电冶熔铸WC/钢复合材料中WC的溶解行为

尤显卿1, 马建国2, 宋雪峰1, 任 昊1, 黄曼平2

(1. 合肥工业大学 材料科学与工程学院, 合肥 230009;

2. 安徽建筑工业学院 机电工程系, 合肥 230022)

摘 要: 用电冶熔铸工艺制备不同WC含量的WC/钢复合材料, 研究了WC颗粒在复合材料钢基体中的溶解行为和影响因素。 结果表明: 随着WC含量的增加, 碳化物从钢基体晶界处分布逐渐转向晶内分布; 随着WC颗粒尺寸的增大, 在WC颗粒与钢基体界面处形成一层反应物, 它阻止了WC颗粒在钢基体中的进一步溶解, 同时也提高了两相界面的结合强度。 通过调整电冶熔铸工艺参数和WC颗粒的尺寸及含量, 可以控制WC颗粒在复合材料中的溶解行为。

关键词: WC/钢复合材料; 电冶熔铸; WC颗粒; 钢基体 中图分类号: TG331

文献标识码: A

Dissolution behavior of WC particle in WC steel matrix composites by electroslag melting and casting method

YOU Xian-qing1, MA Jian-guo2, SONG Xue-feng1, REN Hao1, HUANG Man-ping2

(1. Institute of Materials Science and Engineering, Hefei University of Technology,Hefei 230009, China;

2. Faculty of Electromechanical Engineering, College of Anhui Architectural Engineering,Hefei 230022, China)

Abstract: The WC/steel composites with various contents of WC were prepared by means of electroslag melting and casting method. The dissolution behavior of WC particle and its effect factors in the composites were researched. A variety of experiment techniques were used to investigate the interactions between tungsten carbide particle and the steel matrix. The results show that the distribution of WC particles varies from intergranular position of the steel matrix to interagranular location with increasing contents of WC particle. Furthermore, the interfacial reaction layer is formed on the vicinity of WC particle owing to the increase of size of WC particle, which prevents the interdiffusion of elements between matrix and WC particle and enhances drastically the interface bonding intensity. The dissolution behavior of WC particle in the composites can be controlled by regulating the processing parameters of elecctroslag melting and casting method and adjusting the powder starting size and contents of WC particle.

Key words: WC/steel composites; electroslag melting and casting method; WC particle; steel matrix

WC/钢复合材料具有高硬度、 高强度及优良的耐磨性, 可以锻造改形和机械切削加工, 还可以通过热处理强韧化。 近二十年来, 这种复合材料愈来愈受到人们的重视, 而且得到广泛的应用。 例如, 用粉末冶金法制备的WC/钢复合材料——碳化钨钢结硬质合金在国内市场已成为一种重要的高档﹑高效工模具材料[1, 2]。

制备WC/钢复合材料的工艺方法除了用传统的粉末冶金法外, 目前研究较多的是用特种铸造法, 如离心铸造法﹑挤压铸造法等。 近年来, 电渣冶金技术发展非常迅速, 因为它具有一系列的优越性 [3, 4], 如金属性能的优异性(如高纯净度、 组织致密、 成分均匀)、 经济的合理性(设备简单、 成本低、 生产周期短)以及可生产大体积工件和工艺的灵活性和可控性。 作者结合粉末冶金和电渣冶金技术的优点, 采用电冶熔铸工艺制备了新型的WC/钢复合材料[5-7]。 作为增强相的WC颗粒, 虽然具有高熔点、 高硬度及良好的稳定性等特性, 但在高温条件下会在基体相中发生溶解[8-11], 这种行为对复合材料的组织结构和性能起到重要的影响。 任何一种制备工艺都有它的优缺点, 因为在电冶熔铸过程中, WC要发生两次溶解, 为了在实验条件下, 更好地研究WC的溶解行为, 专门选择了颗粒粗大的WC粉作为硬质相。 本文作者初步探讨了WC颗粒的粒度及含量对其在电冶熔铸过程中溶解行为的影响, 旨在为电冶熔铸工艺制备WC/钢复合材料过程中如何控制WC颗粒提供理论依据。

1 实验

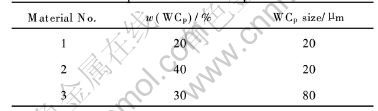

实验用WC/钢复合材料的原材料采用粗大的WC粉作为硬质相, 废弃的 GCr15轴承钢车削碎屑作为钢基体。 WC粉在材料中的含量及粒度列于表1。 钢基体材料的成分列于表2。

表1 复合材料中的WC颗粒含量和粒度

Table 1 Contents and size of WC particles in composites

表2 复合材料中钢基体成分

Table 2 Composition of steel matrix in composites (mass fraction, %)

将配制好的WC粉和轴承钢碎屑在中频感应电炉中制成复合材料电极, 再将该电极在单臂立柱式电渣炉中重熔成实验材料。 用电火花线切割机将实验材料切制成尺寸为15mm×15mm×10mm的试样, 热处理用4kW中温实验电炉, 试样经880℃淬火和160℃, 3h回火处理后, 在HR-150A型硬度计上测得的硬度为HRC62-64, 在PEM光学显微镜上观察金相组织, 用D/max-r B型X射线衍射仪和H-800型透射电镜进行相分析, 用能谱仪分析两相界面处的成分变化。

2 结果与讨论

2.1 WC含量对WC溶解的影响

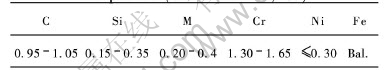

电冶熔铸工艺结合了铸件凝固成型和电渣重熔精炼两道工序, 熔铸温度一般为1700~1800℃, 在这样的温度下, WC颗粒不会发生组织转变, 但会发生溶解行为, 导致WC颗粒的形态和在材料中的分布状态都发生了变化。 一般认为颗粒增强复合材料中的硬质相粒子的最佳分布是在基体的晶内而不是在晶界上[12-15]。 本实验发现, WC在材料中的分布状态与WC颗粒的含量有关。 在WC含量为20%的材料中, 碳化物以链状沿晶界呈不连续的网状分布(见图1(a)); 在WC含量为40%的材料中, 碳化物却呈颗粒状均匀地分布在钢基体中, 特别是

图1 电冶熔铸WC/钢复合材料的显微组织

Fig.1 Microstructures of WC/steel composites made by electroslag melting and casting

其中的三角形和四边形WC颗粒的尖锐棱角清晰可辨(见图1(b))。

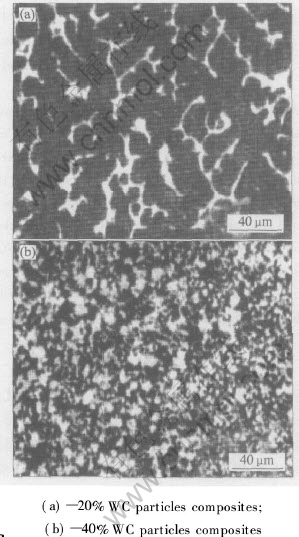

本实验的熔铸温度较高(1780~1790℃), 在WC颗粒较小情况下(20μm), 低含量WC颗粒在材料制备过程中更易于溶解在高温钢液中并与钢基体发生反应, 生成如图1(a)所示的复式网状碳化物, 经X射线衍射分析[5]和透射电镜分析为面心立方的Fe3W3C, 衍射花样标定见图2。 这种沿晶界分布的碳化物往往损伤材料的性能, 承受载荷时会成为裂纹源。 在同样的工艺条件下, 由于自耗电极以液滴形式熔化, 所以当WC颗粒含量较高时, 在液滴和熔池中包覆在单个WC颗粒周围的高温液相相对减少, 所以WC被溶解的量就少。 随着粒度较小的WC颗粒被溶解, 较大的WC部分溶解(表面及棱角处), 使其周围的钢液中的W及C含量增高, 两相的成分浓度差减小, 由此降低了WC的溶解度。 另外, WC含量高时, 电磁搅拌所产生的对流没有WC含量少时强, 因而WC溶解扩散速率相对较小, 在快速凝固(非平衡态)时, 使大量的WC颗粒被保留下来且保留其原始的内部成分与结构。 这种过饱和的钢液在随后的冷却过程中, 同时还会在钢基体中析出细小棒状或粒状的碳化物结晶体(图3), 通过X射线衍射谱分析[5]认为可能为Cr7C3、 WC或粒状的Fe3W3C。 由此可见, 在本实验条件下WC/钢复合材料中的WC颗粒在钢基体中的溶解度受到WC含量的影响, 进而影响WC颗粒在材料中的分布状态。

图2 反应产物透射电镜衍射花样及[001]晶带轴标定

Fig.2 TEM diffraction patterns and indexes of reaction products

图3 钢基体中析出的碳化物晶粒

Fig.3 Fine carbides separated out from steel matrix

2.2 WC颗粒粒度对WC溶解的影响

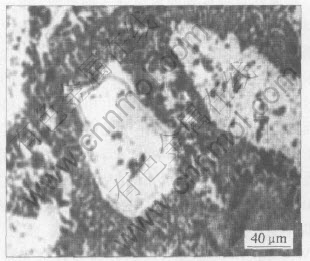

在制备含30%WC的实验材料中, 特意选择粗颗粒的WC(80μm), 目的是观察WC颗粒的粒度对WC在钢基体相中溶解行为的影响。 结果发现: 在粗颗粒WC周围包覆着一层反应层, 从X射线衍射谱和能谱分析来看可能为Fe3W3C。 在该反应层外围, 分布着细网状碳化物, 而棱角分明的WC颗粒明显被“圆化”(见图4)。

图4 WC颗粒的边缘溶解

Fig.4 Dissolution at adge of WCp

由于粗颗粒WC在溶解时需要更多的钢液来包覆, 再加上电冶熔铸工艺在高温下停留的时间短, 尤其是在二次重熔结晶过程中是小液滴结晶, 使得包覆WC颗粒的钢液更少, 导致WC颗粒的溶解受到了限制, 溶解速度减慢, 而主要是参与与钢基体的界面反应, 使得反应层的厚度达到微米级。 该反应层不仅实现了复合材料中硬质相WC与钢基体的冶金结合, 而且阻碍了WC颗粒在钢液中进一步溶解, 使WC以圆形粒状形态被保留下来。

反应层的厚度不仅影响WC颗粒在钢液中的溶解速度, 而且也影响WC与钢基体的结合强度。 研究人员通过对Al2O3、 SiC等在不同合金中界面化学反应动力学进行了研究, 得出界面的化学反应可用一个简单的抛物线生长规律来近似描述[12-15]。 该生长规律表明反应是扩散控制的, 对于给定的温度, 反应层的平均厚度x可以描述为

x=kt1/2(1)

式中 k为抛物线速率常数; t为反应时间。

式(1)为金属基复合材料的界面反应控制提供了有用的依据。 在本实验中, 在相同的熔铸温度下, 通过改变凝固速度, 从而来调整反应时间, 在非常快速的凝固过程中没有明显的界面反应层出现, 由菲克定律可知, 由于凝固速度太快, Fe、 W等元素的扩散流量不大, 因而没有反应层或反应层不明显。 而在相对较慢的凝固过程中, 出现较明显的反应层。 因而可以认为电冶熔铸过程中WC颗粒周围的反应层基本上符合此规律, 即通过控制反应时间来调整反应层厚度, 由此控制WC颗粒在钢基体中的溶解行为。

2.3 WC/钢界面反应对WC溶解的影响

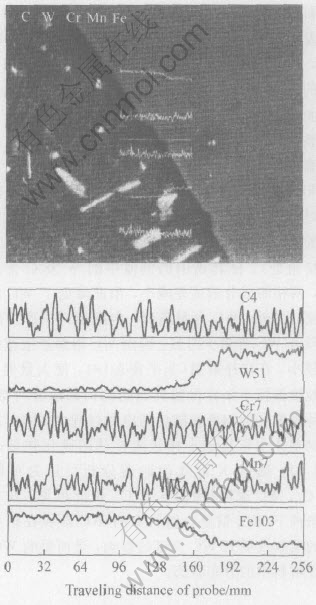

金属基复合材料的界面分3种类型: 第一种是平整界面。 增强体和基体不反应亦互不溶解, 界面两侧靠机械铆合以及范德华力的物理结合, 这是一种很弱的界面结合方式。 第二种为犬牙交错的溶解扩散界面, 增强体与基体间发生相互溶解。 第三种界面则有界面反应物, 属化学反应结合。 本实验应属于第3种界面, 即化学反应形成的冶金结合。 X射线衍射分析表明[5], 界面出现了Fe3W3C这一中间相, 它的存在说明在复合材料制备过程中WC与钢基体之间已发生相互溶解并在界面处生成Fe3W3C相。 WC/钢复合材料界面处合金元素含量能谱分析(图5), 可以发现界面处的W、 Fe含量存在明显的过渡区, 是一个缓慢变化的过程, 而不是通常认为的那种界面元素浓度存在着突变, 这种极少缺陷的界面状态使WC颗粒与钢基体有着良好的界面结合, 可以在有外力作用时有效地把外加载荷传递给WC增强颗粒, 也会使WC颗粒的脱落受到抑制。 在进行磨损实验时, 发现界面反应层的出现可以明显提高复合材料的耐磨性[16]。

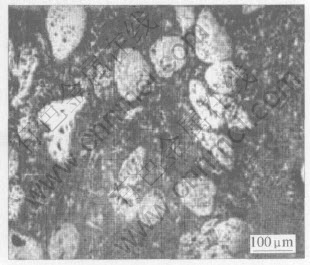

实验中还发现, 电冶熔铸WC/钢复合材料的界面反应主要受两个方面的因素控制: 一是材料制备过程中的温度, 适当的温度可以控制界面反应的进行程度, 过高的温度会导致过度的界面反应, WC颗粒会在其心部发生溶解, 成为一种“空壳”粒子(见图6箭头所指), 而失去增强颗粒的作用, 其原因可能是由于局部温度过高, 原子扩散速率加

图5 WC颗粒附近Fe、 W等元素含量线扫描

Fig.5 Element linar scanning curves of Fe and W etc near to single WC particle

图6 心部溶解的WC颗粒

Fig.6 WC particles dissolved in center

快, WC颗粒在边缘溶解同时, 在WC粒子表面显微缺陷处优先溶解, 且显微缺陷处的溶解曲率半径更小, 溶解速率更快, 因而此处成为溶解主要区; 二是WC颗粒的粒度选择要适宜, 粒度过大, 粗大的颗粒会受到重力的影响而产生严重的铸造偏析, 而且还容易产生脆性裂纹; 粒度过小, 颗粒比表面积大, 溶解严重, 导致颗粒体积分数减少, 达不到增强的目的, 同时过细的颗粒会增加钢液的粘度, 从而使得电磁搅拌不充分所带来的WC粒子的偏聚增加, 不能有效地形成颗粒沉淀强化。 因此, 应合理控制熔铸温度和WC颗粒的粒度。 图7所示为WC颗粒平均粒度为120~130μm产生铸造偏聚时的组织形貌。

图7 粗大WC粒子偏聚时的显微组织

Fig.7 Microstructure of clustering of coarse WC particles

3 结论

1) 用电冶熔铸工艺制备WC/钢复合材料过程中, 高熔点的WC颗粒在钢的基体中要发生溶解, 其溶解行为受WC粒度及在材料中的含量影响, 同时溶解行为也影响复合材料的组织结构。

2) 当WC颗粒较小(20μm)、 含量也较少(20%)时, 它们基本上溶解在钢基体中, 在随后的冷却过程中, 从晶界处析出不连续的网状碳化物Fe3W3C。 随着WC含量的增加, 溶解度逐渐减小, 被保留的WC颗粒增多, 在钢基体相内有粒状碳化物析出, 即碳化物颗粒在材料中的分布从晶界逐渐向晶内转移。

3) 大颗粒WC周围生成反应层, 它对WC颗粒起保护作用, 阻止WC颗粒进一步在钢基体中的溶解, 改善了WC相与钢基体的结合方式, 提高了界面结合强度。 为了获得合适的反应层, WC颗粒的粒度应在50~80μm之间选择, 同时还要控制好电冶熔铸过程中的温度及时间。

REFERENCES

[1]株洲硬质合金厂. 钢结硬质合金[M]. 北京: 冶金工业出版社, 1995.

Zhuzhou Cemented Carbide Factory. Steel Bonded Carbide[M]. Beijing: Metallurgical Industry Press, 1995.

[2]张春友, 熊惟皓. 钢结硬质合金在模具工业中的应用[J]. 机械工程材料, 1998, 22(6): 39-42.

ZHANG chun-you, XIONG Wei-hao. Application of steel bonded carbide in die industry[J]. Materials for Mechanical Engineering , 1998, 22(6): 39-42.

[3]田世江. 电渣技术在我国铸造业中的应用[J] 特种铸造及有色合金, 2000, 20(3): 50-52.

TIAN Shi-jiang. Application of electroslag technology in china foundary trade [J]. Special Casting and Nonferrous Alloys , 2000, 20(3): 50-52.

[4]程希春, 冯涤, 傅杰, 等. 电渣冶金的最新进展[J]. 钢铁研究学报, 2003, 15(2): 62-67.

CHEN Xi-chun, FENG Di, FU Jie, et al. Recent development of electroslag metallurgy[J]. Journal of Iron and Steel Research, 2003, 15(2): 62-67.

[5]尤显卿, 王基才, 任昊. 电冶熔铸WC/钢复合材料的显微缺陷[J]. 中国有色金属学报, 2004, 14(4): 645-651.

YOU Xian-qing, WANG Ji-cai, REN Hao. Microdefects in tungsten carbide particulates reinforced steel matrix composites by electroslag melting and casting[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(4): 645-651.

[6]尤显卿, 任昊, 郑玉春, 等. 电渣熔铸WC/钢复合材料的磨损性能研究[J] . 特种铸造及有色合金, 2003, 23(6): 19-21.

YOU Xian-qing, REN Hao, ZHENG Yu-chun, et al. Study on wear resistance of electroslag melting and casting WC/steel composites[J]. Special Casting & Nonferrous Alloys, 2003, 23(6): 19-21.

[7]尤显卿, 郑玉春, 黄曼平, 等. 电冶熔铸碳化钨钢结硬质合金的显微组织研究[J]. 矿冶工程, 2003, 23(2): 87-90.

YOU Xian-qing, ZHENG Yu-chun, HUANG Man-ping, et al. Research on microstructure of steel bonded tungsten carbide by electroslag melting and casting[J]. Mining and Metallurgical Engineering, 2003, 23(2): 87-90.

[8]索进平, 冯涤, 骆合力, 等. WC颗粒在堆焊过程中溶解机理的研究[J]. 功能材料, 2003, 34(2): 221-223.

SUO Jin-ping, FENG di, LUO He-li, et al. Dissolving behavior of WC particles in lap welding[J]. Journal of Functional Materials, 2003, 34(2): 221-223.

[9]王澈, 钟涛兴, 周美玲. 烧熔的钢结硬质合金组织的研究[J]. 稀有金属与硬质合金, 2001, 28(1): 18-23.

WANG Che, ZHONG Tao-xing, ZHOU Mei-ling. Investigation on microstructure of steel-bonded cemented carbides[J]. Rare Metals and Cemented Carbides, 2001, 28(1): 18-23.

[10]梁作俭, 邢建东, 鲍崇高, 等. 碳化钨/铁基铸造复合材料的抗冲蚀磨损性能[J]. 铸造, 2000, 49(5): 265-267.

LIANG Zuo-jian, XING Jian-dong, BAO Chong-gao, et al. Brosive resistance of WC particle reinforced cast iron matrix composites[J]. Foundary, 2000, 49(5): 265-267.

[11]王溪, 胡汉起. WCp/Fe-Ni钢基复合材料的界面[J]. 钢铁研究学报, 1998, 10(4): 46-49.

WANG Xi, HU Han-qi. Interface of WCp/Fe-Ni steel matrix composite[J]. Journal of Iron and Steel Research, 1998, 10(4): 46-49.

[12]Berns H, Franco S D. Effect of coarse hard particle on high temperature sliding abrasion of new metal matrix composites[J]. Wear, 1997, (203-204): 608-614.

[13]Taha M A, Mohamed A. Practicalization of cast metal matrix composites (MMCCs)[J]. Materials and Design, 2001, 22(6): 431-441.

[14]Hashim J, Looney L, Hashmi M S J. Particle distribution in cast metal matrix composites (part Ⅰ)[J]. Journal of Materials Processing Technology, 2002, 123(2): 251-257.

[15]Pelleg J. Reactions in the matrix and interface of the Fe-WC metal matrix composite system[J]. Mater Sci Eng A, 1999, A269: 225-241.

[16]尤显卿, 马建国, 任昊, 等. 电冶熔铸WC/GCr15钢复合材料的摩擦磨损特性[J]. 材料热处理学报, 2004, 25(6): 40-43.

YOU Xian-qing, MA Jian-guo, REN Hao, et al. Wear behavior of electroslag melting and casting WC/GCr15 steel composites[J]. Transactions of Materials and Heat Treatment, 2004, 25(6): 40-43.

(编辑陈爱华)

基金项目: 安徽省教育厅重点资助项目(2003KJ016ZD)

收稿日期: 2005-04-20; 修订日期: 2005-07-07

作者简介: 尤显卿(1949-), 男, 教授.

通讯作者: 宋雪峰; 电话: 0551-2902961; E-mail: songxuefeng111 @tom. com