Abstract: The microstructure and properties of Al-20Si-2Cu-1Ni-0.4Mg alloy fabricated with semi-solid rheo-diecasting process were studied. A newly developed direct ultrasonic vibration process (DUV process) was used in the preparation of the semi-solid slurry of this alloy. The results show that the primary Si particles in this alloy is about 20 μm in size under DUV for 90 s in the semi-solid temperature range, compared to about 30 μm in the alloy without DUV. It is discovered that the primary Si particles distribute more homogeneously and have regular shape, but have lower volume fraction after DUV. The tensile strength at room temperature is about 310 MPa, and the tensile strength and elongation of the semi-solid die castings are increased by 34% and 45%, respectively, compared with the traditional liquid die castings. The high-temperature tensile strength at 300 ℃ of this high Si aluminum alloy reaches 167 MPa, and the coefficient of thermal expansion is 17.37×10-6/℃ between 25 and 300 ℃. This indicates that this high Si content Al-Si alloy produced with the DUV process is suitable to be used in the manufacture of pistons or other heat-resistant parts.

Key words: semi-solid metals; rheocasting; Al-Si alloy; ultrasonic vibration; properties

1 Introduction

Hypereutectic Al-Si alloys with high Si content, which have the superior performances such as excellent wear resistance,good thermal stability, and low coefficient of thermal expansion, are ideal candidates for making such heat-resistant parts as pistons of high speed engines. However, conventional casting techniques get coarse primary Si particles and lamellar eutectic Si in the matrix of hypereutectic Al-Si alloys when Si content is greater than 16%, which are detrimental to the mechanical properties[1-2].

It has been known that ultrasonic vibration has the effects of refining microstructure of metals. Ultrasonic vibration was employed in the field of metal’s semi-solid processing in applications as continuously casting in the middle of 1990s [3-4]. But it was used to produce semi-solid billet for thixoforming. The rheocasting of the slurry made by ultrasonic vibration has seldom been studied. Recently, WU et al[5-8] developed a direct ultrasonic vibration process (DUV process) for the preparation of the semi-solid slurry of metals, which imposes the vibration head directly in the melt and vibrates a short time to get semi-solid slurry around the liquidus temperature of the alloys. It was demonstrated that the DUV has the effects of forming non-dendrite primary a(Al) crystals of hypoeutectic Al-Si alloys and refining semi-solid microstructures[9-10]. However, there are very few researches on its application in production of semi-solid slurry for rheocasting of metal parts, and especially for production of slurry of high Si content Al-Si alloys. And the influences of the DUV on mold-filling ability and parts-forming properties of high Si content Al-Si alloys are also not yet received enough concerns. In this work, it was discovered that the semi-solid microstructure of rheo-diecasted Al-20Si- 2Cu-1Ni-0.4Mg alloy was improved with DUV, and relatively high mechanical properties and low thermal expansion coefficient of this alloy were obtained with this rheo-diecasting process. From the results it is indicated that this high Si content Al-Si alloy produced with the DUV process is suitable to be used in the manufacture of pistons or other heat-resistant parts.

2 Experimental

The alloys to be used in this work were high silicon Al-Si alloys Al-20Si-2Cu-0.4Mg-1Ni-0.5Mn, which were prepared by using raw materials of Al-25.8%Si (mass fraction,the same in the following) and Al-10%Mn master alloys, commercial purity aluminum (99.7%), 99.99% Cu, 99.9% Mg, and 99.99% Ni. The final real compositions of the die casting samples analyzed with fluorescence analysis meters were 20% Si, 1.86% Cu, 0.314% Mg, 1.02% Ni, 0.214% Fe, 0.507% Mn, 0.24% Ce, 0.24% La, 0.047% Zn, 0.022% Ti,and balance Al. The liquidus temperature of this alloy analyzed by DSC was 694 ℃, and the solidus temperature was 533 ℃.

The installation of DUV for high silicon Al-Si alloy in Ref. [5, 8] was employed in the experiments. The applied ultrasonic power in this work was 1.8 kW, and the frequency of DUV was 20 kHz. The ultrasonic vibrator was composed of firmly connected transducer and amplitude made from titanium alloy.

The alloy was melted in a resistance furnace at 820-850 ℃ with complex modification of 0.08% P (Cu- 14%P) and 0.6% RE (Al-15%RE, in which the RE was composed of 63%Ce and 36%La). The P and RE were modification agents for primary Si and eutectic Si respectively. The melt was held at 740-780 ℃, and a metal cup was preheated to 680-700 ℃ by the heating furnace simultaneously. Subsequently, about 600 g liquid metal was poured into the preheated metal cup followed by application of DUV with the ultrasonic vibrator immersed into the melt 15-20 mm from the surface. The slurry with certain solid fraction was poured into a cold chamber die-casting machine after treatment with DUV for 90 s at 710-680 ℃, and standard tensile samples with diameter of 6.4 mm were obtained by die-casting.

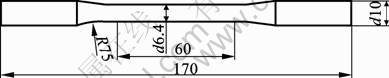

The shape and dimensions of die-casted sample are shown in Fig.1. Four test bars were made in a metallic mold at one time by die-casting. The injection speed of die-casting was 4 m/s, and the specific pressure of injection was 40 MPa. For comparison, traditional liquid die-casting samples were also made without DUV at the pouring temperature of 790 ℃.

Fig.1 Schematic of tensile samples made by die-casting (Unit: mm)

One half of the tensile samples were kept as-cast, the others were heat treated with T6 treatment. The tensile tests were carried out using a WDW3200 type testing machine. For comparison, all specimens were cut from d10 mm ends of tensile tested samples for microstructure observation and metallographic analysis. After the specimens were embedded, polished and etched by 0.5% hydrofluoric acid solution they were observed with an optical microscope. The sizes and the volume fraction of the primary Si particles were measured statistically by means of a software system, in which the size of the primary Si particles was characterized by average particles diameter (APD) [5]. In order to analyze the constituent phases, specimens etched by 8% sodium hydroxide solution, were examined using a Quanta 200 scanning electron microscope (SEM) and EDS.

3 Results and discussion

3.1 Microstructure of DUV treated high Si aluminum alloy with semi-solid rheo-diecasting

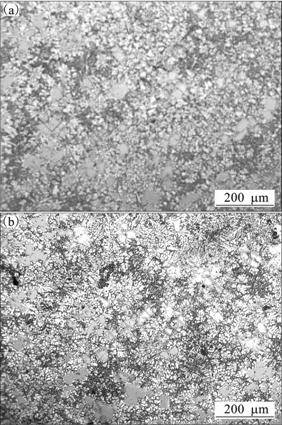

The microstructure of samples with diameter of 6.4 mm of high silicon Al-Si alloy slurry rheo-diecast at 690 ℃ is shown in Fig.2(a). The microstructure of liquid die-casting sample is shown in Fig.2(b). The results show that, with ultrasonic vibration to the alloy melt around or below liquidus temperature for 90 s, the primary Si particles can be refined, and semi-solid microstructure can be obtained. The Si particles in Fig.2(a) are smaller and rounder than that of Fig.2(b), with average particle diameter (APD) of 20 mm and uniformly distributed in the matrix. In Fig.2(b), although Si particles are also small because of the effect of P modification, the a(Al) is distinctively in dendrites.

Fig.2 As-cast microstructures of semi-solid and liquid die-casting samples: (a) Semi-solid rheo-diecasting at 690 ℃; (b) Liquid die-casting at 790 ℃

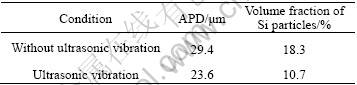

Table 1 illustrates APD and volume fraction of the primary Si particles corresponding to Fig.2. Because of the good effect of P modification on primary Si, the size of Si particles without ultrasonic vibration was about 30 μm. After ultrasonic vibration to the alloy melt in the semi-solid temperature range for 90 s, the primary Si particles can be further refined, with APD of 23.6 μm.

Table 1 Effect of DUV on primary Si of aluminum alloy

The microstructure of high silicon Al-Si alloy consists of a(Al), primary Si, eutectic Si, and some other intermetallic compounds such as Mg2Si, AlCuNi, NiSi2, Al3Ni2, AlCe3, and RE-rich Al-RE-Si-Cu-Ni compounds[11-12]. Generally, the primary Si particles with no P modification present as coarse plates larger than 100 μm, and the primary Si particles can be refined to 30-50 μm only with P modification[13].

When ultrasonic vibration is introduced into melt, acoustic cavitation and streaming will be produced[3]. The convection between the cup and melt is strengthened by the combination of micro-flows generated by the movement of cavitation bubbles and the acoustic stream, which homogenizes the solute field and temperature field of the melt. Thus, on one hand, it brings out the uniform distribution of heterogeneous nuclei. On the other hand, it suppresses the rapid growth of crystals into dendrites, which would benefit to form equiaxed grains. Consequently, the primary Si particles distribute evenly with round shape and be further refined with DUV followed by semi-solid rheo-diecasting process.

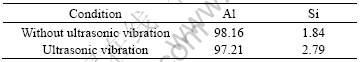

The comparison of Figs.2(a) and (b) shows that the volume fraction of the primary Si particles decreased remarkably with DUV. In order to expose the role of DUV on the solid solubility of the primary Si, the quantitative analysis software for semi-solid microstructure was employed to analyze the volume fraction of the primary Si particles. The average volume fraction of five fields is shown in Table 1. It can be seen that, the volume fraction of the primary Si particles reduced from 18.3% to 10.7% when DUV was imposed on the alloy. Table 2 shows the analysis results of the mass fraction of element Si in a(Al) matrix analyzed by EDS. This indicates that the solid solubility of element Si in a(Al) phase increased from 1.84% to 2.79% after DUV.

Table 2 Elements of a(Al) matrix by EDS analysis (mass fraction, %)

It is considered that the following factors caused the variations of the volume fraction of the primary Si particles and the solid solubility of element Si in a(Al) matrix after DUV. Firstly, the convection caused by cavitation and acoustic streaming, promotes the growth of primary Si in non-dendritic and restricts its rapid growth, both of which increase the concentration of Si relatively in the rest melt. Secondly, the super-saturation of Si atom in a(Al) matrix increased because of the high pressure produced by DUV and higher cooling rate caused by semi-solid processing poured at much lower temperature into the metal mold with the same preheated temperature.

The SEM microstructures of the alloys after T6 heat treatment are shown in Fig.3. The eutectic Si phases were granulated after T6 treatment. The shape of primary Si particles was also passivated. However, the great difference between semi-solid die-casting (Fig.3(a)) and traditional liquid die-casting (Fig.3(b)) was that gas holes appeared in the microstructure of liquid die-casting samples (Fig.3(b)). The reason is that air entrapment is easy to occur in traditional liquid die-casting process, the gas content in the die cast parts is big, and the entrapped gas will separate out as gas hole during heat treatment. Therefore, the parts made with liquid die-casting process are not suitable for heat treatment. But the air entrapment is very weak in the semi-solid die-casting process, and the part can be heat treated to get enhanced properties. The primary Si particles and intermetallic compounds in Fig.3(a) are also much smaller than those in Fig.3(b).

Fig.3 Microstructures of samples after T6 heat treatment: (a) Semi-solid rheo-diecasting at 690 ℃; (b) Liquid die-casting at 790 ℃

3.2 Mechanical properties of rheo-casted high Si aluminum alloys

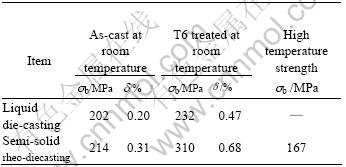

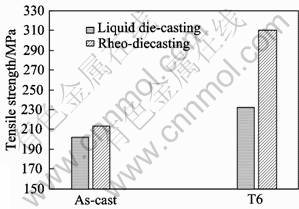

The mechanical properties of high silicon Al-Si alloy with and without DUV are shown in Table 3, and Fig.4 gives the comparison of tensile strength of samples in as-cast and T6 states. It can be known from Table 3 and Fig.4 that the tensile strength and elongation were obviously improved with DUV, especially the sample after T6 treatment. When the tested alloys imposed by DUV for 90 s in the semi-solid temperature range, excellent combination of strength and plasticity was obtained. The as-cast tensile strength sb of alloy with DUV was 214 MPa and the elongation d was 0.31%, which were increased by 6% and 55% respectively compared to that of the alloy without DUV. The tensile strength of the alloy with DUV after T6 treatment was 310 MPa and the elongation was 0.68%, which were increased by 34% and 47% respectively compared to that of the alloy without DUV. The high temperature tensile strength at 300 ℃ of this high Si aluminum alloy after T6 treatment reached 167 MPa, a much higher value compared to A390 alloys[14].

Table 3 Mechanical properties of 20%Si aluminum alloy at room and high temperatures

Fig.4 Comparison of tensile strength of samples in as-cast and T6 states

The mechanical properties of high silicon Al-Si alloy are affected by the primary Si, eutectic Si, and the main intermetallic compounds. Both tensile strength and elongation were improved due to the microstructure refinement of the high silicon Al-Si alloy with DUV and rheo-diecasting process. The refining and spheroidization of the microstructure with DUV could be mainly attributed to the cavitation and acoustic streaming induced by DUV, and it could be explained from two aspects, namely nucleation and growth of crystals. It has been commonly accepted that cavitation has an effect of promoting nucleation in melt, which is likely due to the activation of insoluble inclusions or/and undercooling of the melt at cavitation bubble surface resulting from its expansion and liquid evaporation inside[10, 15]. As for the effect of DUV on growth of formed nuclei, firstly, the melt convection caused by the acoustic streaming homogenizes the solute field and temperature field around primary Si particles, thus the primary Si particles would grow in the same rate at all direction, and accordingly lead to globular growth other than polyhedral or plate-like growth. Secondly, due to the micro-flows near the primary Si particles engendered by collapse of cavitation bubbles, the stagnant boundary layer around a particle is thinned and the constitutional undercooling is decreased, which eventually slows the growth speed of primary Si particles. The intermetallic compounds, such as Al-RE-Si-Cu-Ni compound, can also be refined by DUV and their cutting effect to the matrix of the alloy is minimized. As a result, the microstructure of slurry with DUV applied is improved, and the mechanical properties of the formed parts are enhanced.

Another merit of the semi-solid rheo-diecasting process is that there is very small amount of air entrapment in the parts, and the parts can be heat treated to further increase the properties. The parts made with liquid die-casting process are not suitable for heat treatment, as gas holes or porosities will be produced because of expansion of entrapped air during heat treatment. Therefore, the strength of the semi-solid rheo-diecast samples was greatly increased after T6 treatment.

3.3 Thermal expansion property of alloy

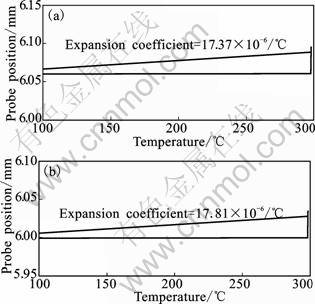

The coefficient of thermal expansion (CTE) at 25-300 ℃ of this alloy is given in Fig.5. The CTE of semi-solid rheo-diecas sample was 17.37×10-6/℃ (Fig.5(a)), and 17.8×10-6/℃ (Fig.5(b)) for liquid die casted sample. The difference between the two was small, and the CTE of semi-solid rheo-diecased sample was somewhat lower. These CTE values of the Al-20%Si alloys are small, much smaller than those of the traditional piston alloys A336 or A354. The CTE of A336 or A354 is around 23×10-6/℃ [14], therefore, the CTE of the high Si aluminium alloy in this work is 25% smaller. The thermal expansion property of Al-Si alloys is mainly determined by the relative amount of a(Al) and Si phases, as the CTE of pure Si is very small, which is (2.8-7.2)×10-6/℃. The silicon content of A336 or A354 is 10%-13% Si, and that of the AlSiCuNiMg alloy in this work is 20% Si. The volume fraction of Si phases in the later alloy is higher than that of the former. In addition, CTE is also related with amounts of elements such as Cu, Ni, RE, and factors such as modification.

Fig.5 Thermal expansion coefficient curves (part) and CTE values of alloy: (a) Semi-solid rheo-diecast sample; (b) Liquid diecast sample

4 Conclusions

1) The primary Si particles of Al-20Si-2Cu-1Ni-0.4 Mg alloy, modified with P and RE, can be further refined to about 20 μm, and in good roundness, as well as uniformly distributed in the α(Al) matrix, when treated by direct ultrasonic vibration (DUV) for 90 s in the semi-solid temperature range and with semi-solid rheo-diecasting. The effect of DUV on semi-solid aluminum alloy increases the solid solubility of element Si in α(Al) phase and the volume fraction of primary Si particles decreases from 18.3% to 10.7%.

2) The mechanical properties of this alloy are improved greatly with DUV and semi-solid process. The ultimate tensile strength of this alloy after T6 treatment is 310 MPa and the elongation is 0.68%,which is increased by 34% and 45% respectively, compared to that of the alloy without DUV.

3) The coefficient of thermal expansion (CTE) of this alloy is 17.37×10-6/℃ between 25 and 300 ℃, and the high temperature tensile strength at 300 ℃ of this high Si aluminum alloy reaches 167 MPa.

References

[1] CHEN C, LIU Z X, REN B, WANG M X, WENG Y G, LIU Z Y. Influences of complex modification of P and RE on microstructure and mechanical properties of hypereutectic Al-20Si alloy [J]. Trans Nonferrous Met Soc China, 2007, 17: 301?306.

[2] HAQUE M M, MALEQUE M A. Effect of process variables on structure and properties of aluminum-silicon piston alloy [J]. Journal of Materials Processing Technology, 1998, 77: 122?128.

[3] ESKIN G I. Influence of cavitation treatment of melts on the processes of nucleation and growth of crystals during solidification of ingots and castings from light alloys [J]. Ultrasonics Sonochemistry, 1994, 1(1): 59?63.

[4] GABATHULER J P, BUXMANN K. Process for producing a liquid-solid metal alloy phase for further processing as material in the thixotropic state [P]. US: 5186236, 1993.

[5] WU S S, ZHAO J W, ZHANG L P, AN P, MAO Y W. Development of non-dendritic microstructure of aluminum alloy in semi-solid state under ultrasonic vibration [J]. Solid State Phenomena, 2008, 141/142/143: 451?456.

[6] ZHAO J W, WU S S, AN P, MAO Y W. Preparation of semi-solid slurry of hypereutectic Al-Si alloy by ultrasonic vibration [J]. Solid State Phenomena, 2008, 141/142/143: 767?771.

[7] WU S S, XIE L Z, ZHAO J W, NAKAE H. Formation of non-dendritic microstructure of semi-solid aluminum alloy under vibration [J]. Scripta Materialia, 2008, 58: 556?559.

[8] ZHAO J W, WU S S, WAN L, CHEN Q H, AN P. Evolution of microstructure of semisoid metal slurry in ultrsound field [J]. Acta Metallurgica Sinica, 2009, 45(3): 314?319. (in Chinese)

[9] FENG H K, YU S R, LI Y L, GONG L Y. Effect of ultrasonic treatment on microstructures of hypereutectic Al-Si alloy [J]. Journal of Materials Processing Technology, 2008, 208: 1?6.

[10] ABRAMOV V O, ABRAMOV O V, STRAUMAL B B, GUST W. Hypereutectic Al-Si based alloys with a thixotropic microstructure produced by ultrasonic treatment [J]. Materials & Design, 2007, 18(4): 323?326.

[11] ZHONG G, WU S S, JIANG H, AN P. Effects of ultrasonic vibration on the iron-containing intermetallic compounds of high silicon aluminum alloy with 2%Fe [J]. Journal of Alloys and Compounds, 2010, 492: 482?487.

[12] LASA L, RODRIGUEZ J M. Evolution of the main intermetallic phases in Al-Si-Cu-Mg casting alloys during solution treatment [J]. Journal of Materials Science, 2004, 39 (4): 1343?1355.

[13] WU S S, TU X L, FUKUDA Y, KANNO T, NAKAE H. Modification mechanism of hypereutectic Al-Si Alloy with P-Na addition [J]. Trans Nonferrous Met Soc China, 2003, 13(6): 1285?1289.

[14] JOHN E H. Aluminum properties and physical metallurgy [M]. Metals Park, Ohio: American Society for Metals, 1984.

[15] JIAN X, XU H, MEEK T T. Effect of power ultrasound on solidification of aluminum A356 alloy [J]. Materials Letters, 2005, 59: 190?193.

(Edited by YANG You-ping)

Foundation item: Project (2007AA03Z557) supported by the National High-Tech Research and Development Program of China; Project (50775086) supported by the National Natural Science Foundation of China.

Corresponding author: WU Shu-sen; Tel: +86-27-87556262; E-mail: ssw636@hust.edu.cn