文章编号:1004-0609(2010)06-1209-05

铝/镀银层/钢的扩散钎焊及界面化合物的生长行为

吴铭方1, 2,司乃潮1,陈 健2

(1. 江苏大学 材料科学与工程学院,镇江 212013;

2. 江苏科技大学 材料科学与工程学院,镇江 212003)

摘 要:采用扩散钎焊方法对6063铝合金/镀银层/1Cr18Ni9Ti不锈钢进行焊接,探讨焊接界面金属间化合物的生长行为。结果表明:钎缝中靠近不锈钢一侧为Fe-Al金属间化合物层,靠近铝合金一侧主要是Ag(Al)固溶体,中心区域由Ag-Al化合物和Ag(Al)固溶体混合而成;随着低温扩散保温时间的延长,化合物层厚度随之增加,Ag在铝合金一侧富集出现晶界渗透现象;钎缝中首先产生Ag-Al金属间化合物,之后共晶液相中的Al原子穿越Ag-Al金属间化合物层和残余镀银层扩散至不锈钢一侧,与Fe原子生成Fe-Al金属间化合物;在任意给定的扩散钎焊低条件下,可以对化合物层厚度进行初步估算。

关键词:铝合金;6063铝合金;不锈钢;Ag;扩散钎焊;化合物生长

中图分类号:TG454 文献标志码:A

Diffusion brazing of Al/Ag plating layer/steel and growth behavior of interface compound

WU Ming-fang1, 2, SI Nai-chao1, CHEN Jian2

(1. School of Material Science and Engineering, Jiangsu University, Zhenjiang 212013, China;

2. School of Materials Science and Engineering, Jiangsu University of Science and Technology, Zhenjiang 212003, China)

Abstract: The 6063 Al alloy/Ag plating layer/1Cr18Ni9Ti was joined by diffusion brazing. The growth behavior of the intermetallics (IMC) at the interface was discussed. The results show that Fe-Al IMC layer and Ag (Al) solid solution form in the side of stainless steel and Al alloy in the joint, respectively. Meanwhile, the microstructure at the centre zone is composed of Ag-Al IMC and Ag (Al) solid solution. As the diffusion holding time at low temperature is prolonged, the thickness of IMC layer increases. The grain boundary penetration is obvious due to the side of Al alloy rich in Ag. Ag-Al IMC forms initially, and then Fe-Al IMC occurs as Al atom diffusing through Ag-Al IMC layer and residual Ag plating layer and reacting with Fe atom in the stainless steel. The thickness of IMC layer can be estimated in the optional given condition of diffusion brazing.

Key word: Al alloy; 6063 aluminum alloy; stainless steel; Ag; diffusion brazing; compound growth

接触反应钎焊是利用母材与接触反应材料形成共晶体的特点,在界面接触良好且加热温度超过共晶温度的条件下,通过原子间相互扩散在被连接材料表面形成液相并完成润湿铺展,从而实现材料连接的方法。与常规钎焊相比,接触反应钎焊时无需添加钎剂,连接过程所需加热温度较低,且具有一定的自清理母材表面氧化膜的作用[1-5]。固相扩散焊具有连接温度低、残余应力小和焊接冶金缺陷少等特点[6-7]。为了充分发挥两者的特点,本文作者提出采用扩散钎焊连接6063铝合金与1Cr18Ni9Ti不锈钢。基本工艺过程如下:首先在真空条件下加热至Al-Ag共晶熔点以上,待其熔化充分完成对基体材料的润湿铺展之后迅速降到Al-Ag共晶点温度以下进行保温,以期减少焊缝中Al-Fe金属间化合物的含量,消除焊缝的微观缺陷,防止母材性能恶化,最终实现提高接头性能的目的。

选择Ag作为接触反应材料是基于以下几点考 虑[8-9]:由Al-Ag二元合金相图可知,当加热温度达到566 ℃、Ag的含量为72%(质量分数)、Al的含量为28%(质量分数)时,在Al/Ag紧密接触界面可以发生共晶反应而产生液相,填充接头间隙,从而为后续低温扩散焊的顺利实施及获得致密接头提供保障;由于Ag较软,在扩散钎焊加热初期借助其塑性变形促进与6063铝合金连接界面的紧密接触,且其热膨胀系数介于6063铝合金和1Cr18Ni9Ti不锈钢的之间,可以缓解焊接应力;在焊缝中生成一定量的Ag-Al金属间化合物,从而可以减少Fe-Al金属间化合物的生成量。由于Ag-Al金属间化合物的脆性小于Fe-Al的,这对于防止接头严重脆化具有一定的意义。

在此,本文作者通过对6063铝合金/镀银层/ 1Cr18Ni9Ti不锈钢的扩散钎焊试验,重点研究界面金属间化合物的生长行为,从而为优化工艺参数、解决工程实际应用提供理论依据。

1 实验

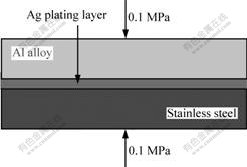

试验母材为6063铝合金和1Cr18Ni9Ti不锈钢,试样尺寸15 mm×15 mm×2 mm,按图1所示进行装配,并外加0.1 MPa压力。中间反应层材料Ag采用焊接前预置在不锈钢表面,厚度为10 ?m。具体步骤如下:不锈钢待镀面打磨—清洗—活化—镀银—清洗。6063铝合金试样焊接前,使用金相砂纸打磨并用超声波在丙酮溶液中清洗。

图1 试样装配示意图

Fig.1 Schematic diagram of specimen assembly

铝合金具有很强的化学活性,为了防止6063铝合金表面出现二次氧化现象,整个焊接过程在真空环境中完成。根据Al-Ag共晶温度(566 ℃)及6063铝合金液-固相线温度(615~655 ℃),选择初次加热温度590 ℃,待镀银层完全溶解充分并完成对基体材料表面的润湿铺展之后,迅速降温进行扩散保温,低温扩散温度分别为530和550 ℃,保温时间控制在10~120 min范围内。焊接结束后,借助扫描电子显微镜和电子探针对接头的微观组织及Fe-Al金属间化合物生长情况进行测试和分析。

2 结果与分析

2.1 保温时间对组织的影响

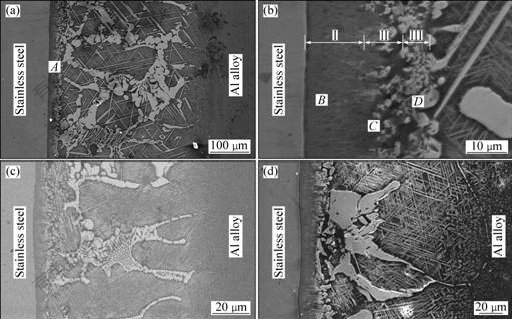

6063铝合金/镀银层/1Cr18Ni9Ti不锈钢扩散钎焊接头的SEM像如图2所示。图2(b)所示为图2(a)中A区域的放大图。初次加热熔化温度T1都为590 ℃,低温扩散温度T2为550 ℃,保温时间分别为10 min、30 min、60 min。

图2 550 ℃时保温不同时间后接头界面的微观组织

Fig.2 Microstructures of interface of joint after holding at 550 ℃ for different times: (a) 50 min; (b) Magnification of zone A in Fig.2(a); (c) 10 min; (d) 60 min

由图2(b)可以发现,整个焊缝明显由3层组成,即靠近1Cr18Ni9Ti不锈钢一侧的Ⅰ区,靠近6063铝合金一侧的Ⅲ区,焊缝中心深灰色组织和颗粒状浅灰色组织混合而成的Ⅱ区。Ⅰ区宽度约12 μm,Ⅱ区宽度8 μm左右,Ⅲ区形状不规则,最大区域宽度达到6~7 μm,最小区域宽度仅2~3 μm。能谱测试结果表明,B点处Al含量为21.90%(摩尔分数,下同),Fe含量为70.45%,Ag含量为3.38%,Ni含量为4.27%;C点处Al含量为64.17%,Fe含量为2.01%,Ag含量为33.82%;D点处Al含量17.44%,Ag含量为82.56%。根据以上测试结果并结合Al-Ag、Al-Fe二元合金相图及已有的研究成果可以认为,靠近不锈钢一侧的Ⅰ区(B点)由Al与Fe、Ag、Ni形成的化合物构成,主要含Fe-Al化合物;Ⅱ区基本由Ag-Al化合物和Ag(Al)固溶体混合而成;块状浅灰色组织(Ⅲ区)主要为Ag(Al)固溶体。保温时间10 min后(见图2(c)),靠近不锈钢一侧界面已形成明显的反应层,总厚度约为8~10 μm,但分层现象不明显,界面无缩孔、未钎透等微观焊接缺陷;6063铝合金一侧基体白色针状析出组织已清晰可见,但相互交替生长呈网格状现象尚不明显,中间反应层Ag沿6063铝合金晶界扩散已非常显著,在晶界与Al形成了大量的Ag-Al共晶组织。当保温时间从10 min延长至60 min(见图2(d)),不锈钢一侧界面反应层生长迅速,厚度达到23 μm左右;6063铝合金一侧基体白色针状析出相更加明显,交替生长呈网格状一目了然,6063铝合金晶界因晶界渗透而生成的Ag-Al共晶组织已基本消失,说明Ag在6063铝合金中的活性较大,首先沿晶界产生选择性扩散形成共晶液相后,迅速向6063铝合金基体中发生体积扩散。

2.2 界面金属间化合物层的生长行为

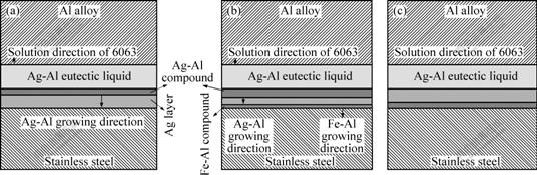

图3所示为Ag-Al共晶反应及化合物生成过程。由图3可看出,加热6063铝合金/镀银层/1Cr18Ni9Ti不锈钢试样,Al和Ag原子产生相互扩散,当加热温度达到共晶温度566 ℃时、界面Ag和Al达到共晶点浓度时,Ag-Al发生共晶反应生成液相,从而在6063铝合金与镀银层之间产生固液界面,与此同时在镀银层一侧界面生成Ag-Al金属间化合物。随着扩散钎焊加热温度升高至590 ℃,由于界面两侧的Al和Ag原子存在极大的浓度差,在扩散驱动力的作用下,6063铝合金中的Al原子迅速向Ag侧扩散,镀银层中的Ag原子向6063铝合金基体中扩散,导致6063铝合金因共晶反应而进一步溶解,宏观上表现为液相区的宽度不断增大。因此,可以说该液相区增宽的原因是因为镀银层中的Ag原子源源不断地经共晶液相层扩散至6063铝合金一侧界面形成的。另外,由于共晶液相中的Al原子经Ag-Al金属间化合物层扩散至镀银层。因此,可以看到随着加热过程的持续,Ag-Al金属间化合物层不断增厚,其生长方向指向镀银层,以消耗镀银层中的Ag原子为代价连续向镀银层中生长(见图3(a))。在共晶温度以上长时间加热,共晶液相中的Al原子不仅产生Ag-Al金属间化合物,甚至穿越镀银层扩散至不锈钢一侧界面而生成Fe-Al金属间化合物层,镀银层最终因参与共晶反应及与Al发生化学反应生成Ag-Al金属间化合物而逐渐消失(见图3(b))。在随后的降温扩散保温过程中,Ag-Al共晶液相发生共晶反应,生成Ag(Al)固溶体和Ag-Al金属间化合物,另外Ag-Al金属间化合物层、Fe-Al金属间化合物层厚度进一步增加(见图3(c))。

图3 Ag-Al共晶反应及化合物生成过程示意图

Fig.3 Schematic diagrams of Ag-Al eutectic reaction and formation process of compound: (a) First stage of diffusion;(b) Intermediate stage of diffusion brazing; (c) Final stage of diffusion brazing

由以上分析可知,采用扩散钎焊连接6063铝合金/镀银层/1Cr18Ni9Ti不锈钢,在不锈钢一侧会生成Fe-Al、Ag-Al金属间化合物层。当低温扩散温度为550 ℃、保温10 min时,金属间化合物复合层厚度达到10 μm;当保温时间延长至60 min,复合层厚度增加到23 μm左右。何鹏等[10]通过对相变扩散连接界面生成金属间化合物的数值分析表明,原子扩散速度是制约金属间化合物相生长的主要因素,而原子扩散速度与温度和时间有着密切的关系。

当使用扩散钎焊、钎焊、扩散焊和接触反应钎焊等焊接方法连接异种材料时,界面反应层的生长,特别是金属间化合物反应层的增厚对接头性能将产生严重影响[11-14]。因此,分析和研究界面金属间化合物的形成及长大规律,进而在焊接过程中对其进行严格控制,防止其快速生长,甚至将金属间化合物反应层厚度限制在特点的范围内,这对于提高焊接接头的致密性和力学性能非常重要。

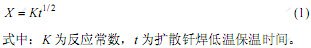

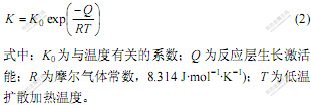

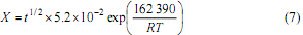

大量研究表明[15-16],界面金属间化合物反应层厚度(X)与焊接时间的平方根成正比,即

其中K与温度之间的关系可表示如下:

将式(2)代入式(1)可得:

对式(3)两边取自然对数得

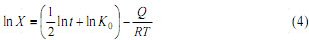

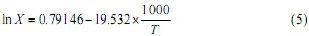

以lnX与1/T作图,得一直线,该直线的斜率即为-Q/R,在lnX轴上的截距即为1/2lnt+lnk0。lnX与1/T的关系曲线如图4所示。

图4 金属间化合物厚度与温度的关系

Fig.4 Relationship between temperature and thickness of intermetallics

经拟合后的lnX与1/T直线方程可表示为

即

计算得

由 -19.532×103,计算得Q=162.39 kJ/mol。

-19.532×103,计算得Q=162.39 kJ/mol。

因此,在任意给定的扩散钎焊低温保温温度下,可以用式(7)对不锈钢界面金属间化合物的厚度进行初步估算,以确立低温扩散温度与保温时间的最佳偶合值。

3 结论

1) 在合适的工艺参数条件下,接头组织致密。靠近不锈钢一侧为Fe-Al化合物层,靠近铝合金一侧主要是Ag(Al)固溶体,焊缝中心区域由Ag-Al化合物和Ag(Al)固溶体混合而成。随着低温扩散保温时间的延长,化合物层厚度增加,Ag在铝合金基体一侧富集,出现晶界渗透现象。

2) Fe-Al和Ag-Al金属间化合物的出现具有先后次序,由于Al原子扩散路径的缘故,首先产生Ag-Al金属间化合物,然后共晶液相中的Al原子穿越Ag-Al金属间化合物层和残余镀银层扩散至不锈钢一侧,与Fe原子生成Fe-Al金属间化合物,即Fe-Al金属间化合物的产生具有延迟特性。

3) 在任意给定的扩散钎焊低温保温温度和时间条件下,可以通过 对化合物层厚度进行初步估算。

对化合物层厚度进行初步估算。

REFERENCES

[1] 邱小明, 孙大谦, 殷世强. Al共晶接触反应钎焊接头形成过程和机理[J]. 机械工程学报, 2001, 37(4): 53-55.

QIU Xiao-ming, SUN Da-qian YIN Shi-qiang. Process and mechanism of al eutectic contacting reaction brazing[J]. Chinese Journal of Mechanical Engineering, 2001, 37(4): 53-55.

[2] 吕学勤, 杨尚磊, 吴毅雄, 石忠贤. 铝合金与不锈钢的过渡层钎焊[J]. 焊接学报, 2004, 25(1): 95-102.

L? Xue-qin, YANG Shang-lei, WU Yi-xiong, SHI Zhong-xian. Transitional layers brazing of Al-alloy and stainless steel[J]. Transactions of the China Welding Institution, 2004, 25(1): 95-102.

[3] 董占贵, 钱乙余, 石素琴, 吴培莲. Al/Cu/Al接触反应钎焊液相行为及其连接[J]. 焊接学报, 2001, 22(6): 45-47.

DONG Zhan-gui, QIAN Yi-yu, SHI Su-qin, WU Pei-lian. Behavior of Al/Cu/Al contact reaction liquid and its brazing[J]. Transactions of the China Welding Institution, 2001, 22(6): 45-47.

[4] 董占贵, 钱乙余, 马 鑫, 石素琴. 接触反应钎焊中间层材料的选择原则—接触反应共晶液相产生的方向性[J].中国有色金属学报, 2002, 12(2): 241-244.

DONG Zhan-gui, QIAN Yi-yu, MA Xin, SHI Su-qin. Law for selecting interlayer in contact reactive brazing—Orientation of production of eutectic liquid in contact reaction[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(2): 241-244.

[5] 何 鹏, 钱乙余, 冯吉才, 韩杰才, 麦汉辉, 黄振凤. 复合电热餐具铝/不锈钢接触反应钎焊新技术[J]. 中国有色金属学报, 2003, 13(6): 1519-1522.

HE Peng, QIAN Yi-yu, FENG Ji-cai, HAN Jie-cai, MAI Han-hui, HUANG Zhen-feng. A new technology for contact reactive brazing of aluminum to stainless steel in composite electro-thermal cooker[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(6): 1519-1522.

[6] KOTANI K, IKEUCHI K, MATSUDA F. Interfacial phase in diffusion-bonded joints of commercial Al alloys[J]. Quarterly Journal of the Japan Welding Society, 1996, 14(2): 3822-388.

[7] ENJO T, IKEUCHI K, YOSHIKAWA H. Behavior of superflcial oxide film in diffusion bonding of Al-Si-Mg series 6063 alloy[J]. IIW Doc No. IX-1561-89.

[8] KAZUYOSHI S, SHIN-ICHI K, KAZUTOSHI N. Improvement in interfacial reactivity of A6061 by eutectic reaction between A6061 and precoated metals[J]. Quarterly Journal of the Japan Welding Society, 2005, 23(3): 405-411.

[9] NISHIMOTO K, SAIDA K, KURODA S. Removing of surface oxide film of SUS316 and improvement of diffusion-bond ability of A6061 aluminum alloy to SUS316 stainless steel using surface-activated pre-coating technique[J]. Quarterly Journal of the Japan Welding Society, 2000, 18(4): 563-571.

[10] 何 鹏, 张九海, 冯吉才, 钱乙余. 相变扩散连接界面生成金属间化合物的数值模拟[J]. 焊接学报, 2002, 21(3): 75-78.

HE Peng, ZHANG Jiu-hai, FENG Ji-cai, QIAN Yi-yu. Numeric simulation for interface intermetallic compounds of phase transformation diffusion bonding[J]. Transactions of the China Welding Institution, 2002, 21(3): 75-78.

[11] LIU S, SUZUMURA A, IKESHOJI T T, YAMAZAKI T. Brazing of stainless steel to various aluminum alloys in air[J]. JSME Int J Series A, 2005, 48(4): 420-425.

[12] IKESHOJI T T, LIU Shu-ying, SUZUMURA A, YAMAZAKI T. Effect of isothermal solidification behavior of Al-Si brazing filler layer on the braze-ability of Al-alloy to stainless steel in the air[J]. Quarterly Journal of the Japan Welding Society, 2006, 24(4): 362-367.

[13] IKEUCHI K, KOTANI K, MATSUDA F. Behavior of oxide at diffusion-bonded interface of Al-Mg-Si series 6063 alloy[J]. Quarterly Journal of the Japan Welding Society, 1996, 14(1): 122-128.

[14] ENJO T, IKEUCHI K J. Diffusion welding of Al-Cu-Mg series 2017 alloy[J]. Quarterly Journal of the Japan Welding Society, 1984, 2(4): 599-605.

[15] PATIL R V, KALE G B, GAWDE P S. Diffusion rea1ctions in titanium/Inconel-600 system[J]. Journal of Nuclear Materials, 2001, 297: 153-160.

[16] 周 飞, 李志章. Ti/Cu/Ti部分瞬间液相连接Si3N4的界面反应和连接强度[J]. 中国有色金属学报, 2001, 11(2): 273-278.

ZHOU Fei, LI Zhi-zhang. Interfacial reaction and joint strength of Si3N4 partial transient liquid-phase bonded with Ti/Cu/Ti multi-interlayer[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(2): 273-278.

________________________________

基金项目:江苏省研究生创新计划资助项目(CX08S_008Z)

收稿日期:2009-01-05;修订日期:2010-01-18

通信作者:吴铭方, 教授; 电话: 0511-84401185; E-mail: Wu_MingFang@163.com

(编辑 龙怀中)