文章编号:1004-0609-(2006)03-0400-06

挤压铸造工艺对汽车空调器摇盘组织和性能的影响

胡茂良1, 赵 密1, 吉泽升1, 孙光滨2, 朴永吉2

(1. 哈尔滨理工大学 材料科学与工程学院, 哈尔滨 150040;

2. 牡丹江富通汽车空调有限公司, 牡丹江 157003)

摘 要: 选用4A11铝合金, 利用挤压铸造技术生产汽车空调器摇盘。 当浇注温度为740℃, 模具预热温度280℃, 施加的压力1900kN, 即比压为139.45MPa时, 摇盘的力学性能最好。 在最佳工艺参数条件下, 摇盘的强度σb为310~330MPa; 维氏硬度HV0.1为100~110; 延伸率能达到9%, 摇盘的微观组织良好, Si颗粒分布均匀, 无严重粗化现象, 摇盘表面及内部无冷隔、 气孔、 缩孔、 裂纹等缺陷。 通过对拉伸断口分析, 进口制件和最佳工艺下形成的制件都具有韧窝断口特征, 进口制件断口韧窝较多, 其相对塑性较高, 最佳工艺条件下制件的韧窝较大。

关键词: 空调器摇盘; 挤压铸造; 显微组织; 力学性能 中图分类号: TG249; TG316

文献标识码: A

Effect of squeezing casting technology on structures and

properties of air-conditioner swaying tray of automobile

HU Mao-liang1, ZHAO Mi1, JI Ze-sheng1, SUN Guang-bin2, PIAO Yong-ji2

(1. School of Materials Science and Engineering,

Harbin University of Science and Technology, Harbin 150040, China;

2. Mudanjiang Foton Automobile Air Conditioner Co. Ltd, Mudanjiang 157003, China)

Abstract: The air-conditioner swaying tray of automobile made of 4A11 aluminum alloy was manufactured by squeezing casting technology. When the pouring temperature is 740℃, the preheating temperature of the die set is 280℃ and the applying pressure is 1900kN (139.45MPa), the mechanical property of swaying tray is the finest. Under the condition of the optimal technological parameters, the tensile strength, Vickers hardness (HV0.1) and elongation of swaying tray reach 310-330MPa, HV100-110, 9%, respectively. The microstructures of swaying tray are fine, Si grains are uniformly distributed and no phenomena of coarsening are observed, and the surface and inside of swaying tray have no cold shut, gas cavity, shrinkage cavity and crack, etc. By means of analyzing tensile fractures, the importing pieces and the pieces with the optimal technological parameters both have the fracture characteristics of the dimple. The number of dimples of the importing pieces are greater, so the plasticity is higher. The dimples of the pieces with the optimal technological parameters are bigger.

Key words: air-conditioner swaying tray; squeezing casting; microstructure; mechanical property

挤压铸造是一种高效经济的工艺成形方法, 是一种借鉴于压力铸造和普通热模锻工艺而发展起来的金属加工工艺, 其工艺参数灵活性较大, 决定了成形制件的组织和性能。 在工业发达国家, 挤压铸造成形完全依赖于技术创新和研究成果开发, 即原创性研究。 国内在挤压铸造成形方面的研究也取得了显著成绩, 越来越受到学者和厂家的重视[1-3]。

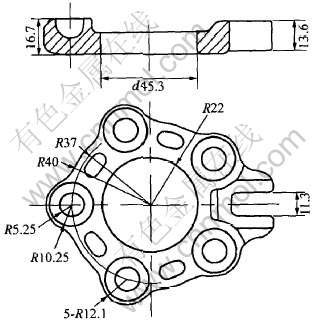

汽车空调器摇盘在工作过程中, 5个凹孔传动力较大, 随着方向改变, 键槽处易受到冲击, 要求σb≥280MPa; δ≥10%; HV0.1为100~120, 零件在100℃下台架试验1500h无形状尺寸变化, 摇盘表面及内部要求无冷隔、 气孔、 缩孔、 裂纹等缺陷, 其结构简图见图1。 采用金属型重力铸造或金属压力铸造, 其性能满足不了工作环境要求。 采用挤压铸造成形制件, 力学性能尤其是塑性显著提高, 且具有减少或消除缩孔、 缩松、 冷隔、 气孔和裂纹等缺陷, 减轻偏析, 细化和改善组织等优点。 为了获得优质的摇盘制件, 本文作者研究了挤压铸造过程中压力(比压)、 铝合金液浇注温度、 模具预热温度对摇盘制件组织和性能的影响, 优选出成形制件最佳工艺参数, 为提高摇盘的性能和成品率提供依据。

图1 汽车空调器摇盘结构简图

Fig.1 Schematic of air-conditioner swaying tray of automobile (Unit: mm)

1 实验

在石墨坩埚电阻炉内熔化和精炼4A11铝合金, 用定量勺浇入模具型腔, 采用挤压铸造工艺, 在THP16-200挤压铸造液压机上成形摇盘制件。 摇盘在性能测试和台架实验之前, 还需进行固溶时效处理, 采用T6工艺, 条件为(535±5)℃保温3h淬火, (175±5)℃保温6h回火。

组织观察在GX71-6230A(日本产)型金相显微镜上进行, 选用Al2O3为抛光剂, 绒布抛光, 4%硝酸酒精腐蚀显示金相显微组织。 由于受到摇盘结构和尺寸的限制, 拉伸试样只能加工成非标准试样, 比例试样标距l0为

式中 K取4.52, S0为矩形试样面积, 取样具体位置和尺寸如图2和图3所示。 在WDW-10型微机控制电子万能实验机上进行拉伸实验, 在日本瑞利公司生产的S-4700扫描电子显微镜(加速电压20.0kV)上进行断口形貌观察。

图2 摇盘拉伸试样线切割位置示意图

Fig.2 Positional sketch of swaying tray using linear incision

图3 摇盘拉伸试样尺寸示意图

Fig.3 Dimensional sketch of tensile sample of swaying tray (Unit: mm)

2 结果与讨论

2.1 压力对摇盘组织和性能的影响

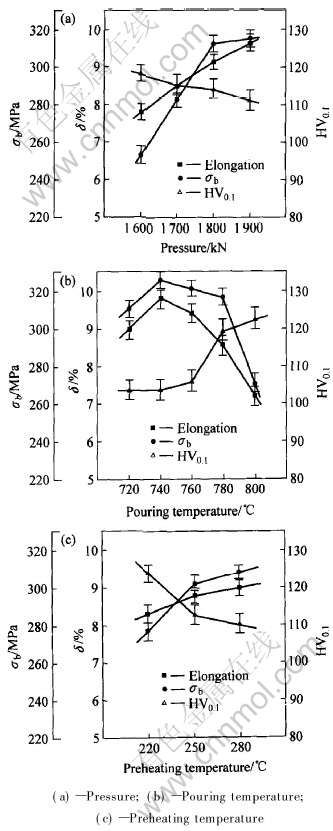

图4(a)所示为在浇注温度760℃, 模具预热温度240℃条件下压力对摇盘力学性能的影响。 由图可见, 随着压力的增加, 摇盘制件的抗拉强度和延伸率均提高。 当压力为1900kN时抗拉强度达到315MPa, 延伸率大于或等于9%, 维氏硬度110左右, 制件获得了较好的综合力学性能。 进一步提高压力, 维氏硬度下降, 抗拉强度和延伸率略有增加。

施加的压力是摇盘成形重要的工艺参数, 因为压力对铝合金液结晶过程、 制件的热量分布和制件与模具间的传热都有重要的影响, 对摇盘的力学性能指标、 表面质量和内部组织都有影响[4, 5]。 压力的提高会直接缩短凝固时间, 从而提高凝固速度, 压力太小不利于制件的补缩和细化组织, 5个圆台不易充满, 提高压力可以强制除去铝合金液中的气体, 压实缩孔和缩松, 从而使摇盘缺陷降低, 但会降低模具寿命, 增加动力消耗和设备费用。

图4 工艺参数对摇盘力学性能的影响

Fig.4 Effect of technological parameters on mechanical properties of swaying tray

挤压铸造属于铸锻结合的工艺, 铸造成形的一些规律同样适用于挤压铸造, 在成形过程中凝固形核率提高, 组织变细。 未热处理时, 金相组织无明显变化, 如图5所示。 制件热处理后, 随着比压的增加, 结晶组织越致密, Si颗粒越细小[6-8], 越均匀, 对制件强制性补缩作用增强。

图5 摇盘未热处理时的微观组织

Fig.5 Microstructure of swaying tray without heat treatment

2.2 浇注温度对摇盘组织和性能的影响

图4(b)所示为在压力1800kN, 模具预热温度240℃条件下铝合金液浇注温度对摇盘力学性能的影响。 由图可见, 随着浇注温度的增加, 摇盘制件的抗拉强度和延伸率均降低。 当浇注温度为740℃时抗拉强度达到320MPa, 延伸率大于或等于9%, 维氏硬度100左右, 制件获得较好的综合力学性能。 进一步降低浇注温度, 抗拉强度和延伸率下降, 维氏硬度不变。

浇注温度太高会使铝合金液吸气, 氧化严重, 会造成制件中缺陷过多, 影响其力学性能。 另外, 浇注温度太高, 还会使结晶形核需要的临界过冷形成过程减慢。 如果液压机的下行速度过快就会使形核率大大降低, 使组织粗化严重, 缺陷增多, 力学性能降低[9-12]。 这时候即使加大施加的压力, 晶粒细化效果也不明显。

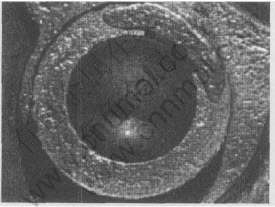

当浇注温度低于720℃时, 在模壁的快速冷却下, 一部分液体已经凝固, 失去加压的作用, 摇盘5个凹孔处极易产生缩松、 缩孔和裂纹, 如图6所示。 同时与压力下流动充型凝固的液体之间产生冷隔, 宏观上产生分层, 如图7所示。

2.3 预热温度对摇盘组织和性能的影响

由于摇盘壁薄且尺寸变化较大, 模具必须预热。 图4(c)所示为在压力1800kN、 铝合金浇注温度760℃条件下模具预热温度对摇盘力学性能的影响。 由图可见, 随着预热温度的增加, 摇盘制件的抗拉强度和延伸率均增大。 当模具预热温度为280℃时抗拉强度达到300MPa, 延伸率≥9%, 维氏硬度110左右, 制件获得较好的综合力学性能。

图6 凹孔处缩孔和裂纹

Fig.6 Shrinkage porosity and crack in hollowness

图7 凹孔圆台处冷隔

Fig.7 Cold shut on round platform of hollowness

凝固组织的晶粒大小与过冷度、 金属的熔化焓、 熔体的粘度等因素密切相关, 过冷度越高, 晶粒越小[13, 14]。 预热温度的降低, 有利于获得细小的晶粒, 如图8(a)、 (b)和(c)所示, 预热温度低, Si颗粒越细。 模具预热温度过高, 形核率降低, 使结晶组织粗大、 不均匀, 甚至造成粗化严重, 使摇盘的力学性能反而降低, 如图8(d)所示。

从受力的角度讲, 组织要求越细越好。 因为细晶粒对受力而产生的变形均匀, 每个晶粒的变形几乎相差不多, 这样就能把宏观受到的较大的力的作用平均分配到每个晶粒上, 每个晶粒产生相应的变形, 微观应力达到晶粒所能承受的极限时, 就会发生破坏。 另外, 晶粒细小使得晶界面积增大, 每个晶粒晶界的受力在微观上就会相应小一些, 会使宏观上的受力分配到微观晶界上相应减少, 使力学性能提高。 如果晶粒粗大, 会使晶界面积减少, 这样晶界的平均受力就会相应增加, 使力学性能不好。 但从图8(a)所示可以看出, Si颗粒偏聚较多, 导致力学性能有一些下降。

图8 不同预热温度下的微观组织

Fig.8 Microstructures at different preheating temperatures

2.4 其他工艺参数

采用挤压铸造工艺生产汽车空调器摇盘过程中, 还须考虑如下工艺参数:加压开始时间、 保压时间、 铝合金熔炼、 模具的润滑等[15]。

加压开始时间以铝合金液冷却到不低于其固相线温度为准, 根据实际经验, 加压开始时间应控制在5s以内。 为了尽可能地避免缩松和缩孔, 保压时间不宜太短, 控制在50s左右。 润滑剂选用石墨机油, 即按5∶95的质量比将粒径在44~74μm之间的石墨粉加入到机油中, 搅拌均匀即可, 用喷枪均匀喷涂。 铝合金块在加入熔炼炉之前, 表面必须清理干净。 熔炼过程中可选用2号精炼熔剂, 液体仔细除气精炼, 平稳浇注, 防止气孔影响摇盘的力学性能和表面质量。 浇勺要及时清理干净, 浇注过程中有未熔的金属料或沉淀物时, 不进行浇注。 浇注之前可把浇勺放入坩埚中预热, 夹杂在摇盘工作过程中产生破坏作用。

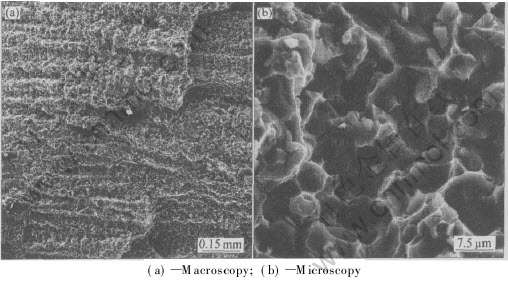

2.5 断口分析

挤压铸造是一种优质、 高效的工艺方法, 只要各工艺环节控制合理, 就能保证做出内部组织致密、 表面光洁、 力学性能优良的摇盘制件。 在保证其他工艺参数不变的条件下, 选取在压力为1900kN, 浇注温度740℃, 模具预热温度280℃下制得的试样, 与韩国进口摇盘制件进行比较。

从图9(a)和10(a)所示的宏观断口可以看出, 两种条件下的摇盘制件都呈现一种伴随大量塑性形变的断裂方式, 断口为纤维状, 只是方向不同。 从图9(b)和10(b)所示的微观断口可以看出, 两种材料成形的制件拉伸断口都呈韧窝状断口的特征, 都是由一些大小不等的圆形或者椭圆形的凹坑——韧窝所组成。 在韧窝中可以看出含有脆性相。 微观断口形貌有等轴韧窝的特点, 主要是拉伸作用在断口表面上分布均匀, 显微孔洞沿空间三个方向上均匀长大, 形成等轴韧窝。 进口摇盘断口的韧窝较多, 其相对塑性较高, 本实验最佳工艺条件下的试样韧窝较大。

图9 进口摇盘制件拉伸断口形貌

Fig.9 Tensile fracture morphologies of imported swaying tray

图10 最佳工艺参数条件下摇盘制件拉伸断口形貌

Fig.10 Tensile fracture morphologies of swaying tray with optimal technological parameters

3 结论

1) 在浇注温度为740℃, 模具预热温度280℃, 施加的压力1900kN, 即比压为139.45MPa时, 摇盘的力学性能最好。 在最佳工艺参数条件下, 摇盘的强度σb为310~330MPa; 维氏硬度HV0.1为100~110; 延伸率能达到9%。

2) 通过对摇盘组织的分析, 可以看出选用4A11铝合金在挤压铸造工艺下成形, 摇盘的微观组织良好, 大部分试验制件的微观组织均匀, Si颗粒分布均匀, 无严重粗化现象, 摇盘表面及内部无冷隔、 气孔、 缩孔、 裂纹等缺陷。

3) 通过对拉伸断口分析, 进口制件和最佳工艺下形成的制件都具有韧窝断口特征, 进口制件断口韧窝较多, 其相对塑性较高, 最佳工艺条件下的试样韧窝较大。

REFERENCES

[1]Yue T M, Chadwick G A. Squeezing casting of light alloys and their composites[J]. Journal of Materials Processing Technology, 1996, 58: 302-307.

[2]罗继相, 白旭白, 谌伟, 等. 铝合金挤压铸造技术的研究与应用[J]. 铸造, 2002, 51(8): 464-469.

LUO Ji-xiang, BAI Xu-bai, CHEN Wei, et al. Study and application on squeezing casting technology of aluminium alloys[J]. Foundry, 2002, 51(8): 464-469.

[3]齐丕骧. 国内外挤压铸造技术发展概况[J]. 特种铸造及有色合金, 2002, 22(2): 20-23.

QI Pi-xiang. Survey of squeezing casting technology development home and abroad[J]. Special Casting & Nonferrous Alloys, 2002, 22(2): 20-23.

[4]WANG Hong-wei, WEI Zun-jie, ZENG Song-yan. Grain refinement and mechanical improvement of casting A357 alloy by high pressure differential pressure casting process[J]. Trans Nonferrous Met Soc China, 2005, 15(S2): 124-127.

[5]Yin F, Wang G X, Hong S Z, et al. Technological study of liquid die forging for the aluminum alloy connecting rod of an air compressor[J]. Journal of Materials Processing Technology, 2003, 139: 462-464.

[6]Cabibbo M, Evangelista E, Moschini R, et al. Kinetics of precipitation and mechanical properties of a semi-solid A357 aluminum alloy subjected to T5 and T6[A]. Proceedings of the 8th S2P2004[C]. Limassol, Cyprus, 2004.

[7]Deepak S, Diran A, Rathindra D G. SSM processing of hypereutectic Al-Si alloys — An overview[A]. Proceedings of the 8th S2P2004[C]. Limassol, Cyprus, 2004. 12.

[8]Hiroyuki T, Jun K, Toshiro K, et al. Assessment of thermo-mechanical fatigue behaviors of cast Al-Si alloys by experiments and muti-step numerical simulation[J]. Materials Transactions, 2005, 46(1): 111-117.

[9]郭洪民, 杨湘杰, 胡斌. 转动输送管制浆工艺参数对A356合金半固态组织的影响[J]. 中国有色金属学报, 2004, 14(12): 2049-2054.

GUO Hong-min, YANG Xiang-jie, HU Bin. Effects of parameters of slurry-making process with rotating duct on semi-solid microstructure of A356 alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(12): 2049-2054.

[10]Ivan E. Physical property measurements of liquid metals at high temperatures under microgravity[J]. Materials Transactions, 2004, 45(12): 3235-3240.

[11]XUE Xiang, LI Hong-wei. Influence of pressure on shrinkage porosity prediction[J]. Trans Nonferrous Met Soc China, 2005, 15(S2): 217-221.

[12]Yang L J. The effect of casting temperature on the properties of squeeze cast aluminium and zinc alloys[J]. Journal of Materials Processing Technology, 2003, 140: 391-396.

[13]胡茂良, 赵密, 吉泽升, 等. 汽车空调器摇盘挤压铸造模具设计及工艺研究[J]. 特种铸造及有色合金, 2005, 25(3): 155-157.

HU Mao-liang, ZHAO Mi, JI Ze-sheng, et al. Design of die casting die for air-conditioner swaying tray of automobile in squeezing casting[J]. Special Casting & Nonferrous Alloys, 2005, 25(3): 155-157.

[14]MA Xu-liang, WANG Hong-wei, ZENG Song-yan. Effects of cooling rate on microstructure and mechanical properties of A357 alloy during differential pressure casting process[J]. Trans Nonferrous Met Soc China, 2005, 15(S2): 128-131.

[15]Shih T S, Wen K Y. Effects of degassing and fluxing on the quality of Al-7%Si and A356.2 alloys[J]. Materials Transactions, 2005, 46(2): 263-271.

基金项目: 哈尔滨市青年科学研究基金资助项目(2003AFTXJ015)

收稿日期: 2005-09-06; 修订日期: 2005-12-12

作者简介: 胡茂良(1980-), 男, 博士研究生

通讯作者: 胡茂良, 博士研究生; 电话: 0451-86392557; E-mail: humaoliang1980@163.com

(编辑何学锋)