Micro precision casting based on investment casting for micro structures with high aspect ratio

YANG Chuang(杨 闯)1, 2, LI Bang-sheng(李邦盛)1, 2, REN Ming-xing(任明星)1, 2, FU Heng-zhi(傅恒志)1

1. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;

2. Key Laboratory of Micro-systems and Micro-structures Manufacturing, Ministry of Education,

Harbin Institute of Technology, Harbin 150001, China

Received 10 June 2009; accepted 15 August 2009

Abstract: Microcasting is one of the significant technologies for the production of metallic micro parts with high aspect ratio (ratio of flow length to diameter). A micro precision casting technology based on investment casting using centrifugal method was investigated. The micro parts of Zn-4%Al alloy with an aspect ratio up to 200 was produced at the centrifugal speed of 1 500 r/min and the mold temperature of 270 ℃. The investigations on the relationship between flow length and rotational speed were carried out. For microcasting, the flow length is not only dependent on the centrifugal speed under the constant centrifugal radius, but also on the preheating temperature of mold. The flow length increases as the rotational speed and the mold temperature increase, and is much higher at a mold temperature of 270 ℃ than at other mold temperatures.

Key words: microcasting; centrifugal rotation; aspect ratio; investment casting

1 Introduction

The production of micro parts is one of the significant technologies in the present century. Micro components are widely applied to many developing fields, such as biotechnology, and information technology. They can be prepared by various microsystem technologies, for example, LIGA technique proposed by BECHER et al[1], micro powder injection molding[2-3], micro-electrical discharge machining [4-5], microcasting based on permanent mold[6] and micro precision casting based on investment casting [7-9]. Additionally, a new vacuum casting method was suggested by THIAN et al[10]. Many microsystem technologies are limited by materials, size, shaping and high aspect ratio of micro parts prepared. However, micro precision casting based on investment casting is a newly developing technology, and is possible to meet the requirements of modern production.

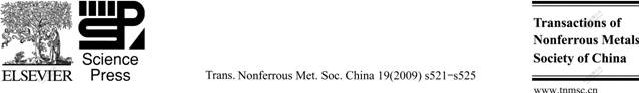

Investment casting is used to produce high-value parts. It is often chosen to prepare the parts which are difficult and/or expensive to finish[11]. Investment casting of micro parts is derived from the well-known process of dental casting introduced first by PHILBROOK in 1897[12] and applied by TAGGART in 1907[13]. However, micro precision casting based on investment casting is suitable for manufacturing complex micro parts of more than 50 μm or bigger ones with extremely fine details in the micrometer range[7-8, 11]. The aspect ratio (ratio of flow length to diameter) of micro parts prepared is up to 143[14]. The process of micro precision casting based on investment casting consists of several steps. The schematic diagram is shown in Fig.1. First, an injection-molded plastic master is embedded in a gypsum slip. After drying the gypsum, mold is sintered. During this process the master is lost by melting and pyrolysis. The preheated gypsum mold is then filled with a metal melt by centrifugal or pressure casting. After removing the mold from the casting, the cast structure is cleaned and the micro parts are separated from the gate system[7-9]. Nowadays, pressure casting method is widely applied to micro precision casting[14]. This may be due to the fact that high filling pressure is not easy to be obtained because of difficulty to achieve high rotational speed of centrifuge without crack of gypsum mold.

Additionally, the research and development concerning micro precision casting was started with precious alloys, such as gold alloy, because they have an excellent corrosion resistance and low oxidation affinity during the casting process[8]. The Sn-36Pb-2Ag alloys were also used[14]. One common property, good fluidity, is found in the previous alloys. But they are rarely employed in industrial production. And aluminum alloy has good fluidity[15-16]. So, Zn-4%Al alloy was used in the present investigation.

Fig.1 Schematic diagram of microcasting process: (a) Nylon and wax master; (b) Master embedded in investment pattern; (c) Hollow form by burning; (d) Filling molds by centrifugal rotation; (e) Cleaned gypsum-bonded investment; (f) Micro parts

In this work, micro precision casting based on investment casting and centrifugal casting were integrated into a new process. Further improvements of small components with high aspect ratio can be achieved either by increasing the mold preheating temperature or the rotational speed. The investigations on the relationship between flow length and rotational speed were carried out.

2 Experimental

2.1 Casting alloy

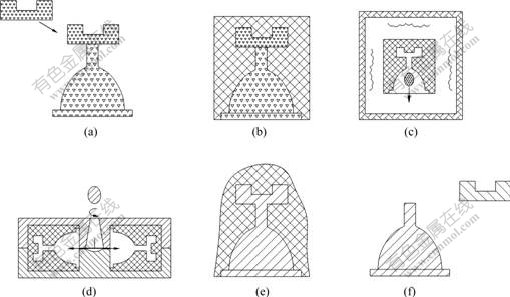

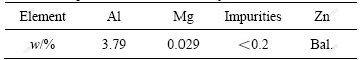

Zn-4%Al alloy was chosen for this study because of its good corrosion resistance, metal brightness and good fluidity. On the other hand, it is widely used in industrial production and has good application prospect. The composition, physical and mechanical properties of Zn-4%Al alloy are shown in Tables 1 and 2, respectively.

Table 1 Composition of Zn-4%Al alloy

Table 2 Physical and mechanical properties of Zn-4%Al alloy

2.2 Preparation of centrifuge and die

The machine was desktop centrifuge (LD4-2A) purchased from Beijing Jingli Centrifuge Co., Ltd. China, and refitted by authors in this study. The machine includes the centrifugal system and the die preheating system. The maximum speed of centrifugal rotation is up to 3 000 r/min and the maximum preheating temperature is 600 ℃.

The die is made of graphite because of its high melting point for preheating and low density for balance of centrifugal rotation. The die is divided into cope and counter die, and composed of the gating system and four mold cavities. Four gypsum molds are placed on four cavities in the graphite die. The cope and counter die are closed during casting process. The liquid metal is filled from the gate into the gypsum molds in the mold cavities.

2.3 Preparation of mold

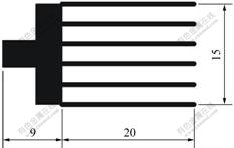

The investment materials were prepared by mixing fine-grained quartz powders with hard plaster. The raw materials were calcium sulfate α-hemihydrate and quartz powders purchased from Yongtai Gypsum Industrial Corp (China) and Andi Mining Corp (China), respectively. Materials were weighed on a laboratory scale, and the mass ratio of hard plaster to quartz powders was 60?40. For investigating the effect of centrifugal force and preheating temperature on flow length, the samples consisted of 6 microwires with 20 mm in length. Three different samples in which wires were 100 μm, 200 μm and 300 μm in diameter were used in this study. The structure of samples is shown in Fig.2. It was chosen because of its applicability to test flow length[14].

Fig.2 Schematic diagram of model with microwires(unit: mm)

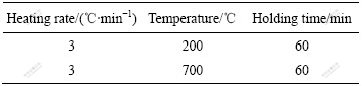

The gypsum molds were trimmed for needs of the graphite die. Then, the molds were put into a furnace in order to melt the pattern and to sinter the gypsum. Temperature of furnace was slowly increased to final mold temperature of 700 ℃ because the cracks of the mold were easy to form due to the expansion of gypsum heated. Temperature project of the furnace was presented in Table 3. The slow heating rate and the holding time at different temperatures ensured the thermal equilibrium conditions and sufficient time for chemical reactions.

Table 3 Temperature project of furnace for heating up molds

2.4 Preparation of micro structures

As mentioned above, Fig.1 shows the micro precision casting process based on investment casting. The methods mentioned in Ref.[16] are subdivided into centrifugal casting and pressure casting. As shown in Fig.1(d), the method of centrifugal casting was used in the present study. The Zn-4%Al alloy was put into the ceramic crucible and molten in vacuum resistance furnace (GR-20 type). In microcasting a casting temperature of 440 ℃ was used and the holding time was 30 min. The graphite die with the gypsum molds was installed in the casting centrifuge. The influence of various preheating temperatures (130, 200 and 270 ℃) and centrifugal speeds (500, 1 000 and 1 500 r/min) on the flow length was investigated. The diameters of microwires were 100, 200 and 300 μm.

3 Results

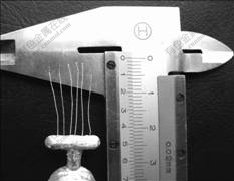

Fig.3 presents a picture of the casting structure prepared at a mold temperature of 270 ℃ and a centrifugal speed of 1 500 r/min. The diameter and the length of each microwire are 100 μm and 20 mm, respectively.

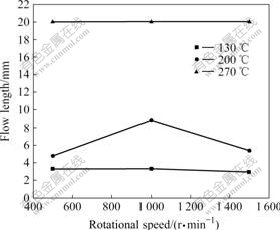

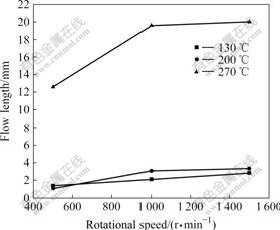

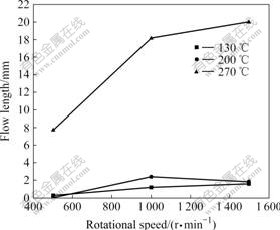

Figs.4-6 show the resulting flow length on dependency of the arithmetical mean value of the 6 microwires. The diameters of microwires in Figs.4-6 are 300 μm, 200 μm and 100 μm, respectively. It is shown in Fig.4 that at different rotational speeds, the maximum flow length of 20 mm is obtained at a mold temperature of 270 ℃. At mold temperature of 130 ℃, the flow length is little changed at different rotational speeds. However, the flow length is different at mold temperature of 200 ℃. The flow length with 1 000 r/min is obviously higher than that obtained with other rotational speeds. This may be due to the permeability of mold, which could be the special one during manufacturing mold process. But this might not influence the results of experiments, which can be verified by the results shown in Figs.5 and 6. It is seen in Figs.5 and 6 that at mold temperatures of 130 ℃ and 200 ℃, the influence of rotational speed on the flow length is not significant. At mold temperature of 270 ℃, the flow length increases with increasing rotational speed from 500 to 1 500 r/min.

Fig.3 Micro metal wires with 100 μm in diameter after microcasting at molding temperature of 270 ℃ and rotational speed of 1 500 r/min

Fig.4 Flow length of micro-metal wires with 300 μm in diameter at various mold temperatures

Fig.5 Flow length of micro-metal wires with 200 μm in diameter at various mold temperatures

Fig.6 Flow length of micro-metal wires with 100 μm in diameter at various mold temperatures

4 Discussion

Figs.4-6 show that the flow length decreases with decreasing the diameter of microwires for the same mold temperature and rotational speed. It was presented in Ref.[10] that capillary pressure by surface tension is equal to the absolute pressure for form filling if the influence of pressure due to enclosed gas is not taken into account because of the open porosity of the mold. Additionally, the pressure losses along the flow length and the change of viscosity with decreasing temperature during filling is neglected. So, the counter pressure is 2σcosθ/r and the filling pressure is ω2ρhR; in which σ is interfacial tension between liquid and gas; θ is contact angle of the liquid; r is radius of the micro hollow form; ω is angular speed; ρ is density of metal; h is height of the mold to the center of gravity and R is radius of rotation. Assuming the contact angle is 180?, the flow of liquid metal could be completed only when ω2ρhR≥2σ/r. R is the constant in this study. The relation is true only when ω increases sharply with decreasing r under 200 μm. It can be shown in Figs.4-6.

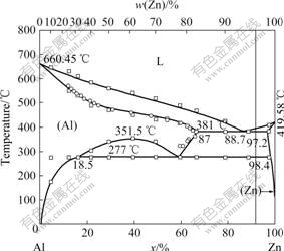

Additionally, with increasing mold temperature, the flow length is increased. In other words, the influence of solidification on flow length is important as mold temperature increases. It is presented in Figs.4-6 that at mold temperature of 270 ℃ the flow length increases more significantly than that at other mold temperatures. This may be due to the physical properties of Zn-Al alloy. Fig.7 shows the phase diagram of Zn-Al alloy[17]. The black line in Fig.7 represents the composition of alloy used in present study. The mold temperature of 270 ℃ is close to the temperature of an eutectoid transformation of the used alloy, 277 ℃. The fine precipitations begin to appear at the temperature of eutectoid transformation. This is likely to be benefit for the form filling.

Fig.7 Phase diagram of Zn-Al alloy[17]

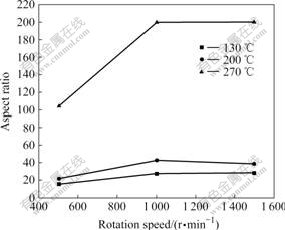

Fig.8 shows the maximum aspect ratio of the microwires in different diameters at various mold temperatures and rotational speeds. The achievable maximum aspect ratio is 200. The aspect ratio of casting micro structure increases as the mold preheating temperature increases. It can be shown that for Zn-4%Al alloy the mold temperature is important not only for filling a microchannel, but also for producing high aspect ratio structure. It is therefore suggested that the mold temperature of 270 ℃ should be used.

Fig.8 Aspect ratio of casting microwires at various mold temperatures and rotational speeds

5 Conclusions

1) A new centrifugal micro precision casing technology based on gypsum-bonded investment casting was used to produce the micro structure.

2) For microcasting, the flow length is dependent not only on the centrifugal speed under the constant of centrifugal radius, but also on the preheating temperature of mold. The experimental results of casting Zn-4%Al present that the flow length increases as the rotational speed and the mold temperature increase. For filling form, the pressure produced by centrifugal rotation is much higher than the capillary pressure caused by the surface tension.

3) The temperature of eutectoid transformation (277 ℃) is important for filling form. The experimental results show that the flow length is much higher at the mold temperature of 270 ℃ than that at other mold temperatures. Meanwhile, the microwires of high aspect ratio are obtained in the case of the centrifugal speed of 1 500 r/min and the mold temperature of 270 ℃, and the aspect ratio is up to 200 for Zn-4%Al.

References

[1] BECHER E W, EHRFELD W, HAGMANN P, MANER A, M?NCHMEYER D. Fabrication of microstructures with high aspect ratios and great structural heights by synchrotron radiation lithography, galvanoforming and plastic moulding(LIGA process) [J]. Microelectron Eng, 1986, 4(1): 35-56.

[2] RUPRECHT R, BENZLER T, HANEMANN T, M?LLER K, KONYS J, PIOTTER V, SCHANZ G, SCHMIDT L, THIES A, W?LLMER H, HAUBELT J. Various replication techniques for manufacturing three-dimensional metal microstructures [J]. Microsyst Technol, 1997, 4(1): 28-31.

[3] FU G, LOH N H, TOR S B, MURAKOSHI Y, MAEDA R. Replication of metal microstructures by micro powder injection molding [J]. Mater Des, 2004, 25(8): 729-733.

[4] PAUL-HENRI'S H, DOMINIEK R, HENDRIK V B. Micro-structuring of silicon by electro-discharge machining (EDM)—part I: Theory [J]. Sens Actuator A—Phys, 1997, 60(3): 212-218.

[5] PAUL-HENRI’S H, DOMINIEK R, HENDRIK V B. Micro-structuring of silicon by electro-discharge machining (EDM)—part Ⅱ: Applications [J]. Sens Actuator A—Phys, 1997, 61(3): 379-386.

[6] LI Bang-sheng, REN Ming-xing, YANG Chuang, FU Heng-zhi. Microstructure of Zn-Al4 alloy microcastings by micro precision casting based on metal mold [J]. Trans Nonferrous Met Soc China, 2008, 18(2): 327-332.

[7] BAUMEISTER G, RUPRECHT R, HAUSSEKT J. Microcasting of parts made of metal alloys [J]. Microsyst Technol, 2004, 10(3): 261-264.

[8] BAUMEISTER G, RUPRECHT R, HAUSSEKT J. Replication of LIGA structures using microcasting [J]. Microsyst Technol, 2004, 10(7): 484-488.

[9] BAUMEISTER G, MURLLER K, RUPRECHT R, HAUSSELT J. Production of metallic high aspect ratio microstructures by microcasting [J]. Microsyst Technol, 2002, 8(2): 105-108.

[10] THIAN S C H, TANG Y, TAN W K, FUH J Y H, WONG Y S, LOH H T, LU L. The manufacture of micromould and microparts by vacuum casting [J]. Int J Adv Manuf Technol, 2008, 38: 944-948.

[11] BATH J, DUBOVICK W A, MEEDER F H, PORTER C H, RAUSCH J H, SCHWEDES L R. Investment casting handbook [M]. Chicago: Thiessen, 1968: 3-9.

[12] PHILBROOK B F. Casting fillings [M]. Iowa State Dent Soc Trans, 1897: 277-279.

[13] TAGGART W H. A new and accurate method of making gold inlays [J]. Dental Cosmos, 1907, 47: 1117-1121.

[14] TSAO L C, CHUANG J C. A study of microstructure and high aspect ratio of Sn-36Pb-2Ag alloy by microcasting technology [J]. Journal of Taiwan Foundry Society, 2005, 31(2): 16-22. (in Chinese)

[15] ZHANG Ming, ZHANG Wei-wen, ZHAO Hai-dong, ZHANG Da-tong, LI Yuan-yuan. Effect of pressure on microstructures and mechanical properties of Al-Cu-based alloy prepared by squeeze casting [J]. Trans Nonferrous Met Soc China, 2007, 17(3): 496-501.

[16] LIU Xiao-bo, XU Qing-yan, JING Tao, LIU Bai-cheng. Microstructure of aluminum twin-roll casting based on cellular automation [J]. Trans Nonferrous Met Soc China, 2008, 18(4): 944-948.

[17] OKAMOTO H. Comment on Al-Zn [J]. J Phase Equilib, 1994, 15: 125-126.

(Edited by LI Xiang-qun)

Corresponding author: YANG Chuang; Tel: +86-451-86403268; E-mail: crbs2006@hit.edu.cn