3 翼缝形状对翼型气动性能的影响

针对表2中6种开缝方案,分2组讨论,研究不同翼缝形状对翼型性能的提升作用。首先研究不同弧形半径的翼缝,然后利用最佳弧形与直线形相组合,得到最佳开缝方案。

3.1 弧形半径

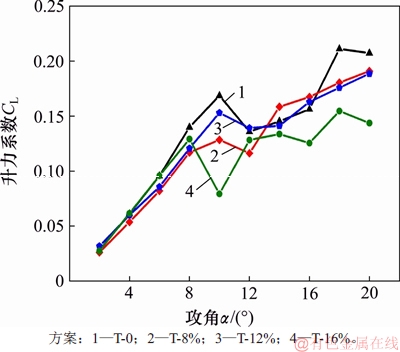

按照翼缝半径占弦长之比,提出3种弧形开缝方案,即表2中T-8%,T-12%和T-16%,值得注意的是,能够实现弧形与翼型边界相切的最小半径在r/c在8%左右,所以,将T-8%看作是能够满足翼型开缝的最小半径方案。针对不同的弧形开缝方案,分别进行二维流体力学仿真,整理得到不同开缝方案下的翼型升力系数,如图6所示。

图6 不同弧形半径方案翼型升力系数

Fig. 6 Airfoil lift coefficient of different arc radius scheme

由图6可以看出:3种弧形开缝方案对翼型升力系数的提升效果均不明显,开缝翼型对应的升力系数整体上比常规翼型的小,且随着弧形半径的增加,附面层发生分离对应的攻角变小,即翼型失速相对于常规翼型提前发生,说明弧形翼缝方案对延迟临界攻角起到的作用较小。

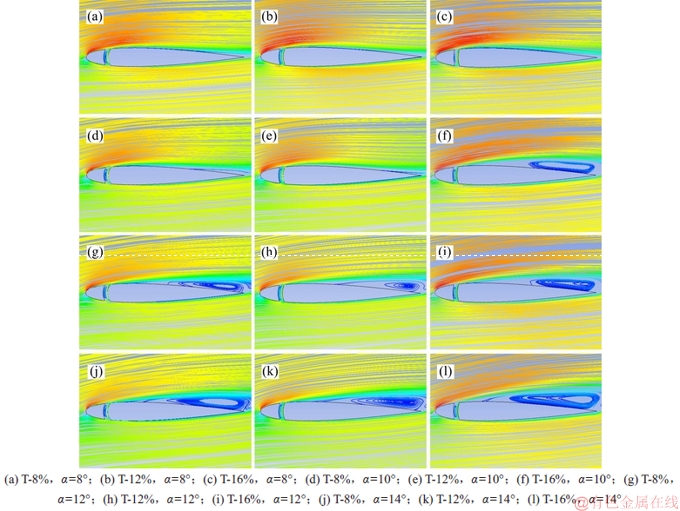

为观察弧形翼缝对延迟翼型附面层分离点的作用,得到翼型临界攻角附近的流线图,如图7所示。

图7 弧形开缝方案不同攻角下翼型流线图

Fig 7 Streamlines of slotted airfoil under different attack angles

由图7可知:T-16%翼型在攻角α=10°时就已完全失速,翼型表面已经形成失速涡,相较于其他2种方案,其对翼型气动性能的提升效果最差;而T-8%和T-12%开缝方案在相同攻角下流线图非常接近,且对延迟附面层分离点都有一定效果,相较于图4,附面层分离点均有明显后移,这说明对于开缝翼型,压力面的部分气体通过翼缝吹向吸力面,增加翼型吸力面的气流动能,达到延迟附面层分离的效果。

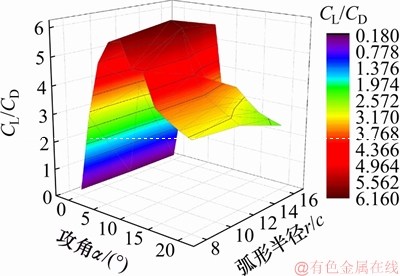

考虑到开缝翼型改变升力系数的同时,也会使阻力系数发生改变。翼型升阻比是翼型升力系数与阻力系数的比值,升阻比越大,说明翼型在同一攻角下的升力系数远大于阻力系数,翼型的气动性能越好[18]。因此,为合理地选择最优弧形半径,通过对比不同弧形半径下各攻角所对应的翼型升阻比,来选择弧形翼缝的最佳半径。不同弧形半径下各攻角所对应的升阻比如图8所示。

图8 不同弧形半径下各攻角所对应的升阻比

Fig. 8 Lift-drag ratio of attack angle under different arc radius scheme

由图8可知:当攻角α<10°时,不同弧形半径在同一攻角下对应的升阻比非常接近,在攻角α=10°时,弧形半径r=12%c的升阻比最大;当α>10°时,随着弧形半径变小,翼型升阻比变大,即翼型的气动性能更好。而要解决的翼型失速问题主要出现在大攻角下[19],因此,认为r=8%c为最佳弧形半径,即选择T-8%为弧形开缝方案的最佳翼型。

由图7可知:弧形翼缝使翼型升力系数下降的主要原因是弧形翼缝的迎风端与气流方向呈负夹角,使得翼型压力面的气体在进入翼缝时受到一定阻碍,同时在翼缝内部形成环形气流,增加气流动能的损失。

3.2 不同组合形式翼缝

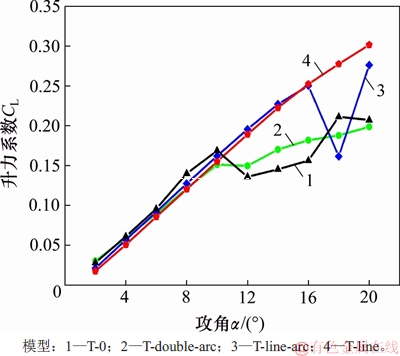

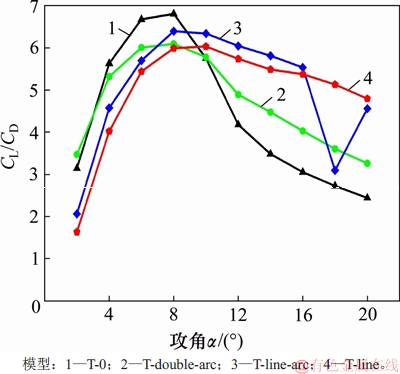

为解决弧形翼缝迎风端与来流风速方向不匹配问题,通过改变弧形翼缝迎风端即气流入口方向得到以下3种开缝方案,即表2中的T-double-arc,T-line-arc和T-line。同时,为减少翼缝倾斜角度对求解翼型升阻力系数带来的影响,在不同的开缝方案中,保证翼缝的两端相对位置不变。通过改变攻角,得到不同开缝方案下的翼型升力系数与升阻比曲线分别如图9和图10所示。

图9 不同组合方式翼型升力系数

Fig. 9 Lift coefficient under different combination types

图10 不同组合形式翼型升阻比

Fig. 10 Lift-drag ratio under different combination types

由图9可见:T-double-arc在翼型升力系数提升方面效果不佳,没能起到延迟临界失速攻角的作用。而T-line-arc和T-line对升力系数的提升较为明显,尤其在攻角α超过10°部分,翼型升力系数较常规翼型Type-0有了显著提高;在攻角α小于16°部分,T-line-arc和T-line对翼型升力的提升效果较为接近,但T-line-arc在攻角α大于16°后发生了失速,而T-line在攻角α小于20°未发生失速。通过进一步研究发现,T-line发生失速时的攻角为26°,说明T-line-arc和T-line这2种开缝方案在增大临界攻角方面都起到了较好的效果,且T-line的作用效果更好。

由图10可知:T-line-arc在未发生失速之前,即攻角α小于16°,对翼型的气动性能提升有更好的效果,发生失速后,翼型的升阻比下降较为明显,而 T-line在所研究攻角范围内对翼型气动性能的提升作用更稳定。值得注意的是:当风力机工作在小攻角范围,即攻角α<10°时,对翼型进行开缝反而会降低翼型的气动参数,主要原因在于翼缝的存在增加了翼型表面对气流的阻力,这个问题可以通过加装翼缝开关来解决,即通过加装控制系统,在小攻角下关闭翼缝,大攻角下打开翼缝,使翼型的出力效果最优[10]。

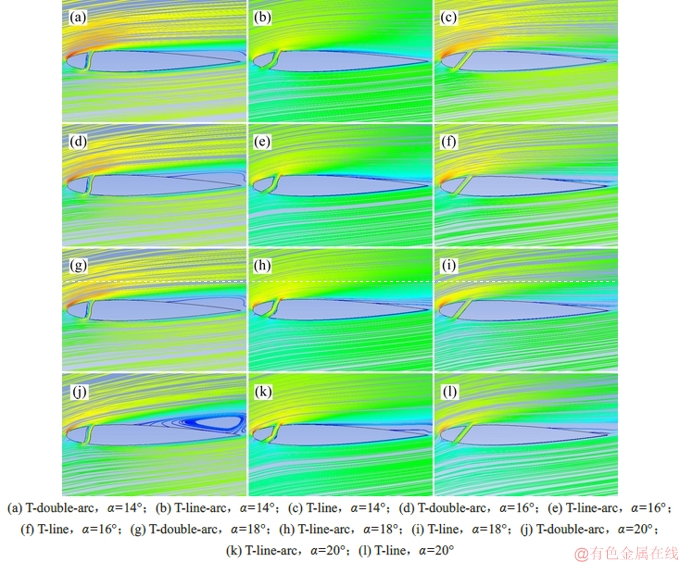

为进一步观察翼缝形状对延迟附面层分离点的影响,得到大攻角下翼型的流线,如图11所示。由图11可知:3种开缝形式在延迟附面层分离和推迟失速涡形成方面都起到了较好的效果,其中,T-double-arc相较于其他2种形式效果较差,在攻角α=20°时形成了失速涡,而T-line-arc和T-line在所研究攻角范围内都未出现失速涡,对延迟附面层分离方面也都起到了较好作用。

图11 大攻角下不同组合形式翼型流线图

Fig 11 Streamline profiles of different combinations at large attack angles

开缝方案的选择与风力机旋转过程中所能达到的最大攻角有关,而最大攻角可由叶尖速比计算得到[20],当风力机运行工况的叶尖速比λ≥3.5时,翼型旋转过程中叶片最大攻角不会超过16°,在该情况下,可选择T-line-arc为开缝方案;当风力机工作在低叶尖速比下即λ<3.5时,叶片攻角可以达到较大值,例如本文中叶尖速比λ=2.0,叶片攻角最大值可以达到30°,而T-line开缝方案在大攻角下对翼型气动性能的提升有显著的效果,所以,在低叶尖速比下选择T-line为最佳开缝方案。

4 结果与讨论

4.1 不同风区翼型开缝机理分析

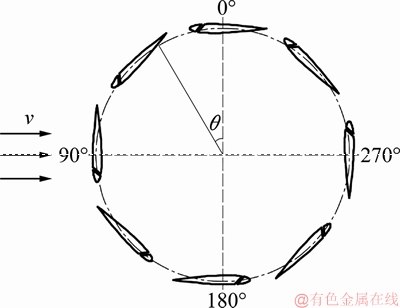

针对本文给出的开缝方案,以T-line开缝方案为例,得到其风轮旋转1周过程中叶片的位置图如图12所示。其中,θ为叶片方位角,当方位角θ位于(0°,180°]时,该区域称为风轮的上风区;当θ位于(180°,360°]时,称为风轮的下风区。

图12 风轮旋转一周叶片位置图

Fig. 12 Blade position in pace of the wheel rotation

由于靠近来流风向的一面为压力面,当叶片位于上风区时,其外侧为压力面,而当叶片处在下风区时,其内侧为压力面[21]。观察图12可以发现:本文上述开缝方案中翼缝的方向仅适用于下风区,对于上风区,压力面的气流通过翼缝进入吸力面后,会使吸力面气流向翼型前缘流动,对于延迟附面层分离起到反作用。考虑到上下风区叶片攻角的对称性,其对翼缝的研究也是对称的,所以,对于垂直轴风力机翼型,提出在上下风区对称开缝的方法,翼型分风区开缝方案如表4所示。

表4 翼型分风区开缝方案

Table 4 Airfoil slit scheme in different windstream area

按照表4所示分风区开缝方案,可保证风轮旋转1周过程中,压力面气流都可通过翼缝吹向翼型吸力面后缘,达到延迟附面层分离的目的。因此,对叶片进行对称开缝,通过加装控制装置,实现叶片处于不同风区时翼缝方向的改变。

4.2 对称开缝翼型效果分析

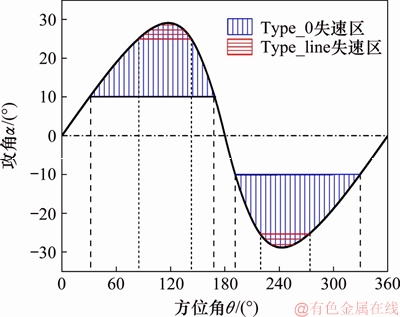

针对叶尖速比λ=2的情形,根据双制动盘多流管理论进行MATLAB编程,得到风轮旋转1周过程中叶片攻角随方位角呈类正弦变化规律[22]。由上述分析可知,常规翼型T-0在攻角α≥11°时出现失速现象,而采用T-line开缝方案后,翼型的临界攻角出现了延迟;当攻角α≥26°时,翼型才进入失速状态。图13所示为翼型对称开缝前后叶片失速区范围示意图。

由图13可以看出:在风轮旋转1周过程中,常规翼型T-0在方位角30°≤θ≤170°和190°≤θ≤330°时,攻角α≥11°,即叶片处在失速区的方位角范围高达77.8%;采用T-line开缝方案后,攻角α≥26°的方位角处于85°≤θ≤140°和220°≤θ≤275°附近,叶片发生失速的区域占整周的30.5%左右。因此,采用开缝翼型后,叶片失速区范围下降了61.5%,叶片在大部分工况下可以保持高升力系数。

图13 翼型对称开缝前后叶片失速区范围示意图

Fig. 13 Schematic diagram of the stall area of the blade before and after the symmetrical slotted is adopted

5 结论

1) 针对垂直轴风力机在大攻角下的附面层分离问题,提出了6种开缝方案,并进行网格独立性验证得到翼型划分网格的最佳数目为4.6×104个。

2) 翼型的临界攻角α=11°,在该临界攻角下计算得到x=1/8c为理想开缝位置。

3) 弧形开缝翼型在延迟翼型临界攻角上作用较小,但可有效推迟附面层分离点,同时以获得最大升阻比为研究目标,得到最佳的弧形半径r=8%c。

4) 当叶尖速比λ≥3.5时,采用T-line-arc为开缝方案;当叶尖速比λ<3.5时,采用T-line为开缝方案。以λ=2.0为例分析显示,采用对称开缝翼型,叶片失速区范围下降61.5%。

参考文献:

[1] 田海姣, 王铁龙, 王颖. 垂直轴风力发电机发展概述[J]. 应用能源技术, 2006(11): 22-27.

TIAN Haijiao, WANG Tielong, WANG Ying. Summarize of the development of the vertical-axis wind turbine[J]. Applied Energy Technology, 2006(11): 22-27.

[2] CHEHOURI A, YOUNES R, ILINCA A, et al. Review of performance optimization techniques applied to wind turbines[J]. Applied Energy, 2015, 142: 361-388.

[3] GBADEBO S A, CUMPSTY N A, HYNES T P. Three-dimensional separations in axial compressors[J]. Journal of Turbomachinery, 2005, 127(2): 331.

[4] CHEN Xiao, JING Ping. Application of submerged vortex generators for separation control of a subsonic diffuser[J]. Journal of Aerospace Power , 1992: 226-228.

[5] LI J Y, LI R, GAO Y, et al. Aerodynamic optimization of wind turbine airfoils using response surface techniques[J]. Proceedings of the Institution of Mechanical Engineers, Part A: Journal of Power and Energy, 2010, 224(6): 827-838.

[6] BARLAS T K, VAN KUIK G A M . Review of state of the art in smart rotor control research for wind turbines[J]. Progress in Aerospace Sciences, 2010, 46(1): 1-27.

[7] 杨科, 王会社, 徐建中, 等. 开缝式风力机静态失速特性的研究[J]. 工程热物理学报, 2008, 29(1): 32-35.

YANG Ke, WANG Huishe, XU Jianzhong, et al. Stalling feature research of wind turbine with fin[J]. Journal of Engineering Thermophysics, 2008, 29(1): 32-35.

[8] 叶建, 邹正平, 陆利蓬, 等. 低雷诺数下翼型前缘流动分离机制的研究[J]. 北京航空航天大学学报, 2004, 30(8): 693-697.

YE Jian, ZOU Zhengping, LU Lipeng, et al. Investigation of separation mechanism for airfoil leading fedge flow at low Reynolds number[J]. Journal of Beijing University of Aeronautics and Astronautics, 2004, 30(8): 693-697.

[9] CO OIU C I, GEORGESCU A M, DEGERATU M, et al. Numerical predictions of the flow around a profiled casing equipped with passive flow control devices[J]. Journal of Wind Engineering and Industrial Aerodynamics, 2013, 114: 48-61.

OIU C I, GEORGESCU A M, DEGERATU M, et al. Numerical predictions of the flow around a profiled casing equipped with passive flow control devices[J]. Journal of Wind Engineering and Industrial Aerodynamics, 2013, 114: 48-61.

[10] BELAMADI R, DJEMILI A, ILINCA A, et al. Aerodynamic performance analysis of slotted airfoils for application to wind turbine blades[J]. Journal of Wind Engineering and Industrial Aerodynamics, 2016, 151: 79-99.

[11] 王龙, 孙伦业, 张瑾. 大攻角下开缝位置改变对风力机叶片影响研究[J]. 合肥工业大学学报(自然科学版), 2017, 40(8): 1037-1041.

WANG Long, SUN Lunye, ZHANG Jin. Study of the impact of the change of slotted position at high angle of attack on wind turbine blades[J]. Journal of Hefei University of Technology(Natural Science), 2017, 40(8): 1037-1041.

[12] 惠增宏, 竹朝霞, 张理. 带缝翼多段翼型气动特性的实验研究[J]. 实验流体力学, 2007, 21(2): 17-20, 24.

HUI Zenghong, ZHU Zhaoxia, ZHANG Li. Experimental investigation of aerodynamics performance of multi-element airfoil with leading-edge slat[J]. Journal of Experiments in Fluid Mechanics, 2007, 21(2): 17-20, 24.

[13] GRASSO F. Usage of numerical optimization in wind turbine airfoil design[J]. Journal of Aircraft, 2011, 48(1): 248-255.

[14] BUHL T, ANDERSEN P B, BARLAS A. 2D numerical comparison of trailing edge flaps - Upwind WP1B3[J]. Aerospace Engineering, 2007: 1-21.

[15] 唐进. 提高风力机叶型气动性能的研究[D]. 北京: 清华大学热能工程系, 2004:48-52.

TANG Jin. Research of improving aerodynamic performance of wind turbinesblade profile[D]. Beijing: Tsinghua Univesity, Department of Energy and Power Engineering, 2004:48-52.

[16] 伊恩·帕拉斯基沃尤(ION Paraschivoiu)著. 垂直轴风力机原理与设计[M]. 李春, 叶舟, 高伟译. 上海: 上海科学技术出版社, 2013.

ION Paraschivoiu. Principle and design of vertical axis wind turbine [M]. LI Chun, YE Zhou, GAO Wei. Shanghai: Shanghai Science and Technology Press, 2013.

[17] SAGHARICHI A, MAGHREBI M J, ARABGOLARCHEH A. Variable pitch blades: An approach for improving performance of Darrieus wind turbine[J]. Journal of Renewable and Sustainable Energy, 2016, 8(5):1-25.

[18] 吕黎, 毕长飞, 崔鹏宇. 垂直轴风力机叶片翼型的气动性能分析[J]. 热力发电, 2014, 43(12): 126-129.

LYU Li , BI Changfei, CUI Pengyu. Numerical simulation on aerodynamic performance of a vertical axis wind turbine airfoil[J]. Thermal Power Generation, 2014, 43(12): 126-129.

[19] RAMAKRISHNAN R. Wind-turbines fundamentals, technologies, application, economics [book review][J]. IEEE Electrical Insulation Magazine, 2003, 19(2): 48.

[20] 张立勋, 梁迎彬, 尉越啸, 等. 垂直轴风力机主动式变桨距控制规律[J]. 中南大学学报(自然科学版), 2013, 44(6): 2561-2568.

ZHANG Lixun, LIANG Yingbin, WEI Yuexiao, et al. Active variable-pitch control laws for vertical axis wind turbine[J]. Journal of Central South University(Science and Technology), 2013, 44(6): 2561-2568.

[21] 高强, 蔡新, 潘盼, 等. 叶片失速延迟控制垂直轴风力机气动性能[J]. 中南大学学报(自然科学版), 2017, 48(3): 830-836.

GAO Qiang, CAI Xin, PAN Pan, et al. Aerodynamic characteristics of blade stall delay control vertical axis wind turbine[J]. Journal of Central South University(Science and Technology), 2017, 48(3): 830-836.

[22] 张立军, 刘华, 赵昕辉, 等. 垂直轴风力机非对称翼型叶片变攻角方法[J]. 可再生能源, 2016, 34(2): 232-237.

ZHANG Lijun, LIU Hua, ZHAO Xinhui, et al. The method for wind turbine to vary angle of attack of asymmetric airfoil blade[J]. Renewable Energy Resources, 2016, 34(2): 232-237.

(编辑 秦明阳)

收稿日期: 2018 -08 -12; 修回日期: 2018 -10 -30

基金项目(Foundation item):国家自然科学基金资助项目(51707204);中央高校基本科研业务专项资助项目(17CX05021) (Project (51707204) supported by the National Natural Science Foundation of China; Project(17CX05021) supported by the Fundamental Research Funds for the Central Universities);

通信作者:张立军,博士,教授,硕士生导师,从事可再生能源技术和绿色装备制造研究;E-mail:zhanglijun@upc.edu.cn