DOI:10.19476/j.ysxb.1004.0609.2019.02.03

AZ61镁合金电磁连铸过程流场-温度场-组织的数值模拟

张威武1,汪渊源2,李 彬2,任忠鸣2,钟云波2,雷作胜2

(1. 上海宝信软件股份有限公司,上海 201203;

2. 上海大学 材料科学与工程学院 省部共建高品质特殊钢冶金与制备国家重点实验室,上海 200444)

摘 要:在镁合金连铸过程中,结晶器内镁液的流场和温度场分布对镁合金凝固组织有着重大的影响。深入了解连铸结晶器内镁液流场及温度场的分布可以在很大程度上改善铸坯的质量。采用有限元方法对AZ61镁合金圆坯结晶器电磁搅拌(Electromagnetic stirring, EMS)过程中流场及温度场进行数值模拟,同时对电磁搅拌条件下镁合金组织进行数值模拟。结果表明:在旋转电磁搅拌条件下镁合金受到旋转的电磁力,镁液在水平方向上围绕结晶器中心做旋转运动。随着磁感应强度从0增大到100 Gs,水平方向平均流速从0增大到6 mm/s,熔体凝固速度加快,结晶器内液相穴深度从20.2 cm减小到10.6 cm,结晶器中心到边部温度梯度减小。在电磁搅拌条件下,镁合金凝固组织中等轴晶比率增大;当磁感应强度增大到40 Gs时,晶粒由枝晶状态完全转化为类球状,晶粒平均尺寸由未搅拌时的366 μm变为110 μm。

关键词:镁合金;电磁搅拌;流场;温度场;凝固组织

文章编号:1004-0609(2019)-02-0241-07 中图分类号:TG339 文献标志码:A

镁合金被誉为21世纪最具应用前景的“绿色工程材料”[1-2]。迄今为止,镁合金作为在工程上应用最轻的金属结构材料,具有密度小、比强度高、铸造性能好、优良的导电和导热性及抗电磁干扰等众多优点。目前,镁合金坯料的制备主要是采用半连续铸造技术,但由于镁合金具有低热容、低熔化热和低导热能力等性能,使镁合金凝固散热困难,凝固边界与熔体中心温度差别巨大,导致凝固组织中的晶粒粗大、枝晶发达、组织不均[3-4]。因此,镁合金连铸过程中控制结晶器内镁液的流场和温度场[5-6]至关重要。电磁搅拌作为改善连铸坯表面和内部质量的有效手段之一,通过改变钢液凝固过程流动、传热和晶粒生长,实现对铸坯偏析、疏松、凝固组织的优化控制[7]。已经在钢铁连铸生产中得到广泛应用[8-9]。

多年来,国内外众多学者对结晶器电磁搅拌做了大量的研究工作。SPITZER等[10]提出电磁搅拌下铸坯内钢液流动的二次模式,并将圆坯简化为无限长,推导了圆坯内电磁力分布的二维解析解,同时用数值模拟的方法模拟了铸坯内流场的分布,并用实验予以验证。FUJISAKI等[11]对结晶器电磁搅拌进行了大量创新性的研究工作,建立了交变磁场下三维数学模型,研究了结晶器电磁搅拌过程的磁场特征。CHEN等[12]建立了磁场-流场-温度场耦合的数学模型,分析了电磁搅拌对结晶器内流场和温度场的影响。以上研究工作大部分针对钢铁连铸过程进行磁场流场及温度场的模拟,而对于镁合金铸坯组织计算工作鲜见报道,尤其是镁合金圆坯结晶器电磁搅拌条件下三维多场耦合分析更是未见报道。

本文建立了镁合金连铸电磁搅拌条件下结晶器内流场、温度场、组织的数学模型,利用有限元法对电磁搅拌条件下结晶器内流场和温度场进行耦合计算,并以此为基础对电磁搅拌条件下晶粒组织进行数值计算,在此基础上分析了该技术的工作原理,重点考察了电磁搅拌对流场、温度场、组织的影响规律,为该技术的生产应用提供理论依据。

1 数学模型

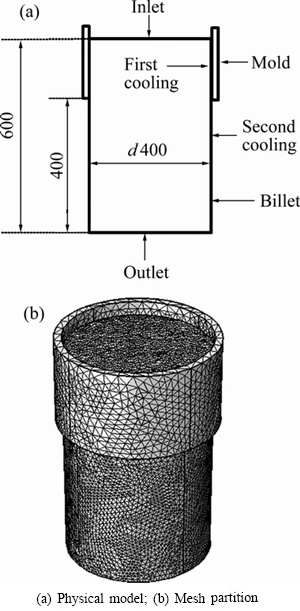

几何模型如图1所示。结晶器底部所在的面为水平面,拉坯方向为z轴负方向。结晶器高度为240 mm,内径400 mm,外径440 mm,自由液面距离结晶器上沿40 mm。图1(a)所示为几何模型示意图,图1(b)所示为三维模型网格划分示意图,网格为四面体网格。

1.1 流动与传热模型

1.1.1 模型假设

由于结晶器内镁液流动过程的复杂性,为了便于数学模型的建立以及后续的数值模拟计算,对模型进行适当的假设是必要的。具体的假设如下。

1) 金属液为不可压缩黏性流体,且金属液的流动为稳态流动;2) 各物性参数均为不随时间变化的常数;3) 忽略实际连铸过程中坯壳的生长过程,认为在整个计算区域内只有金属液,只考虑液相的流动;4) 忽略拉坯方向的传热,只考虑圆坯径向的传热,模型为三维模型;5) 镁液的导热系数在结晶器内和结晶器外设置成有效导热系数[13]。

图1 连铸过程结晶器物理模型及网格划分示意图

Fig. 1 Geometric model of M-EMS and mesh system in continuous casting (Unit: mm)

1.1.2 基本控制方程

连续性方程如下:

(1)

(1)

动量方程如下:

(2)

(2)

式中: 为密度,kg/m3;p为压力,Pa;

为密度,kg/m3;p为压力,Pa; 为湍流黏度系数,kg/(m·s);

为湍流黏度系数,kg/(m·s); 为

为 方向上速度分量,m/s;

方向上速度分量,m/s; 为不同方向坐标,m;

为不同方向坐标,m; 为xi方向上时均电磁力分量,N/m3。

为xi方向上时均电磁力分量,N/m3。

在三维直角坐标系中,传热基本方程表示如下:

(3)

(3)

式中:T为温度;k为热导率;Q为单位体积的热能;cp为定压比热容; 为速度场;

为速度场; 为液态金属密度。

为液态金属密度。

液态金属在结晶器内冷却凝固,释放大量的潜热。对比于纯金属,合金经历更大的相变温度区间,存在糊状区。为了计算相变潜热量,用( )代替cp,

)代替cp, 为焓变,

为焓变, 为高斯曲线,其变化过程大致可表示等效热容随温度的变化趋势。

为高斯曲线,其变化过程大致可表示等效热容随温度的变化趋势。

(4)

(4)

式中:Tm为液固相线的中点; 为糊状区的半宽。通过式(5)可在计算过程中将焓变转化为热容的变化:

为糊状区的半宽。通过式(5)可在计算过程中将焓变转化为热容的变化:

(5)

(5)

数值模拟过程采用商用软件COMSOL进行计算,本文建立了三维流场与温度场耦合的数学模型研究电磁搅拌对镁合金凝固过程中温度场的影响,如图1所示,电磁搅拌的引入采用直接在模型中加入电磁力的方式,搅拌中心位置为z=0.1 m,搅拌区间为z=0.08 m到z=0.12 m。根据文献[11],时均电磁力可分解成r方向和 方向两个力的合力,其表达式为

方向两个力的合力,其表达式为

(6)

(6)

(7)

(7)

式中: 为铸坯水平切面半径r方向上的时均电磁力;

为铸坯水平切面半径r方向上的时均电磁力; 为铸坯水平切面

为铸坯水平切面 方向上的时均电磁力;

方向上的时均电磁力; 为搅拌电流角速度;

为搅拌电流角速度; 为角度

为角度 方向的线速度;

方向的线速度; 为电导率;

为电导率; 为磁导率;

为磁导率; 为磁感应强度。

为磁感应强度。

1.2 元胞自动机模型

单元自动控制-有限元耦合模型(Cellular automation-finite element model,CAFE)采用有限元法对铸件凝固时发生的热传导过程进行求解,接着通过组织形成的微观物理机制在局部建立元胞形核和长大的规则,将有限元计算结果耦合到元胞的演化规则中,进行组织的演化模拟[14]。根据凝固理论,晶粒组织主要取决于晶粒在结晶器壁和熔池液相中的异质形核和枝晶生长动力学。

1.2.1 形核

采用连续而非离散的分布函数 用来描述晶粒密度的变化[14],其中dn是由过冷度

用来描述晶粒密度的变化[14],其中dn是由过冷度 的增大引起的晶粒密度的增加,其高斯分布如下:

的增大引起的晶粒密度的增加,其高斯分布如下:

(8)

(8)

式中: 为平均形核过冷度,K;

为平均形核过冷度,K; 为形核过冷度标准方差,K;nmax为正态分布从0到

为形核过冷度标准方差,K;nmax为正态分布从0到 积分得到的最大形核密度,m-3。

积分得到的最大形核密度,m-3。

1.2.2 枝晶尖端生长动力学

连铸坯生长凝固计算中,枝晶生长模型通常采用简化的KGT模型[15]

(9)

(9)

式中: 、

、 分别为拟合多项式的系数;

分别为拟合多项式的系数; 为枝晶尖端总过冷度,K。

为枝晶尖端总过冷度,K。

1.2.3 电磁搅拌对凝固组织的影响

电磁搅拌从两个方面对连铸过程晶粒组织产生影响[16-17]。一方面,电磁搅拌使得铸坯内部液体产生强烈的对流流动,打断细小的枝晶尖端或促进枝晶臂的熔断,并通过流动将这些枝晶碎片带入到中心的液相形成新的形核质点,从而提高铸坯的形核率。另一方面,电磁搅拌造成的对流流动加速了铸坯中心过热钢水向铸坯传热,使得液芯内部过热度快速消除,为柱状晶向等轴晶过渡提供条件。

液态金属热量传递过程分别为传导传热、对流传热和辐射传热。连铸过程中通过增大对流区域导热系数的方式将液态金属作为假想的固态处理应用已十分广泛[18-19]。流体对流换热准数方程中的贝克来数Pe反映了流场的热对流能力与热传导能力的对比,该准数可有效地将流体导热能力转化成固态物质导热能力,对流换热准数贝克莱数(Pe):

(10)

(10)

式中: 为液态密度,kg/m3;c为流体比热容,kJ/kg3;l为流场的特征尺寸,m;

为液态密度,kg/m3;c为流体比热容,kJ/kg3;l为流场的特征尺寸,m; 为流体导热率,W/(m2·K);v为流体速度,m/s。

为流体导热率,W/(m2·K);v为流体速度,m/s。

对流传热过程中引入有效导热系数[20],电磁搅拌对流体传热的影响通过增大对流区域导热系数的方式将液态金属作为假想的固态处理。由式(10)可得,当其他参数不变的情况下,流体导热率与流体速度成正比关系:

(11)

(11)

式中:vcast为拉速,mm/s;v为流场计算结果所得的结晶器内镁液流速,mm/s; 为无电磁搅拌时镁液的导热率,W/(m2·K)。

为无电磁搅拌时镁液的导热率,W/(m2·K)。

本文镁合金连铸过程晶粒的数值计算过程中,忽略电磁搅拌对铸坯形核的影响,通过改变糊状区导热系数的方式,将电磁搅拌效果考虑到铸坯凝固过程当中,根据COMSOL中得到的流速计算晶粒模拟过程中的有效导热系数 。

。

1.3 材料物性与边界条件

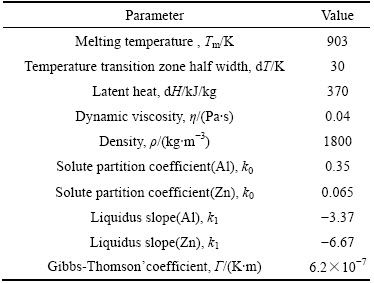

本模拟中AZ61镁合金,合金化学成分和物性参数[21]见表1和表2。

表1 AZ61镁合金化学成分

Table 1 Chemical composition of AZ61 magnesium alloy (mass fraction, %)

表2 AZ61镁合金物性参数

Table 2 Physical property parameters of AZ61 magnesium alloy

2 计算结果与讨论分析

2.1 磁感应强度对流场的影响

本文将时均电磁力引入流场控制方程,并验证电磁搅拌模型的正确性。忽略液态的镁合金流动对磁场的影响。图2所示为不同搅拌强度下,圆坯搅拌中心横断面液态镁合金的速度分布矢量图。图2中箭头方向表示流速方向,颜色深浅代表流速大小。由图2可以看出,当没有电磁搅拌的情况下,由于模型中镁液自由液面处设置的为入口速度,所以液态镁合金水平方向没有速度;加入旋转电磁搅拌后,结晶器内镁液围绕中心做旋转运动(见图2(b)),其中箭头方向代表了镁液的流速方向),速度大小呈中心对称分布,镁液边缘速度大于中心速度。

图2 不同磁感应强度下结晶器横断面镁液速度分布矢量图

Fig. 2 Distribution of velocity field of molten Mg with different B0 in mold

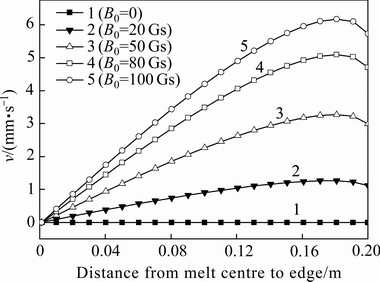

图3所示为圆坯横断面电磁感应强度为20、50、80、100 Gs时结晶器内镁液径向上的速度分布。研究表明,不同磁感应强度下速度分布趋势基本相同,即靠近结晶器中心处镁液速度较小,边缘处速度较大。铸坯中心处速度基本为零,速度大小在半径方向上呈先增大后减小的趋势。这是由于施加电磁搅拌后镁液在水平方向上受到旋转的电磁力,根据式(6)和式(7)可以发现,越靠近结晶器边缘时镁合金收到的电磁力越大,所以镁液边缘速度大于中心速度,而结晶器边缘的镁液会受到运动过程中会受到来自结晶器的阻力,所以速度略有下降。

图3 不同磁感应强度下结晶器内镁液速度在径向上的分布图

Fig. 3 Radial distribution of velocity of molten Mg with different B0 in mold

2.2 磁感应强度对温度场的影响

图4所示为镁合金凝固过程中不同磁感应强度下的铸坯拉坯方向中心面温度场分布计算结果。图4中上方蓝色线条为镁合金凝固过程中的液相等温线,下方蓝色线条为固相等温线。如图4(a)所示,镁合金与钢铁材料不同,在铸坯出结晶器之前,合金已完全凝固,且随着磁感应强度的增大,固相等温线上移,液相穴变浅,固相等温线更平滑。这是由于随着电磁搅拌的加入,镁液在结晶器内形成旋转的流动,从而提高了镁液的传热效率,结晶器内整个降温过程加快。

选取结晶器内合金凝固过程中初始凝固点中心到边部半径上的点进行分析,得到有无电磁搅拌条件下,沿镁合金熔体半径方向上的温度场分布结果如图5所示。由图5可见,在不施加电磁搅拌的情况下,当边部温度降为843 K,熔体中心温度为912 K,只比浇注温度低了1 K,心部和边部的温度梯度为69 K;当施加电磁搅拌后,熔体中心温度为866 K,边部温度843 K,心部和边部的温度梯度为23 K,此时熔体的大部分区域已经处于固液两相区,熔体中开始同时形核,有利于获得好的组织。这是由于在无电磁搅拌情况下,镁合金熔体内部的热量主要是通过热传导的形式进行,熔体内外温度梯度较大,冷却过程由外向内进行,熔体边部温度降低比中心快,造成熔体内外温差较大;在电磁搅拌条件下[22],镁合金熔体受到旋转的电磁力作用,从而熔体内形成了水平的旋转运动,此时熔体内部热量传输由热传导和电磁搅拌所带来的熔体传质来完成。该过程降低了熔体内外部温度梯度,同时加速了熔体内部和整体的温度降低。

图4 不同磁感应强度下铸坯拉坯方向中心面温度场分布

Fig. 4 Distribution of temperature field of molten Mg in center face along casting direction with different B0 in mold

图5 有无电磁搅拌条件下沿熔体径向温度分布图

Fig. 5 Distribution of temperature fields in radial direaction without and with EMS

2.3 电磁搅拌对凝固组织的影响

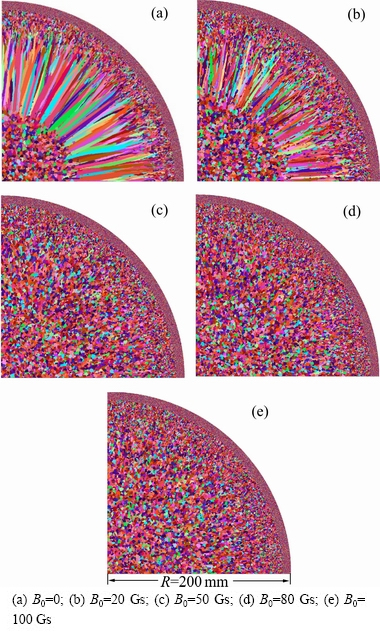

图6(a)所示为无电磁搅拌情况下镁合金圆坯晶粒组织,从图6(a)可以看出,镁合金组织中柱状晶较发达,等轴晶区较小。施加电磁搅拌后,如图6(b)~(e)所示,柱状晶明显减少,向等轴晶转变,等轴晶比增大;图7所示为磁感应强度对晶粒平均尺寸的影响。由图7可以看出,晶粒平均尺寸由无电磁搅拌情况下的366 μm减小到110 μm。且在本模型下当磁感应强度超过40 Gs后,晶粒尺寸基本保持不变。这是由于电磁搅拌对组织形成的影响等效于对熔体导热速率的影响,改变的导热系数决定熔体的冷却速度及过冷度,使熔体同时达到形核过冷度的体积增大,增加形核数量,从而减小晶粒尺寸。但当搅拌到达一定强度后,镁合金晶粒尺寸细化效果不再明显,这是由于只考虑了电磁搅拌对组织形成过程中过冷度的影响,但忽略了电磁搅拌对铸坯内部液体产生强烈的对流流动,打断细小的枝晶尖端或促进枝晶臂的熔断,并通过流动将这些枝晶碎片带入到中心的液相形成新的形核质点,从而提高铸坯的形核率的影响。

图6 有无电磁搅拌下铸坯组织

Fig. 6 Solidification structures of Mg alloy with different B0

图7 磁感应强度对晶粒平均尺寸的影响

Fig. 7 Influence of electromagnetic density on grain size

3 结论

1) 建立了流场-温度场的数学模型,对电磁搅拌条件下镁合金连铸结晶器内镁液的流场-温度场进行了数值计算,结果表明:施加旋转电磁搅拌后,结晶器内镁液在水平方向上产生旋转的运动,速度在铸坯水平截面上呈周向分布,速度由铸坯中心向坯壳方向逐渐增大,但接近结晶器部分呈略微减小的趋势。随着搅拌强度的增加旋转速度也相应的增大。其他参数不变的情况下,增加电磁搅拌的强度,镁液之间对流换热强度变大。在不施加电磁搅拌的情况下,熔体中心温度为912 K,边部温度为843 K,心部和边部的温度梯度为69 K;当施加电磁搅拌后,熔体中心温度为866 K,边部温度843 K,心部和边部的温度梯度为23 K,此时熔体的大部分区域已经处于固液两相区,熔体中开始同时形核,有利于获得好的组织。铸坯中心液相降温更快,温度更均匀,液相穴更浅。

2) 建立了镁合金连铸过程中组织生长的数学模型,对镁合金连铸过程凝固组织进行了数值计算,结果表明:其他参数不变的情况下,施加电磁搅拌可以增大铸坯的等轴晶比率。晶粒由粗大的柱状晶变为类球晶,平均尺寸由无电磁搅拌时的366 μm降到110 μm左右。本模型中当磁感应强度为40 Gs时晶粒平均尺寸降到最低,且随着磁感应强度的增强,细化效果不再明显。

REFERENCES

[1] MORDIKE B L, EBERT T. Magnesium: Properties- applications-potential[J]. Materials Science and Engineering A, 2001, 302(1): 37-45.

[2] BAE J W, KANG C G, KANG S B. Mathematical model for the twin roll type strip continuous casting of magnesium alloy considering thermal flow phenomena[J]. Journal of Materials Processing Technology, 2007, 191(1): 251-255.

[3] KURZ G, PETERSEN T, BOHLEN J, LETZIG D. Variation of rare earth elements in the magnesium alloy ME21 for the sheet production[C]// Magnesium Technology 2017. Springer, Cham, 2017: 353-363.

[4] 冀焕明, 罗天骄, 杨院生. AZ80镁合金低压脉冲磁场半连续铸造过程的数值模拟和实验研究[J]. 中国有色金属学报, 2017, 27(3): 468-476.

JI Huan-ming, LUO Tian-jiao, YANG Yuan-sheng. Numerical simulation and experimental research of low voltage pulsed magnetic field DC casting of AZ80 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(3): 468-476.

[5] CHEN X, LE Q, WANG X, LIAO Q. Variable-frequency ultrasonic treatment on microstructure and mechanical properties of ZK60 alloy during large diameter semi-continuous casting[J]. Metals, 2017, 7(5): 173.

[6] 杨满红, 郭志鹏, 熊守美. 对流作用下镁合金凝固组织演变的数值模拟[J]. 中国有色金属学报, 2015, 25(4): 835-843.

YANG Man-hong, GUO Zhi-peng Xiong Shou-mei. Numerical simulation of dendritic growth of magnesium alloy with convection[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(4): 835-843.

[7] POOLE G M, HEYEN M, NASTAC L, EL-KADDAH N. Numerical modeling of macrosegregation in binary alloys solidifying in the presence of electromagnetic stirring[J]. Metallurgical and Materials Transactions B, 2014, 45(5): 1834-1841.

[8] YAO Q, LUO Z, LI Y, YAN F Y, DUAN R. Effect of electromagnetic stirring on the microstructures and mechanical properties of magnesium alloy resistance spot weld[J]. Materials & Design, 2014, 63: 200-207.

[9] WILLERS B, BARNA M, REITER J, ECKERT S. Experimental investigations of rotary electromagnetic mould stirring in continuous casting using a cold liquid metal model[J]. ISIJ International, 2017, 57(3): 468-477.

[10] SPITZER K H, DUBKE M, SCHWERDTFEGER K. Rotational electromagnetic stirring in continuous casting of round strands[J]. Metallurgical and Materials Transactions B, 1986, 17(1): 119-131.

[11] FUJISAKI K, UEYAMA T, OKAZAWA K. Magneto hydrodynamic calculation of in-mold electromagnetic stirring[J]. IEEE Transactions on Magnetics, 1997, 33(2): 1642-1645.

[12] REN B Z, CHEN D F, WANG H D, LONG M J, HAN Z W. Numerical simulation of fluid flow and solidification in bloom continuous casting mould with electromagnetic stirring[J]. Ironmaking & Steelmaking, 2015, 42(6): 401-408.

[13] OKSMAN P, YU S, KYTONEN H, LOUHENKILPI S. The effective thermal conductivity method in continuous casting of steel[J]. Acta Polytechnica Hungarica, 2014, 11(9): 6-22.

[14] GANDIN C A, RAPPAZ M. A coupled finite element-cellular automaton model for the prediction of dendritic grain structures in solidification processes[J]. Acta Metallurgica et Materialia, 1994, 42(7): 2233-2246.

[15] KURZ W, GIOVANOLA B, TRIVEDI R. Theory of microstructural development during rapid solidification[J]. Acta Metallurgica, 1986, 34(5): 823-830.

[16] 蔡开科. 连铸坯质量控制[M]. 北京: 冶金工业出版社, 2010.

CAI Kai-ke. Quality control for steel continuous casting[M]. Beijing: Metallurgical Industry Press, 2010.

[17] AGRAWAL S, GHOSE A K, CHAKRABARTY I. Effect of rotary electromagnetic stirring during solidification of In-situ Al-TiB2 composites[J]. Materials & Design, 2017, 113: 195-206.

[18] THOMAS B G, NAJJAR F M. Finite element modelling of turbulent fluid flow and heat transfer in continuous casting[J]. Applied Mathematical Modelling, 1991, 15(5): 226-243.

[19] MAZUMDAR D. Mathematical modelling of transport phenomena in continuous casting of steel[J]. ISIJ international, 1994, 34(7): 584-592.

[20] TAKAHASHI T, KUDOH M, ICHIKAWA K. Fluidity of the liquid in the solid-liquid coexisting zone[J]. Transactions of the Japan Institute of Metals, 1980, 21(8): 531-538.

[21] 刘静安, 谢水生, 马志新. 简明镁合金材料手册[M]. 北京: 冶金工业出版社, 2016.

LIU Jing-an, XIE Shui-sheng, MA Zhi-xin. Magnesium alloy material handbook[M]. Beijing: Metallurgical Industry Press, 2016.

[22] 陈兴润, 张志峰, 徐 骏, 石力开. 电磁搅拌法制备半固态浆料过程电磁场、流场和温度场的数值模拟[J]. 中国有色金属学报, 2010, 20(5): 937-945.

CHEN Xing-rui, ZHANG Zhi-feng, XU Jun, SHI Li-kai. Numerical simulation of electromagnetic field, flow field and temperature field in semi-solid slurry preparation by electromagnetic stirring[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(5): 937-945.

Numerical simulation on flow-temperature field and solidification during electromagnetic of continuous casting of magnesium alloy

ZHANG Wei-wu1, WANG Yuan-yuan2, LI Bin2, REN Zhong-ming2, ZHONG Yun-bo2, LEI Zuo-sheng2

(1. Shanghai Baosight Software Co., Ltd., Shanghai 201203, China;

2. State Key Laboratory of Advanced Special Steel, School of Materials Science and Engineering, Shanghai University, Shanghai 200444, China)

Abstract: The flow field and temperature field of molten magnesium alloy in the mold have significant influence on dendritic growth process during continuous casting. It is important to understand the distribution of flow field and temperature field. The flow field, temperature field during the electromagnetic stirring (EMS) of continuous casting of AZ61 magnesium alloy were simulated with finite element method, and the microstructure of round cast billet was simulated. The simulation results indicate that the liquid magnesium alloy flows around the mold in horizontal plane with rotational electromagnetic force. With the magnetic induction intensity increasing from 0 to 100 Gs, the flow velocity increases from 0 to 6 mm/s, and the depth of liquid phase decreases from 20.2 cm to 10.6 cm. The electromagnetic stirring accelerates the solidification rate, and the temperature difference between the melt edge and the melt centre becomes small. The equiaxed crystal ratio of solidification structure is improved significantly under the effect of the electromagnetic stirring. Meanwhile, the grain becomes more fine uniform spheroidal particals with size about 110 μm.

Key words: magnesium alloy; electromagnetic stirring; flow-field; temperature-field; solidification structure

Foundation item: Projects(U1560202, 51274137, U1860107) supported by the National Natural Science Foundation of China; Project (CXY-2016-015) supported by Shanghai Municipal Commission of Economy and Information, China; Project(SKLASS 2017-Z021) supported by the Independent Research and Development Project of State Key Laboratory of Advanced Special Steel, China

Received date: 2018-01-19; Accepted date: 2018-03-30

Corresponding author: LEI Zuo-sheng; Tel: +86-21-56335470; E-mail: lei_zsh@staff.shu.edu.cn

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(U1560202,51274137,U1860107);上海市经济与信息化委员会项目(CXY-2016-015);上海大学省部共建高品质特殊钢冶金与制备国家重点实验室自主研发课题资助项目(SKLASS 2017-Z021)

收稿日期:2018-01-19;修订日期:2018-03-30

通信作者:雷作胜,教授,博士;电话:021-56335470;E-mail:lei_zsh@staff.shu.edu.cn