文章编号:1004-0609(2016)-12-2530-07

TiB2对TiAl基合金显微组织、力学性能及抗氧化性的影响

肖树龙1, 2,荆 科1,徐丽娟1,陈玉勇1, 2

(1. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001;

2. 哈尔滨工业大学 金属精密热加工国家级重点实验室,哈尔滨 150001)

摘 要:采用水冷铜坩埚真空感应熔炼(ISM)技术制备β型TiAl合金Ti-45Al-2Nb-1.5V-1Mo-0.3Y(摩尔分数,%)及其复合材料Ti-45Al-2Nb-1.5V-1Mo-0.3Y(摩尔分数,%)+3%TiB2(体积分数)两种材料,并对TiAl合金及其复合材料的显微组织、力学性能和抗氧化性能进行研究。结果表明:加入TiB2后,TiAl合金中的晶粒尺寸和层片间距都得到细化,显微硬度、室温和高温抗拉强度提高,但室温伸长率略有下降,高温时复合材料表现出良好的塑性;800 ℃循环氧化100 h后,TiAl合金和复合材料氧化表面均保持完整,未产生剥落;加入TiB2后,导致两种材料表面氧化物的生长形态发生变化,但两种材料的氧化增量和氧化层厚度相近,因此,TiB2对氧化物的生长形态有影响,但对抗氧化性能影响不大。

关键词:TiAl合金;显微组织;力学性能;抗氧化性;TiB2

中图分类号:TG146.2 文献标志码:A

随着航空航天、汽车等领域的不断发展,对于材料的强度、性能提出了更高的要求。TiAl合金与传统的高温、高强钛合金和镍基、铁基高温合金相比,具有独特的综合性能,如低密度(为镍基高温合金的一半)、强度高(高温强度与镍基合金相当)、高熔点以及优良的抗蠕变性能等。如果采用TiAl合金代替部分镍基与铁基合金航空发动机高温结构件、低压涡轮叶片、旋流器和航天飞机外部高温蒙皮等部位,可以达到很好的减轻质量目的,TiAl合金因此也成为目前研究的热点[1-4]。但是由于TiAl合金室温的伸长率较低、成形性差、高温抗氧化性能较差,800 ℃以上抗氧化性能迅速下降,因此,改善合金的力学性能和抗氧化性能已经成为TiAl合金广泛应用的关键[5-6]。

近年来通过材料的复合化改善材料的力学性能成为了一种趋势,如在合金中加入陶瓷纤维、难熔金属纤维、陶瓷颗粒等进行材料的复合。大量研究表明[7-8],TiB2的热膨胀系数与TiAl合金和Al2O3较为接近,并与TiAl合金的化学相容性非常好,因此,TiB2成为TiAl合金的首选增强相。有研究表明[9-10],TiB2相的生长形貌、尺寸和分布状态对材料的层片间距和力学性能具有较大的影响,当B含量超过1%时,硼化物呈颗粒状,硼化物尺寸减小对减小层片间距和提高伸长率具有积极的作用,但目前对TiB2对TiAl合金的抗氧化性能的研究还较少。

本文作者采用水冷铜坩埚真空感应熔炼法制备一种新型的TiB2颗粒增强TiAl合金,主要研究TiB2对于合金显微组织与力学性能的影响,并重点研究TiB2对TiAl合金抗氧化性能的影响。

1 实验

本实验中采用水冷铜坩埚真空感应熔炼技术(ISM)制备了TiAl合金基体Ti-45Al-2Nb-1.5V-1Mo- 0.3Y(摩尔粉数,%)和复合材料Ti-45Al-2Nb-1.5V- 1Mo-0.3Y+3%TiB2。实验原材料为海绵钛(99.9%,质量分数)、高纯铝(99.99%),其他合金元素均采用中间合金的形式,如Al-Nb合金(52.6% Nb,质量分数)、Al-V合金(58.5% V)、Al-Y合金(80.2% Y)、Al-Mo合金(50.7% Mo);先将复合材料在V型搅拌器中按照Ti-20%Al-10%B的配比进行混合,之后冷压缩成块,熔炼前将合金块放入坩埚中。考虑合金元素在熔炼过程中的挥发行为,Al的补偿量为总量的2%~10%(质量分数),其他元素的烧损可以忽略。

显微组织观察和抗氧化实验的试样均采用线切割法切取,尺寸为10 mm×10 mm×8 mm,将试样6个表面在砂纸上由粗到细磨至2000号。显微组织观察试样采取电解抛光的方法,氧化试样进行机械抛光,最后用酒精清洗后晾干。用高温电阻炉进行高温循环氧化实验,温度为800 ℃,每个坩埚放4个试样,试样与坩埚内壁点(线)接触,使试样的表面能够充分的暴露在高温氧化氛围中。循环氧化周次N=10,每周次在800 ℃下保温10 h,采用随炉冷却,每周次采用电子天平(精度0.1 mg)进行称量,实验结果为4个试样的算术平均值。

采用带有能谱分析仪(EDS)的Quanta200FEG扫描电子显微镜(SEM)观察TiAl合金及其复合材料的显微组织、氧化表面和剖面形貌;采用Philips X,Pert X射线衍射仪对氧化前后的TiAl合金及其复合材料进行物相分析;采用CLEMEX全自动显微硬度计进行显微硬度测试,实验载荷为0.98 N,保压时间为15 s,每个试样测试6个点;采用Instron-5569型电子万能材料试验机对TiAl合金及其复合材料的室温和高温(800 ℃)拉伸性能进行测试;采用线切割法制备拉伸试样,用砂纸将试样磨光,拉伸试验加载速率为0.5 mm/min。

2 结果与讨论

2.1 TiB2对显微组织和力学性能的影响

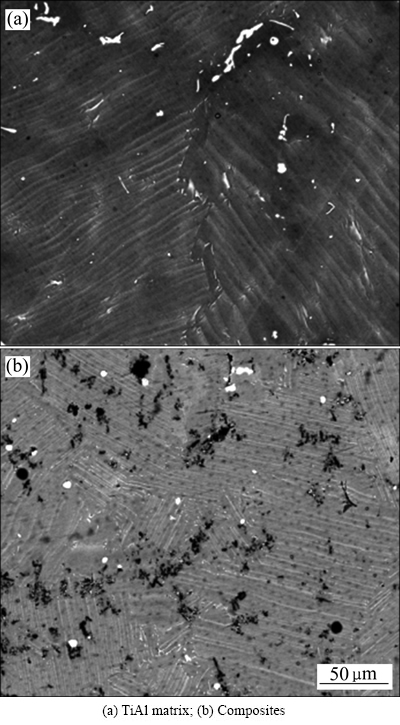

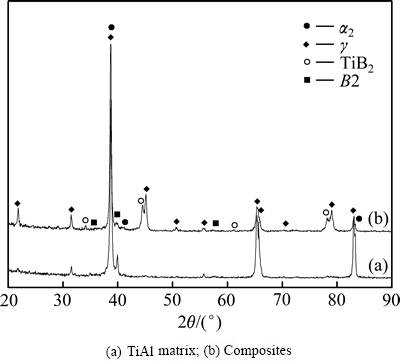

图1所示为铸态TiAl合金及其复合材料氧化前的显微组织。图2所示为基体合金及其复合材料的XRD谱。从图1可以看出,两种材料均为全层片的显微组织,并且层片取向呈一定的角度,复合材料的晶粒尺寸(约为50 mm)明显小于基体的晶粒尺寸(>200 mm)。由图2可知,两种材料都含有α2、γ和B2相,复合材料在凝固过程中还产生了TiB2相,这也与HYMAN等[11]的结论相同,即当合金的Al含量大于44%(质量分数)时,加入B后,在凝固过程中仅形成TiB2相。对比图1和2可知,复合材料中的黑色物质为TiB2相,主要分布在晶界处,也有少量分布在晶粒内部,这是由于在凝固过程中TiB2在枝晶间和晶界处的析出导致的[11]。此外,在凝固过程中,由于成分起伏的原因,初生TiB2相析出增加了非均匀形核的质点,从而起到细化晶粒的作用。因此TiB2是通过增加形核质点以及晶界的钉扎作用,从而达到细化晶粒和减小层片间距的目的[12-13]。

图1 TiAl合金及其复合材料氧化前的显微组织

Fig. 1 Microstructures of TiAl alloy and composites before oxidation

图2 TiAl合金及其复合材料的XRD谱

Fig. 2 XRD patterns of TiAl alloy and composites

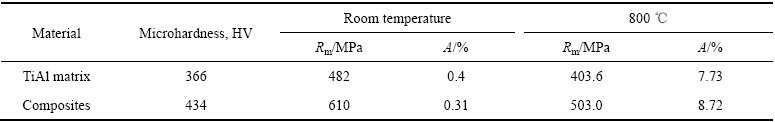

表1 TiAl合金及其复合材料的力学性能

Table 1 Mechanical properties of TiAl alloy matrix and composites

TiAl合金及其复合材料的显微硬度、室温拉伸和800 ℃高温拉伸试验结果如表1所列。从表1可以得出,加入TiB2后,复合材料的显微硬度、室温和高温抗拉强度明显升高,材料的室温伸长率略微降低,由于硬质点TiB2在材料晶粒内部和晶界处分布,无论是晶粒内部还是外部的TiB2都对位错滑移造成阻碍,使得位错在硬质点处发生塞积,造成复合材料的塑性降低。与室温性能相比,基体及其复合材料800 ℃时的抗拉强度均降低,伸长率明显增大,且复合材料的伸长率(8.72%)大于基体的(7.73%)。复合材料的高温塑性优于基体合金的,主要是由于TiB2相对晶粒的细化作用:在相同条件下使变形分布在更多的晶粒中进行,在高温条件下不容易形成位错塞积群和应力集中,因此,复合材料能够承受较大变形量,得到较好的伸长率。

2.2 TiB2对抗氧化性能的影响

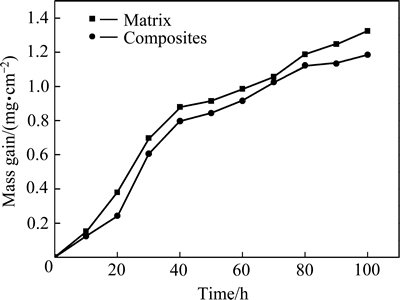

图3 800 ℃氧化100 h的氧化增量曲线

Fig. 3 Mass gain curves of materials during oxidation in air at 800 ℃

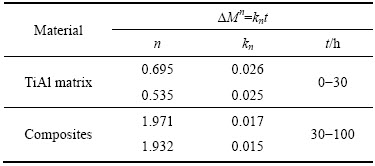

表2 TiAl合金及其复合材料在800 ℃下的循环氧化动力学参数

Table 2 Kinetic parameters of cycled oxidation of materials at 800 ℃

图3所示为TiAl合金及其复合材料在800 ℃循环氧化100 h的氧化动力学曲线。从图3可以看出,经过100 h循环氧化实验后,基体和复合材料的氧化增量分别为1.32和1.19 mg/cm2,添加少量TiB2后,对于合金的抗氧化性能并没有较大影响。氧化开始时,基体及其复合材料都呈现出先加速(t≤30 h)氧化、之后氧化速度降低的氧化行为(t>30 h),且在氧化70 h时,基体和复合材料的氧化增量相近。整体上来看,基体和复合材料的氧化增量呈近似抛物线规律。图3中氧化减速阶段的速度变化可用式(1)来表示[14]:

(1)

(1)

其中: 为氧化增量,mg;n为幂指数;kn为氧化反应速率常数;t为氧化时间,h。

为氧化增量,mg;n为幂指数;kn为氧化反应速率常数;t为氧化时间,h。

对式(1)两边取对数后,通过软件对试验点的回归拟合,可以得到速度指数n和氧化反应速率常数kn,结果如表2所示。基体和复合材料在氧化初期,氧化增量明显,因此不符合抛物线规律。加速阶段过后(t>30 h),基体与复合材料氧化增量减缓,氧化速率指数n相近且都约等于2,呈抛物线规律。

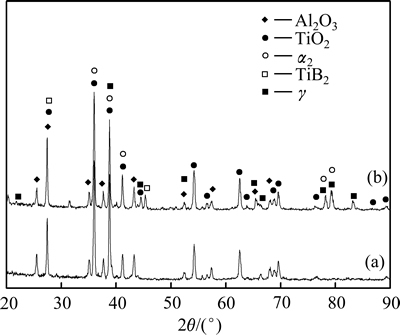

图4所示为TiAl合金及其复合材料经过100 h氧化后的XRD谱,对氧化表面分析结果表明,基体和复合材料经过800 ℃循环氧化100 h后,基体主要的相组成为γ相、α2相和Al2O3相,复合材料中含有少量的TiB2相,主要由γ相、α2相、Al2O3相和TiB2相组成。从图6可以看出,氧化层的厚度较薄,X射线的穿透深度为7~35 mm,在XRD谱上可以看到基体相的衍射峰,表明X射线可以穿透氧化层到达合金基体表面。

图4 TiAl合金及其复合材料经过100 h氧化后的XRD谱

Fig. 4 XRD patterns of TiAl matrix(a) and composites(b) oxidized in air at 800 ℃ for 100 h

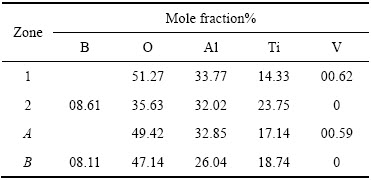

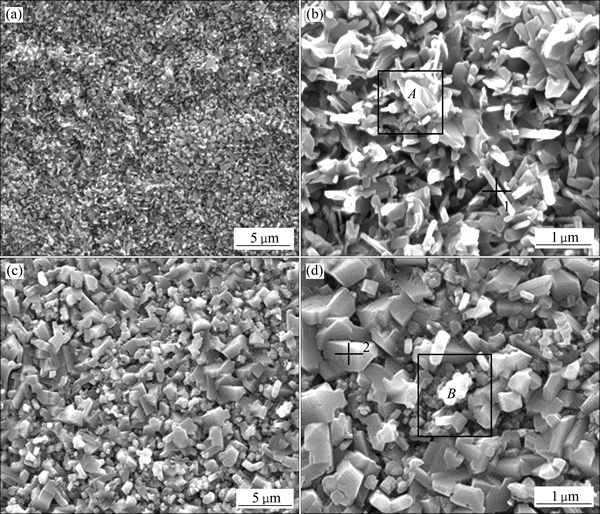

TiAl合金及其复合材料在800℃循环氧化100h后的氧化表面形貌如图5所示,表3所列为图5中1、2点和A、B区域的EDS分析结果。XRD和EDS定量分析综合表明,两种结构物质主要是由TiO2和Al2O3组成。从图6可以看出,整个氧化层表明并没有发现纯TiO2或Al2O3,氧化物呈混合状态。从图5(b)可以看出,基体的氧化表面由截面为六边形的杆状物质(0.2~0.5 mm)及团簇状物质(3~8 mm)组成,并且以跟基体表面呈一定角度的方式长大。杆状氧化物(点1)为富Al氧化物(70.2%Al2O3+29.8%TiO2),尺寸较为细小,分布较为均匀;团簇状物质(区域A)由较多杆状物质聚集在一起而产生的,空隙较小[15]。从图5(b)还可以看出,团簇相对周围物质生长较快,表明团簇处氧化物易优先形核长大,但是成分没有变化,经过EDS能谱分析,其含有Al、Ti和O这3种元素,为富Al氧化物(65.7%Al2O3+34.3%TiO2)。从图5(c)可以看出,复合材料的氧化物呈棱柱状和小颗粒团簇(0.5~1 mm)的形貌特征,与基体相比,氧化物的尺寸较大,但排列相对紧密(见图5(d)),棱柱间的空隙分布较多小颗粒团簇,阻碍了氧原子扩散的通道。EDS定量分析结果表明棱柱状物质(点2)为富Ti氧化物(59.7%TiO2+40.3%Al2O3),氧化物分布较为均匀,即Ti、Al元素呈弥散分布。结合氧化增量曲线和氧化表面的观察可以推断,由于加入少量TiB2,对氧化层的生长方式和氧化层表面形貌产生了影响,但是对合金的抗氧化性影响不大,TiAl合金的抗氧化性能与其复合材料的抗氧化性能相当。

表3 图5中各点的EDS分析结果

Table 3 EDS analysis results on points shown in Fig. 5

图5 TiAl合金及其复合材料经过800 ℃氧化100 h后的氧化表面形貌

Fig. 5 Surface morphologies of TiAl matrix((a), (b)) and composites((c), (d)) after oxidation at 800 ℃ for 100 h

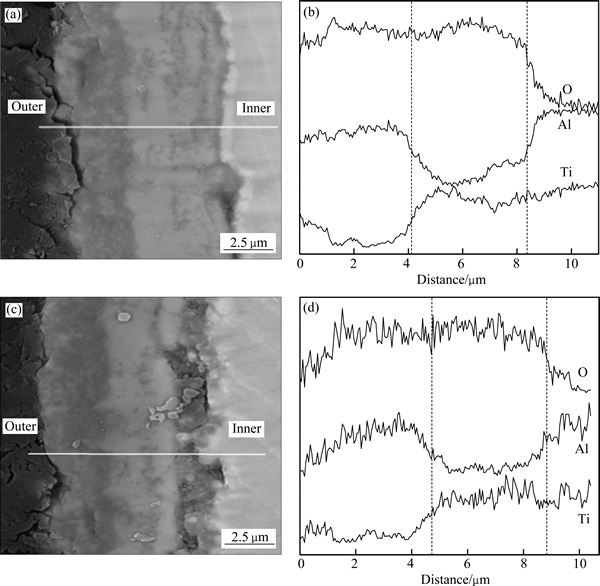

图6 TiAl合金及其复合材料经过800 ℃循环氧化100 h后的剖面结构及其元素线分布图

Fig. 6 Cross-sectional morphologies and corresponding elemental distribution profiles of TiAl matrix((a), (b)) and composites((c), (d)) oxidized at 800 ℃ for 100 h

基体和复合材料经过800 ℃循环氧化后的氧化剖面结构如图6所示。由图6(a)和(b)可以看出,氧化存在分层现象,并且主要由(TiO2+Al2O3)复合氧化层组成。基体与复合材料的氧化分层大致相同,由外到内主要分为3层:Al2O3层(含很少量TiO2)/TiO2层(含少量Al2O3)/基体。其中,在Al2O3层/TiO2层之间Al元素和Ti元素存在明显的浓度梯度,氧化产物由富Al氧化物向富Ti氧化物转变;而在TiO2层/基体之间则存在明显的富氧固溶体过渡层。两种合金的氧化层总厚度约为8 mm,表明基体和复合材料的抗氧化性相当,加入少量TiB2,只是对氧化层的生长方式和氧化层表面形貌产生了影响,对合金的抗氧化性影响不大。

3 结论

1) TiAl基复合材料与TiAl合金相比,加入TiB2后,显微组织得到显著细化,这主要由于初生TiB2相增加了非均匀形核质点,以及TiB2对晶界的钉扎作用,从而达到细化晶粒和减小层片间距的目的。

2) 加入TiB2后,复合材料的显微硬度和室温抗拉强度大于基体,但伸长率降低;800 ℃时,复合材料的抗拉强度大于基体的,且其伸长率(8.72%)也大于基体的(7.73%),这表明高温下复合材料的塑性得到改善。

3) 基体与复合材料氧化层主要由TiO2和Al2O3组成,氧化层弥散分布,800 ℃循环氧化100 h后没有氧化层脱落现象;加入TiB2后,氧化物的形态和生长方式发生改变,但是对材料抗氧性能影响不大。

REFERENCE

[1] APPEL F, CLEMENTS H, FISCHER F D. Modeling concepts for intermetallic titanium aluminides[J]. Progress in Materials Science, 2016, 81: 55-124.

[2] XIAO Shu-long, XU Li-juan, CHEN Yu-yong, YU Hong-bao. Microstructure and mechanical properties of TiAl-based alloy prepared by double mechanical milling and spark plasma sintering[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(5): 1086-1091.

[3] ZHAO L L, LI G Y, ZHANG L Q, LIN J P, SONG X P, YE F, CHEN G L. Influence of Y addition on the long time oxidation behaviors of high Nb containing TiAl alloys at 900 ℃[J]. Intermetallics, 2010, 18: 1586-1596.

[4] 彭小敏, 夏长清, 王志辉, 黄 珍, 王金惠. TiAl合金高温氧化及防护的研究进展[J]. 中国有色金属学报, 2010, 20(6): 1116-1130.

PENG Xiao-min, XIA Chang-qing, WANG Zhi-hui, HUANG Zhen, WANG Jin-hui. Development of high temperature oxidation and protection of TiAl-based alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(6): 1116-1130.

[5] FANG Lu, DING Xian-fei, HE Jian-ping, ZHANG Lai-qi, LIN Zhi, LIN Jun-pin. Microstructure instability of fully lamellar TiAl alloy containing high content of Nb after long-term thermal cycling[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(10): 3095-3102.

[6] 赵振兴, 孙红亮, 黄泽文. 长期热暴露对不同表面状态的Ti-44Al-5Nb-1W-1B合金疲劳性能的影响[J]. 中国有色金属学报, 2015, 25(6): 1458-1465.

ZHAO Zhen-xing, SUN Hong-liang, HUANG Ze-wen. Effects of long-term thermal exposure on fatigue behavior of Ti-44Al-5Nb-1W-1B alloy with varied surface conditions[J]. The Chinese Journal of Nonferrous Metals, 2016, 25(6): 1458-1465.

[7] 陈玉勇, 牛红志, 田 竟, 孔凡涛, 肖树龙. 颗粒增强TiAl基复合材料的研究进展[J]. 稀有金属材料与工程, 2011, 40(11): 2060-2064.

CEHN Yu-yong, NIU Hong-zhi, TIAN Jing, KONG Fan-tao, XIAO Shu-long. Research progress of particulates reinforced TiAl based composites[J]. Rare Metal Materials and Engineering, 2011, 40(11): 2060-2064.

[8] ZHANG X J, LI Q, ZHAO S Y, GAO C X, WANG L, ZHANG J. Improvement in the oxidation resistance of a γ-TiAl-based alloys by sol-gel derived Al2O3 film[J]. Applied Surface Science, 2008, 255: 1860-1864.

[9] HU Da-wei. Role of boron in TiAl alloy development: A review[J]. Rare Metals, 2016, 35(1): 1-14.

[10] 齐立春, 李臻煕, 曹京霞, 黄 旭. TiAl合金中TiB2相生长形态及其对力学性能的影响[J]. 稀有金属, 2012, 36(3): 347-352.

QI Li-chun, LI Zhen-xi, CAO Jing-xia, HUANG Xu. Growth morphology of TiB2 phase and its effect on mechanical properties of TiAl alloys[J]. Chinese Journal of Rare Metals, 2012, 36(3): 347-352.

[11] HYMAN M E, McCULLOUGH C, LEVI C G, MEHRABIAN R. Evolution of boride morphologies in TiAl-B alloys[J]. Metallurgical Transactions A, 1991, 22(7): 1647-1662.

[12] NIU H Z, XIAO S L, KONG F T, ZHANG C J, CHEN Y Y. Microstructure characterization and mechanical properties of TiB2/TiAl in situ composite by induction skull melting process[J]. Materials Science and Engineering A, 2012, 532: 522-527.

[13] HUANG Z W, HU W. Thermal stability of an intermediate strength fully lamellar Ti-45Al-2Mn-2Nb-0.8vol.%TiB2 alloy[J]. Intermetallics, 2014, 54: 49-55.

[14] TAKASAKI A, OJIMA K, TANEDA Y, HOSHIYA T, MITSUHASHI A. High-temperature oxidation process of intermetallic compound Ti-42at% Al[J]. Journal of Material Science, 1993, 28(4): 1067-1073.

[15] 曲恒磊, 周 廉, 魏海荣. 钛铝高温氧化表面分析[J]. 稀有金属材料与工程, 2000, 29(2): 90-93.

QU Heng-lei, ZHOU Lian, WEI Hai-rong. Surface analyses of high-temperature oxidated TiAl-based alloys[J]. Rare Metal Materials and Engineering, 2000, 29(2): 90-93.

Effect of TiB2 on microstructure, mechanical properties and oxidation resistance of TiAl-based alloys

XIAO Shu-long1, 2, JING Ke1, XU Li-juan1, CHEN Yu-yong1, 2

(1. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;

2. National Key Laboratory for Precision Hot Processing of Metals,

Harbin Institute of Technology, Harbin 150001, China)

Abstract: TiAl-based alloy Ti-45Al-2Nb-1.5V-1Mo-0.3Y (mole fraction, %) and composites Ti-45Al-2Nb-1.5V-1Mo-0.3Y (mole fraction, %)+3%TiB2 (volume fraction) were prepared by induction skull melting (ISM). The microstructure, mechanical properties and oxidation resistance were studied. The results show that the composites exhibit much finer lamellar colony size and lamellar spacing compared with matrix. The micro-hardness and tensile fracture strength are improved at room temperature and 800 ℃, while the tensile elongation decreases at room temperature. The composites show good plastics at 800 ℃. After oxidation in air at 800 ℃ for 100 h, the oxidation surfaces of matrix and composites show good quality with no micro-cracks observed. The growth morphologies of matrix oxidation surface change compared with those of composites. But the mass gain and thickness of oxide scale of composites are almost the same as those of matrix. So, TiB2 has some influence on the growth morphologies of oxide scale, but nearly has no influence on the oxidation resistance.

Key words: TiAl-based alloy; microstructure; mechanical property; oxidation resistance; TiB2

Foundation item: Projects(51001040, 51371064) supported by the National Natural Science Foundation of China; Project(SAST201428) supported by the Shanghai Aerospace Science and Technology Innovation Fund, China

Received date: 2015-05-08; Accepted date: 2016-05-28

Corresponding author: XIAO Shu-long; Tel: +86-451-86418802; E-mail: xiaoshulong@hit.edu.cn

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51001040,51371064);上海航天科技创新基金资助项目(SAST201428)

收稿日期:2015-05-08;修订日期:2016-05-28

通信作者:肖树龙,副教授,博士;电话:0451-86418802;E-mail: xiaoshulong@hit.edu.cn