T6热处理对锻造Al-4.4Cu-0.7Mg-0.6Si合金显微组织及力学性能的影响

来源期刊:中国有色金属学报(英文版)2017年第12期

论文作者:李慧中 朱泽晓 梁霄鹏 李鹏伟 齐叶龙 吕凤 黄岚

文章页码:2539 - 2547

关键词:锻造Al-4.4Cu-0.7Mg-0.6Si合金;时效热处理;力学性能;θ析出相

Key words:forged Al-4.4Cu-0.7Mg-0.6Si alloy; aging treatment; mechanical properties; θ precipitates

摘 要:用透射电子显微镜、扫描电子显微镜、硬度及拉伸测试研究时效处理对锻造Al-4.4Cu-0.7Mg-0.6Si合金显微组织及力学性能的影响。结果表明,经170 °C时效16 h后,合金力学性能优良,抗拉强度为504 MPa,伸长率为10.1%。当测试温度升高到150 °C时,合金的抗拉强度缓慢下降到483 MPa;继续升高温度到200 °C以上时,合金强度快速下降。大量θ''''析出相及AlMgSiCu四元析出相(Q相)导致合金峰时效的高强度。稳定的细小弥散θ''''相使得该合金在150 °C下仍保持较优的力学性能;当温度高于150 °C时,θ''''和Q相的粗化以及θ相的析出导致合金强度的快速下降。

Abstract: Transmission electron microscopy (TEM), scanning electron microscopy (SEM), hardness tests and tensile tests were performed to investigate the effect of aging on microstructure and mechanical properties of forged Al-4.4Cu-0.7Mg-0.6Si alloy. The results show that the alloy exhibits splendid mechanical properties with an ultimate tensile strength of 504 MPa and an elongation of 10.1% after aging at 170 °C for 16 h. With tensile testing temperature increasing to 150 °C, the strength of the alloy declines slightly to 483 MPa. Then, the strength drops quickly when temperature reaches over 200 °C. The high strength of the alloy in peak-aged condition is caused by a considerable amount of θ'''' and AlMgSiCu (Q) precipitates. The relatively stable mechanical properties tested below 150 °C are mainly ascribed to the stability of θ'''' precipitates. The growth of θ'''' and Q precipitates and the generation of θ phase lead to a rapid drop of the strength when temperature is over 150 °C.

Trans. Nonferrous Met. Soc. China 27(2017) 2539-2547

Hui-zhong LI1,2,3, Ze-xiao ZHU1, Xiao-peng LIANG1,2,3, Peng-wei LI1,3, Ye-long QI1, Feng LV1, Lan HUANG3

1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Metal Materials Science and Engineering, Ministry of Education, Central South University, Changsha 410083, China;

3. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China

Received 17 August 2016; accepted 15 December 2016

Abstract: Transmission electron microscopy (TEM), scanning electron microscopy (SEM), hardness tests and tensile tests were performed to investigate the effect of aging on microstructure and mechanical properties of forged Al-4.4Cu-0.7Mg-0.6Si alloy. The results show that the alloy exhibits splendid mechanical properties with an ultimate tensile strength of 504 MPa and an elongation of 10.1% after aging at 170 °C for 16 h. With tensile testing temperature increasing to 150 °C, the strength of the alloy declines slightly to 483 MPa. Then, the strength drops quickly when temperature reaches over 200 °C. The high strength of the alloy in peak-aged condition is caused by a considerable amount of θ' and AlMgSiCu (Q) precipitates. The relatively stable mechanical properties tested below 150 °C are mainly ascribed to the stability of θ' precipitates. The growth of θ' and Q precipitates and the generation of θ phase lead to a rapid drop of the strength when temperature is over 150 °C.

Key words: forged Al-4.4Cu-0.7Mg-0.6Si alloy; aging treatment; mechanical properties; θ precipitates

1 Introduction

Al-Cu-Mg-Si alloys are commonly used to manufacture some main potent structures in the fields of aviation and aerospace because of their high specific strength, good forgeability and weldability [1,2]. However, the demands for strength, ductility, thermal stability and other special performances of Al-Cu-Mg-Si alloys are much higher than before because of the great development of aeronautical equipments nowadays.

As age-strengthened aluminum alloys, the strengthening of Al-Cu-Mg-Si alloys is normally attributed to the precipitation of θ'-Al2Cu and S'-Al2MgCu phases [3-5]. θ' and S', which can either develop from precursors (the Cu-rich GP zones and the Cu, Mg-rich GPB zones, respectively) or form on heterogeneous nucleation sites, are intermediate structures of the two equilibrium phases θ and S [6]. It is found that different types of precipitates may generate and coexist when artificial aging treatment or micro-alloying was carried out on Al-Cu-Mg-Si alloys [7-9]. By adding different contents of Si into Al-Cu-Mg alloys, HUTCHINSON and RINGER [10] found a dispersive distribution of fine S precipitates which can enhance the level of hardness during over-aging. DHAL et al [11] studied the effect of annealing treatment on precipitation of 2014 alloy subjected to cryorolling and found that the pinning effect of θ phase and equilibrium Q phase led to a high thermal stability of the alloy. In Al-Cu-Mg-Si alloy, Q phase usually exhibits a lathy or needle-like morphology, and it has been reported that Q phase can promote the precipitation of θ' phase [12]. Thus, a combination of different kinds of precipitates with an appropriate proportion obtained by various thermal treatments can effectively improve the comprehensive mechanical properties of the alloy at room temperature or high temperatures. Based on the preceding analysis, a deep study of the effects of artificial aging treatments on the microstructure and mechanical properties of micro- alloying Al-Cu-Mg-Si forged alloys is significant for the application in the fields of aviation and aerospace.

In this work, T6 treatments with different aging temperatures were carried out on a forged Al-4.4Cu- 0.7Mg-0.6Si alloy which was used for manufacturing large aircraft hub. The tensile tests at different temperatures especially at high temperatures which were seldom investigated in other studies were conducted. Besides, the microstructure and strengthening mechanism of the alloy under different peak-aged conditions and testing conditions were analyzed in detail.

2 Experimental

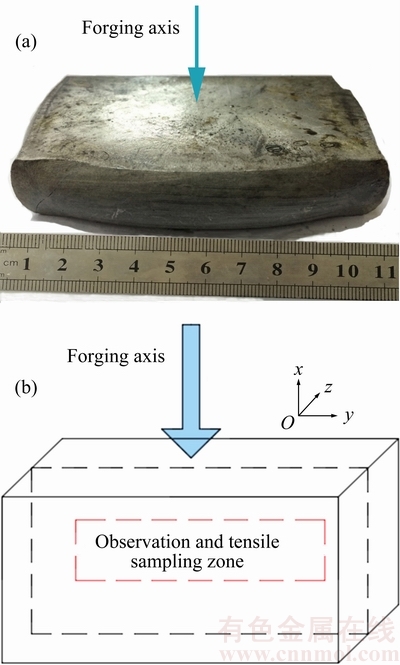

The experimental materials used in this study were semi-continuous casting ingots with the chemical composition shown in Table 1. Rectangular samples with dimensions of 40 mm × 40 mm × 60 mm were machined from the ingots and homogenized at 505 °C for 20 h. The rectangular samples were hold at 420 °C for 2 h before forging. The samples after forging with a true strain of 0.6 are shown in Fig. 1(a). Then, the samples were solution-treated at 520 °C for 1 h followed by water quenching immediately. Finally, the samples were aged at 160, 170, 180 and 200 °C, respectively.

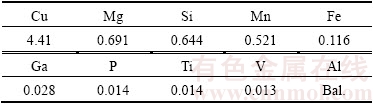

Table 1 Chemical composition of studied alloy (mass fraction, %)

The samples for microstructure analysis and mechanical tests were sectioned in the central part of the specimens and parallel to the compression axis x, the observation plane for microstructure is xy plane and the tensile axis is y, as shown in Fig. 1(b). Thermal analysis of the forged Al-4.4Cu-0.7Mg-0.6Si sample was performed in the as-solutionized condition. The differential scanning calorimetry (DSC) was used in an argon atmosphere at a heating rate of 10 °C/min. The TEM specimens were mechanically polished to 80 μm in thickness and electrolytically polished in a solution of 30% nitric acid and 70% methanol at -30 °C and 12 V. The hardness was tested with a 200HVS-5 Vickers hardness tester, and an average hardness value was taken from at least five indentations of each specimen. The tensile testing of the peak-aged specimens at room temperature and high temperatures was implemented at a strain rate of 1×10-3 s-1 on an MTS810 tension machine. The high temperature tensile testing was conducted after being hold at the testing temperature for 15 min. Three samples were used for each test condition to ensure the repeatability and reproducibility of the results and average values were reported. The fracture surfaces of the tensile samples were observed by SEM.

Fig. 1 Specimen after forging (a) and sampling zone (b)

3 Results

3.1 Mechanical properties

The aging hardness curves of the forged Al-4.4Cu-0.7Mg-0.6Si alloy at 160, 170, 180 and 200 °C are shown in Fig. 2(a). As can be seen from the curves, the peak hardness increases firstly and then decreases as aging temperature increases. While the time for reaching peak hardness decreases with increasing the aging temperature. Meanwhile, the hardness shows the same trend with respect to all aging temperatures, i.e., the hardness increases significantly and then reaches the peak value with increasing holding time. Further aging leads to a slow decrease when aging at 160 and 170 °C. While aging at 180 and 200 °C, the hardness decreases quickly. The hardness of the alloy after solution treatment is HV 120.1. The highest peak hardness of HV 164.1 is obtained after aging at 170 °C for 16 h while the lowest peak hardness of HV 158.0 occurs after aging at 160 °C for 24 h. For aging at 180 and 200 °C, the alloy reaches the peak hardness values of HV 161.1 and HV 160.3 with the holding time of 10 and 6 h, respectively. In summary, the hardness becomes more sensitive to aging time with increasing aging temperature.

Fig. 2 Aging hardness curves of forged alloy at different temperatures (a) and room temperature tensile properties of forged Al-4.4Cu-0.7Mg-0.6Si alloy under peak-aged condition when aging at different temperatures (b)

The room temperature tensile properties of the peak-aged alloy at different aging temperatures are shown in Fig. 2(b). It can be seen that the ultimate tensile strength and yield strength increase firstly and then decrease with increasing the aging temperature. The highest ultimate tensile strength is 504 MPa and yield strength is 448 MPa when the aging temperature is 170 °C. And the lowest ultimate tensile strength of 464 MPa and yield strength of 402 MPa are obtained when aging at 160 °C. The elongation decreases with increasing the aging temperature. The maximum elongation of 13.9% and minimum elongation of 8.4% are obtained when aging at 160 and 200 °C, respectively.

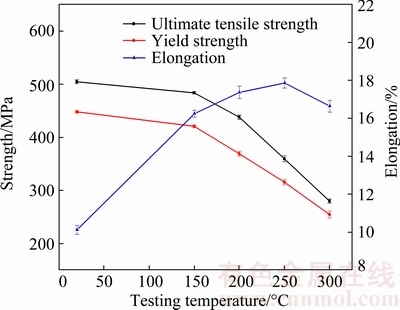

Figure 3 shows the effect of testing temperature on the mechanical properties of the specimen under 170 °C peak-aged condition. As can be seen, the ultimate tensile strength and yield strength decrease slightly when the testing temperature increases to 150 °C and then decrease rapidly with further increasing of the testing temperature. The ultimate tensile strength and yield strength are 483 and 420 MPa, respectively at the testing temperature of 150 °C. When the testing temperature is 300 °C, the ultimate tensile strength and the yield strength decrease to 280 and 254 MPa, respectively. At the same time, the alloy shows a significant increase of elongation from 10.1% to 17.9% when the testing temperature increases from room temperature to 250 °C. However, increasing the testing temperature further to 300 °C, the elongation decreases slightly to 16.6%.

Fig. 3 High temperature tensile properties of forged Al-4.4Cu- 0.7Mg-0.6Si alloy under 170 °C peak-aging condition

3.2 Microstructures

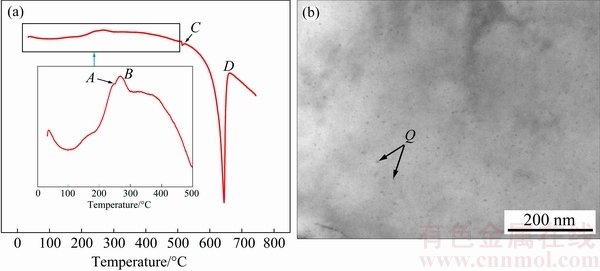

Figure 4 shows the DSC analysis (Fig. 4(a)) of the sample in solid-solution state, which exhibits two consecutive exotherms (peaks A and B): peak A corresponds to the precipitation of the Q phase and peak B to that of the θ' phase. The larger endotherm (peak C) signifies the dissolution of the precipitates and the largest one (peak D) signifies the dissolution of Al matrix. Besides, the TEM image of the sample aging at 200 °C for 5 min (Fig. 4(b)) shows that a large amount of fine Q precipitates are dispersedly distributed in the matrix.

Fig. 4 DSC plot of Al-4.4Cu-0.7Mg-0.6Si alloy in solid-solution state (a) and bright field TEM image of forged alloy after aging at 200 °C for 5 min (b)

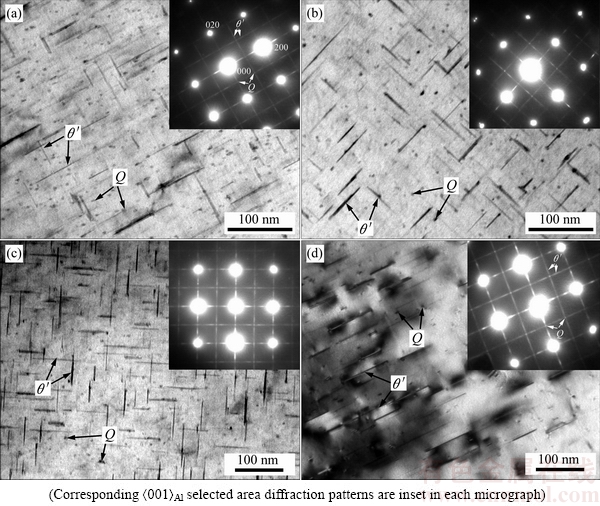

Fig. 5 Bright field TEM images of alloy under peak-aged condition when aging at 160 °C (a), 170 °C (b), 180 °C (c) and 200 °C (d)

Figure 5 shows the bright field TEM images of the forged Al-4.4Cu-0.7Mg-0.6Si alloy under different peak-aged conditions, and the corresponding <001>Al selected area diffraction patterns are inserted in each image. As is observed in Fig. 5, the plate-like precipitates orientate along <010>Al directions and a lot of fine dots can be clearly seen in the matrix of the alloy. The selected area diffraction pattern inset in Fig. 5(a) shows faint streaks along [010]Al and [100]Al, which indicates that the plate-like precipitates are θ' phase. Close examination of the dark dots reveals that most of them are needle or rod shape. In addition, the typical diffraction spots marked in the corresponding selected area diffraction pattern (Fig. 5(a)) indicate that the dark dots are Q phases, which have also been observed by MIAO and LAUGHLIN [13]. Compared with that of the sample aged at 160 °C, the length of θ' precipitates changes very little but increases in number density when the aging temperature is 170 °C (Fig. 5(b)). That is because the precipitation process is a diffusion- controlled process which is determined by aging temperature and time. Thus, more θ' precipitates without growing in size at 170 °C may be attributed to the higher temperature and shorter aging time. As shown in Figs. 5(c) and (d), further increasing the aging temperature to 180 and 200 °C, both the coarsening and the growth in length of θ' precipitates can be observed. Inversely, the amount of θ' precipitates decreases a little. The phenomenon that the diffraction streaks along [010]Al and [100]Al become bright also implies the coarsening of θ' precipitates. The results shown in Fig. 4 manifest that the Q phase and θ' phase can coexist in the aging samples when the aging temperature reaches 200 °C. Thus, it is understandable that a large amount of θ' and Q precipitates appear in the microstructure under peak-aged condition when aging at 160 °C (Fig. 5(a)). Moreover, it can be observed that the size of Q precipitates grows but the number density decreases with increasing aging temperature.

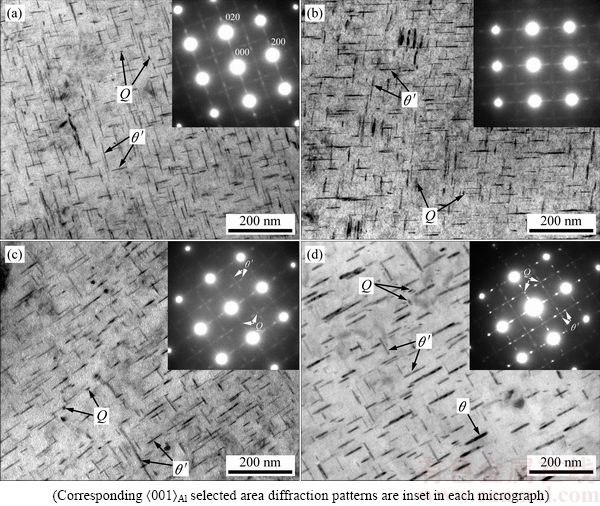

After high temperature tensile testing, the TEM microstructures near fracture surface and the corresponding <001>Al selected area diffraction patterns of the samples are shown in Fig. 6. It can be observed that the θ' precipitates are relatively stable without obvious growing or aggregating when the testing temperature increases from room temperature (Fig. 5(b)) to 150 °C (Fig. 6(a)). Nevertheless, the length of θ' precipitates increases and the precipitates become coarser when the testing temperature exceeds 150 °C (Figs. 6(b), (c) and (d)). Meanwhile, the faint streaks along [010]Al and [100]Al are broken and the diffraction spots as marked in the corresponding selected area diffraction patterns (Figs. 6(c) and (d)) become clear and bright, which also indicates that the θ' precipitates become coarser. At testing temperature of 300 °C, thick θ' precipitates and some unusual thick θ precipitates are observed in the matrix (Fig. 6(d)). Moreover, Q precipitates grow in size but decrease in number density with increasing testing temperature, as shown in Fig. 6.

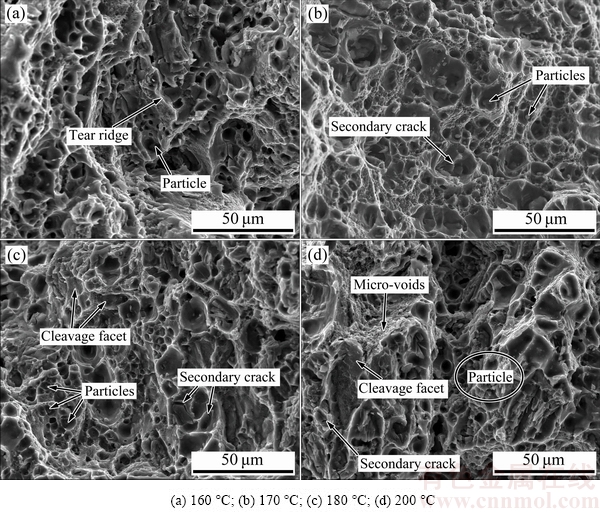

3.3 Characterization of tensile fracture surfaces

The tensile fracture morphologies of the samples tested at room temperature are shown in Fig. 7. The fracture surfaces of the samples aging at 160 and 170 °C are covered with tear ridges and deep dimples with small particles embedded in (Figs. 7(a) and (b)), which indicates good ductility. But the dimples become shallow and more particles can be observed in dimples as aging temperature increases to 170 °C. Moreover, as a brittle fracture characteristic, the secondary crack marked in Fig. 7(b) can also be found. Further increasing aging temperature (Figs. 7(c) and (d)), the dimples become shallower with a decreasing amount and more particles can be found in dimples. Simultaneously, the secondary cracks are observed generating in the matrix. What else, some brittle fracture characteristics like small cleavage facets and facets covered with micro-voids can be clearly observed on the fracture surface of the sample aging at 200 °C, as shown in Fig. 7(d). All these features indicate that the fracture surfaces of the forged alloy aging at 180 and 200 °C are mixed ductile and brittle fractures.

Fig. 6 Bright field TEM images of tensile specimens for 170 °C peak-aged alloy after being tested at 150 °C (a), 200 °C (b), 250 °C (c) and 300 °C (d)

Fig. 7 Tensile fracture morphologies of specimens obtained at room temperature under peak-aged condition at different aging temperatures

Fig. 8 Tensile fracture morphologies of 170 °C peak-aged alloy tested at different temperatures

Figure 8 shows the fracture morphologies of the 170 °C peak-aged alloy tested at different temperatures. By comparing Fig. 7(b) with Figs. 8(a), (b) and (c), the microscopic observation reveals similar fracture behavior for the samples tested below 250 °C. All the fracture surfaces consist of dimples, particles, tear ridges and secondary cracks. As seen in Fig. 8, more dimples and tear ridges generate and the dimples become deeper as the testing temperature rises from 150 to 250 °C. These are the indications of softness of the matrix and decrease of the alloy strength. When the sample is tested at 300°C, the fracture morphology (Fig. 8(d)) appears, which is very different from those of other temperatures. As shown in Fig. 8(d), the fracture surface is covered with larger and deeper dimples. In addition, some small dimples gather on the micro-voids which distribute along the edge of larger dimples. Moreover, no secondary cracks can be seen and some large crushed particles are observed in dimples. Overall, all the fracture surfaces of the forged alloy tested at high temperatures exhibit features of ductile transgranular mode.

4 Discussion

4.1 Influence of temperature and time on aging strengthening

As is well known, the high strength of Al-Cu-Mg-Si alloys is obtained by aging at an intermediate temperature for an appropriate time to form fine precipitates. But these alloys with different Cu/Mg ratios can form complex precipitates [14-16]. Before aging, the super-saturation of vacancies caused by solid-solution makes it easier for diffusion and clustering of solute atoms to occur [17-19]. It has been reported that the binding energy between Mg atoms and the vacancies is higher than that between Cu atoms and vacancies [17,20,21]. However, if aging at temperatures above 150 °C for a long time especially in Al-Cu- Mg-Si alloys with Mg content below 0.8% (mass fraction), it is easier for Cu-Cu cluster to form GP zones rather than GPB zones [21]. Combining with Fig. 4, it makes sense that the Q phase and θ' phase can still coexist when the aging temperature reaches 200 °C, as shown in Fig. 5.

Generally, the degree of strengthening is related to the size, distribution and coherency of the precipitates in the matrix [22]. Moving dislocations may be hindered by the particles and be forced to take a path around the obstacles with a dislocation loop leaving around the particles, which can effectively increase the flow stress for the following dislocations to pass the particles [23]. The flow stress required can be described as

τ=2kGb/λ (1)

where G is the shear modulus, b is the Burger’s vector, k is a constant related to the material and λ is the spacing between nearby particles. As plotted in Fig. 5, the amount of θ' precipitates changes a little when the aging temperature increases to 180 °C and even decreases when the aging temperature is 200 °C. The length of θ' basically remains unchanged as the aging temperature rises from 160 to 170 °C. Conversely, the size of Q precipitates increases while the number density decreases obviously (Fig. 5). It has been reported that θ' phase is the primary strengthening phase compared with Q phase [24]. As a result, the strength of the alloy under peak-aged condition increases when aging temperature increases from 160 to 170 °C. With further increasing aging temperature from 170 to 200 °C, both θ' and Q precipitates increase in size and decrease in amount (Fig. 5(d)), which results in lower hardness and strength, as shown in Figs. 2(a) and (b), respectively.

4.2 Strengthening mechanism at high temperatures

The tensile testing results (Fig. 3) show that the strength and elongation are very sensitive to the testing temperature. In general, the cross-slip of dislocations can be thermally activated as the testing temperature increases, which will cause a reduction in material strength [24,25]. However, the fine precipitates can hinder the motion of dislocations greatly by pinning at grain and sub-grain boundaries during thermal- mechanical processing, which results in the enhancement of high temperature properties [26-28].

Compared with 170 °C peak-aged condition (Fig. 5(b)), the TEM image in Fig. 6(a) shows that the morphology of θ' precipitates is relatively stable as the testing temperature increases to 150 °C. The dispersively distributed θ' precipitates can greatly hinder the motion of dislocations in spite of the softness of the matrix and the thermal activation of dislocations. This can be the main reason to explain the fact that the strength of the alloy decreases slightly when the testing temperature is below 150 °C. When raising the testing temperature beyond 200 °C, the strength drops quickly and linearly (Fig. 3). Combined with the TEM images in Fig. 6, the growth of θ' and Q precipitates can be observed. According to Eq. (1), a lower stress, τ, is required for dislocations to pass the precipitates with larger size which would result in a larger inter-particle spacing, λ. And the dynamic recovery occurs widely at these temperatures because of the cross-slip and climbing of dislocations [29,30]. That is why the strength of the alloy drops faster when the testing temperature increases beyond 200 °C. The mechanical properties shown in Fig. 3 indicate that the elongation has an abnormal decline when the temperature increases to 300 °C. At this temperature, θ' precipitates grow or evolve to incoherent equilibrium θ precipitates, which will weaken the bonding between precipitates and the matrix. Thus, the nucleation and aggregation of micro-voids easily occur at the interface between coarse precipitates and the matrix, which will accelerate the brakeage of the alloy. As a result, both the strength and the elongation decrease. Consequently, the typical feature of fracture surface is the larger crushed particles surrounded by micro-voids, as shown in Fig. 8(d). Moreover, the larger tearing dimples with small dimples gathering at the edge dominate the fracture surface (Fig. 8(d)), which indicates that the solid loses its general properties and it is easy for dislocations to climb to a new slip plane when impeded.

5 Conclusions

1) With increasing aging temperature from 160 to 200 °C, the maximum peak hardness value of HV 164.1 is obtained by aging at 170 °C for 16 h, and the corresponding tensile properties are ultimate tensile strength of 504 MPa, yield strength of 448 MPa, and elongation of 10.1%.

2) Fine θ' phase is the primary strengthening phase of the forged alloy under peak-aged condition. Simultaneously, serious loss of elongation as aging temperature increases is mainly ascribed to the coarse θ' precipitates with decrease in number density.

3) The ultimate tensile strength of the 170 °C peak-aged alloy decreases from 483 to 280 MPa with increasing testing temperature from 150 to 300 °C. Simultaneously, the elongation increases rapidly to 17.9% at 250 °C and then decreases slightly to 16.6% at 300 °C.

4) The slight decrease of strength when testing temperature increases to 150 °C is mainly attributed to the stable size and number density of θ' precipitates. Then, the coarsening of θ' and Q precipitates as well as the generation of θ precipitates makes the strength decrease rapidly when the testing temperature increases to over 200 °C.

References

[1] KENT D, SCHAFFER G B, DRENNAN J. Age hardening of a sintered As-Cu-Mg-Si-(Sn) alloy [J]. Materials Science and Engineering A, 2005, 405: 65-73.

[2] LIANG Xiao-peng, LI Hui-zhong, HUANG Lan, HONG Tao, MA Bing, LIU Yong. Microstructural evolution of 2519-T87 aluminum alloy obliquely impacted by projectile with velocity of 816 m/s [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 1270-1279.

[3] DASGUPTA R, MEENAI H, DAS S. Age hardening of Al 201-alloy and 2014-SiC composites [J]. Journal of Materials Science Letters, 2003, 22: 391-394.

[4] LI Hui-zhong, LIU Ruo-mei, LIANG Xiao-peng, DENG Min, LIAO Hui-juan, HUANG Lan. Effect of pre-deformation on microstructures and mechanical properties of high purity Al-Cu-Mg alloy [J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 1482-1490.

[5] ESKIN D G. Decomposition of supersaturated solid solutions in Al-Cu-Mg-Si alloys [J]. Journal of Materials Science, 2003, 38: 279-290.

[6] RINGER S P, SAKURAI T, POLMEAR I J. Origins of hardening in aged Al-Cu-Mg-(Ag) alloys [J]. Acta Materialia, 1997, 45: 3731- 3744.

[7] WANG Fang, ZENG Yan-qi, XIONG Bai-qing, ZHANG Yong-an, LI Xi-wu, LI Zhi-hui, LIU Hong-wei. Effect of Si addition on the microstructure and mechanical properties of Al-Cu-Mg alloy [J]. Journal of Alloy and Compounds, 2014, 585: 474-478.

[8] ELISABETTA G, PAOLA B, MIHAELA A, FERDINAND H. Presence of silver in the strengthening particles of an Al-Cu-Mg-Si-Zr-Ti-Ag alloy during severe overaging and creep [J]. Acta Materialia, 2017, 125: 50-57.

[9] LI Xi-feng, LEI Kun, SONG Peng, LIU Xin-qin, ZHANG Fei, LI Jian-fei, CHEN Jun. Strengthening of aluminum alloy 2219 by thermo-mechanical treatment [J]. Journal of Materials Engineering and Performance, 2015, 24: 3905-3911.

[10] HUTCHINSON C R, RINGER S P. Precipitation processes in Al-Cu-Mg alloys microalloyed with Si [J]. Metallurgical and Materials Transactions A, 2000, 31: 2721-2733.

[11] DHAL A, PANIGRAHI S K, SHUNMUGAM M S. Precipitation phenomena, thermal stability and grain growth kinetics in an ultra-fine grained Al 2014 alloy after annealing treatment [J]. Journal of Alloys and Compounds, 2015, 649: 229-238.

[12] DUTTA I, HARPER C P, DUTTA G. Role of Al2O3 particulate reinforcements on precipitation in 2014 Al-matrix composites [J]. Metallurgical and Materials Transactions A, 1994, 25: 1591-1602.

[13] MIAO W F, LAUGHLIN D E. Effects of Cu content and preaging on precipitation characteristics in aluminum alloy [J]. Metallurgical and Materials Transactions A, 2000, 31: 361-371.

[14] LIU J Z, YANG S S, WANG S B, CHEN J H, WU C L. The influence of Cu/Mg atomic ratios on precipitation scenarios and mechanical properties of Al-Cu-Mg alloy [J]. Journal of Alloy and Compounds, 2014, 613: 139-142.

[15] LIU L, CHEN J H, WANG S B, LIU C H, YANG S S, WU C L. The effect of Si on precipitation in Al-Cu-Mg alloy with a high Cu/Mg ratio [J]. Materials Science and Engineering A, 2014, 606: 187-195.

[16] GABLE B M, SHIFLET G J, STARKE E A Jr. The effect of Si additions on Ω precipitation in Al-Cu-Mg-(Ag) alloys [J]. Scripta Materialia, 2004, 50: 149-153.

[17] ALFONSO I, MALDONADO C, GONZALEZ G, ARNOLDO B. Effect of Mg content and solution treatment on the microstructure of Al-Si-Cu-Mg alloys [J]. Journal of Materials Science, 2006, 41: 1945-1952.

[18] EIVANI A R, TAHERI A K. Modeling age hardening kinetics of an Al-Mg-Si-Cu aluminum alloy [J]. Journal of Materials Processing Technology, 2008, 205: 388-393.

[19] ALEXOPOULOS N D, VELONAKI Z, STERGIOU C I, KOURKOULIS S K. Effect of ageing on precipitation kinetics, tensile and work hardening behavior of Al-Cu-Mg (2024) alloy [J]. Materials Science and Engineering A, 2017, 700: 457-467.

[20] GAO Ying-jun, HOU Xiao-hua, MO Qi-feng, WEI Cheng-yang, QIN Xiao-bing. Atomic bonding of precipitate and phase transformation of Al-Cu-Mg alloy [J]. Journal of Alloys and Compounds, 2007, 441: 241-245.

[21] RINGER S P, HONO K, POLMEAR I J, SAKURAI T. Nucleation of precipitates in aged Al-Cu-Mg-(Ag) alloys with high Cu:Mg ratios [J]. Acta Materialia, 1996, 44: 1883-1898.

[22] XUE Z, HUANG Y, LI M. Particle size effect in metallic materials: a study by the theory of mechanism-based strain gradient plasticity [J]. Acta Materialia, 2002, 50: 149-160.

[23] SINGH S, GOEL D B. Influence of thermomechanical ageing on tensile properties of 2014 aluminium alloy [J]. Journal of Materials Science, 1990, 25: 3894-3900.

[24] BISWAS A, SIEGEL D J, SEIDMAN D N. Compositional evolution of Q-phase precipitates in an aluminum alloy [J]. Acta Materialia, 2014, 75: 322-336.

[25] ARZT E,  J. The kinetics of dislocation climb over hard particles—II. Effects of an attractive particle-dislocation interaction [J]. Acta Metallurgica, 1988, 36: 1053-1060.

J. The kinetics of dislocation climb over hard particles—II. Effects of an attractive particle-dislocation interaction [J]. Acta Metallurgica, 1988, 36: 1053-1060.

[26] MARQUIS E A, DUNAND D C. Model for creep threshold stress in precipitation-strengthened alloys with coherent particles [J]. Scripta Materialia, 2002, 47: 503-508.

[27] KNIPLING K E, SEIDMAN D N, DUNAND D C. Ambient-and high-temperature mechanical properties of isochronally aged Al– 0.06Sc, Al-0.06Zr and Al-0.06Sc-0.06Zr (at.%) alloys [J]. Acta Materialia, 2011, 59: 943-954.

[28] SHAHA S K, CZERWINSKI F, KASPRZAK W, FRIEDMAN J, CHEN D L. Ageing characteristics and high-temperature tensile properties of Al-Si-Cu-Mg alloys with micro-additions of Cr, Ti, V and Zr [J]. Materials Science and Engineering A, 2016, 652: 353-364.

[29] XIANG Yang, SROLOVITZ D J, CHENG L T, WEINAN E. Level set simulations of dislocation-particle bypass mechanisms [J]. Acta Materialia, 2004, 52: 1745-1760.

[30] XIANG Yang, SROLOVITZ D J. Dislocation climb effects on particle bypass mechanisms [J]. Philosophical Magazine, 2006, 86: 3937-3957.

李慧中1,2,3,朱泽晓1,梁霄鹏1,2,3,李鹏伟1,3,齐叶龙1,吕 凤1,黄 岚3

1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 有色金属材料科学与工程教育部重点实验室,长沙 410083;

3. 中南大学 粉末冶金国家重点实验室,长沙 410083

摘 要:用透射电子显微镜、扫描电子显微镜、硬度及拉伸测试研究时效处理对锻造Al-4.4Cu-0.7Mg-0.6Si合金显微组织及力学性能的影响。结果表明,经170 °C时效16 h后,合金力学性能优良,抗拉强度为504 MPa,伸长率为10.1%。当测试温度升高到150 °C时,合金的抗拉强度缓慢下降到483 MPa;继续升高温度到200 °C以上时,合金强度快速下降。大量θ'析出相及AlMgSiCu四元析出相(Q相)导致合金峰时效的高强度。稳定的细小弥散θ'相使得该合金在150 °C下仍保持较优的力学性能;当温度高于150 °C时,θ'和Q相的粗化以及θ相的析出导致合金强度的快速下降。

关键词:锻造Al-4.4Cu-0.7Mg-0.6Si合金;时效热处理;力学性能;θ析出相

(Edited by Wei-ping CHEN)

Foundation item: Project (51301209) supported by the National Natural Science Foundation of China

Corresponding author: Xiao-peng LIANG; Tel: +86-731-88830377; Fax: +86-731-88830257; E-mail: liangxp@csu.edu.cn; mselxp@163.com

DOI: 10.1016/S1003-6326(17)60282-6