DOI: 10.11817/j.issn.1672-7207.2016.09.008

变形参数对BR1500HS材料性能与微观组织的影响

尚欣,周杰,卓芳,黄磊

(重庆大学 材料科学与工程学院,重庆,400044)

摘要:通过高温拉伸实验研究超高强度钢BR1500HS不同变形参数对真应力-真应变曲线及抗拉强度的影响,并采用光学显微镜观察不同变形参数下的微观结构,利用扫描电子显微镜SEM分析所得材料的断口形貌。研究结果表明:不同变形参数对抗拉强度、流变应力的影响规律不同,增大变形温度或减小应变速率均可减小材料流变应力;当变形温度在800~900 ℃时,其材料流变抗力小、塑性好,有利于成形;在相同应变速率条件下,当变形温度区间为300~400 ℃,500~700 ℃以及800 ℃以上时,其微观结构组织分别主要为马氏体、贝氏体以及奥氏体;在相同应变速率下,当变形温度区间为300~400 ℃和500~900 ℃时,其断裂方式分别为脆性断裂、韧性断裂,且在800~900 ℃时,其韧窝断口形貌较好。

关键词:BR1500HS;材料性能;微观组织;变形参数

中图分类号:TG142.1 文献标志码:A 文章编号:1672-7207(2016)09-2958-10

Effect of forming parameters on material properties and microstructure of BR1500HS

SHANG Xin, ZHOU Jie, ZHUO Fang, HUANG Lei

(College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China)

Abstract: The effects of different deformational parameters on true stress-true strain curves, tensile strength, microstructure and morphology of BR1500HS were investigated through tensile tests, metallographic optical microscope (OM), scanning electron microscope (SEM). The results show that different deformation parameter ranges have different effects on true stress-true strain curves and tensile strength. Both the increasing deformational temperature and decreasing strain rate can decrease the flow stress. At the temperature ranging from 800 to 900 ℃, the flow stress of material is small and the material’s plastic is better, which greatly benefits material forming. At the deformational temperature ranges from 300 to 400 ℃, 500 to 700 ℃ and above 800 ℃, the corresponding major microstructures are martensite, bainite and austenite respectively with the same strain rate. Meanwhile, at the deformational temperature ranges from 300 to 400 ℃ and 500 to 900 ℃, the corresponding fracture mechanisms are brittle fracture and dimple fracture, especially at the temperature ranges from 800 to 900 ℃, the dimple fracture morphology is better.

Key words: BR1500HS; material properties; microstructure; deformation parameters

超高强度钢板因具有安全、减重以及节能环保等优势,在车身结构应用上有广泛的前景。但因其具有极高的屈服应力和抗拉强度以及较低硬化指数、厚向异性系数和伸长率[1-4],需在高温条件成形,即采用热冲压成形。热冲压技术是将坯料加热到一定温度并保温使组织完全奥氏体化,随后采用专用模具进行成形并同步冷却淬火,得到强度比极高的零件。热冲压过程为塑性力学、热力学相互耦合过程,板料因受温度、应力-应变和组织三者相互作用,其零件质量较难控制,正确认识变形参数对材料性能及内部微观组织演变规律的影响可为热冲压工艺的合理设计奠定基础[5-8]。近年来,国内外学者就热成形技术中的变形工艺参数进行了较多研究。MERKLEINL等[9-10]对热成形硼钢在高温下的流动行为及材料热物性参数进行了测定,并将数值模拟与实验研究结合起来,研究材料在高温下的力学性能。TURETTA等[11]在Nakazima理论基础上,在不同的变形参数(流动应力、温度以及应变率)条件下进行热拉伸、淬火,将所得数据用于模拟仿真,提出并优化了用于克服高强度钢板成性能差的试验方法。PAUL[12]基于热冲压试验数据,建立了准确的热冲压成形有限元模型以预测板料变形过程及各变形参数对零件力学性能的影响,提高了热冲压模拟仿真的精确度。KARBASIAN等[13]对热冲压成形技术中的热、机械性能、微观结构和技术领域的最新状况进行了阐述,指出整个成形过程中相变和连续流变行为都与力学性能、几何形状密切相关。林建平等[14]以超高强度硼钢USIBOR1500为实验材料,在不同变形温度、应变速率条件进行热拉伸实验,建立了此材料的热流变抗力模型,同时获得变形温度、应变速率对其力学性能的影响规律。LIU等[15]基于不同变形参数下的热拉伸试验,测试了对应条件下的力学性能,并考虑应变、应变速率及温度等参数建立了材料本构模型,同时分析了凸模速度、模具温度等参数对热成形盒形件的性能影响,优化了凸模速度、模具温度参数。MA等[16-19]对热成形过程进行了热成形热、力、相变耦合分析,还通过将数值模拟与实验相结合,建立了材料本构关系并提出了用于热成形模具设计及工艺过程分析的新方法。XING等[20]通过不同参数条件下硼钢成形试验,建立了有效的材料模型,并进一步阐述了各变形参数对材料性能的影响。但对于超强钢板BR1500HS热成形工艺参数对材料组织、性能以及成形缺陷的影响规律研究相对较少。本文作者主要研究变形参数对BR1500HS 超高强钢的抗拉强度、硬度、微观组织及断口形貌等的影响规律。根据BR1500HS 的热成形过程的关键特征试验路线设计并完成实验步骤,获得测试试样并观察各条件下材料的微观组织结构。利用 Gleeble-1500材料热模拟实验机在不同变形温度、变形速率下试样的真应力-真应变曲线;使用扫描电子显微镜(SEM)对BR1500HS 淬火后拉伸断口形貌进行分析。通过对变形温度、变形速率对材料性能以及组织形貌的影响规律进行分析,了解不同变形参数对材料内部微观组织演变规律的影响。

1 实验

1.1 材料及设备

实验材料为中国宝山钢铁股份有限公司研发的1.8 mm厚的BR1500HS热轧钢板。根据GB/T4338—2006金属材料高温拉伸试验方法的规定,制成如图1所示拉伸试样。采用Gleeble-1500材料热模拟实验机进行热拉伸实验。在热模拟实验中,为了保证实验准确可靠,采用自制专用板料夹具对板料进行夹持。基于金相技术,采用 OLYMPUS OLS3000激光共聚交显微镜对BR1500HS热拉伸后冷却至室温的试样组织进行观察与分析。同时基于SEM技术,通过采用Quanta 200F高分辨扫描电镜观察BR1500HS拉断后冷却至室温的断口形貌。

1.2 实验方案

图2所示为热拉伸工艺方案。本实验参照热成形过程的所有关键特征试验路线图(图2)来设计实验方案。图2中:ti为目标变形温度;tA3为奥氏体化温度;tMs为马氏体转变开始温度,tMf为马氏体转变结束温度。

由图2可见:以10 ℃/s的加热速率将试样加热至950 ℃,保温10 s,然后以40 ℃/s的冷却速度将试样分别冷却至900,800,700,600,500,400和300 ℃,分别在各目标变形温度进行等温拉伸,各目标变形温度下均采用0.03 /s和0.6 /s的应变速率拉至试样断裂。在拉伸过程中,通过试验机的微机处理系统采集实验数据。变形结束后,待试样冷却至室温,对试样中部均温区的变形组织、晶粒粒度及断口形貌进行分析。

图1 热拉伸试样

Fig. 1 Specimen of hot tensile

图2 热拉伸工艺方案

Fig. 2 Hot tensile process

2 结果与分析

2.1 变形参数对显微组织的影响

为了深入研究热成形温度对 BR1500HS材料组织的影响,将测试试样经过处理并在光学显微镜下观察,得到材料显微组织的分布情况如图3和图4所示。

从图3可以看出:当 =0.03 s-1时,温度冷却至300~400 ℃拉伸后(图3(a),(b)),材料组织出现了很多马氏体组织;当温度为500~700 ℃时(图3(c)~(e)),其微观组织为珠光体,且其中贝氏体含量相对较高;当温度为800 ℃以上时(图3(f),(g)),材料未发生组织转变,材料仍然完全处于奥氏体化状态。这是因为当材料奥氏体化后降温至300~400 ℃时,温度低于贝氏体开始转变温度并接近马氏体开始转变温度,且应变速率较小,试样拉伸变形所产生的形变热少,使得试样温度仍保持在马氏体转变温度区间,试样有较多组织发生马氏体转变,从而使得显微结构组织主要为马氏体;降温至500~700 ℃时,因其温度较高,其温度达不到马氏体产生的条件,故其组织多为贝氏体;当温度为800 ℃以上时,奥氏体组织呈稳定态,故材料未发生组织转变,仍完全处于奥氏体化状态。

=0.03 s-1时,温度冷却至300~400 ℃拉伸后(图3(a),(b)),材料组织出现了很多马氏体组织;当温度为500~700 ℃时(图3(c)~(e)),其微观组织为珠光体,且其中贝氏体含量相对较高;当温度为800 ℃以上时(图3(f),(g)),材料未发生组织转变,材料仍然完全处于奥氏体化状态。这是因为当材料奥氏体化后降温至300~400 ℃时,温度低于贝氏体开始转变温度并接近马氏体开始转变温度,且应变速率较小,试样拉伸变形所产生的形变热少,使得试样温度仍保持在马氏体转变温度区间,试样有较多组织发生马氏体转变,从而使得显微结构组织主要为马氏体;降温至500~700 ℃时,因其温度较高,其温度达不到马氏体产生的条件,故其组织多为贝氏体;当温度为800 ℃以上时,奥氏体组织呈稳定态,故材料未发生组织转变,仍完全处于奥氏体化状态。

图3 当 =0.03 s-1时,不同温度下材料的显微组织

=0.03 s-1时,不同温度下材料的显微组织

Fig. 3 Microstructures of materials at different temperatures when  =0.03 s-1

=0.03 s-1

图4 当 =0.6 s-1时,不同温度下材料的显微组织

=0.6 s-1时,不同温度下材料的显微组织

Fig. 4 Microstructures of materials at different temperatures when  =0.6 s-1

=0.6 s-1

与应变速率 =0.03 s-1时的显微组织进行对比,应变速率

=0.03 s-1时的显微组织进行对比,应变速率 =0.6 s-1时,材料拉伸至断裂时间短。即随着应变速率增大,拉伸变形所用的时间减少,这对微观组织变化有很大影响。从图4可以看出:当温度冷却至300~400 ℃时,出现了马氏体组织,但其马氏体含量低于

=0.6 s-1时,材料拉伸至断裂时间短。即随着应变速率增大,拉伸变形所用的时间减少,这对微观组织变化有很大影响。从图4可以看出:当温度冷却至300~400 ℃时,出现了马氏体组织,但其马氏体含量低于 =0.03 s-1时的马氏体含量。其部分原因是应变速率高时,所需变形时间短,材料拉伸变形产生的形变热高,使得材料温度升高,高于马氏体转变温度,使得马氏体转化进行得不够充分。同理可知:当温度为500~700 ℃时,其主要微观组织是贝氏体,且应变速率增大,产生的形变热增大,使得贝氏体转换不够充分,故使得贝氏体含量比应变速率为0.03 s-1时的贝氏体含量要少;当温度为800 ℃以上时,材料未发生组织转变,材料仍完全处于奥氏体化状态。

=0.03 s-1时的马氏体含量。其部分原因是应变速率高时,所需变形时间短,材料拉伸变形产生的形变热高,使得材料温度升高,高于马氏体转变温度,使得马氏体转化进行得不够充分。同理可知:当温度为500~700 ℃时,其主要微观组织是贝氏体,且应变速率增大,产生的形变热增大,使得贝氏体转换不够充分,故使得贝氏体含量比应变速率为0.03 s-1时的贝氏体含量要少;当温度为800 ℃以上时,材料未发生组织转变,材料仍完全处于奥氏体化状态。

2.2 变形条参数对材料抗拉强度的影响

温度、应变速率对材料抗拉强度的综合影响如图5所示。从图5可以看出:在同一应变速率条件下,材料抗拉强度随温度降低呈明显的上升趋势。这是由于随着温度降低,材料金属原子间结合力升高,增加了晶间滑移的临界切应力,晶间滑移难以进行,造成材料的抗拉强度也随之增大。当温度为600 ℃以上时,抗拉强度随着应变速率的升高而增加,而当温度为550 ℃以下时,抗拉强度反而随着应变速率的增加而降低。这是由于当温度高于600 ℃时,应变速率升高,增加了滑移临界切应力以及晶界间的破坏极限应力,使金属的流变应力增加,且使应变强化效应显著,材料抗拉强度也就随着应变速率的增加而增大。而在400~600 ℃时,温度低于贝氏体开始转变温度且接近马氏体开始转变温度,在较低应变速率条件下材料变形产生形变热较少,试样温度处于贝氏体或马氏体的转变温度区间,可产生较短、强度较高的贝氏体或马氏体,故在较低应变速率下抗拉强度反而比较高应变速率下的抗拉强度要高。综上所述,可使超高强度钢板在800~900 ℃成形,此时材料变形抗力较小,其塑性相对较好,有利于零件成形。

图5 变形温度、应变速率与抗拉强度之间的关系

Fig. 5 Relationships among temperature, strain rate and tensile strength

2.3 变形参数对流变应力的影响

2.3.1 温度对流变应力的影响

图6所示为材料在同一应变速率、不同温度下的真应力-真应变曲线。由图6 可知:温度对超高强度钢板BR1500HS材料的力学性能有较大影响;当应变速率保持恒定时,流变应力和真应力-真应变曲线的斜率都随着变形温度增高而降低,且应变速率越低时金属材料对温度的敏感度越高。其原因是随着温度的升高,材料的热激活作用增强,金属原子平均动能增加,晶界切变抗力显著降低,晶间滑移易于进行,使材料的流变应力降低。同时,随着温度升高,动态回复与动态再结晶也容易进行,使得位错密度下降,对塑性变形过程中的加工硬化的抵消作用增大,降低了材料的流变应力,提高了金属的塑性,从而显著地降低了材料的真应力-真应变曲线的斜率。

图6 同一应变速率下不同温度条件下材料的真应力-真应变曲线

Fig. 6 True strain-true stress curves of materials at different temperatures with the same strain rate

在相同温度下,随着变形量增加,经过初始应变硬化,动态回复作用加强,应变硬化和软化有趋于平衡的趋势,应力-应变曲线逐渐平缓。

同时,可看出高温BR1500HS的流变应力-应变曲线属于动态再结晶类型。在变形的开始阶段,存在明显的加工硬化,应力随着应变的增加达到峰值,且变形温度和应变速率均对加工硬化产生很大的影响,降低变形温度或增大应变速率都可以加剧加工硬化并增大对应的峰值应力-应变。当流变应力越过峰值时,其值反而随着应变的增加而下降。这是因为动态再结晶的软化效应大于热加工硬化的强化效应,使整体上呈现应变软化。图6中存在着流变应力基本不随应变的增大而发生变化的阶段,因为此时动态再结晶引起的晶粒细化导致热加工硬化较峰值时更为剧烈,使得动态再结晶软化效应与热加工效应处于相对的平衡状态[21-22],即材料进入了稳态流动阶段。

2.3.2 应变速率对流变应力的影响

图7所示为同一温度不同应变速率条件下材料的真应力-真应变曲线。从图7可以看出:在相同温度下,应变速率对材料力学性能影响显著,且与不同变形温度下的影响各不相同;当温度为500 ℃时,随着应变速率的升高,材料真应力-真应变曲线的斜率降低;当温度为300,400,600,700,800和900 ℃时,材料的真应力-真应变曲线斜率随着应变速率升高而升高,但是其真应力并不随之升高。

图7 在同一温度不同应变速率条件下材料的真应力-真应变曲线

Fig. 7 True strain-true stress curves of materials at different strain rates and the same temperature

当金属试样的变形温度和应变速率保持恒定时,随着金属变形量增加,材料的真应力-真应变曲线在最初呈现出直线上升的趋势,这主要是起初材料的变形量很小,金属尚处于弹性阶段。随后金属进入塑性变形阶段,该曲线不再表现为直线,此时金属虽然发生加工硬化现象,但是金属动态回复和动态再结晶的出现对金属材料形成了软化作用,致使曲线的斜率不断降低,直到应力达到最大值。然后曲线开始呈现下降趋势,最终处于相对比较稳定的状态,这主要是因为金属的动态回复和动态再结晶的软化作用增强,它与加工硬化引起的材料强度、硬度、变形抗力升高现象达到了一个动态平衡[23-25]。

当变形温度一定时,应变速率越高则流变应力越大,这是因为应变速率越高,动态回复和动态再结晶的程度越小,软化作用不能抵消加工硬化作用。动态再结晶可使流变应力达到峰值后呈下降趋势,因为动态再结晶,可综合了加工硬化对材料变形抗力的影响,使得材料最终在加工硬化和动态再结晶的综合作用下处于一种动态平衡。

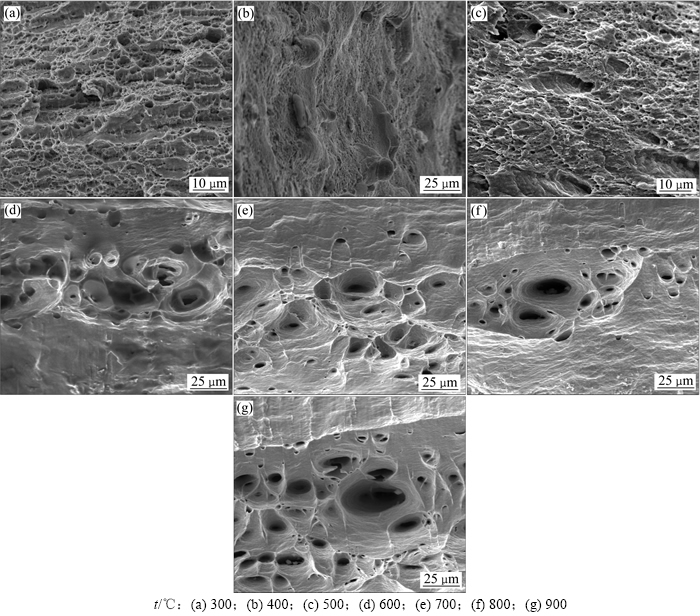

2.4 变形参数对拉伸断口形貌的影响

图8所示为应变速率 =0.03 s-1,应变温度为300~900 ℃时的试样拉伸断口扫描电镜照片。从图8可看出:冷却至300和400 ℃时试样淬火拉伸的断口形貌为脆性穿晶断裂。断口组织均匀,排列比较紧密, 几乎没有出现空洞缺陷。这是因为在高温加热时,试样组织处于完全奥氏体化状态,淬后组织主要为少量铁素体和大量马氏体的混合组织,材料中少有杂质析出偏聚晶界,铁素体马氏体的存在使淬火试样有较高的强度,拉伸试样在单向拉伸过程中有较大的变形,引起晶格畸变,加工硬化程度加重,容易导致裂纹和脆性断裂。

=0.03 s-1,应变温度为300~900 ℃时的试样拉伸断口扫描电镜照片。从图8可看出:冷却至300和400 ℃时试样淬火拉伸的断口形貌为脆性穿晶断裂。断口组织均匀,排列比较紧密, 几乎没有出现空洞缺陷。这是因为在高温加热时,试样组织处于完全奥氏体化状态,淬后组织主要为少量铁素体和大量马氏体的混合组织,材料中少有杂质析出偏聚晶界,铁素体马氏体的存在使淬火试样有较高的强度,拉伸试样在单向拉伸过程中有较大的变形,引起晶格畸变,加工硬化程度加重,容易导致裂纹和脆性断裂。

图8 当 =0.03 s-1时,不同温度下材料的断口形貌

=0.03 s-1时,不同温度下材料的断口形貌

Fig. 8 Fracture morphologies of materials at different temperatures when  =0.03 s-1

=0.03 s-1

在500~900 ℃进行淬火拉伸时,在高温加热时(950 ℃),铁素体和珠光体可完全转变为奥氏体,在保温过程中,材料中的杂质(如P,S,Si和Ti等)在晶界上偏聚或脱溶,成为空洞核,在晶界形成孔洞等缺陷,并随着温度升高逐渐长大。淬火试样在拉应力作用下促使位错聚积,空洞相互连接而导致材料断裂,为延性断裂中的韧性断裂,具有较高的吸能性。在一般情况下,断裂在晶界缺陷处形成,断裂面微观形态呈蜂窝状,在断裂前伴有一定的塑性变形,断裂方式主要为穿晶和沿晶断裂,试样的延性断裂说明淬火BR1500HS试样中的马氏体组织具有相当的韧性,而且随着BR1500HS试样拉伸时温度的升高和保温时间延长,韧窝的尺寸会变大,有利于提高材料的韧性,但是当韧窝的尺寸过大时,反而会降低材料的韧性。对BR1500HS试样加热到tAc3(811 ℃)以上进行淬火,然后冷却至400 ℃以下,由于组织完全转变成马氏体,所以其强度依然上升。

通过对各冷却至温度为300,400,500,600,700,800和900 ℃并保温2 min试样的单向拉断试样的断口形貌进行分析,发现试样在300~400 ℃淬火时,断裂方式主要为脆性断裂,在500~900 ℃淬火时断裂主要为韧性断裂,但由于温度过高形成的空洞较大,导致试样塑性下降,而试样在800~900 ℃时,也就是在其tAc3以上10~100 ℃时,具有较好的韧窝断口形貌,较高的伸长率适合于热成形。

图9所示为当 =0.6 s-1时,不同温度下材料的断口形貌。从图9可以看出:随着应变速率的增加,在不同温度下韧窝断口的微观形貌特征是一些大小不等的圆形或椭圆形的凹坑韧窝。在韧窝内经常可以看到夹杂物,此时夹杂物或粒子分布在2个匹配断口上。这些形状取决于应力状态。等轴韧窝主要是圆形微坑,这是在拉伸正应力作用下形成的。应力在整个断口表面上分布均匀,显微空洞沿着空间3个方向上均匀长大而形成等轴韧窝。在实际断裂零件中,零件局部区域受力状态复杂,在断口上可能出现各种不同形状的韧窝。在500~800 ℃之间,出现了大小不一的韧窝,这主要取决于材料的塑性和试验温度。在材料的塑性及其他条件相同情况下,韧窝的深度主要受塑性变形能力的影响。材料的塑性变形能力大,韧窝深度大,反之韧窝深度小。

=0.6 s-1时,不同温度下材料的断口形貌。从图9可以看出:随着应变速率的增加,在不同温度下韧窝断口的微观形貌特征是一些大小不等的圆形或椭圆形的凹坑韧窝。在韧窝内经常可以看到夹杂物,此时夹杂物或粒子分布在2个匹配断口上。这些形状取决于应力状态。等轴韧窝主要是圆形微坑,这是在拉伸正应力作用下形成的。应力在整个断口表面上分布均匀,显微空洞沿着空间3个方向上均匀长大而形成等轴韧窝。在实际断裂零件中,零件局部区域受力状态复杂,在断口上可能出现各种不同形状的韧窝。在500~800 ℃之间,出现了大小不一的韧窝,这主要取决于材料的塑性和试验温度。在材料的塑性及其他条件相同情况下,韧窝的深度主要受塑性变形能力的影响。材料的塑性变形能力大,韧窝深度大,反之韧窝深度小。

图9 当 =0.6 s-1时,不同温度下材料的断口形貌

=0.6 s-1时,不同温度下材料的断口形貌

Fig. 9 Fracture morphologies of materials at different temperatures when  =0.6 s-1

=0.6 s-1

3 结论

1) 在相同应变速率下,当试样冷却至300~400 ℃时,材料显微组织出现明显马氏体组织。在较低应变速率条件下拉伸速度较慢,当温度为500~700 ℃时,其微观组织主要为贝氏体。当温度为800 ℃以上时,微观组织完全处于奥氏体化状态。

2) 当温度为600 ℃以上,材料的抗拉强度随着应变速率的升高而增加;而当温度为550 ℃以下时,材料的抗拉强度随着应变速率的增加而降低。在同一应变速率下,材料的抗拉强度随着温度的降低而升高。可使超高强度钢板在800~900 ℃成形,在此温度下材料变形抗力小、塑性好,有利于零件的成形。

3) 增大变形温度或减小应变速率均可减小材料流变应力;当温度为500 ℃时,随着应变速率的升高,真应力-真应变曲线的斜率降低;当温度为300,400,600,700,800和900 ℃时,真应力-真应变曲线斜率随着应变速率的升高而升高;当变形温度、应变速率保持恒定时,真应力-真应变曲线在最初处于弹性变形呈直线上升,随后进入塑性变形不再呈直线状态,因动态回复和动态再结晶的软化作用抵消加工硬化使得曲线的斜率降低,直到应力达到最大值。

4) 当应变速率为0.03 s-1时,试样在300~400 ℃断裂方式主要为脆性断裂,在500~900 ℃断裂主要为韧性断裂,且在800~900 ℃时,具有较好的韧窝断口形貌。当应变速率为0.6 s-1时,各温度下试样断裂方式均为韧性断裂,试样断口形貌为大小不等的圆形或椭圆形的凹坑韧窝。

参考文献:

[1] 王立影. 超高强度钢板热冲压成形技术研究[D]. 上海: 同济大学机械工程学院, 2008: 2-3.

WANG Liying. The research of hot stamping ultra high strength steel[D]. Shanghai: Tongji University. School of Mechanical Engineering, 2008: 2-3.

[2] 蒋峥嵘. 高强度钢板热冲压工艺研究及有限元分析[D]. 重庆: 重庆大学材料科学与工程学院, 2011: 10-15.

JIANG Zhengrong. Hot stamping process research and FEA of high strength steel[D]. Chongqing: Chongqing University. College of Materials Science and Engineering, 2011: 10-15.

[3] BARIANI PFS, BRUSCHI A, GHIOTTI. Testing formability in the hot stamping of HSS[J]. CIRP Annals-Manufacturing Technology. College of Materials Science and Engineering, 2008, 57: 265-268.

[4] LORENZ D, NADERI M, KETABCHI M, et al. Analysis of microstructure and mechanical properties of different high strength carbon steels after hot stamping[J]. Journal of Materials Processing Technology, 2011, 211: 1117-1125.

[5] 徐伟力, 管曙荣, 艾健, 等. 钢板热冲压新技术介绍[J]. 塑性工程学报, 2009, 16(4): 39-43.

XU Weili, GUAN Shurong, AI Jian, et al. Introduction of the new hot stamping technology of steel plate[J]. Journal of Plasticity Engineering, 2009, 16(4): 39-43.

[6] SO H, FASSMANN D, HOFFMANN H. An investigation of the blanking process of the quenchable boron alloyed steel 22MnB5 before and after hot stamping process[J]. Journal of Materials Processing Technology, 2012, 212: 437-449.

[7] NADERI M, SAEED-AKBARI A, BLECK W. The effects of non-isothermal deformation on martensitic transformation in 22MnB5 steel[J]. Journal of Materials Science and Engineering, 2008, 478: 445-455.

[8] KATSUYOSHI I, JUN Y. Valuation method for effects of hot stamping process parameters on product properties using hot forming simulator[J]. Journal of Materials Processing Technology, 2011, 211: 1441-1447.

[9] MERKLEINL M, LECHLER J. Investigation of the thermo-mechanical properties of hot stamping steels[J]. Journal of Materials Processing Technology, 2006, 177: 452-455.

[10] MERKLEINL M, LECHLER J. Determination of material and process characteristics for hot stamping processes of quenchenable ultra high strength steels with respect to a FE-based process design[J]. SAE World Congress, 2008, 8(23): 1728-1736.

[11] TURETTA A, BRUSCHI S, GHIOTTI A. Investigation of 22MnB5 formability in hot stamping operations[J]. Journal of Materials Processing Technology, 2006, 177: 396-400.

[12] PAUL A. Modelling and simulation of hot stamping[D]. Sweden: Lule University of Technology, 2006: 25-30.

[13] KARBASIAN H, TEKKAYA A E. A review on hot stamping[J]. Journal of Materials Processing Technology, 2010, 210: 2103-2118.

[14] 林建平, 王立影, 田浩彬, 等. 超高强度钢热流变行为[J]. 塑性工程学, 2009(2): 186-189.

LIN Jianping, WANG Liying, TIAN Haobin, et al. Research on hot forming behavior of ultrahigh strength steel[J]. Journal of Plasticity Engineering, 2009(2): 186-189.

[15] LIU Wei, LIU Hongsheng, XING Zhongwen, et al. Effect of tool temperature and punch speed on hot stamping of ultra high strength steel[J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 534-541.

[16] MA Ning, HU Ping, et al. Model and numerical simulation of hot forming[C]// International Symposium on Automotive Steel, ISAS Conference Proceedings. Beijing: China, Metallurgical Industry Press, 2009: 362-367.

[17] 马宁, 胡平, 闫康康, 等. 高强度硼钢热成形技术研究及其应用[J]. 机械工程学报, 2010, 46(14): 68-72.

MA Ni, HU Ping, YAN Kangkang, et al. Research on boron steel for hot forming and its application[J]. Journal of Mechanical Engineering, 2010, 46(14): 68-72.

[18] 马宁, 胡平, 郭威. 热成形硼钢热、力及相变耦合关系[J]. 材料热处理学报, 2010, 11: 33-36, 41.

MA Ning, HU Ping, GUO Wei. Experiments and analysis of relations among heat, stress and transformation of boron steel for hot forming[J]. Transactions of Materials and Heat Treatment, 2010, 11: 33-36, 41.

[19] 马宁, 武文华, 申国哲, 等. 高强度钢板热成形数值模拟-静力显式[J]. 计算力学学报, 2011, 28(3): 371-376.

MA Ni, WU Wenhua, SHEN Guozhe, et al. Numerical simulation-static explicit hot forming high strength steel[J]. Chinese Journal of Computational Mechanics, 2011, 28(3): 371-376.

[20] XING Zhongwen, BAO Jun, YANG Yuying. Numerical simulation of hot stamping of quenchable boron steel[J]. Materials Science and Engineering A, 2009, 499(1/2): 28-31.

[21] SELLARS C M,MCTEGART W J.On the mechanism of hot Constitutive equation of AZ3l magnesium alloy for hot deformation[J].ACTA Metallurgiea, 1966, 14: 1136-1138.

[22] WANG Lingyun, HUANG Guangsheng, et al. Grain refinement of wrought AZ31 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(3): 594-599.

[23] PARK K, KIM Y S. The effect of material and process variables on the stamping formability of sheet materials[J]. Journal of Materials Processing Technology, 1995, 51: 64-78.

[24] CADA R. Comparison of formability of steels strips, which are used for deep drawing of stampings[J]. Journal of Materials Processing Technology, 1996, 60(60): 283-290.

[25] ZENER C, HOLLOMON J H. Effect of strain rate on the plastic flow of steel[J]. Applied Physics A, 1994, 15(1): 22-32.

(编辑 陈爱华)

收稿日期:2015-11-05;修回日期:2015-12-30

基金项目(Foundation item):重庆市自然科学基金重点资助项目(CSTC2009BA4065) (Project(CSTC2009BA4065) supported by Natural Science Foundation of CQ CSTC)

通信作者:周杰,教授,博士生导师,从事汽车用超高强钢板热冲压关键技术研究;E-mail: cqzf0223@163.com