热轧带钢冷却过程奥氏体相变与温度耦合模型

彭 艳1,李修琨2,刘宏民1

(1. 燕山大学 轧制设备及成套技术教育部工程研究中心,河北 秦皇岛,066004;

2. 河北省首钢迁安钢铁有限责任公司热轧分厂,河北 迁安,064404)

摘 要:为精确模拟奥氏体相变行为,建立一种新的预测模型,该模型通过考虑潜热影响的板带轧后二维温度场将相变体积分数和温度联系起来进行耦合计算。冷却过程释放的潜热通过双亚点阵模型进行计算,计算结果通过在热分析仪STA449C上进行DSC实验验证。在相同的变形条件下,热模拟实验在Gleeble-3800热力模拟试验机上进行。相变与温度耦合模型的计算结果与连续冷却相变体积分数模型的计算结果相比更接近实测结果。研究结果表明:随着碳含量的增大,潜热释放量也明显的增大,当碳含量(质量分数)高于0.45%时,潜热释放量也趋于稳定;通过对计算结果和实测数据系统的比较,证明相变与温度耦合模型的优越性和精确性,耦合模型与现有模型相比,铁素体、珠光体和贝氏体的计算结果精确度最高分别提高24.77%,21.07%和31.85%。

关键词:热轧带钢;奥氏体;相变;潜热;温度分布;耦合

中图分类号:TG142.25 文献标识码:A 文章编号:1672-7207(2009)03-0699-07

Model of austenite transformation and temperature coupling for hot rolled strip during cooling process

PENG Yan1, LI Xiu-kun2, LIU Hong-min1

(1. Engineering Research Center of Rolling Equipment and Complete Technology of Ministry of Education,

Yanshan University, Qinhuangdao 066004, China;

2. Hot Rolling Department, Hebei Shougang Qian’an Iron & Steel Co. Ltd., Qian’an 064404, China)

Abstract: In order to simulate austenite transformation process exactly, a new model for austenite transformation volume fraction and temperature coupling in the two-dim unstable temperature fields considering latent heat was established. The latent heat releasing during cooling process was calculated by two-sublattice thermodynamic model and the results were testified by heat transfer tests performed on STA449C thermal analyzer (DSC). The experiment was carried out on a Gleeble 3800 thermomechanical simulator under the similar deforming conditions. The results show that the latent heat increases drastically with increasing carbon content and gradually levels off at about 0.45% carbon. By comparing volume fraction of the three phases obtained by kinetic model, temperature coupling model and experiment, it is indicated that the coupling model has superiority and the calculation accuracy of the three phases can be maximally increased by 24.77%, 21.07% and 31.85%, respectively.

Key words: hot rolling strip; austenite; transformation; latent heat; temperature distribution; coupling

众所周知,热轧后冷却过程的相变行为对钢铁产品的组织性能有着非常重要的影响[1-3]。而现有的相变体积分数模型的计算结果都与实测结果有一定的偏 差[4-5]。究其原因,是由于奥氏体分解过程释放的潜热使轧件温度回升,而温度的改变又反作用于相变本 身[6]。奥氏体分解过程中释放的热量是非常大的,不应被忽视[7]。研究人员用示差扫描热分析仪(DTA)和示差扫描量热仪(DSC)对潜热进行了实验研究,如有些研究者建立模型对潜热进行计算,但其模型并未与体积分数模型联系起来,因而不能反映出相变的实质。一些研究者建立了相变与温度迭代计算模型,但其模型中计算潜热的模型基于回归模型[8]或经验模型[9-10]。总之,现有模型都不是基于相变实质,因而不能精确地对奥氏体相变行为进行描述。在此,本文作者在研究连续冷却过程相变体积分数计算模型和相变潜热计算模型的基础上,运用Matlab语言编程工具,提出一种考虑潜热影响的相变与温度耦合计算模型。应用双亚点阵模型计算相变潜热,计算结果通过DSC实验的测量结果进行验证。相变产物体积分数与温度通过二维温度场联系起来,进行迭代计算,直到结果收敛为止。最终,通过对比耦合模型计算结果、连续冷却相变模型计算结果和热模拟实验结果,来证明相变与温度耦合模型的优越性和准确性。

1 连续冷却过程相变体积分数模型

1.1 铁素体相变

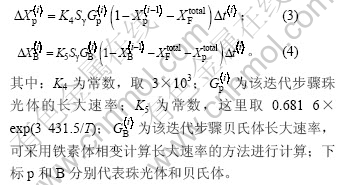

建立该模型的基本思想是将连续冷却相变处理成微小等温相变之和。相变发生后,γ→α,P和B满足或近似满足可加性法则。在γ→α相变前期,相变以“形核长大”机制进行,式(1)和(2)给出了相变动力学方程中相变率的增量?X(i)随时间增量?t(i)的变化[11]:

1.2 珠光体和贝氏体相变

珠光体和贝氏体的体积分数增量可分别由以下两式表示:

2 相变潜热计算模型

2.1 热力学模型

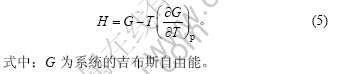

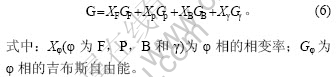

在经典热力学中,系统的摩尔焓H可表示为[12]:

对于包括奥氏体、铁素体、珠光体以及贝氏体的系统,其摩尔吉布斯自由能可表示为[13]:

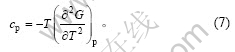

由已确定的吉布斯自由能确定比定压热容:

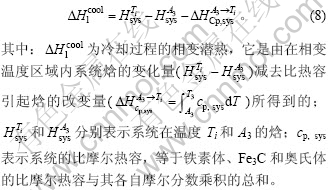

在冷却过程中,A1和A3之间任意温度Ti时系统释放的潜热可表示为[14]:

从ti-1时刻到ti时刻中释放的相变潜热增量可表示为:

2.2 结果及讨论

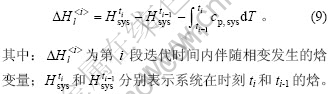

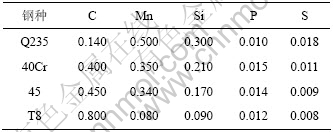

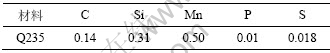

实验用钢化学成分见表1,实验[15]在STA449C热分析仪(DSC)上进行。将试样加工成直径×高为 4 mm×4 mm的圆柱体,加热温度为完全奥氏体化温度(40℃),温度及各试样质量见表2。

表1 实验用钢的化学成分

Table 1 Chemical compositions of experimental specimens w/%

表2 各试样加热温度和质量

Table 2 Heating temperature and quality of steels

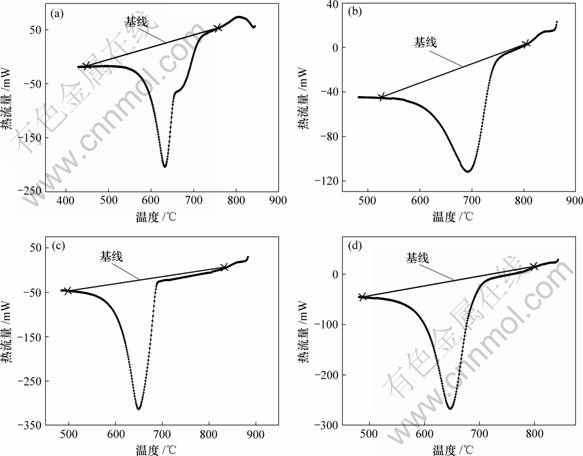

热分析仪记录每个时刻参照盘与试样盘的温度差?T,通过调整参照和试样的补偿功率,将?T转换为热流量。相变开始时,热流量曲线开始偏离基线,在相变过程中形成峰值,当相变结束时,该曲线回归基线。相变过程曲线峰值与基线间包围的封闭区间的面积即为冷却过程释放的潜热量。

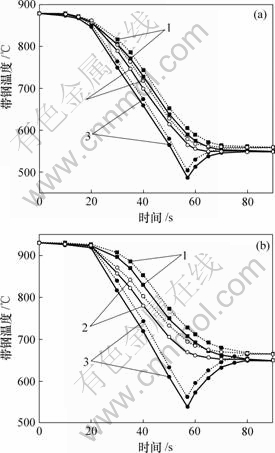

图1所示为用DSC测得的各试样热流量变化曲线。在相变温度区域内,碳含量较低的试样的热流量曲线放热过程偏离基线区域较小,而碳含量较高的试样热流量曲线放热过程偏离基线区域明显增大。热流量曲线放热过程偏离基线区域代表相变过程释放的潜热量,随着C含量的增大,相变潜热也增大。

(a) Q235; (b) 40Cr; (c) 45; (d) T8

图1 DSC测得的各试样热流量的变化

Fig.1 Heat flow changes of various steels determined using DSC during cooling process

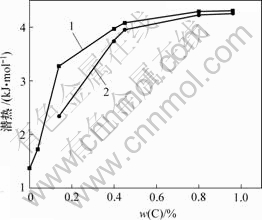

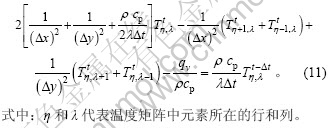

用热力学模型对相变过程释放的潜热量进行计算的结果与DSC测得结果对比如图2所示。通过2种方法得到的潜热对比可以看出,随着碳含量的增大,潜热释放量也明显增大,当碳含量高于0.45%时,潜热释放量也趋于稳定。碳含量较低时,计算结果比实测结果高300~1 000 J/mol,当碳含量较高时,2种结果能够很好地吻合。

1—热力学模型计算结果;2—DSC实测结果

图2 相变潜热计算结果与实验结果对比

Fig.2 Comparison of latent heat determined using DSC and thermodynamic calculation

3 温度场模型

3.1 热交换方程

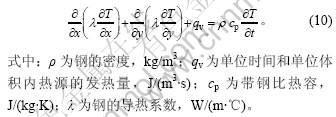

对于带钢在冷却中的热交换过程,由于带钢宽度B和厚度h远远小于带钢长度,可忽略长度方向的热量流动,而仅考虑横向和厚度方向的热量流动。若考虑相变过程释放的潜热,则不能忽略内热源,含内热源的二维非稳态热交换方程为[16]:

3.2 有限差分计算

从数学观点出发,在求解区域网格各节点处,用差商近似代替微商,经过积分中值定理的变化,就可得到导热微分方程的有限差分近似表达式:

3.3 模拟条件及结果

对轧后板带冷却过程的温度场进行模拟,分别对忽略内热源和含内热源的传热方程进行计算。模拟对象如下:

a. 较薄规格板带,厚度为6.3 mm,终轧温度为880 ℃,终冷温度为480 ℃;

b. 较厚规格板带,厚度为12 mm,终轧温度为930 ℃,终冷温度为540 ℃。冷却方式均采用前段主冷,冷速为38.45 ℃/s。

图3所示为带钢在冷却过程中,用有限差分法对忽略内热源的和含内热源这2种传热方程计算的带钢表面、平均温度和心部温度随时间的变化。可见,随着轧件厚度的增加,带钢厚度方向上的温差、潜热使温度升高值、返红温度都逐渐增加,例如对较薄规格带钢,表面与心部温差约为60 ℃,

(a) 较薄规格板带;(b) 较厚规格板带

实线:未考虑潜热;虚线:考虑潜热

1—心部温度;2—平均温度;3—表面温度

图3 带钢表面、心部和平均温度的变化

Fig.3 Variations of temperature of strip surface, center and average temperature

潜热使温度升高约10 ℃,返红温度可达70 ℃,持续时间为10 s左右;而较厚规格带钢,表面与心部温差约为80 ℃,潜热使温度升高约17 ℃,返红温度可达110 ℃,持续时间为15 s左右。因此,在建立带钢冷却过程温度场模型和进行计算时,尤其对于中厚板的温度场模拟,要充分考虑相变潜热和带钢厚度及内部传热的影响。

4 相变与温度耦合模型

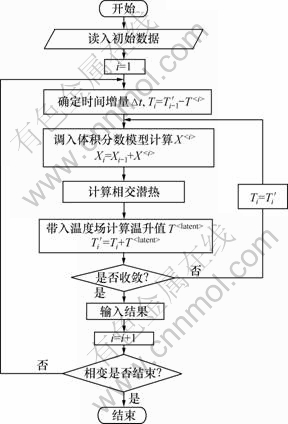

相变与温度耦合计算流程见图4。建立相变与温度耦合模型的基本思路是:

图4 相变与温度耦合计算流程图

Fig.4 Flowchart for coupling calculation of transformation and temperature

a. 在已有的连续冷却体积分数计算模型的基础上,根据第i-1时间段开始温度Ti-1、结束温度Ti= Ti-1+Ti、相变转变增量?Xi来计算此时系统的吉布斯自由能、焓和比定压热容,进而计算出该时间段相变过程伴随的潜热释放量。

b. 将潜热带入二维非稳态热交换方程中进行传热计算,得到温度Tlatent,则系统新的温度为 =Ti+ Tlatent,判断是否收敛,若不收敛,则返回重新计算;若收敛,将T代入式(1)计算相变转变增量?X。

=Ti+ Tlatent,判断是否收敛,若不收敛,则返回重新计算;若收敛,将T代入式(1)计算相变转变增量?X。

c. 将潜热引发的相转变分数增量与原有的相加?Xi=?Xi+?Xlatent,即得到该时间段内相转变分数。修正i时刻温度Ti=Ti-1+Ti和转变分数Xi=Xi-1+?Xi,继续进行第i+1时间段的转变增量?Xi+1的计算,重复此计算过程,直到相变结束,就可以得到考虑潜热影响的最终各相体积分数。

5 实验方法及结果验证

5.1 实验方法

实验用钢化学成分如表3所示,热模拟实验在Gleebe-3500热力模拟试验机上进行。具体实验步骤为:将尺寸为6 mm×80 mm(直径×高)的圆柱体试样以 20 ℃/s的速度加热到1 150 ℃,保温5 min,然后,以10 ℃/s的冷速冷却到变形温度850 ℃,保温10 s后进行压缩,变形量为20%,变形速率为1/s,再以不同冷却速率(0.1,0.2,0.5,1,2,5,10,15和20 ℃/s)冷却至200 ℃。记录冷却过程膨胀量—温度曲线,从该曲线的变化,结合金相试样的观察结果可确定相变的开始温度和结束温度。

表3 实验用钢的化学成分

Table1 Chemical compositions of experimental steels 质量分数/%

5.2 结果验证

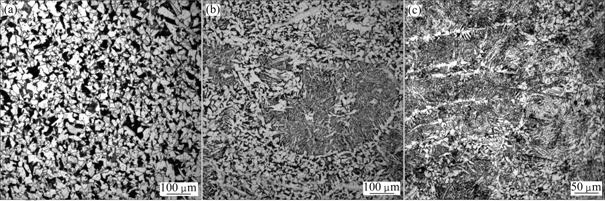

图5所示为热膨胀实验试样的典型显微组织。从图5可以看出,在较低冷速时,组织以铁素体+珠光体为主,在较高冷速时,组织以铁素体+贝氏体为主,同时,还会产生少量的马氏体。

(a) 铁素体和珠光体,冷却速率为0.1 ℃/s;(b) 针状铁素体、珠光体和贝氏体,冷却速率为2 ℃/s;

(c) 针状铁素体、珠光体、贝氏体和少量马氏体,冷却速率为15 ℃/s

图 5 不同冷却速率下试样的显微组织

Fig.5 Microstructures of experimental steels at different cooling rates

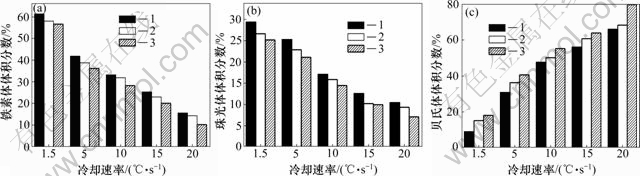

图6所示为铁素体、珠光体和贝氏体相变体积分数随冷却速率的变化。可以看出:随着冷却速率的增加,铁素体和珠光体的相变体积分数逐渐降低,而贝氏体的相变体积分数则逐渐升高;当冷却速率小于5 ℃/s时,生成物主要为铁素体与珠光体;当冷却速率大于8 ℃/s时,生成物主要为铁素体与贝氏体;当冷却速率大于5 ℃/s而小于8 ℃/s时,生成物为铁素体、珠光体与贝氏体的混合物。

1—实验结果;2—耦合模型计算结果;3—动力学模型计算结果

(a) 铁素体;(b) 珠光体;(c) 贝氏体

图6 铁素体、珠光体和贝氏体体积分数随冷却速率的变化

Fig.6 Variations of ferrite, pearlite and bainite volume fraction at different cooling rates

表4所示为铁素体、珠光体和贝氏体体积分数精确率随冷却速率的变化。可以看出:采用耦合模型计算所得的铁素体、珠光体和贝氏体体积分数精确率均比采用动力学模型所得的体积分数精确率高,提高值最高分别达到24.77%,21.07%和31.85%;随着冷却速率的增加,铁素体和珠光体计算结果的精确率提高值呈现上升趋势,而贝氏体计算结果的精确率提高呈现下降趋势。这说明在冷却速率较高的情况下,潜热对铁素体和珠光体计算结果的影响较低冷速时大,而对贝氏体计算结果的影响较低冷速时小。

表4 铁素体、珠光体和贝氏体计算结果精确率随冷却速率的变化

Table 4 Variation of calculation accuracy of ferrite, pearlite and bainite volume fraction at different cooling rates

由以上分析可以看出,铁素体、珠光体、贝氏体各自的计算结果与实测结果吻合良好。对比3种相变产物的体积分数计算结果可看到,耦合模型模拟结果比连续冷却相变模型计算结果更接近实测结果,验证了常规模型和耦合模型的精确性,也体现出耦合模型的优越性。

6 结 论

a. 将连续冷却相变处理成微小等温相变之和,计算了奥氏体→铁素体、珠光体及贝氏体的相变体积分数。采用该思想得到的最终相变产物是铁素体+珠光体,铁素体+贝氏体,以及铁素体+珠光体+贝氏体,较全面地反映了相变的实质。

b. 随着碳含量的增大,潜热释放量也明显增大,当碳含量高于0.45%时,潜热释放量趋于稳定。计算结果与DSC实测结果吻合良好。

c. 采用有限差分法分别对忽略内热源的和含内热源的热交换方程进行求解,对于薄、厚2种规格带钢轧后横断面温度分布,表面与心部温差分别达到约60 ℃和80 ℃,潜热使温度升高分别约为10 ℃和 17 ℃,返红温度分别达到70 ℃和110 ℃,持续时间分别为10 s和15 s左右。

d. 建立了奥氏体相变与温度耦合计算模型,并在Gleebe-3500热模拟机上进行了实验验证。由耦合模型计算的铁素体、珠光体和贝氏体体积分数精确率均比用动力学模型所得计算结果的精确率高,最高分别达到24.77%,21.07%和31.85%;随着冷却速率的增加,铁素体和珠光体计算结果的精确率提高值呈现上升趋势,而贝氏体计算结果的精确率提高呈现下降趋势。

参考文献:

[1] Yoshida H, Yorifuji A, Koseki S, et al. An integrated mathematical simulation of temperatures, rolling loads and metallurgical properties in hot strip mills[J]. ISIJ International, 1991, 31(6): 571-576.

[2] Lee K J, Lee J K, Kang K B, et al. Mathematical modeling of transformation in Nb microalloyed steels[J]. ISIJ International, 1992, 32(3): 326-334.

[3] 许云波. 基于物理冶金和人工智能的热轧钢材组织-性能预测与控制[D]. 沈阳: 东北大学轧制技术及连轧自动化国家重点实验室, 2003: 14-17.

XU Yun-bo. Prediction and control of microstructure and properties of hot-rolled steels based on physical metallurgy and artificial intelligence[D]. Shenyang: The State Key Laboratory of Rolling, Technology and Automation, Northeastern University, 2003: 14-17.

[4] 陈连升, 狄国标, 任吉堂, 等. 热变形奥氏体CCT曲线实用化修正研究[J]. 上海金属, 2006, 28(2): 21-25.

CHEN Lian-sheng, DI Guo-biao, REN Ji-tang, et al. The practical correction research on CCT curves of hot deformation austenite[J]. Shanghai Metals, 2006, 28(2): 21-25.

[5] Yoshie A, Fujioka M, Watanabe Y, et al. Modelling of microstructural evolution and mechanical properties of steel plates produced by Thermo-Mechanical control process[J]. ISIJ International,1992, 32(3): 395-404.

[6] 蔡 正, 王国栋, 刘相华, 等. 热轧带钢在冷却中温度与相变的耦合解析[J]. 塑性工程学报, 2000, 7(2): 16-19.

CAI Zheng, WANG Guo-dong, LIU Xiang-hua, et al. A coupling analysis of temperature and phase transformation during cooling of hot-rolled strip[J]. Journal of Plasticity Engineering, 2000, 7(2): 16-19.

[7] Miettinen J. Simple semiempirical model for prediction of austenite decomposition and related heat release during cooling of low alloyed steels[J]. Ironmaking and Steelmaking, 1996, 23(4): 346-356.

[8] 支 颖. 热轧带钢全线温度演变的模拟计算与软件开发[D]. 沈阳: 东北大学轧制技术及连轧自动化国家重点实验室, 2004: 1-4.

ZHI Ying. Simulating calculation and software development of the temperature evolution for the whole process of rolled strip[D]. Shenyang: The State Key Laboratory of Rolling, Technology and Automation, Northeastern University, 2004: 1-4.

[9] 余万华, 张中平. 热轧钢板在加速冷却时的温度模型[J]. 北京科技大学学报, 2005, 27(5): 567-570.

YU Wan-hua, ZHANG Zhong-ping. Temperature model of hot rolled strips in accelerate cooling process[J]. Journal of University of Science and Technology Beijing, 2005, 27(5): 567-570.

[10] 王晓东, 何安瑞, 杨 荃. 热轧带钢层流冷却过程中温度与相变耦合预测模型[J]. 北京科技大学学报, 2006, 28(10): 964-968.

WANG Xiao-dong, HE An-rui, YANG Quan. Prediction model of temperature and transformation coupling for hot rolled strips in laminar cooling process[J]. Journal of University of Science and Technology Beijing, 2006, 28(10): 964-968.

[11] Liu J S, Yanagida K, Umio S, et al. The analysis of phase transformation for the prediction of microstructure change after hot forming[J]. ISIJ International, 2001, 41(12): 1510-1516.

[12] Huang W. A thermodynamic assessment of the Fe-Mn-C system[J]. Metall Trans A, 1990, 21A: 2115-2123.

[13] 刘振宇, 许云波, 王国栋. 热轧钢材组织-性能演变的模拟和预测[M]. 沈阳: 东北大学出版社, 2004: 130-131.

LIU Zhen-yu, XU Yun-bo, WANG Guo-dong. Simulation and prediction of the evolution of microstructure and properties of hot rolled steels[M]. Shenyang: Northeastern University Press, 2004: 130-131.

[14] Lee J L, Chen J K, Pan Y T, et al. Evaluation of transformation latent heat in C-Mn steels[J]. ISIJ International, 1999, 39(4): 281-287.

[15] XIAO Yu-de, LI Min, HONG Jue, et al. Devitrification behavior of rapidly solidified Al87Ni7Cu3Nd3 amorphous alloy prepared by melt spinning method[J]. Journal of Central South University of Technology, 2007, 14(3): 285-290.

[16] Serajzadeh S. Prediction of temperature distribution and phase transformation on the run-out table in the process of hot strip rolling[J]. Appl Math Modelling, 2003, 27(2): 861-875.

收稿日期:2008-06-25;修回日期:2008-09-22

基金项目:霍英东教育基金会高等院校青年教师基金资助项目(101048);河北省自然科学基金资助项目(E2008000835)

通信作者:彭 艳(1972-),男,安徽宿松人,博士,教授,博士生导师,从事金属塑性三维数值分析及板形控制理论、轧机动态控制系统研究;电话:0335-8387651;E-mail: pengyan@ysu.edu.cn