文章编号:1004-0609(2008)09-1607-06

累积复合轧制对镁合金组织和力学性能的影响

张 兵,袁守谦,张西锋,吕 爽,王 超

(西安建筑科技大学 材料科学与工程学院,西安 710055)

摘 要:采用累积复合轧制技术对MB2镁合金进行轧制。采用光学显微镜、透射电镜和电子拉伸机等设备分析变形前及不同道次后MB2镁合金的微观组织和力学性能。结果表明:MB2镁合金经ARB轧制后,材料平均晶粒尺寸由变形前17.8 μm有效细化到1.2 μm;材料的抗拉强度和显微硬度值分别提高到300 MPa和82.1;伸长率在ARB1道次后从24%下降到11.2%,且随着ARB轧制道次的增加,材料组织的均匀程度提高,抗拉强度和硬度值变化平缓,伸长率回升至22.5%。

关键词:MB2镁合金;累积复合轧制;组织细化;力学性能

中图分类号:TG 146.2 文献标识码:A

Effect of accumulative roll bonding on microstructures and mechanical properties of MB2 magnesium

ZHANG Bing, YUAN Shou-qian, ZHANG Xi-feng, L? Shuang, WANG Chao

(School of Materials Science and Engineering, Xi’an University of Architecture and Technology, Xi’an 710055, China)

Abstract: MB2 magnesium alloy was deformed by accumulative roll bonding (ARB) technology. The microstructures and mechanical properties of MB2 magnesium alloy after different pass ARB were observed and analyzed by optical microscopy, TEM and tensile testing machine. The results show that the average grain size is refined from 17.8 μm to 1.2 μm after MB2 magnesium alloy is deformed by ARB process. The tensile strength and microhardness rise to 300 MPa and 82.1, respectively. The elongation rate after ARB1 decreases from 24% to 11.2%. With the increase of ARB rolling pass, the homogeneous of materials is improved, the tensile strength and hardness change relatively smooth, but the elongation rate rise to 22.5%.

Key words: MB2 magnesium alloy; accumulative roll bonding(ARB); microstructure refinement; mechanical properties

镁合金是目前最轻的金属结构材料,具有密度低、比强度和比刚度高、阻尼减振性好、导热性好、电子屏蔽效果佳及良好的机械加工性和尺寸稳定性等特点,近年来受到人们的关注,特别是在汽车和航天航空工业领域的应用[1]。但由于镁及镁合金具有密排六方(HCP)晶体结构,滑移系少,同其他材料(Al和钢等)相比,具有塑性变形能力差,从而限制了其在工业上应用。因此,研究变形镁合金及其晶粒细化具有十分重要的意义。

晶粒细化可以提高镁及镁合金材料强度和韧 性,改善材料综合性能。同时,由于晶界协调变形在镁合金的塑性变形过程中起着相当重要的作用,可通过晶粒细化有效提高其晶界协调作用[1]。剧烈塑性变形(SPD)技术是制备块体超细晶材料的有效方法之一,目前,已知的剧烈塑性变形技术有:等通道角挤(ECAP)[2?3]、高压扭转(HPT)[4]、多向锻造(MF)[5]、往复挤压(CEC)[6?7]、累积复合轧制(ARB)[8?9]等。这些方法不但可以使金属材料产生较高的塑性应变,材料的晶粒尺寸得到有效细化,强度提高,且在一定的温度和变形速率条件下具有超塑性。文献[10?13]表明,镁合金经剧烈塑性变形后,晶粒细化,屈服强度和塑性提高,具有反Hall-Patch关系以及低温和高应变速率超塑性特征。

ARB是日本学者SAITO等提出的一种剧烈塑性变形方法,它的突出特点是通过多次重复复合轧制使材料获得较大的累积应变,而轧制后不改变材料的最终尺寸,有效细化材料组织和提高材料强度。由于这种方法具有工业化连续生产的可能,而受到越来越多的关注。CHEN等[14]、DEL VALLE等[15]、P?REZ- PREDO[16]和KIM等[17]对AZ31、AZ61和AZ91镁合金进行了多层堆垛式ARB工艺研究,分析了镁合金在变形过程中的显微组织及力学性能的变化,但其细化机制还有待全面和深入地研究。本文作者选用MB2镁合金为原料,研究了ARB技术对材料显微组织和力学性能的影响,分析ARB技术的晶粒细化机制。

1 实验

所选用的实验材料为尺寸为300 mm×100 mm×1.35 mm的热轧态MB2镁合金薄板,其化学成分为:3Al,0.8Zn,0.3Mn,余Mg(质量分数,%)。在箱式电阻炉中经400 ℃,1 h退火。用钢丝刷和丙酮对两块试样结合表面进行清理,去除氧化层和油污,并使试样表面具有一定的粗糙度,然后叠合在一起,经轧机无润滑轧制复合,道次压下量50%(即每道次的真应变等于0.8,总应变ε=0.8n,n是轧制道次[9]),轧制后空冷至室温,接着将轧后的薄板剪切成两块,表面处理后再进行轧制复合,共进行4道次实验。为了使镁合金材料能够很好地轧制复合,每道次轧制前,试样在350 ℃(高于再结晶温度)加热5 min,轧制时轧辊不加热。轧制实验在d 170 mm的二辊轧机上进行,轧辊转速为0.42 m/s(即变形速率为23 /s)。

用日本产OLYMPAS?GX51光学显微镜和JEM?200CXTEM透射电镜对轧制前和轧制后不同道次试样进行显微组织观察分析。拉伸性能测试在INSTRON?1341电子拉伸仪上进行,加载速度为1.0 mm/min,最大载荷为10 kN。采用WOLPERT? 401MVD显微硬度仪测量母材和轧制各道次试样表面的硬度值,载荷为1 N,时间为10 s。

2 结果与分析

2.1 光学显微组织变化

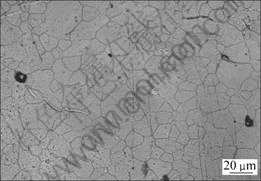

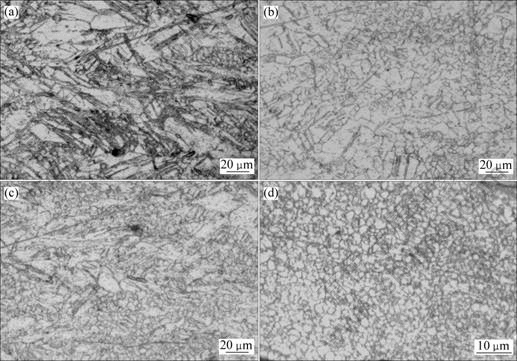

MB2镁合金轧制前的显微组织如图1所示。合金组织以白色α-Mg为基体相组成的单相固溶体,平均晶粒尺寸约为17.8 μm。ARB轧制变形后的组织如图2所示。由图2可看出,经过ARB1道次轧制后,原始试样的等轴晶粒在轧制力的作用下沿轧制方向拉长压扁,晶界不清晰,形变组织以孪晶为主,大部分孪晶穿过整个晶粒,在晶界及孪晶附近局部应变集中区域形成少量的细小动态再结晶晶粒,其所占比例很小。试样的晶粒尺寸没有明显细化,显微组织由大晶粒、孪晶和动态再结晶的小晶粒组成;经ARB2道次轧制后,试样中粗大晶粒数量减少明显,细小再结晶晶粒区域增大,但孪晶还占有相当大的区域(见图2(b));随着ARB轧制道次及应变量的增加,大晶粒数量不断减少,动态再结晶程度加大,再结晶组织大量增加,原晶粒的晶界处和晶内形成无畸变的细小晶粒(见图2(c));经ARB4道次后(见图2(d)),试样的组织基本上全是再结晶组织,组织均匀程度明显提高,细小晶粒所占比例达到90%,平均晶粒尺寸约为1.2 μm。

图1 ARB轧制前MB2镁合金显微组织

Fig.1 Microstructure of MB2 Mg alloy before ARB rolling

图2 试样经ARB轧制不同道次后的显微组织

Fig.2 Microstructures of samples after ARB rolling different passes: (a) ARB1; (b) ARB2; (c) ARB3; (d) ARB4

2.2 ARB3透射电镜组织

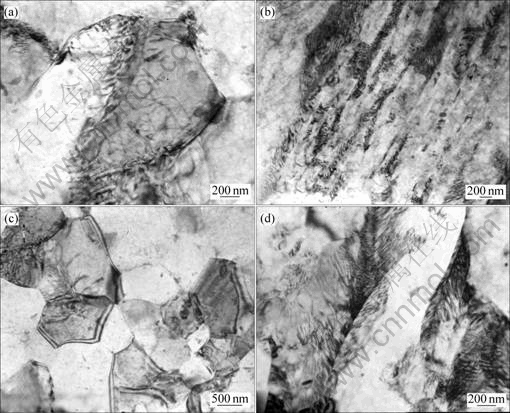

在ARB剧烈塑性变形过程中,MB2镁合金材料的微观组织变化主要是位错密度变化和位错的重新排列。图3所示为ARB 3道次试样的TEM明场像。由图3中可看出,经过ARB3道次变形后,材料的微观组织结构极不均匀,在晶粒内和晶界均分布着高密度位错(见图3(a))。同时,在试样中可以看到一些拉长亚晶的平行变形带穿过整个视场区域,变形带的位向 差增大,间距减小,形成高密度流线组织(见图3(b));在局部区域内,一些再结晶晶粒内没有位错,而其他晶粒内存在明显的位错(见图3(c))。这是由于在ARB变形时,材料内部产生位错,位错积累形成位错墙和位错胞,随着变形的继续,位错胞壁锐化形成亚晶(见图3(d))。在ARB下一道次轧制变形时,由于剧烈变形生成的高密度位错使材料内部储存了大量的能量,导致动态再结晶温度下降,还有变形时产生的热量,在位错密度较大的区域容易发生动态再结晶,形成新晶粒,致使区域内位错密度减小。因此,材料内有变形粗晶、亚晶和再结晶晶粒共存,组织结构极不均匀。随着ARB轧制道次的增加,材料的组织均匀性提高,试样内细小再结晶晶粒占据大部分区域。

图3 试样经ARB3道次后的TEM明场像

Fig.3 TEM bright field images of samples after ARB3 passed: (a) Dislocation in grain; (b) Sub-grains; (c) Recrystallized grains; (d) Dislocation cell

2.3 力学性能

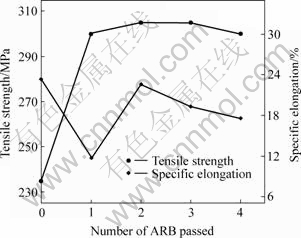

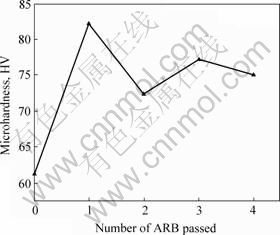

图4所示为MB2镁合金抗拉强度和伸长率随ARB道次的变化曲线。图5所示为MB2镁合金硬度随ARB道次的变化曲线。从图4和5可看出,经过ARB剧烈塑性变形后,MB2镁合金材料的抗拉强度和硬度均有提高。在ARB1道次后,抗拉强度由轧制前的235 MPa提高到300 MPa,增加了65 MPa,维氏硬度由轧制前的61.3提高到82.1;随着变形量的增加,抗拉强度变化平缓,显微硬度值略有下降,并趋于稳定。另一方面,ARB1道次后,MB2材料的伸长率由母材的24%下降到11.2%,且随着轧制道次的增加,伸长率在ARB2道次后回升至22.5%,然后略有减小。MB2镁合金材料经ARB1道次变形后,由于试样内引入大量的位错,位错密度增加,位错间的相互缠结和相互作用,使材料内应力增加,产生加工硬化,强度升高,塑性下降;经ARB2道次后,细小晶粒比例增

图4 MB2镁合金抗拉强度和伸长率随ARB道次的变化

Fig.4 Changes of tensile strength and specific elongation of MB2 Mg alloy with number of ARB passed

图5 MB2镁合金硬度随ARB道次的变化

Fig.5 Changes of microhardness of MB2 Mg alloy with number of ARB passed

加,材料的塑性得到一定的回复;经ARB3道次后,基体内位错密度达到饱和,强度达到最大值。但由于镁合金材料的密排六方晶体结构,滑移系少,加上轧制是在无润滑的条件下进行,容易在材料表面产生微裂纹等缺陷,从而使材料的伸长率下降。因此,随着ARB变形量的增加,超细晶粒数量增加和均匀程度的提高,对材料的强度、塑性和延展性均有所改善。同时,MB2镁合金经过ARB变形后,晶粒细化、织构变化、晶界结构以及残余应力的分布等因素对材料力学性能的提高有着重要的影响,有待进一步研究。

3 ARB细化机制

对于MB2镁合金的ARB剧烈塑性变形,其晶粒细化机制主要是形变诱导晶粒细化和热机械变形细化晶粒。由于累积变形量很大,导致材料动态再结晶温度下降,发生动态再结晶的临界点降低。本研究发现,在剧烈塑性变形作用下,变形带在粗晶内部沿切应力方向产生,产生的变形带可松弛局部应力集中,随着变形的继续,晶粒沿着变形带破碎细化。加上镁合金的滑移系少,粗晶晶界处应变协调性差,变形时易出现位错塞积,位错间的交互作用,形成胞状组织,随着变形量的增加,胞状组织转变为亚晶粒,进一步增加变形量,亚晶转变为新的再结晶晶粒,并在材料内储存能的驱动下促使更多的新晶粒形成。

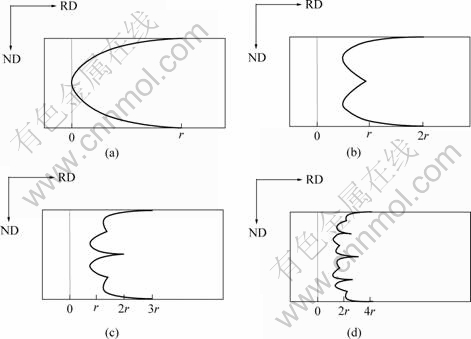

同时,ARB轧制时无润滑,轧辊和材料之间的摩擦作用,根据轧制变形理论和文献[17]研究显示,在板材次表面产生较大的剪切变形,且在厚度方向上存在较大的应变梯度,导致材料组织和织构在轧制后沿板材厚度方向分布不均,因此,材料内部容易产生取向各异、彼此交错的变形带,随着ARB轧制道次的增加,变形组织分布更为复杂。图6所示为材料经ARB工艺剪切变形示意图。经分析比较,ARB1道次后,板材表面的剪切变形程度明显比板材中心区域大(见图6(a));经过ARB2道次后,板材的表面进入材料的中心,将剪切变形带入材料内部(见图6(b));并随着ARB道次的增加,剪切应变沿厚度方向分布逐渐均匀(见图6(c)和(d)),材料的组织也逐步趋于 均匀。

图6 试样经ARB工艺剪切变形的示意图

Fig.6 Schematic diagram of samples after ARB deformation: (a) ARB1; (b) ARB2; (c) ARB3; (d) ARB4

4 结论

1) ARB技术可有效细化镁合金晶粒,经过ARB4道次后,平均晶粒尺寸由17.8 μm减小到1.2 μm。

2) 经过ARB变形后,MB2镁合金材料的强度和硬度值均有提高,而伸长率经ARB1道次后减小,并随着变形量的增加,强度和硬度值变化平缓,伸长率得到一定程度的回升。

3) 经350 ℃加热5 min后,MB2镁合金材料经ARB剧烈塑性变形时发生动态再结晶,并随着ARB轧制道次的增加,组织均匀性提高。

REFERENCES

[1] 陈振华. 变形镁合金[M]. 北京: 化学工业出版社, 2005.

CHEN Zhen-hua. Wrought magnesium alloy[M]. Beijing: Chemical Industry Press, 2005.

[2] SEGAL V M, REZNIKOV V I, DROBYSHEVSKII A E. Plasticheskaya obrabotka metallov prostym sdvigom(plastic metal working by simple shear)[J]. Metally, 1981, 1(1): 115?123.

[3] VALIEV R Z, KRASILNIKOV N A,TSENEV N K. Plastic deformation of alloys with submicron-grained structure[J]. Mater Sci Eng A,1991, 137(15): 35?40.

[4] VALIEV R Z, ISIAMGALIEV R K. Bulk nanostructural materials from severe plastic deformation[J]. Progress in Materials Science, 2000, 45(2): 103?189.

[5] 张小明, 张廷杰, 田 锋, 李忠奎, 马光来, 周 建. 多向锻造对改善7075铝合金性能的作用[J]. 稀有金属材料与工程, 2003, 32(5): 372?374.

ZHANG Xiao-ming, ZHANG Ting-jie, TIAN Feng, LI Zhong-kui, MA Guang-lai, ZHOU Jian. Effects of multi-direction forging on improving properties of 7075 aluminum alloy[J]. Rare Metal Materials and Engineering, 2003, 32(5): 372?374.

[6] RICHERT M, LIU Q, HANSEN N. Microstructural evolution over a large strain range in aluminum deformed by cyclic extrusion compression[J]. Mater Sci Eng A, 1999, 260(1/2): 275?283.

[7] 陆文林, 王 勇, 冯泽舟, 海锦涛. 沙漏挤压镦粗复合加工技术[J]. 塑性工程学报, 2000, 7(4): 1?4.

LU Wen-lin, WANG Yong, FENG Ze-zhou, HAI Jin-tao. Extrusion-upsetting multiple processing in sandglass[J]. Journal of Plasticity Engineering, 2000, 7(4): 1?4.

[8] NOBUHIRO T, YOSHIHIRO S, HEE L S, MINAMINO Y. ARB (accumulative roll-bonding) and other new techniques to produce bulk ultrafine grained materials[J]. Advanced Engineering Materials, 2003, 5(5): 338?344.

[9] SAITO Y, UTSUNOMIYA H, TSUJI N, SAKAI T, HONG R G. Ultra-fine grained bulk aluminum produced by accumulative roll bonding(ARB) process[J]. Scripta Materialia, 1998, 39(9): 1221?1227.

[10] JANE?EK M, POPOV M, KRIEGER M G, HELLMIG R J, ESTRIN Y. Mechanical properties and microstructure of a Mg alloy AZ31 prepared by equal-channel angular pressing[J]. Mater Sci Eng, 2007, 462(1): 116?120.

[11] KIM W J, AN C W, KIM Y S. Mechanical properties and microstructure of an AZ61 Mg alloy produced by equal channel angular pressing[J]. Scripta Mater, 2002, 47(1): 39?44.

[12] KIM H K, KIM W J. Microstructure instability and strength of an AZ31 Mg alloy after severe plastic deformation[J]. Mater Sci Eng A, 2004, 385(1/2): 300?308.

[13] KOIKE J. New deformation mechanisms in fine-grain Mg alloys[J]. Materials Science Forum, 2003, 419/422(1): 189?194.

[14] CHEN M C, HSIEH H C, WU W T. The evolution of microstructures and mechanical properties during accumulative roll bonding of Al/Mg composite[J]. Journal of Alloys and Compounds, 2006, 416(1/2): 169?172.

[15] DEL VALLE J A, P?REZE-PRADO M T, RIANO O A. Accumulative roll bonding of a Mg-based AZ61 alloy[J]. Mater Sci Eng A, 2005, 410/411: 353?357.

[16] P?REZE-PRADO M T, DEL VALLE J A, RIANO O A. Grain refinement of Mg-Al-Zn alloys via accumulative roll bonding[J]. Scripta Mater, 2004, 51(11): 1093?1097.

[17] KIM H W, KANG S B, TSUJI N. Elongation increase in ultra-fine grained Al-Fe-Si alloy sheets[J]. Acta Materials, 2005, 53(6): 1737?1749.

收稿日期:2007-10-15;修订日期:2008-05-25

通讯作者:袁守谦,教授,博士;电话:029-82202322;E-mail: bingzhang1112@yahoo.com.cn

(编辑 李艳红)