Reinforcing and toughening of TiAl composites by doping Sm2O3

WANG Xiao-feng, WANG Fen, ZHU Jian-feng, XIANG Liu-yi

Key Laboratory of Auxiliary Chemistry and Technology for Chemical Industry of Ministry of Education,

School of Materials Science and Engineering, Shaanxi University of Science and Technology, Xi’an 710021, China

Received 18 October 2010; accepted 28 November 2010

Abstract: Al2O3/TiAl composites were fabricated by in-situ reaction synthesis using Ti, Al, TiO2 and Sm2O3 as starting materials. Effect of the doping Sm2O3 on the microstructures and properties of the Al2O3/TiAl composites was analyzed by X-ray diffraction (XRD), scanning electron microscopy (SEM) and universal properties tests. The results show that the phases of the Sm2O3-doped composites are mainly composed of γ-TiAl/α2-Ti3Al matrix and reinforcing phases of Al2O3 and SmAl. The microstructures of Al2O3/TiAl composites are significantly refined with doping Sm2O3. Doping Sm2O3 has a positive effect on improving the mechanical properties of Al2O3/TiAl composites. When the Sm content is 5% (mass fraction), the flexural strength and fracture toughness reach the maximum values of 658.9 MPa and 10.13 MPa·m1/2, respectively.

Key words: TiAl; Sm2O3; grain size; mechanical properties

1 Introduction

Titanium aluminides exhibit numerous attractive properties for high-temperature structural applications due to their high elastic modulus, low density, and good creep resistance to high temperatures [1]. A further increase of application may be accomplished through microstructural control and alloy modi?cation [2-3]. Generally, coarse grain fully lamellar microstructures exhibit relatively poor tensile ductility and strength, but relative grain-refining near-γ or duplex microstructures show better tensile properties [4]. Therefore, controlling and re?ning microstructure is one way to attain ideal mechanical properties. Several routes are commonly used for this purpose, such as activation of selected phase transformations, wrought processing or addition of grain growth inhibitors [5].

There are different second-phase particles, such as TiB2, SiC, TiC, Ti2AlC and Al2O3. Al2O3 has been chosen as a ceramic reinforcement because of its advantageous thermo-mechanical behavior, inclusive of wear resistance, environmental stability, high temperature strength, and so on [6]. The ductility and strength can be improved by reducing grain size and lamellar spacing without compromising the fracture toughness and creep resistance. Rare earths (RE) are widely used in metallurgical fields, due to improved performance of sintering, heat-machining, mechanics, oxidation/corrosion and wear resistance by means of purifying, transformation and alloying processes [7].

Previous researches on TiAl intermetallic alloys were focused mainly on RE addition, but the effects of doping RE2O3 on TiAl were not studied in detail. In this work, Sm2O3 was added to the starting materials of Ti, Al, TiO2 to modify the Al2O3/TiAl in situ composites. The effects of Sm2O3 addition on the microstructure and mechanical properties of the composites were investigated. Furthermore, the refined mechanism was also discussed.

2 Experimental

For the production of the Al2O3/TiAl composite, reactant samples were prepared from the mixture of Ti (Strem chemicals, 53 μm, 99.3% of purity), Al (Showa Chemical Co, 75 μm, 99% of purity), TiO2 (0.5 μm, 99% of purity), and Sm2O3 (30 μm, 99.9% of purity) powders by the stoichiometry according to the following reaction:

xTi+(x+13)Al +3TiO2+Sm2O3=

(x+3)TiAl+3Al2O3+2SmAl2 (1)

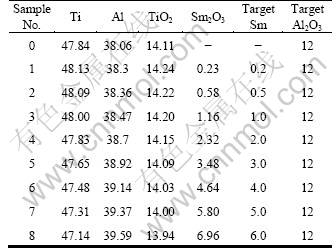

where the stoichiometric parameter x is 16.97, which represents the Al2O3 content is 12% (mass fraction) in the target TiAl-matrix composites, and the Sm mass fraction varies from 0 to 6%. Eight samples were designed in Table 1.

Table 1 Composition of samples (mass fraction, %)

The desired mixtures were ball milled in ethanol for 1 h. The mass ratio of ball to powder was 3:1, and the rotational velocity was kept at 800 r/min. Further processing included drying at 60 °C for 5 h and sieving through 75 μm-sieve. The reactive sintering of the as-milled powders was performed in a sintering furnace under vacuum less than 10-2 MPa. The compacted powder mixture was heated at a rate of 10 °C/min from room temperature to 500, 700, 900, 1 100, 1 200, 1 250 and 1 300 °C and held for 2 h, respectively, wherein the pressure was gradually increased to 35 MPa. Finally, the sample was cooled down in furnace to room temperature.

The phase composition of the fabricated samples was analyzed by an X-ray diffractmeter (Rigaku D/max 2000P) with Cu Kα radiation operating at 40 kV. The microstructure, fracture surfaces and crack propagation of the samples were investigated by scanning electron microscopy (SEM) (JSM-6700F SEM).

The Vickers hardness of Al2O3/TiAl composites was measured at room temperature on a HXD-1000 tester with a diamond indenter under 10 N for 15 s. The density measurements were performed via Archimedes principle. The samples were cut and ground into strip specimens with dimensions of 25 mm×4 mm×3 mm for measuring the three-point bending strength on a universal testing machine with a span of 25 mm at a cross-head speed of 5 mm/min at room temperature. The bending strength was calculated by the following equation:

σ=3PL/(2bh2) (2)

where P is the breaking load of the specimen, and L, b, and h denote the span, width, and height, respectively.

The fracture toughness was measured on the universal testing machine by using the single-edge notch beam (SEPB) method with specimen dimensions of 36 mm×4 mm×8 mm. The notch depth was 4 mm with ~0.15 mm in width. The crosshead speed was 0.05 mm/min, with a loading span of 30 mm. The fracture toughness, KIC, was calculated by the following equation:

KIC=Y×3PL a1/2/(2bh2) (3)

where a is the notch length, and Y is a geometrical factor.

3 Results and discussion

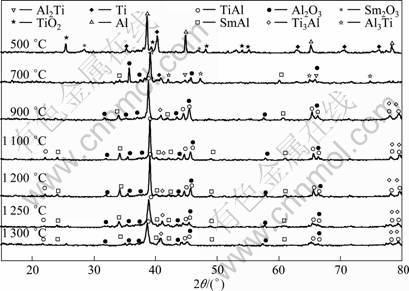

Figure 1 shows the X-ray diffraction patterns of Al2O3/TiAl composites with 5% Sm after being hot pressed at various temperatures for 2 h. According to XRD analysis, there is no reaction among Ti, Al, TiO2 and Sm2O3 powders when the mixed powders are sintered at 500 °C for 2 h. When the temperatures is increased to 700 °C (higher than the melting points of Al), the as-sintered samples mainly consist of Al3Ti and Al2O3 as two major phases together with a significantly smaller amount of Al2Ti, SmAl and unreacted Ti phase.

Fig. 1 XRD patterns of composites at various temperatures

When the temperatures is 800 °C, the values of free-energy change,  of reactions among Al,Sm and O2 are as follows [8]:

of reactions among Al,Sm and O2 are as follows [8]:

=-1 829.69-(-1 098.15×402.38×10-3)

=-1 829.69-(-1 098.15×402.38×10-3)

=-1 387.82 kJ/mol (4)

=-1 583.99-(-319.23×10-3)×(800+298.15)

=-1 583.99-(-319.23×10-3)×(800+298.15)

= -1 233.43 kJ/mol (5)

According to the Gibbs free-energy change, there is no thermite reaction between Sm2O3 and Al, which indicates that the formation of SmAl is thermodynamically infeasible. However, Sm2O3 can decompose into [Sm] and [O] because of active effect of the massive reaction heat released by Ti and molten aluminum, which can affect the kinetics or the mechanism of reaction between Sm2O3 and Al, which leads to the formation of SmAl.

When the temperature is increased to 900 °C, the composite mainly consists of γ-TiAl, α2-Ti3Al, Al2O3 and SmAl phases. The presence of the above-mentioned phases in the composites samples confirms the feasibility of the following in-situ reactions:

3TiO2+4Al=2Al2O3+3Ti (6)

Sm2O3+4Al=Al2O3+2SmAl (7)

4Ti+2Al=TiAl+Ti3Al (8)

When the temperature was increased from 900 to 1 250 °C, it can be found that there were no much changes in phase composition, but the TiAl diffraction peaks were weakened and broadened gradually; on the contrary, the Ti3Al diffraction peaks were increased because some TiAl phase transformed to Ti3Al phase and formed the duplex microstructures, which is beneficial to increasing the combination properties of Al2O3/TiAl composites [9].

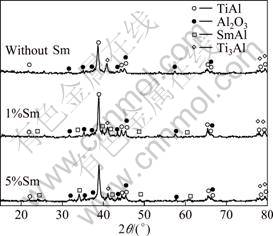

Figure 2 presents the XRD patterns of the in-situ composite samples with different contents of Sm2O3 hot-pressed at 1 250 °C for 2 h. Compared with Sm2O3 free samples, the samples with Sm2O3 addition consisted of the same three major phases of γ-TiAl, α2-Ti3Al and Al2O3. But a significant smaller amount of SmAl phase was produced. Although it is hard to quantify the individual phases in the products, it is clear that the intensity of the SmAl diffraction peaks increases with the increase of the content of Sm2O3.

Fig. 2 XRD patterns of in-situ composites with various Sm2O3 contents

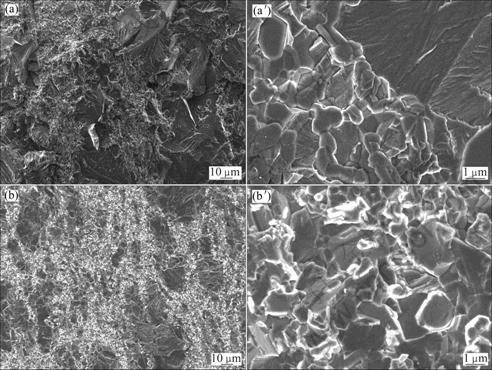

Figure 3 shows the typical fracture microstructures of the Al2O3/TiAl composites with various Sm2O3 contents after being hot-pressed at 1 250 °C for 2 h. The fracture microstructure of the composites is characterized by numerous brighter reinforcing phase of Al2O3 and black matrix phases of TiAl, Ti3Al and SmAl. The fracture surface is uneven and few pores exist. The brighter areas present interpenetrating network structure. The Sm2O3 doping results in finer microstructure and more uniform distribution of Al2O3 particles without obvious agglomeration. It is attributed to Sm2O3 that the wettability between Al2O3 and TiAl increases because of its surface-active action [10].

Figure 3 shows that composites consist of single phase regions of γ-TiAl, lamellar regions of γ-TiAl+α2-Ti3Al with a dispersion of randomly oriented Al2O3 particles and SmAl distributing at grain boundaries, where most of the Al2O3 particles have smaller average grain size. These observations are found to be in agreement with the inferences drawn from the XRD studies. The average grain size of the composites with Sm2O3 addition was 0.3-0.5 ?m. According to Ref. [11], the additions of other beta-stabilizing elements are beneficial to preventing peritectic growth. In this work, the addition of Sm2O3 hinders the growth of the TiAl matrix and Al2O3 grains and re?nes the grain size.

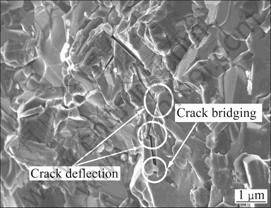

Figure 4 shows the crack propagation paths of the Al2O3/TiAl composites. Microstructures of the representative crack propagation paths reveal that variously complex toughening mechanisms can be found in the as-synthesized composite including extensive crack deflection, crack bridging, particle pullout, which mostly results from particles toughening effect [12].

Fig. 3 Fracture microstructures of Al2O3/TiAl composites with various Sm2O3 contents: (a), (a′) Without Sm; (b), (b′) With 5%Sm

Fig. 4 Crack propagation paths of Al2O3/TiAl composites

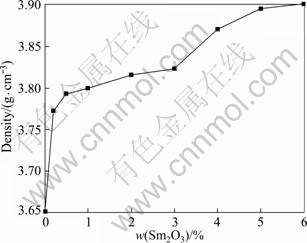

Figure 5 shows the density of the Al2O3/TiAl composite sintered at 1 250 °C for 2 h as a function of Sm2O3 content measured by the Archimedes method. The densities of Al2O3/TiAl increased steadily from 3.65 to 3.9 g/cm3 with the Sm content increasing from 0.2% to 6%. Samples with the addition of Sm2O3 have higher densities due to their lower melting points [13], which increases densities of the TiAl-based composites. The second reason must be the higher densities of Sm2O3 itself, which also improves the densities of the composites. Finally, the densities of the composites increase due to the fine Al2O3 particles filling the pores.

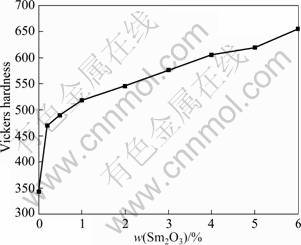

Figure 6 presents the Vickers hardness of samples as a function of Sm2O3 content. A closer observation of the Vickers hardness data reveals that the hardness of the as-sintered composites goes up from HV10 470 to HV10 655.2 with the increase of Sm mass fraction from 0.2% to 6%. The increase of hardness can be correlated with the amount of SmAl reinforced phase. Meanwhile, the SmAl phases have a higher melting point and hardness than γ or α2 phase [14], filling a part of the pores, which significantly increases the hardness of the composites.

Fig. 5 Density of Al2O3/TiAl composite as function of Sm2O3 content

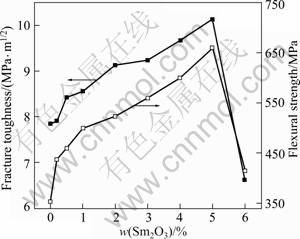

As shown in Fig. 7, the variation trend of the fracture toughness is similar with that of the flexural strength. The fracture toughness and flexural strength increase with the increase of Sm mass fraction from 0.2% to 5%. With 5% Sm addition, the fracture toughness and flexural strength reach the maximum values of 10 MPa·m1/2 and 659 MPa, respectively. When the mass fraction of Sm2O3 is further continuously increased over 5%, both the flexural strength and fracture toughness decrease. Referred to previous work [15], the strength of the composites generally increases with decreasing size of the reinforcements. The addition of Sm2O3 decreases the size of the reinforcements, which is beneficial for the improvement of the mechanical properties of the Al2O3/TiAl composites [16]. However, the fracture toughness and the flexural strength decrease rapidly with excess Sm2O3 addition due to the excessive formation of the brittle SmAl phase.

Fig. 6 Vickers hardness of products as function of Sm2O3 content

Fig. 7 Flexural strength and fracture toughness of products as function of Sm2O3 content

4 Conclusions

1) Al2O3/TiAl composites were fabricated by in-situ reaction synthesis using Ti, Al, TiO2 and Sm2O3 as starting powders. The as-sintered samples mainly consist of α2-Ti3Al, γ-TiAl, Al2O3 and SmAl phases.

2) The grain size of TiAl matrix decreases with the addition of Sm2O3 due to the uniform distribution of the in situ formed fine Al2O3 particles. The densities of the composites increase gradually from 3.5 g/cm3 to 3.9 g/cm3 and Vickers hardness increases from 340 to 655 kg/mm2 with increasing Sm content from 0 to 6%. Both the flexural strength and fracture toughness are modified and reach the maximum values of 659 MPa and 10 MPa·m1/2 respectively when Sm2O3 mass fraction is 5%.

References

[1] TANG Z, NIEWOLAK L, SHEMET V, SINGHERSER L, QUADAKKERS W J, WANG F, WU W, GIL A. Development of oxidation resistant coatings for γ-TiAl based alloys [J]. Materials Science and Engineering A, 2002, 328(1-2): 297-301.

[2] SAAGE H, HUANG A J, HU D, LORETTO M H, WU X. Microstructures and tensile properties of massively transformed and aged Ti46Al8Nb and Ti46Al8Ta alloys [J]. Intermetallics, 2009, 17(1-2): 32-38.

[3] WU Xin-hua. Review of alloy and process development of TiAl alloys[J]. Intermetallics, 2006, 14(10-11): 1114-1122.

[4] ZHANG Chun-ping, ZHANG Kai-feng, WANG Guo-feng. Dependence of heating rate in PCAS on microstructures and high temperature deformation properties of γ-TiAl intermetallic alloys [J]. Intermetallics, 2010, 18(5): 834-840.

[5] LI W, INLSON B, HORITA Z, XIA K. Microstructure observations in rare earth element Gd-modified Ti-44 at% Al[J]. Intermetallics, 2000, 8(5-6): 51-523.

[6] AI Tao-tao. Microstructure and mechanical properties of in-situ synthesized Al2O3/TiAl composites [J]. Chinese Journal of Aeronautics, 2008, 21(6): 559-564.

[7] MA Xing-wei, JIN Zhu-ji, YAN Shi. Effect of La2O3 on microstructure and high-temperature wear property of hot-press sintering FeAl intermetallic compound [J]. Journal of Rare Earths, 2009, 27(6): 1031-1036.

[8] LIANG Ying-jiao, CHE Yin-chang. Inorganic thermodynamic data sheet [M]. Shenyang: Northeastern University Press, 1994: 450. (in Chinese)

[9] MENG F L, ZHOU Y C, WANG J Y. Strengthening of Ti2AlC by substituting Ti with V [J]. Scripta Materialia, 2005, 53(12): 1369-1372.

[10] YU Zhi-qing, WU Gao-hui, JIANG Wen-tao. Effect of surface modification of sub-micron Al2O3 particles by rare-earth on interfacial wettability of Al matrix composites [J]. The Chinese Journal of Nonferrous Metals, 2005, 15(7): 1087-1091. (in Chinese)

[11] HECHT U, WITUSIEWICZ V, DREVERMANN A, ZOLLINGER J. Grain refinement by low boron additions in niobium-rich TiAl-based alloys [J]. Intermetallics, 2008, 16(8): 969-978.

[12] CAO R, LIN Y Z, HU D, CHEN J H. Fracture behaviour of a TiAl alloy under various loading modes [J]. Engineering Fracture Mechanics, 2008, 75(15): 4343-4362.

[13] WU Chao-feng, MA Ming-xing, LIU Wen-jin, ZHONG Min-lin, ZHANG Hong-jun, ZHANG Wei-ming. Laser cladding in-situ carbide particle reinforced Fe-based composite coatings with rare earth oxide addition [J]. Journal of Rare Earths, 2009, 27(6): 997-1002.

[14] XU Fu-song, GENG Hao-ran, WANG Shou-ren. Effect of adding La on the microstructure and mechanics properties of TiAl3 intermetallics[J]. Rare Metal Materials and Engineering, 2009, 38(2): 361-364. (in Chinese)

[15] TJIONG S C, MA Z Y. Microstructural and mechanical characteristics of in situ metal matrix composites [J]. Materials Science and Engineering, 2000, 29(3-4): 49-113.

[16] LI Quan-an, LI Ke-jie, JING Xiao-tian, CHEN Jun, ZHANG Xing-yuan. Effects of Sm on microstructure and mechanical properties of AZ61 alloy [J]. Transactions of Material and Heat Treatment, 2010, 31(1): 100-104. (in Chinese).

Sm2O3掺杂强韧化TiAl复合材料

王晓凤, 王 芬, 朱建锋, 向六一

陕西科技大学 材料科学与工程学院,教育部轻化工助剂化学与技术重点实验室,西安710021

摘 要:以Ti,Al,TiO2和Sm2O3为原料,利用原位合成法制备Al2O3/TiAl复合材料;并借助XRD、SEM和力学性能测试,研究Sm2O3掺杂对Al2O3/TiAl复合材料微观结构和力学性能的影响。结果表明:掺杂Sm2O3的Al2O3/TiAl复合材料由γ-TiAl/α2-Ti3Al基体相以及Al2O3、SmAl增强相组成;掺杂Sm2O3细化了复合材料的微观结构,改善了TiAl复合材料的力学性能;当Sm含量为5%(质量分数)时,该复合材料的弯曲强度和断裂韧性达到最大,分别为658.9 MPa 和10.13 MPa·m1/2。

关键词:TiAl;Sm2O3;晶粒尺寸;力学性能

(Edited by LI Xiang-qun)

Foundation item: Project (51072109) supported by the National Natural Science Foundation of China; Project (XK06010-1) supported by the Foundation of Xianyang, China; Project supported by the Graduate Innovation Fund of Shaanxi University of Science and Technology, China; Project (BJ08-14) supported by the Education Foundation of Shaanxi University of Science and Technology, China

Corresponding author: WANG Fen; Tel: +86-15114805183; E-mail: wangf@sust.edu.cn

DOI: 10.1016/S1003-6326(11)60851-0