文章编号: 1004-0609(2005)05-0799-07

喷焊工艺对钛基体镍基涂层显微组织和性能的影响

王宏宇, 张雪峰, 许晓静, 刘 曦, 陈康敏, 潘 励

(江苏大学 机械工程学院 先进成形技术研究所, 镇江 212013)

摘 要: 采用常规喷焊工艺和改进喷焊工艺, 在Ti-6Al-4V合金表面上制备了镍基耐磨涂层, 分析了涂层的形貌和合金元素的扩散, 测试了涂层的显微硬度, 定性地研究了基体和涂层的结合性能。 结果表明: 改进工艺所制备的涂层组织和性能均优于常规工艺的, 涂层组织的均匀性大大提高, 晶粒得到细化; 基体和涂层为明显的冶金结合; 涂层显微硬度的变化沿层深方向呈连续性和渐变性, 其表层显微硬度高达HV933.2。 采用合理的喷焊工艺能够在钛合金表面制备出性能优良的耐磨涂层。

关键词: 钛合金; 镍基涂层; 火焰喷焊; 显微组织; 性能 中图分类号: TG174.4; TG146.2

文献标识码: A

Influence of spray-welding technology on microstructures and properties of Ni-based coating on titanium substrate

WANG Hong-yu, ZHANG Xue-feng, XU Xiao-jing, LIU Xi, CHEN Kang-min, PAN Li

(Institute of Advanced Forming Technology, School of Mechanical Engineering,

Jiangsu University, Zhenjiang 212013, China)

Abstract: The Ni based wear resistance coatings on the Ti-6Al-4V alloy substrate by common flames spray-welding technique and flames spray-welding improved technique were prepared. The microstructures and the elements distributions of coating were analyzed, and the microhardness and adhesion properties were studied. The results show that the microstructures and properties of coating prepared by the improved technique have been improved obviously, the uniformity of coating microstructure is improved and its grains become smaller, the adhesion of the substrate and the coating is metallurgical bonding. The change of microhardness for coating are continuous and gradual along depth direction, and the microhardness of spray-welding surface is HV933.2. It indicates that adopting improved spray-welding technique is able to prepare excellent wear resistance coating on the titanium alloys substrate.

Key words: titanium alloy; Ni-based coating; flames spray-welding; microstructure; property

钛合金具有比强度高、 耐腐蚀性强、 高温力学性能稳定等优点, 但也存在硬度低、 耐磨性较差的不足, 因此在要求具有抗磨损性能的应用中, 钛合金只有经过改善摩擦学行为的表面改性处理后才被使用。 钛合金表面耐磨处理技术很多, 但都存在不同程度的局限性。 随着钛合金从军用转向民用进程的不断深入, 探讨一种适合于工程实践的钛合金表面耐磨处理技术有着重要意义[1-10]。

火焰喷焊技术是一种较为成熟的表面耐磨处理技术, 以其节能、 价廉、 高效、 灵活等优点被广泛应用于多种材料的表面耐磨处理。 同时, 镍基自熔性合金又是一种具有优良耐磨抗蚀性能的涂层材料。 但关于采用火焰喷焊技术在钛合金表面上制备镍基耐磨涂层, 国内外鲜见报道[11-13], 主要有两个方面的原因: 1) 钛合金表面活性较高, 与氧的亲和力很强, 自熔性合金粉末中的B和Si元素无法将其还原, 很难获得喷焊所需要的清洁表面, 因此一般认为在钛和钛合金基体上不适合采用火焰喷焊; 2) 火焰喷焊温度较高且焊层冷却速度较快, 合金元素的扩散不能充分进行, 残余应力较大, 钛合金基体和涂层很难获得良好的结合性能。

文献[13]的研究表明, 表面预处理工艺和重熔工艺对火焰喷焊涂层的组织性能影响很大, 因此本文着重探讨了表面预处理工艺和重熔工艺对钛合金表面喷焊涂层组织和性能的影响。

1 实验

实验选用Ti-6Al-4V合金为基体材料, 喷焊试样尺寸为d40mm×10mm。 喷焊材料选用上海斯米克焊材有限公司生产的F102镍基自熔性合金粉末, 其化学成分(质量分数, %): 16.4Cr、 4.1B、 4.2Si、 1.9Fe、 0.84C、 Ni为余量, 粒度为106μm。

本研究采用“两步法”喷焊工艺, 使用常规工艺[13]和改进工艺[14]制备试样, 所制备的试样分别标记为试样1和试样2, 两种工艺主要区别在于表面预处理工艺和重熔工艺。 喷焊实验采用SPH-2/h型喷枪, 工艺参数: 氧气压力为0.4MPa, 氧气流量为310~360L/h, 乙炔压力为50~70kPa, 乙炔流量为430~560L/h, 送粉量为1.5kg/h, 喷粉距离为100~120mm, 预热温度为230~270℃。

采用配有AN10000型X射线能谱仪的JXA-840A型扫描电镜进行组织形态观察和化学成分分析, D/max-2500PC型X射线衍射仪进行喷焊层物相分析, HXD-1000TMB型硬度计测定显微硬度, 载荷为29.4N, 加载时间为15s。

2 结果与分析

2.1 显微组织

图1所示为喷焊试样横截面的SEM形貌。 从图1中可看出, 试样1的涂层和基体的界面非常明显, 基体和涂层并未完全熔合, 在基体一侧隐约出现了一个尺寸不足100μm的暗灰色过渡层, 且喷焊层底层和表层的组织差别很大, 有明显的分层。 试样2的界面不规则, 基体和涂层完全熔合, 且在基体与涂层之间形成了大约200~300μm的过渡层, 喷焊层的组织均匀且无分层现象。

图1 喷焊涂层的横截面形貌

Fig.1 SEM morphologies of ross section for coating

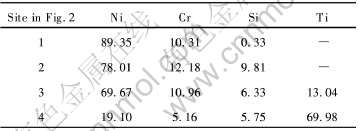

图2所示为试样1喷焊层组织的SEM形貌。 图2(a)和(b)分别取自喷焊层的上部和下部, 图2(c)所示为下部组织的局部放大形貌。 从图2中可以看出, 试样1喷焊层的上部组织有基本相, 呈骨骼分布的胞状枝晶相和微量颗粒相; 而喷焊层的下部组织为不规则爪状组织周围包覆着弥散有颗粒相的灰色大片组织。

根据X射线衍射谱和能谱分析结果(表1)结合Ni-Cr、 Ni-Si、 Ni-Ti等有关相图分析可知, 喷焊层上部的组织以镍基固溶体为主, 其中基本相富含铬和硅; 胞状枝晶相富铬, 而硅的含量很少; 颗粒状组织为Cr23C6、 Cr3C7、 CrB和Ni3B等硬质相。 喷焊层下部含有大量钛元素, 说明基体中的部分钛扩散到了喷焊层, 但几乎所有钛元素都与镍形成针状组织团聚在一起, 其周围被镍基固溶体所包覆。 造成钛元素在喷焊层下部团聚主要是由于喷焊层温度较高且冷却速度较快, 富钛区域中的钛来不及均匀扩散所致。

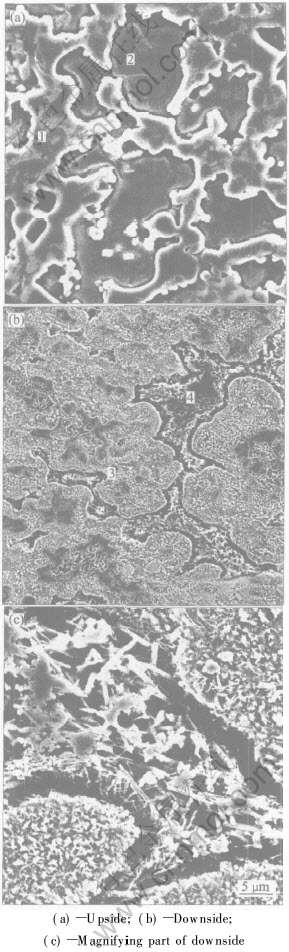

表1 试样1喷焊层显微组织元素的EDAX结果

Table 1 Elements EDAX analysis results of

microstructure for sample 1 (mass fraction,%)

图2 试样1喷焊层的SEM像

Fig.2 SEM morphologies of pray welding layer for sample 1

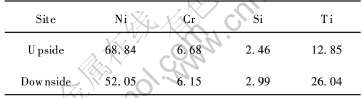

图3所示为试样2喷焊层组织的SEM形貌。 图3(a)取自喷焊层的上部, 图3(b)取自喷焊层的下部。 由图2可见, 试样2喷焊层的组织是在基本相上分布着灰色块状和黑色颗粒组织, 喷焊层的组织比较均匀且晶粒细小, 只是靠近喷焊表层的黑色颗粒状组织增多, 而灰色块状组织相应减少。

图3 试样2喷焊层的SEM像

Fig.3 SEM morphologies of pray welding layer for sample 2

根据X射线衍射谱、 能谱分析结果和相关相图分析结果可知, 基本相为镍基固溶体, 其中固溶了铬、 硅、 钛等元素; 灰色块状组织为富钛的镍基固溶体; 黑色颗粒状组织为Cr23C6、 TiC等碳化物和TiB2、 Ni3B等硼化物硬质颗粒。 在喷焊表层中出现弥散分布的大量硬质颗粒与涂层合金液态停留时间较长[14]和基体的熔解量较大且各元素扩散能力的增强有关, 基体中的钛元素扩散到喷焊表层以及涂层合金中含量较高的铬元素都会与C、 B形成化合物。 虽然喷焊层下部的钛元素含量较高, 但大部分钛固溶在镍中形成富钛的镍基固溶体, 因此在喷焊层下部组织中, 灰色块状较多, 而黑色颗粒状组织较少。

表2 试样2喷焊层显微组织的EDAX结果

Table 2 EDAX analysis results of

microstructure for sample 2 (mass fraction, %)

根据上述分析可见, 试样1和2的喷焊层组织有着明显区别, 这主要是由于钛元素的充分扩散所致, 钛元素在喷焊层以固溶和形成碳化物及硼化物两种形式存在, 强化了喷焊层, 同时还起到了细化晶粒的作用。

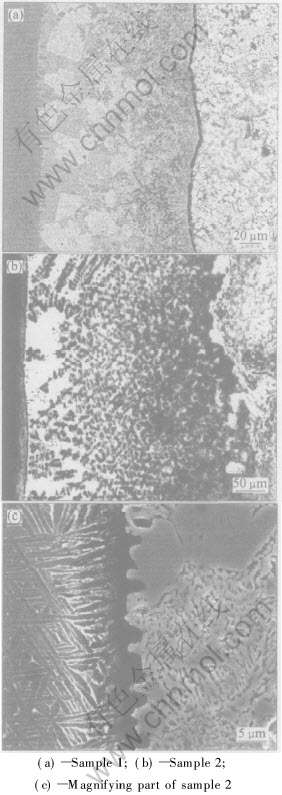

图4所示为过渡层的SEM形貌。 由试样1的过渡层形貌(见图4(a))可知, 其过渡层中虽有元素的扩散, 但基体和涂层并没有明显的熔合, 只是在靠近基体处出现了一些柱状晶, 且过渡层组织比较粗大, 同时在过渡层和喷焊层之间存在大量的夹杂氧化物, 把基体和涂层明显分为两部分。 从图4(b)和(c)中可以看出, 试样2出现了非常明显的熔合现象, 整个过渡层呈现非平衡凝固组织特征, 靠近基体一侧首先形成了平面微晶区, 此后沿热流方向, 结晶形态依次转变为柱状晶、 树枝晶和等轴晶, 且晶粒都比较细小。 过渡层的结晶形态主要受温度梯度(G)和结晶速度(v)两个参数控制[15]。 结晶首先在靠近基体一侧开始, 此时温度梯度(G)大于结晶速度(v), 故形成平面晶; 随着结晶的进行, 温度梯度(G)变小, 而结晶速度(v)逐渐加快, 因此结晶形态由平面晶逐渐向等轴晶转变。

图4 过渡层组织的SEM形貌

Fig.4 SEM morphologies of transition layer

由试样1的过渡层组织特征可知, 采用常规喷焊工艺确实很难在钛合金表面上获得结合性能良好的镍基合金耐磨涂层。 而通过改进的喷焊工艺制备出的试样2, 涂层和基体表现为明显的冶金结合, 过渡层的显微组织沿层深方向呈现连续性和渐变性, 涂层与基体的结合性能优良。 这一点在喷焊后的磨削加工中得到了很好的证实, 试样1在磨削过程中在进给量仅为30μm的情况下就出现了喷焊层的脆断, 脆断发生在靠近基体一侧, 这与其过渡层的显微组织特征相吻合。 而试样2在磨削过程中, 即使砂轮的进给量很大(>0.1mm)情况下, 涂层仍保持完好, 这说明涂层和基体具有很好的结合性能。

根据图4(a), 试样1过渡层的底部组织由于产生了过热变得非常粗大, 虽然图中没有能够很好地反映基体热影响区的组织形貌, 但根据钛合金热导性较差的性能可知, 试样1的基体热影响区组织多为过热组织。

由图4(c)可看出, 试样2靠近过渡层的基体形貌为针状组织, 说明在喷焊时, 基体表层的温度已超过Ti-6Al-4V合金的相变温度, 基体由片层状的(α+β)两相组织转变为单相β组织后, 由于冷却速度较快而形成了过饱和α固溶体所致。 由于靠近结合界面处的基体在喷焊过程中产生了非扩散型相变, 使得喷焊试样的性能变化更加平缓。

2.2 合金元素的扩散

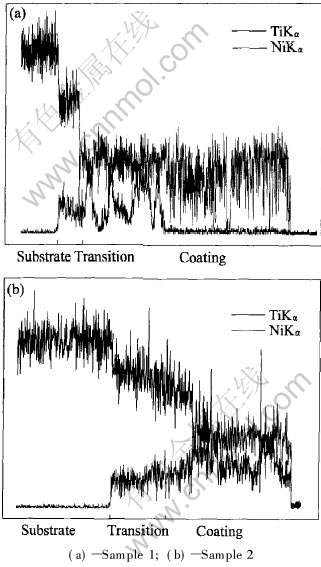

图5所示为喷焊试样基体/涂层中主要元素钛和镍在整个横截面上的分布情况。

图5(a)所示为试样1的线扫描结果, 从图5中可以看出, 钛和镍两元素的扩散在基体/过渡层和过渡层/喷焊层交界处均发生突变。 在喷焊层下部, 钛元素起伏很大; 在喷焊表层, 基本不含钛元素。 这和试样1的组织特征相符, 说明试样1中合金元素的扩散非常有限, 而且分布不均匀。 由图5(b)中试样2的线扫描结果中可知, 钛和镍两元素在整个横截面上相互扩散, 合金元素的分布沿层深变化平缓且具有连续性, 为基体与涂层形成良好的化学结合创造了有利条件, 同时根据前面分析可知, 钛元素已经扩散到喷焊表层并形成了TiC和TiB2等硬质颗粒。

图5 合金元素沿层深分布情况

Fig.5 Elements distributions of lloys along coating depth

2.3 涂层的显微硬度

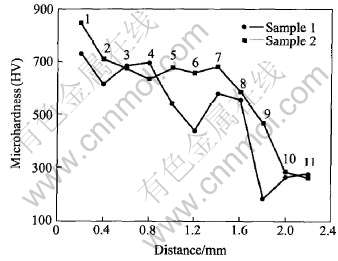

图6所示为喷焊试样横截面显微硬度沿层深方向的变化曲线。 从图6中可以看出, 显微硬度曲线存在3个区域, 这和图1所示的喷焊试样的形貌相吻合, 即1~7为喷焊层, 8、 9是过渡层的硬度, 而10、 11为基体硬度。 试样1的显微硬度变化起伏程度较大, 且6和9出现了两个软点, 这和涂层组织及合金元素的分布情况相一致, 9和6分别处于基体/过渡层和过渡层/喷焊层交界处, 相对来说比较薄弱, 合金元素的扩散在该处也出现了突变。 而试样2的显微硬度变化相对平缓, 有效地解决了在软基体向硬涂层过渡过程中由于硬度突变而引起的综合性能下降的问题。

图6 显微硬度沿层深方向的变化

Fig.6 Various of micro hardness along oating depth

此外, 试样2的喷焊表层硬度比试样1的高, 达到了HV933.2(试样1为HV847.2), 这主要是由于试样2中钛元素扩散到喷焊表层, 对涂层产生了强化所致。

3 讨论

根据本研究结果和分析可知, 采用改进后的喷焊工艺能够在钛合金表面上获得结合性能优良的火焰喷焊涂层。 涂层和基体的结合处具有较为理想的显微组织结构, 界面两侧合金元素的充分扩散以及横切面上显微硬度变化的连续性都较好地证实了这一点。

3.1 表面活化处理

改进后的喷焊工艺在表面预处理中增加了表面活化处理[14]。 钛合金经过活化后, 在表面形成了活化层, 起两个方面的作用: 1) 防护作用 钛合金基体得到了有效的保护, 避免其再次被氧化; 2) 结合作用 在喷焊过程中, 活化层能够被硼和硅元素还原, 为钛和镍等合金元素的扩散创造了条件。

3.2 涂层液态停留时间

在喷焊重熔过程中, 原子或分子间的相互扩散是其结合的基本机理, 这点和钎焊类似。 根据钎焊金属在液态钎料中熔解量公式(1)以及扩散定律的表达式(2)可知, 喷焊合金的液态停留时间是增加基材熔解量和喷焊合金成分扩散量的主要参数之一。

式中 G为熔解量; ρy为液态钎料的密度; Cy为钎焊金属在液态钎料中的极限熔解度; Vy为液态钎料的体积; S为液固相的接触面积; a为钎焊金属的原子在液态钎料中的熔解系数; t为接触时间。

式中 dm为液态组元的扩散量; D为扩散系数; S′为扩散面积; dc/dx为扩散组元在扩散方向的浓度梯度; dt为扩散时间。

基体与涂层的扩散型结合取决于基材熔解量和喷焊合金成分扩散量, 因此重熔时涂层合金的液态停留时间对于结合性能非常重要。 对于45钢等钢铁材料作为基体而言, 重熔时涂层合金的液态较佳停留时间为5~7s[13]。 对于钛合金基体而言, 界面处元素扩散的制约因素较多, 因此在重熔过程中, 当出现镜面反光之后, 要合理操作喷枪, 在保证涂层合金不产生流淌的前提下, 使涂层在液态停留的时间尽可能长一些。

4 结论

1) 采用改进后的喷焊工艺制备的涂层, 涂层的组织均匀性明显提高且晶粒细小, 获得了在强韧性很好的镍基固溶体上弥散分布大量硬质相的耐磨组织。

2) 基体/涂层界面处的组织, 合金元素扩散和显微硬度的连续性、 渐变性和基体和涂层明显的冶金结合都说明了采用改进后的喷焊工艺, 大大提高了涂层和基体的结合性能。 本研究改进了表面预处理工艺以及重熔工艺, 有效保护了钛合金基体, 促进了原子扩散, 增强了涂层和基体界面的结合。

3) 扩散到喷焊层的钛元素以固溶于镍基合金和形成碳化物及硼化物两种形式存在, 细化了晶粒, 强化了喷焊层。

REFERENCES

[1]李文平. 钛合金的应用现状及发展前景[J]. 轻金属, 2002, 39(5): 53-55.

LI Wen-ping. Development and application of titanium alloys[J]. Light Metal, 2002, 39(5): 53-55.

[2]Kathy W. The use of titanium for medical application in USA[J]. Mater Sci Eng A, 1996, A213(12): 134-136.

[3]Budinski K G. Tribological properties of titanium alloys[J]. Wear, 1991, 151(2): 203-213.

[4]Molinari A. Dry sliding wear mechanisms of the Ti-6Al-4V alloy[J]. Wear, 1997, 208(3): 105-112.

[5]孙荣禄, 郭立新, 董尚利. 钛及钛合金表面耐磨热处理[J].宇航材料工艺, 1999, 29(5): 15-19.

SUN Rong-lu, GUO Li-xin, DONG Shang-li. Surface abrasion resistance heat-treatment of titanium and titanium alloys[J]. Aerospace Materials & Technology, 1999, 29(5): 15-19.

[6]Kim D H. Characterization of diamond-like carbon films deposited on commercially pure Ti and Ti-6Al-4V alloy[J]. Mater Sci Eng C, 2002, C22(1): 9-14.

[7]Khor K A. Microstructure and mechanical properties of plasma sprayed HA/YSZ/Ti-6Al-4V composite coatings[J]. Biomaterials, 2004, 25(18): 4009-4017.

[8]向兴华, 刘正义, 陈康年, 等. 炉熔处理对等离子喷涂Ni基WC型涂层组织形态的影响[J]. 中国有色金属学报, 2001, 11(1): 111-115.

XIANG Xing-hua, LIU Zheng-yi, CHEN Kang-nian, et al. Influence of remelting in furnace on microstructure of plasma sprayed WC+Ni base self-fluxing alloy coating[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(1): 111-115.

[9]李晓泉, 于冶水, 王光耀. 钛合金非氧化热喷涂金属钼涂层界面冶金特征[J]. 焊接学报, 2003, 24(4): 25-27, 32.

LI Xiao-quan, YU Ye-shui, WANG Guang-yao. Metallurgy characteristics of interface with titanium alloys coated by molybdenum for non-oxidation spray[J]. Transactions of the China Welding Institution, 2003, 24(4): 25-27, 32.

[10]Liu J L. Laser gas alloying of titanium alloys[J]. Surface & Coatings Technology, 1993, 57(2): 191-195.

[11]Kim H J, Hwang S Y, Lee C H, et al. Assessment of wear performance of flame sprayed and fused Ni-based coating[J]. Surface & Coating Technology, 2003, 172(23): 262-269.

[12]Kahraman N, Behcet G. Abrasive behaviour of powder flame sprayed coatings on steel substrates[J]. Materials & Design, 2002, 23(8): 721-725.

[13]刘曦. 氧乙炔火焰喷焊工艺参数对喷焊层结合强度影响的分析[J].中国机械工程, 1996, 7(3): 96-98.

LIU Xi. Analysis of binding strength of spray weld coating influenced by technological parameter of oxyacetylene spraying[J]. China Mechanical Engineering, 1996, 7(3): 96-98.

[14]许晓静, 王宏宇, 陈康敏. 钛合金表面耐磨涂层的火焰喷焊方法[P]. CN 200410065213.9, 2004.

XU Xiao-jing, WANG Hong-yu, CHEN Kang-min. The Spray-Welding Technique of Wear Resistance Coating on Titanium Alloys Substrate[P]. CN 200410065213.9, 2004.

[15]李平, 邓永瑞. 钛合金表面激光熔覆氧化锆陶瓷涂层的显微组织[J]. 稀有金属材料与工程, 1995, 24(4): 19-24.

LI Ping, DENG Yong-rui. Microstructure of ceramic coating of laser coating ZrO2 on titanium alloy[J]. Rare Metal Materials and Engineering, 1995, 24(4): 19-24.

基金项目: 江苏大学高级人才基金资助项目(1283000007)

收稿日期: 2004-11-19; 修订日期: 2005-03-08

作者简介: 王宏宇(1974-), 男, 讲师, 硕士.

通讯作者: 许晓静, 副教授, 博士; 电话: 0511-8791295; E-mail: xjxu67@sohu.com

(编辑李艳红)