xia, SUN Jing, LU Shi-gang, HUANG Song-tao. Preparation of Al-doped ZnO sputter target by hot pressing[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(7): 1550-1556.

[12] ZHANG Y L, YANG Y, ZHANG X P, WANG W Y, CUI P, SONG W J. Two-step sintering of pristine and aluminum-doped zinc oxide ceramic[J]. International Journal of Applied Ceramic Technology, 2011, 9(3): 1-8.

[13] 王小锋, 王日初, 彭超群, 李婷婷, 刘 兵. 工艺条件对氧化铍凝胶注模坯体强度的影响[J]. 功能材料, 2011, 42(7): 1197-1202.

WANG Xiao-feng, WANG Ri-chu, PENG Chao-qun, LI Ting-ting, LIU Bin. Effect of process conditions on strength of BeO green boby prepared by gelcasting[J]. Journal of Functional Materials, 2011, 42(7): 1197-1202.

[14] YAMAGUCHI H, CHONAN Y, ODA M, KOMIYAMA T, AOTAMA T, SUGIYAMA S. Thermoelectric properties of ZnO ceramic Co-doped with Al and transition metal[J]. Journal of Electronic Materials, 2011, 40(5): 723-727.

[15] CAI K F, MULLER E, DRASAR C, MROTZEK A. Preparation and thermoelectric properties of Al-doped ZnO ceramics[J]. Materials Science and Engineering, 2003, B104(1/2): 45-48.

[16] CHEN H, XU X J, HNG H H, MA J. Characterization of Al-doped ZnO thermoelectric materials prepared by RF plasma powder processing and hot press sintering[J]. Ceramics International, 2009, 35(8): 3067-3072.

[17] TASAKI S, TATAMI J, NAKAKO H, WAKIHARA T, KATSUTOSHI K, MEGURO T. Fabrication of ZnO ceramics using ZnO/Al2O3 nano-composite particles prepared by mechanical treatment[J]. Journal of the Ceramics Society of Japan, 2010, 118(2): 118-121.

[18] SHIROUZU K, OHKUSA T, HOTTA M, ENOMOTO N, HOJO J. Distribution and solubility limit of Al in Al2O3-doped ZnO sintered boby[J]. Journal of the Ceramic Society of Japan, 2007, 115(4): 254-258.

[19] TAGA H, KINMUCHI Y, YILMAZ H W, NAKANO H, NAKANO H, TANAKA S, MAKIYA A, KATO Z, UEMATSU K. Orientation dependence of transport property and microstructual characterization of Al-doped ZnO ceramics[J]. Acta materialia, 2007, 55(14): 4753-4757.

[20] CHENG L H, ZHENG L Y, MENG L, LI G R, GU Y, ZHANG F P, CHU R Q, XU J Z. Electrical properties of Al2O3-doped ZnO varistors prepared by sol-gel progress for device miniaturization[J]. Ceramics International, 2012, 38(S1): S457-S461.

[21] COLDER H, GUILMEAU E, HARNOIS C, MARINEL S, RETOUX R, SAVARY E. Preparation of Ni-doped ZnO ceramics for thermoelectric applications[J]. Journal of the European Ceramic Society, 2011, 31(15): 2957-2963.

[22] HAN J P, Mantas P Q, SENOS A M R. Defect chemistry and electrical characteristic of undoped and Mn-doped ZnO[J]. Journal of the European Ceramic Society, 2002, 22(1): 49-59.

(编辑 李艳红)

收稿日期:2012-07-09;修订日期:2013-07-20

通信作者:彭超群,教授,博士;电话:0731-88877197;E-mail:pcqpcq@csu.edu.cn