文章编号:1004-0609(2010)07-1282-08

电磁软接触铸造7050高强铝合金扁锭的组织和力学性能

郭世杰1, 薛冠霞1, 刘金炎1, 马 科1, 王家淳1, 李廷举2, 曹志强2

(1. 苏州有色金属研究院,苏州 215026;2. 大连理工大学 铸造工程研究中心,大连 116023)

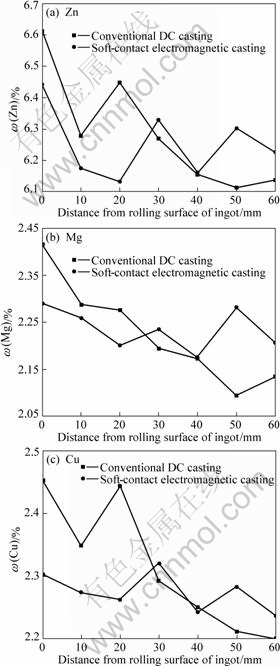

摘 要:通过数值模拟与试验研究的方法,采用软接触电磁铸造技术制备7050高强铝合金扁铸锭。模拟结果表明,施加软接触电磁场后,铸锭内部的流动场和温度场分布均发生改变。试验结果表明:采用电磁软接触铸造技术后,铸锭表面粗糙度由常规铸造时的101.1 mm降低至48.6 mm,平均晶粒由常规铸造时的80~85 mm细化至55~ 70 mm,晶粒尺寸不均匀度由常规铸造的21.69%降低至11.50%;此外,采用电磁软接触铸造工艺后,铸锭的合金化元素偏析得到抑制,Zn、 Mg、 Cu三元素的最大偏析率分别由常规铸造时的6.62%、9.54%、7.92%降低至3.87%、3.63%、1.36%,合金化元素分布更加均匀。

关键词:7050铝合金;电磁软接触铸造;细化;偏析;数值模拟

中图分类号:TG244.1 文献标志码:A

Microstructures and mechanical properties of

soft-contact electromagnetic DC casting 7050 high-strength alloy ingot

GUO Shi-jie1, XUE Guan-xia1, LIU Jin-yan1, MA Ke1, WANG Jia-chun1, LI Ting-ju2, CAO Zhi-qiang2

(1.Suzhou Institute for Nonferrous Metal Process Technology, Suzhou 215026, China;

2. Research Center of Foundry Engineering, Dalian University of Technology, Dalian 116023, China)

Abstract: By the numerical simulation and experimental investigation, the 7050 ingots were successfully produced by soft-contact electromagnetic demicontinuous casting (SEC). Simulation results show that fluid flow field and thermal field inside the ingot are changed by the electromagnetic field. Experimental results show that, with the soft-contact electromagnetic casting, the surface roughness of the ingot decreases from 101.1 mm to 48.6 mm, the grain size and grain unevenness of ingots decrease from 80-85 mm and 21.69% to 55-70 mm and 11.50%, respectively. The segregations of alloying elements Zn, Mg and Cu are suppressed by applying the soft-contact electromagnetic field. In the demicontinuous (DC) casting, the segregation rates of alloying elements Zn, Mg and Cu are 6.62%, 9.54% and 7.92%, respectively. After applying the soft-contact electromagnetic field, the segregation rates of alloying elements Zn, Mg and Cu decrease to 3.87%, 3.63% and 1.36%, respectively. The distributions of alloying elements are more uniform.

Key words: 7050 aluminum alloys; soft-contact electromagnetic demicontinuous casting (SEC); refinement; segregation; numerical simulation

应用电磁场改善铝合金铸锭质量的研究近年来一直受到广泛关注。电磁场在铝合金半连续铸造过程中的应用最早可追溯至20世纪60年代。前苏联铝合金专家GETSELEV首次将电磁场引入到铝合金的半连续铸造领域,在DC铸造的基础上开发了铝合金电磁铸造技术(Electromagnetic casting, EMC)[1-2]。该技术采用2~10 kHz的交变电磁场,利用金属液与电磁场的交互作用产生指向铸锭轴线的电磁推力,在铸造过程中铸锭不与结晶器模壁接触,而是完全依靠电磁推力凝固成形,因此该技术也称无模铸造技术。采用电磁铸造工艺制备的铝合金锭坯表面非常光滑,可以不用铣面而直接进行轧制,生产效率得到显著提高[3]。

在电磁铸造的工艺基础上,相继开发了多种电磁铸造工艺,并取得了较好的试验效果[4-7]。电磁软接触铸造技术(Soft-contact electromagnetic DC casting, SEC)是法国人VIVES[4-5]在电磁铸造技术的基础上于1987年首次提出的,他在传统铝合金结晶器外布置电磁感应线圈,利用电磁力与结晶器内壁共同支撑液态金属,从而实现 “软接触”铸造,并达到改善铸锭冷却过程、细化铸锭显微组织的目的。电磁软接触铸造技术提出后相继在铝合金铸造和钢连铸中得到了持续关 注[8-10]。目前,软接触铸造选择的磁场范围主要有两种:一种是采用频率为几万赫兹或者更高的交变电磁场,这种电磁场形成的金属弯月面稳定性较好,但是在设计制造软接触结晶器和建造复杂的能源供应设备及变频装置等方面存在一定的技术难度;另一种是采用50~1 500 Hz的中低频电磁场,这种方法在结晶器设计难度上大大简化,但是弯月面的稳定控制问题亟待解决。

本文作者以VIVES提出的电磁软接触铸造为研究基础,采用中频交变电磁场,以难熔铸的7050作为试验铝合金[11],采用结构优化设计的结晶器和电磁线圈布置方式[12],解决软接触铸造结晶器的透磁性问题;利用数值模拟与试验研究相结合的方法,实现 133 mm×440 mm 7050铝合金扁锭的软接触电磁铸造过程,并考察该工艺条件下7050铝合金扁锭的组织和力学性能。

1 实验

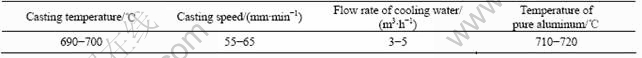

本试验过程采用常规铸造和电磁软接触铸造对比研究的方式。在铸造试验中均采用纯铝铺底的铸造工艺,即先铸造一定长度的工业纯铝,然后再铸造合金铸锭,利用工业纯铝良好的收缩性能来抑制铸锭的底部裂纹。半连续铸造工艺如表1所示。

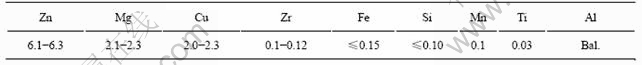

试验用7050铝合金成分如表2所示。采用工业纯铝锭为原料,主合金元素Zn、Cu和Mg分别以纯锌、纯铜和纯镁锭的形式加入,微量元素Zr以铝锆中间合金形式加入。首先,将纯铝锭放入感应炉内熔炼,当炉内铝锭熔化成液体后分别加入Cu锭,炉内温度升高至830~850 ℃时加入锰剂,搅拌熔体;当温度降至690~700 ℃时加入纯镁锭和纯锌锭,然后将合金熔体转入中间包,并进行除气、精炼和静置处理;当熔体温度降低至700~720 ℃时准备进行铸造试验。

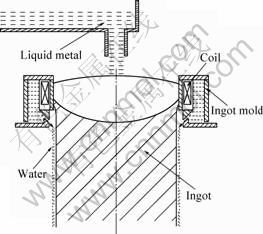

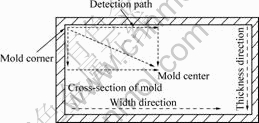

电磁软接触铸造的试验原理示意图如图1所示。采用内置电磁线圈的软接触结晶器,在铸造过程中,线圈内通入1 350 Hz的中频电磁场,依靠金属内的感生电流与外加电磁场交互作用实现“软接触”铸造过程。常规铸造采用的装备与软接触铸造的一致,只是在铸造过程中线圈中不施加交变电磁场。

图1 电磁软接触铸造的试验原理示意图

Fig.1 Principle schematic diagram of soft-contact electro- magnetic casting

表1 半连续铸造工艺

Table 1 Processing parameters of demicontinuous casting

表2 7050合金的化学成分

Table 2 Chemical composition of 7050 aluminum alloys (mass fraction, %)

2 模拟计算模型

根据Maxwell方程组,电磁场在结晶器内的分布规律满足下列方程[13-15]:

(1)

(1)

式中:E 为电场强度;B为磁感应强度;H为磁场强度;D为电位移矢量; 为电流密度;D为电位移矢量;

为电流密度;D为电位移矢量; 为电荷密度。

为电荷密度。

考虑到电磁软接触铸造结晶器系统的对称性,取结晶器的1/4部分作为研究对象,计算模型包括结晶器、感应线圈、铝合金熔体以及结晶器周围的空气区域等,模型建立尺寸与结晶器系统实际尺寸一致,如图2所示。模拟计算用到材料的物理性能如表3所列。

图2 电磁软接触铸造网格模型

Fig.2 Mesh model of soft-contact electromagnetic casting

3 结果与讨论

在软接触电磁连铸中,感应线圈所产生的交变电磁场,其磁感应强度及在空间的分布特性与磁场作用范围内金属导体的位置、形状以及线圈与结晶器的相对位置等因素密切相关。为实现较佳的电磁软接触铸造,要求结晶器内磁场强度达到一定值[16]。

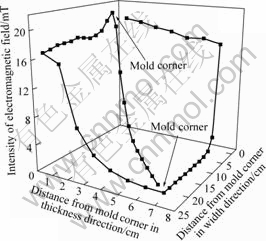

采用特斯拉计分别沿结晶器宽度方向和厚度方向检测结晶器内部磁场强度分布,检测路径如图3所示。为减小电磁场在结晶器角部的集聚,在结晶器内增设屏蔽体。

当线圈中通入频率为1 350 Hz,强度为2 500 A的交变电流时,结晶器内磁场强度变化规律如图4所示。可见,电磁场能够穿透结晶器本体进入结晶器内部,沿结晶器宽度和厚度方向、结晶器内壁靠近线圈的部分磁感应强度均在16~21 mT的范围内变化。在结晶器角部,磁场强度有一定幅度的升高,达20.5 mT。随着靠近结晶器中心距离的减小,电磁场强度逐渐呈指数衰减,在结晶器中心位置几乎检测不到电磁场强度。由检测结果可知,结晶器内电磁场主要集中分布于感应线圈附近,由结晶器内壁至中心,电磁场强度呈指数衰减。

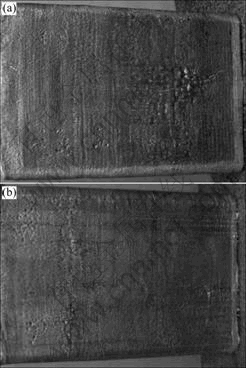

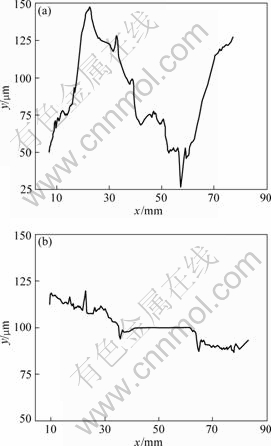

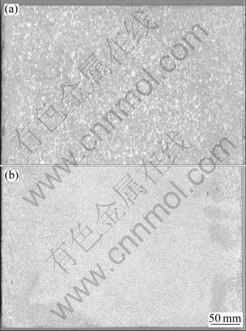

采用常规半连续铸造和电磁软接触铸造制备的铸锭照片如图5所示,两种工艺下铸锭的表面粗糙度如

图3 电磁场检测路径

Fig.3 Detection path of electromagnetic field

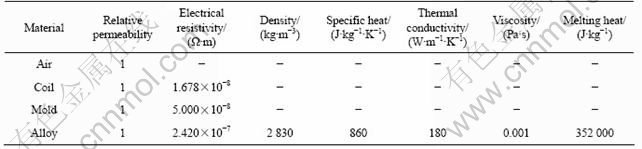

表3 材料的物理性能

Table.3 Physical properties of materials

图4 结晶器内电磁场的分布

Fig.4 Distribution of electromagnetic filed in mold

图5 常规铸造和电磁软接触铸造的7050铸锭照片

Fig.5 Photos of 7050 ingots cast by conventional DC casting (a) and soft-contact electromagnetic casting (b)

图6所示。可见,常规铸造的铸锭表面较粗糙,部分区域分布偏析瘤,表面粗糙度为101.1 mm;软接触铸造的铸锭表面偏析瘤消失,粗糙度降低至48.6 mm,表面更趋光滑。

电磁软接触铸造后,铸锭表面粗糙度降低,其主要原因是电磁推力对液态金属的支撑作用。采用软接触铸造时,线圈中通入中频交变电流,在结晶器内产

图6 常规铸造和电磁软接触铸造的铸坯的表面粗糙度

Fig.6 Surface roughnesses of ingots cast by conventional DC casting (a) and soft-contact electromagnetic casting (b)

生交变磁场B。铸造时结晶器内始终会有一定高度的液态金属熔体,由电磁学可知,处在交变电磁场作用范围内的导电金属熔体内部会产生交变感应涡电流密度 。

。

由麦克斯韦方程组可知,金属内任意一点受到的Lorentz力可表示为

(2)

(2)

式中:μ为磁导率。式(2)中第一项 称为有旋力,即体积旋转力,对金属起强制搅拌的作用;第二项

称为有旋力,即体积旋转力,对金属起强制搅拌的作用;第二项 称为无旋力,起源于电磁压力,它对液态金属起支撑作用。

称为无旋力,起源于电磁压力,它对液态金属起支撑作用。

在本研究的电磁场条件下,结晶器内金属熔体受到的Lorentz力的模拟计算结果如图7所示。与图4的电磁场分布规律类似,Lorentz力主要集中分布在铸锭的边部,即与结晶器内壁接触的部分。Lorentz力的有旋和无旋部分共同决定其方向由铸锭外表面斜向下指向铸锭中心。这样,与常规铸造方式相比,结晶器内的金属熔体除受到结晶器内壁的支撑力外,还受到Lorentz力的支撑作用。铸造过程中熔体与结晶器内壁的接触静压力会因Lorentz力的支撑而减小,滑动摩擦力降低。因此,软接触铸造后,铸锭表面粗糙度降低,表面质量提高。

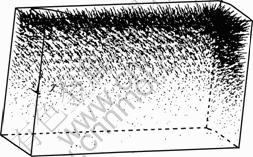

采用常规铸造和电磁软接触铸造的7050铸锭的纵截面宏观组织如图8所示。采用常规铸造的铸锭的晶粒较粗大并且分布非常不均匀,局部区域可见光亮柱状晶粒。而采用电磁软接触铸造的铸锭整个截面组织均匀、细小,未见柱状晶分布区。

图7 铸锭受到的Lorentz力

Fig.7 Lorentz force inside ingot

图8 常规铸造和电磁软接触铸造的铸锭纵截面宏观组织照片

Fig.8 Longitudinal sections of ingots cast by conventional DC casting (a) and soft-contact electromagnetic casting (b)

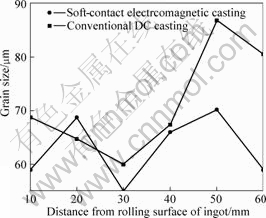

沿板坯横截面依次从铸锭边部至中心每隔10 mm取样,采用直接交割法定量测量试样的晶粒尺寸,每个试样测量20次,取平均值,检测结果如图9所示。采用常规铸造时,接近铸锭表面激冷区的晶粒较细小,晶粒尺寸为60~70 mm,越靠近铸锭中心,铸锭的冷却速率越慢,晶粒尺寸也越大。在铸锭中心区,晶粒尺寸为80~85 mm。计算得到铸锭各区域晶粒尺寸分布的不均匀度为21.69%。采用电磁软接触铸造后,铸锭内各个部分的晶粒均得到细化,从铸锭边部至中心,晶粒尺寸在55~70 mm的范围内。在此工艺条件下,铸锭晶粒分布更加均匀,其尺寸不均匀度减小至11.50%。

图9 常规铸造和电磁软接触铸造的铸锭内部晶粒尺寸变化

Fig.9 Variations of grain sizes inside ingot cast by soft- contact electromagnetic casting and conventional DC casting

由图8所示的铸锭组织可知,采用电磁软接触铸造的7050铸锭内部的显微组织比常规铸造方式的更加细小,铸锭不同区域的晶粒分布也更加均匀。可以认为,铸锭内的显微组织变化与电磁软接触铸造过程中结晶器内的电磁搅拌有关。

已有研究表明[17],无模EMC电磁铸造工艺金属熔体内部的电磁搅拌作用可以细化2024铝合金铸坯的显微组织。在本研究的软接触电磁铸造过程中,采用的工艺和无模电磁铸造的类似,但应用的电磁场频率范围低于无模电磁铸造(EMC)的。

由Lorentz公式可知,其有旋力和无旋力之间的作用关系可表示为[18]:

(3)

(3)

式中:L为特征长度,即铸锭横截面尺寸; 为集肤层深度。

为集肤层深度。

对于一定规格的铝合金铸锭,随着电磁场频率的降低, 逐渐增大,熔体受到的Lorentz力中有旋力越占主导,即电磁搅拌作用越强。因此,电磁软接触铸造过程中结晶器内的电磁搅拌作用比无模电磁铸造工艺的强。

逐渐增大,熔体受到的Lorentz力中有旋力越占主导,即电磁搅拌作用越强。因此,电磁软接触铸造过程中结晶器内的电磁搅拌作用比无模电磁铸造工艺的强。

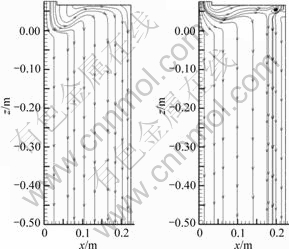

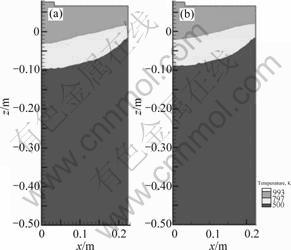

常规铸造和软接触铸造时铸锭沿宽度方向的熔体流动和温度场模拟结果分别如图10和图11所示。从图10和11可以看出,常规铸造时,铸锭内部呈自然

图10 常规铸造和电磁软接触铸造的铸锭内部熔体流动模拟结果

Fig.10 Simulation results of melt flow inside ingots by conventional DC casting (a) and soft-contact electromagnetic casting (b)

图11 常规铸造和电磁软接触铸造的铸锭温度场分布

Fig.11 Distributions of temperature fields inside ingots by conventional DC casting (a) and soft-contact electromagnetic casting (b)

流动状态,高温液态金属受到重力的作用进入结晶器后继续向下流动,冲击至铸锭液穴底部后部分回流补充至铸锭边部,形成沿铸锭轴线对称的两个回旋区。铸锭内金属熔体的最大流动速度即入口速度为0.016 m/s。采用电磁软接触铸造后,铸锭内部的金属流动状态发生改变,除具有常规铸造时存在的自然流动状态外,在靠近结晶器内壁附近存在由电磁搅拌力驱动的顺时针方向的强制对流,金属液被充分搅拌。模拟结果表明,软接触铸造时金属液内部的最大速度为0.93 m/s,远高于常规铸造时铸锭内部的最大速度。同时,在电磁搅拌的作用下,铸锭内温度场的分布也发生改变。从图11所示的温度场模拟结果可知,采用常规铸造时,铸锭的液穴深度为50.4 mm,而采用软接触铸造时,铸锭的液穴深度降低至41.9 mm。也就是说,在电磁搅拌的作用下,电磁力驱动的金属液强制对流能起到均匀铸锭内部温度,降低液穴深度的作用。本文作者认为,正是由于电磁搅拌的存在,在改变铸锭内部熔体流动状态和温度分布的同时,为铸锭内枝晶的破碎和增值提供了良好的环境,铸锭内更加浅平的液穴有利于铸锭内各个区域晶粒的存活和游离,从而在细化铸锭组织的同时改善铸锭晶粒分布的均匀 程度。

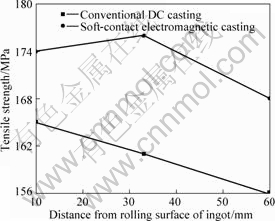

电磁软接触铸造后,7050铸锭的力学性能变化规律如图12所示。可见,常规铸造时,铸锭内部的抗拉强度在155~165 MPa的范围内变化,铸锭中心的抗拉强度最低,边部的最高。采用软接触铸造后,铸锭内部的抗拉强度在167~178 MPa的范围内变化,整体优于常规铸造的,同时铸锭内不同位置的抗拉强度差别也减小。这主要是由于软接触铸造后铸锭内部的显微组织更细小,不同区域晶粒尺寸差别减小所致。

图12 常规铸造和电磁软接触铸造的铸锭内部抗拉强度的变化

Fig.12 Variations of tensile strength inside ingots by conventional DC casting and soft-contact electromagnetic casting

合金元素宏观偏析是高合金化铸锭常易出现的铸造缺陷之一。7050合金铸锭凝固后,合金化元素常易富集于铸锭表面,形成偏析层,并造成在铸锭表层先凝固的区域合金元素含量高,而在后凝固的中心区域合金元素含量低,形成所谓的“反偏析”现象。为定量表示铸锭内合金化元素的偏析程度,采用下式计算合金元素的偏析率ε:

(4)

(4)

式中:w为元素检测含量,wn为元素名义成分。

采用X射线荧光光谱仪定量检测不同工艺下Zn、Mg、Cu主合金元素在铸锭内部的分布,结果如图13所示。采用常规铸造时, Zn、Mg、Cu主合金元素的“反偏析”现象明显,分布极不均匀,Zn、Mg、Cu元素的最大偏析率分别为6.62%、9.54%、7.92%。采用软接触电磁铸造后,Zn、Mg、Cu元素在铸锭边部偏聚的现象得到一定抑制,但在铸锭中心元素含量有一定程度的升高。经计算,采用软接触铸造时,Zn、Mg、Cu元素的最大偏析率分别降低至3.87%、3.63%、1.36%,元素分布更加均匀。

一般认为铸锭内部这种大范围的元素偏析与凝固后期铸锭内枝晶间熔体的宏观流动有关[19]。在铸锭凝固后期,凝固收缩产生的压力差会引发铸锭内部枝晶间富含溶质的熔体向铸锭表面流动,并最终导致铸锭元素“反偏析”现象的出现。而在软接触铸造过程中,电磁搅拌驱动的金属液环流会部分抑制由凝固收缩导致的枝晶间熔体的定向流动,并促使合金元素在整个未凝固液态熔体中的分布更加均匀。同时,铸锭内细化的显微组织会使凝固后期枝晶通道更加细小,熔体定向流动更加困难,从而有利于抑制合金元素向铸锭边部富集,改善宏观偏析。

4 结论

1) 数值模拟研究表明,在软接触铸造过程中,结晶器内熔体受到由铸锭边部斜向下指向铸锭中心的Lorentz力作用,结晶器内部的金属流动场和温度场发生改变,靠近线圈区域存在强制对流,铸锭液穴深度降低。

2) 采用软接触铸造时,金属熔体受到的电磁推力有助于改善铸锭的表面质量。试验研究表明,电磁软接触铸造使7050铸锭表面粗糙度由常规铸造的101.1 mm降低至48.6 mm。

图13 常规铸造和电磁软接触铸造的铸锭内部合金化元素分布

Fig.13 Distributions of alloying elements inside ingots by soft-contact electromagnetic casting and conventional DC casting

3) 采用软接触铸造时,电磁搅拌作用有助于细化铸锭显微组织。试验研究表明,电磁软接触铸造使7050铸锭晶粒尺寸由常规铸造时的80~85 mm细化至55~70 mm,晶粒不均匀度由常规铸造时的21.69%降低至11.50%。

4) 采用常规铸造时,Zn、Mg、Cu元素的最大偏析率分别为6.62%、9.54%、7.92%;软接触铸造后,元素分布更加均匀,Zn、Mg、Cu元素的最大偏析率分别降低至3.87%、3.63%、1.36%。

REFERENCES

[1] GETSELEV Z V. Casting in an electromagnetic field [J]. Journal of Metals, 1971, 23(10): 38-44.

[2] LAVERS J D, BRINGER P P. Electromagnetic transport and confinement of liquid metals [J]. IEEE Transactions on Magnetics, 1989, 25(3): 495-502.

[3] 贾 非, 曹志强, 张兴国, 郝 海, 金俊泽. 电磁铸造2024铝合金组织性能研究[J]. 大连理工大学学报, 2001, 41(5): 572-577.

JIA Fei, CAO Zhi-qiang, ZHANG Xing-guo, HAO Hai, JIN Jun-ze. Research on microstructure and mechanical characteristics of EMC and DDC 2024 aluminium alloys[J]. Journal of Dalian University of Technology, 2001, 41(5): 572- 577.

[4] VIVES C. Electromagnetic refining of aluminum alloys by the CERM process (part Ⅰ): Working principle and metallurgical results [J]. Metallurgical and Materials Transactions B, 1989, 20: 623-630.

[5] VIVES C. Electromagnetic refining of aluminum alloys by the CREM process (part Ⅱ): Specific practical problems and their solutions [J]. Metallurgical and Materials Transactions B, 1989, 20: 631-643.

[6] 董 杰, 崔建忠, 赵志浩. 低频电磁铸造超高强高韧铝合金元素晶内固溶度和力学性能研究[J]. 航空材料学报, 2003, 23(1): 17-20.

DONG Jie, CUI Jian-zhong, ZHAO Zhi-hao. Intracrystalline element solubility and mechanical property of a new super-high strength and toughness Al alloy cast under low frequency electromagnetic field[J]. Journal of Aeronautical Materials, 2003, 23(1): 17-20.

[7] CAO Zhi-qiang, JIA Fei, ZHANG Xing-guo, HAO Hai, JIN Jun-ze. Microstructures and mechanical characteristics of electromagnetic casting and direct-chill casting 2024 aluminum alloys [J]. Mater Sci Eng A, 2002, 327: 133-137.

[8] 段玉波, 唐 剑, 刁文武, 牟大强. 化学成分对7050合金扁锭成型性能的影响[J]. 重庆大学学报, 2004, 27(4): 100-102.

DUAN Yu-bo, TANG Jian, DIAO Wen-wu, MOU Da-qiang. Effect of chemical composition on formation performance of 7050 alloy billets[J]. Journal of Chongqing University, 2004, 27(4): 100-102.

[9] 李 军, 王同敏, 蔡少武, 许菁菁, 王家淳, 曹志强, 李廷举. 硬铝合金软接触电磁连铸矩形结晶器透磁性能模拟[J]. 特种铸造及有色合金, 2008(S1): 523-525.

LI Jun, WANG Tong-min, CAI Shao-wu, XU Jing-jing, WANG Jia-chun, LI Ting-ju. Numerical simulation on magnetic penetrating performance of soft-contact electromagnetic casting rectangular mould for duraluminium alloys[J]. Special Casting & Nonferrous Alloys, 2008(S1): 523-525.

[10] 毕德显. 电磁场理论[M]. 北京: 电子工业出版社, 1985: 300-325.

BI De-xian. Theory of electromagnetic field[M]. Beijing: Electronic Industry Press, 1985: 300-325.

[11] 蔡圣善, 朱 耘. 经典电动力学[M]. 上海: 复旦大学出版社, 1984: 20-37.

CAI Sheng-shan, ZHU Yun. Classical electrodynamics[M]. Shanghai: Fudan University Press, 1984: 20-37.

[12] STRATTON J A. Electromagnetic theory[M]. New York: McGraw-Hill Inc, 1987: 273-279.

[13] 韩至成. 电磁冶金学[M]. 北京: 冶金工业出版社, 1996: 145-146.

HAN Zhi-cheng. Electromagnetic metallurgy[M]. Beijing: Metallurgical Industry Press, 1996: 145-146.

[14] 曹志强, 贾 非, 张兴国, 金俊泽, 郝 海, 金锡元. 电磁铸造与普通连续铸造2024铝合金的组织性能对比[J]. 材料工程, 2002(6): 37-39.

CAO Zhi-qiang, JIA Fei, ZHANG Xing-guo, JIN Jun-ze, HAO Hai, JIN Xi-yuan. Microstructures and mechanical characteristics of EMC and DCC 2024 aluminum alloys[J]. Material Engineering, 2002(6): 37-39.

[15] 房灿峰, 贾 非, 金俊泽, 亓 锋, 李廷举. 铝合金的软接触电磁连铸研究[J]. 铸造, 2004, 53(5): 350-353.

FANG Can-feng, JIA Fei, JIN Jun-ze, QI Feng, LI Ting-ju. Research on soft-contact electromagnetic casting of aluminium alloy[J]. Foundry, 2004, 53(5): 350-353.

[16] YU H, GRANGER D A. Macrosegregation in aluminum alloy ingot cast by the semicontinuous direct chill (DC) method [C]// Aluminum Alloy: Their Physical and Mechanical Properties. UK: EMAS, 1986: 17-29.

[17] DORWARD R C, BEERNTSEN D J. Effects of casting practice on macrosegregation and microstructure of 2024 alloy billet [J]. Light Metals, 1990: 919-924.

[18] RERKO R S, de GROH HC, BECKERMANN C. Effect of melt convection and solid transport on macrosegregation and grain structure in equiaxed Al-Cu alloys [J]. Mater Sci Eng A, 2003, 347: 186-197.

[19] VREEMAN C J, KRANE M J M, INCROPERA F P. The effect of free-floating dendrites and convection on macrosegregation in direct chill cast aluminum alloys. Part I: Model development [J]. International Journal of Heat and Mass Transfer, 2000, 43: 677- 686.

(编辑 杨 华)

基金项目:江苏省自然科学基金资助项目(BK2008562)

收稿日期:2009-08-25;修订日期:2010-04-20

通信作者:李廷举,教授;电话:0411-4708940;E-mail: tjuli@dlut.edu.cn