文章编号:1004-0609(2011)04-0836-07

喷涂用MoSi2粉末的制备及其在等离子弧中的熔化特性

颜建辉1,张厚安2,徐红梅1,吴海江1,唐思文1

(1. 湖南科技大学 新材料制备及应用技术研究所,湘潭 411201;

2. 厦门理工学院 机械工程系,厦门 361024)

摘 要:采用喷雾干燥和真空烧结技术制备MoSi2团聚颗粒,以MoSi2团聚粉末为原料,通过大气等离子喷涂法制备二硅化钼涂层,借助XRD、扫描电镜及能谱对团聚体粉末在等离子焰流中的熔化特性和涂层的组织结构进行研究。结果表明:团聚粉末在1 200 ℃真空热处理1 h后,粉末的流动性和松装密度分别提高55.6%和42.0%,适合等离子喷涂用。MoSi2颗粒经过高温等离子焰流后,粉末熔化充分,大多数团聚体粉末发生烧结过程,颗粒的平均粒度减小,形成较致密的球形颗粒。在喷涂过程中,部分四方相MoSi2(t)转变为六方相MoSi2 (h)或氧化形成了少量的Mo5Si3相,涂层中的富钼相呈“网状”组织结构。

关键词:MoSi2涂层;喷雾干燥;等离子喷涂;熔化特性

中图分类号:TQ174.5 文献标志码:A

Preparation of MoSi2 powder used for plasma-spraying and its melting characteristics in plasma arc

YAN Jian-hui1, ZHANG Hou-an2, XU Hong-mei1, WU Hai-jiang1, TANG Si-wen1

(1. Advanced Materials Synthesis and Application Technology Institute,

Hunan University of Science and Technology, Xiangtan 411201, China;

2. Department of Mechanical Engineering, Xiamen University of Technology, Xiamen 361024, China)

Abstract: The MoSi2 powder used for air plasma spraying was prepared by spray drying and vacuum sintering. By using MoSi2 powders as the raw powders, MoSi2 coating was prepared using air plasma spraying. The melting characteristics of MoSi2 powders in the plasma arc and the microstructures of the coating were studied by scanning electron microscopy (SEM) with energy dispersive spectroscopy (EDS) and X-ray diffraction (XRD). The results show that, when the powders are sintered at 1 200 ℃ for 1 h, the mobility and loose density of powders increase by 42.0% and 55.6%, respectively. Most MoSi2 particles occur during the sintering process, and the average particle sizes of the powders decrease after the MoSi2 powders pass through the high temperature plasma flame. MoSi2 particles are fully melted and the dense spherical particles are formed. During air plasma spraying, part of the tetragonal MoSi2 (t) phase changes into MoSi2 (h) crystal structure or oxidize to form Mo5Si3 phase. The microstructure of molybdenum-rich phase in the MoSi2 coating is similar to the “mesh” structure.

Key words: MoSi2 coating; spray-drying; plasma spraying; melting characteristics

金属间化合物MoSi2由于具有优异的高温抗氧化性能,常用于改善高温合金、难熔金属、石墨以及C/C复合材料的高温抗氧化性能[1]。如MUELLER等[2]认为,铌基片上的(Mo,W)(Si,Ge)2涂层在1 370 ℃的空气中1 h内可承受循环氧化200次,在1 540 ℃下1 h内可承受循环氧化60次,且在500~700 ℃于空气中暴露200 h后也未出现低温加速氧化或“粉化”现象。肖来荣等[3]在铌合金表面制备Mo(Si0.6,Al0.4)2高温抗氧化涂层,高温产生的氧化膜外层主要为Al2O3,内层为Al2O3、SiO2、Al2O3-2SiO2和HfO2的混合物。曾燮榕等[4]和LI等[5]在C/C复合材料试样表面制备致密的MoSi2基复合涂层,该涂层具有很好的抗氧化性能。由此可见,MoSi2基复合材料是一种极具价值的高温涂层材料。

采用料浆烧结法[6]、包埋法[7]、气相沉积法[8]、熔盐法[9]和激光熔覆技术[10]等制备的MoSi2涂层与基体材料可达到冶金结合,涂层具有较好的抗热震性能和高温抗氧化性能。采用真空或低压等离子喷涂 制备MoSi2涂层与基体的结合主要是机械或物理结合[11]。包渗法要求在高温下长时间扩散,试样尺寸受到限制,基材性能易发生变化。气相沉积法制备的涂层,成分变化有限,表面厚度太薄。激光熔覆制备涂层时成型不太好,孔洞较多,不适用于形状复杂的工件。相对而言,采用等离子喷涂技术,基体材料变形小,涂层成分可在较大范围内变化,厚度容易控制。

自蔓延合成的MoSi2粉末(平均粒度约为9.68 μm)在等离子喷涂时流动性较差,粉末出现“发飘”现象,最主要的问题是MoSi2在喷涂过程易氧化生成富钼 相[12]。本文作者以粒度1~2 μm的MoSi2粉末为原料,通过造粒制备MoSi2球形粉末。将经过等离子火焰中的MoSi2喷入蒸馏水中,观察水中收集粉末颗粒的微观组织结构,揭示MoSi2团聚体粉末在等离子喷涂过程中的熔化特性,为等离子喷涂方法制备MoSi2涂层提供理论依据。

1 实验

将自蔓延高温合成的MoSi2粉末在行星式球磨机(转速为200 r/min,球料比为20?1)中破碎3 h使粒度达到1~2 μm。然后,将PVA溶于蒸馏水中形成4%PVA的水溶液,将粒度为1~2 μm的MoSi2与PVA溶液混合。由于细MoSi2粉末颗粒比表面大而容易团聚,故先采用超声波分散技术将MoSi2颗粒在液体中离解分散,然后在周期式搅拌球磨机中加入球磨介质,获得组分均匀的浆料,最后采用LX-10型离心造粒喷雾干燥机将上述浆料进行喷雾干燥造粒。MoSi2团聚粉末的热处理在钼丝真空烧结炉中进行。

MoSi2粉末粒度采用Winnner2000激光粒度测试仪进行测试。粉末松装密度采用标准漏斗法进行测试。用GB1482—84金属粉末流动性的测定标准漏斗法(霍尔流速计)来测量MoSi2粉末热处理前后的流动性,以50 g金属粉末流过规定的孔径(d 2.5 mm)的标准漏斗所需要的时间来表示。上述测量均重复3次,取其平均值。

采用北京航空工艺研究所生产的APS-2000型大气等离子喷涂系统进行喷涂,将MoSi2团聚热处理后粉末喷入蒸馏水中(喷涂工艺参数见表1)。图1所示为粉末收集装置示意图,收集容器与喷枪之间的距离为100 mm。同时,以相同的喷涂工艺参数制备MoSi2涂层。

利用德国D8-Advance型全自动X射线衍射仪检测粉末和涂层的物相组成,采用JSM-5100LV扫描电镜观察粉末和涂层的形貌。

表1 MoSi2喷涂工艺参数

Table 1 Spraying process parameters of MoSi2

图1 粉末收集装置示意图

Fig.1 Schematic diagram of collecting powders from water

2 结果与讨论

2.1 喷雾干燥制备MoSi2粉末的特性

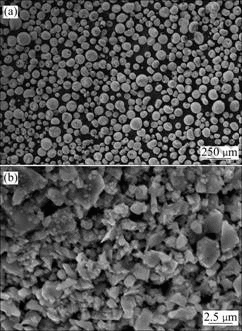

图2所示为喷雾干燥所得到的MoSi2团聚粉末的SEM像。从图2(a)可知,喷雾干燥法制备的MoSi2团聚粉末球形度较好。图2(b)所示为单个团聚MoSi2粉末表面高倍形貌。球形团聚粉末是由许多不规则的细MoSi2粒子通过粘结剂结成的球形颗粒,由于原始细MoSi2粉末颗粒的团聚仅仅是通过粘结剂的作用而结合在一起,其结合不强、孔隙较多,表面较粗糙。该

图2 喷雾干燥团聚MoSi2粉末的形貌

Fig.2 Surface morphologies of spray drying MoSi2 powders

粉末的流动性为0.77 s/g,松装密度为1.48 g/cm3。这种粉末如果不进行热处理而直接进行喷涂,粉末经过等离子喷枪熔化后的液滴呈“雾状”,严重影响粉末的沉积效率和涂层质量。

2.2 真空热处理对MoSi2团聚粉末性能和微观组织的影响

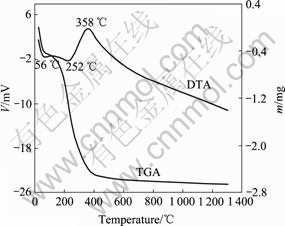

图3所示为喷雾干燥制备的MoSi2粉末的DTA- TGA曲线。从图3可知,在100 ℃左右时,粉末质量有一次明显降低,这是由于粉末中水分的蒸发所造成;在200~400 ℃又有一次显著降低,说明粉末中的有机

图3 MoSi2团聚粉末DTA-TGA曲线

Fig.3 DTA-TGA curves of agglomerated MoSi2 powders

粘结剂在此温度下开始分解;随后随着温度升高,粉末质量慢慢减少;到500 ℃左右,粉末中粘结剂的燃烧己经完成,粉末质量趋于稳定。从图3还可以看出,粉末在56 ℃时有一个吸热峰,说明在此过程中粉末吸收热量,水分开始蒸发。另一个显著的吸热峰出现在252 ℃,这表明此温度为粘结剂开始分解的温度。358℃的放热峰,归因于团聚体粉末中有机物燃烧放热量的缘故。根据MoSi2粉末的DTA-TGA曲线图,制定的MoSi2团聚粉末的真空热处理工艺曲线如图4所示。

图4 MoSi2团聚粉末真空热处理曲线

Fig.4 Heat treatment curve of agglomerated MoSi2 powders

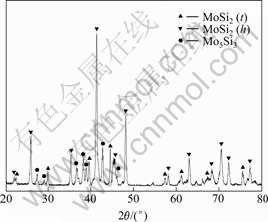

图5所示为喷雾干燥粉末经1 200 ℃真空热处理 1 h后和水中收集粉末的XRD谱。比较图5(a)和(b)可知,真空热处理后,粉末主相还是MoSi2(t),但出现了极少量的Mo5Si3相。Mo5Si3的存在,主要是在真空炉中,MoSi2粉末发生了轻微氧化的缘故。由图5(c)可看出,物相主要由四方相(t)和六方相(h)MoSi2组成,还含有少量四方相的Mo5Si3,但未观察到SiO2相。与真空热处理喷涂粉末(图5(b))相比较,喷涂后Mo5Si3相衍射峰强度有所增加,表明MoSi2发生氧化反应生成了Mo5Si3。另外,喷涂过程中MoSi2还发生了由稳定四方相向不稳定六方相的晶体结构转变。四方相MoSi2在1 900 ℃以下是稳定相,而六方相MoSi2在 1 900 ℃以上是稳定相。MoSi2涂层的使用温度一般在1 800 ℃以下,在使用过程中六方相会全部转变为四方相。

经1 200 ℃真空热处理1 h后,粉末的流动性和松装密度分别为0.342 s/g和2.1 g/cm3,比热处理前分别增加了55.6%和42.0%。图6(a)、(b)和(c)所示为喷雾干燥MoSi2粉末经1 200 ℃热处理后的表面形貌。烧结后,颗粒的球形度稍微变差,一次颗粒(球磨后粉

图5 喷雾干燥、1 200 ℃热处理1 h和水中收集的粉末的XRD谱

Fig.5 XRD patterns of MoSi2 powders after spray drying(a), heat treatment at 1 200 ℃ for 1 h(b) and collected powders in water(c)

末)之间发生晶格或者晶界扩散,尺寸收缩,颗粒表面只存在少量不连续的气孔,从而引起粉体比表面积急剧下降。由此可见,经1 200 ℃热处理不仅将有机粘结剂烧掉,同时让二次颗粒(团聚后粉末)内部的一次小颗粒之间发生烧结,而二次颗粒之间没有任何粘接,这样大大增加一次颗粒之间的结合强度。细MoSi2粉末经喷雾干燥造粒和真空热处理后,粉末的流动性和松装密度均增加,适合大气等离子喷涂用。

图6(d)为喷雾干燥后粉末在1 200 ℃真空热处理1 h后的截面图。由图6(d)可见,喷雾造粒MoSi2热处理后的二次颗粒内部存在一些孔隙,这样的结构将会减少喷涂过程中的热传导,影响粉末的熔化;且内部气体在冷却过程中会往外排出,涂层内会产生气孔,从而影响涂层的致密度。所以,要尽量避免空心粉末的出现。

2.3 MoSi2喷雾干燥粉末在等离子弧中的熔化行为

对于喷涂材料来说,通常认为喷涂材料的充分熔化是获得致密涂层的必要条件。喷涂材料熔化不充分会导致粉末沉积率较低,涂层易形成孔隙,降低涂层性能。

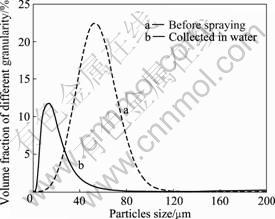

图7所示为MoSi2颗粒的粒度分布曲线。由图7可看出,喷射前粉末的平均粒度为46.29 μm,而水中收集粉末的平均粒度约为14.82 μm。喷涂前粉末的平均粒度为46.29 μm(见图7(a))。由此可见,MoSi2粉末经过等离子弧后,其粒度明显减小。其原因主要有两

图6 团聚MoSi2粉末经1 200 ℃烧结后形貌

Fig.6 Morphologies of spray drying MoSi2 powders sintered at 1 200 ℃: (a) Low magnification; (b) Single powder; (c) High magnification; (d) Section morphology of single particle

图7 MoSi2粉末的粒度分布

Fig.7 Particle size distribution of MoSi2 powders

个方面:1) 大多数MoSi2粉末在喷涂过程中在极短的时间内经过熔融烧结发生致密化的过程,导致粉末颗粒尺寸减小;2) 少量MoSi2颗粒在熔融过程中受到等离子气流的冲击发生了破碎现象。

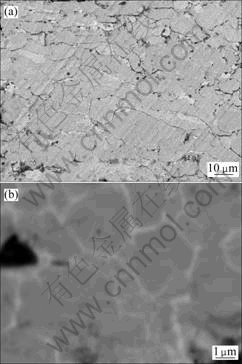

图8所示为经过等离子喷涂后从水中收集MoSi2粉末的表面形貌。由图8可以看出,MoSi2团聚体粉末经过等离子体加热、加速后大多数为单个的球形状,极少数的小颗粒焊合在一起。经过高温等离子弧后,原来较疏松、粗糙、有孔隙的表面(见图6(b)),绝大多数变为致密且光滑并呈烧结态的球形表面(见图8(b)),且颗粒内部非常致密(图8(c))。只有极少数颗粒表面仍然疏松多孔(图8(d)),基本上保持喷涂态粉末状态,这主要是由于这些粉末处于等离子火焰边缘,使得粉末熔化不充分所致。

一般来说,喷涂粉末经过大气等离子焰流并经蒸馏水淬冷作用,其冷却速率大于106 K/s,这一数值与等离子喷涂粉末撞击到基体(采用压缩空气冷却)的冷却速率相当,所以采用这种方法收集的粉末能够代表喷涂粉末在等离子喷涂过程中的熔融状态。大气等离子喷涂制备的纳米团聚ZrO2粉末颗粒只是表面一层熔融结晶的外壳,而内部全部是未熔化的粉末,仍然保留纳米结构,这主要归因于在极短的时间内不足以使团聚体内部的纳米粒子继续长大,而且多孔结构对热流的传输有一定的阻碍[13]。与作为热障涂层的纳米团聚ZrO2粉体在等离子弧中的熔化特点不同,由于MoSi2导热性好,团聚MoSi2粉末经过喷涂后,在短时间内,颗粒内外全部熔化并形成致密态的组织,说明这些粒子在喷涂过程中已经达到全部烧结状态,这种致密的颗粒在基体上经历碰撞、冷却和收缩后,易

图8 水中收集MoSi2粉末的形貌

Fig.8 Morphologies of MoSi2 powders collected in water: (a) Low magnification; (b) Surface morphology of single particle; (c) Cross-sectional morphology of single particle; (d) Unmelted particle

形成致密的MoSi2涂层。

2.4 MoSi2涂层的组织结构

图9所示为用喷雾干燥造粒团聚粉末制备的MoSi2涂层的XRD谱。图10所示为MoSi2涂层的形貌。由图9和10可看出,涂层的衍射结果与水中收集粉末的图谱非常相似,得到以六方相MoSi2为主相的涂层。MoSi2二次团聚颗粒在等离子喷涂过程中,经历了加热、加速、变形和冷却等过程。形成了典型的

图9 喷雾干燥MoSi2涂层的XRD谱

Fig.9 XRD pattern of spray drying MoSi2 coating

图10 喷雾干燥MoSi2涂层的形貌

Fig.10 Morphologies of spray drying MoSi2 coating: (a) Section morphology; (b) High magnification

层状结构,二次颗粒之间存在明显的边界和微小的孔洞,这些缺陷的存在会弱化MoSi2片层与片层之间的结合性能。撞击基体变形后的二次颗粒涂层内部很难看见一次颗粒之间的界限,其组织非常致密,内部出现了许多类似“网状”的结构,在网状的边缘界面部分是由厚度约为0.2 μm白色的物质构成,而内部呈浅灰色。通过能谱分析知道,网状内部Mo和Si摩尔比为1?2,可以推断是MoSi2;而网状的边缘界面部分的Mo和Si的摩尔比接近1?1,结合衍射结果,可以推断是MoSi2和Mo5Si3的混合物。MoSi2颗粒在飞行过程中只是熔滴表面和颗粒边界发生快速初始氧化,随后通过表面氧化物质进行扩散控制的氧化过程来不及进行,所以产生了“网状”的组织结构。MoSi2相的高温抗氧化性能非常好,而富钼相Mo5Si3的高温抗氧化性能较差,“网状”组织结构会降低涂层的高温抗氧化性能。所以,在制备涂层过程中应尽量避免富钼相的出现。

3 结论

1) 以自蔓延高温合成并破碎的MoSi2粉末(1~2 μm)为原料,采用喷雾干燥造粒后的近球形粉末的流动性为0.77 s/g,松装密度为1.48 g/cm3。在1 200 ℃真空烧结1 h后,粉末流动性和松装密度分别为0.342 s/g和2.1 g/cm3,比热处理前分别增加55.6%和42.0%,适合大气等离子喷涂用。

2) MoSi2团聚颗粒在喷涂过程中发生烧结行为,喷涂前后粉末的平均粒度由46.29 μm减小为14.82 μm,颗粒内部形成了致密的组织结构,有利于形成致密的涂层。

3) 团聚MoSi2粉末在喷涂过程中发生了晶体结构的转变,由稳定的四方相(t)部分演变为不稳定的六方相(h)。MoSi2颗粒在熔融过程中发生了氧化,形成了少量的Mo5Si3相。涂层的二次颗粒内部产生了富钼相的“网状”组织结构。

REFERENCES

[1] SMEACETTO F, FERRARICS M, SALVO M. Multilayer coating with self-sealing properties for carbon-carbon composites[J]. Carbon, 2003, 41(11): 2105-2111.

[2] MUELLER A, WANG G, RAPP R A. Oxidation behavior of tungsten and germanium-alloyed molybdenum disilicide coatings[J]. Materials Science and Engineering A, 1992, 155(1/2): 199-207.

[3] 肖来荣, 蔡志刚, 宋 成. Mo(Si, A1)2高温抗氧化涂层的形貌与结构研究[J]. 兵器材料科学与工程, 2006, 29(3): 50-53.

XIAO Lai-rong, CAI Zhi-gang, SONG Cheng. Morphology and structure of Mo(Si, Al)2 high temperature oxidation resistant coating[J]. Ordnance Material Science and Engineering, 2006, 29(3): 50-53.

[4] 曾燮榕, 李贺军, 张建国, 侯晏红, 杨 峥. 碳/碳复合材料防护涂层的抗氧化行为研究[J]. 复合材料学报, 2000, 17(2): 42-45.

ZENG Pei-rong, LI He-jun, ZHANG Jian-guo, HOU Yan-hong, YANG Zheng, Effect of microstructure and component on oxidation resistance of MoSi2-SiC multilayer ceramic coating[J]. Acta Materiae Compositae Sinica, 2000, 17(2): 42-45.

[5] LI H J, JIAO G S, LI K Z. Multilayer oxidation resistant coating for SiC coated carbon/carbon composites at high temperature[J]. Materials Science and Engineering A, 2008, 475(1/2): 279-284.

[6] 来忠红, 朱景川, 全在昊, 尹钟大. C/C复合材料Mo-Si-N抗氧化涂层的制备[J]. 稀有金属材料与工程, 2005, 34(11): 1795-1799.

LAI Zhong-hong, ZHU Jing-chuan, QUAN Zai-hao, YI Zhong-da. Fabrication of Mo-Si-N anti-oxidation coating for C/C composites[J]. Rare Metal Materials and Engineering, 2005, 34(11): 1795-1799.

[7] TANG Z H, ANDREW J, THOM M J. Characterization and oxidation behavior of silicide coating on multiphase Mo-Si-B alloys[J]. Intermetallics, 2008, 16(9): 1125-1133.

[8] 吴 恒, 李贺军, 王永杰, 付前刚, 何子博, 魏建锋. 低压沉积温度对MoSi2涂层微观结构与性能影响[J]. 无机材料学报, 2009, 24(2): 392-396.

WU Heng, LI He-jun, WANG Yong-jie, FU Qian-gang, HE Zi-bo, WEI Jian-feng. Effect of deposition temperature on microstructures and properties of MoSi2 coatings prepared by low pressure chemical vapor deposition[J]. Journal of Inorganic Materials, 2009, 24(2): 392-396.

[9] SUZUKI R O, ISHIKAWA M, ONO K. MoSi2 coating on molybdenum using molten salt[J]. Journal of Alloys and Compounds, 2000, 306(1): 285-291.

[10] HIDOUCI A, PELLETIER J M. Microstructure and mechanical properties of MoSi2 coatings produced by laser processing[J]. Materials Science and Engineering A, 1998, 252(1): 17-26.

[11] REISEL G, WIELAGE B, STEINHAUSER S, MORGENTHAL I, SCHOLL R. High temperature oxidation behavior of HVOF-sprayed unreinforced and reinforced molybdenum disilicide powders[J]. Surface and Coatings Technology, 2001, 19(1/3): 146-147.

[12] 颜建辉, 张厚安, 李益民, 唐思文. 离子喷涂及真空热处理过程中MoSi2涂层的相演变[J]. 焊接学报, 2008, 32(8): 29-33.

YAN Jian-hui, ZHANG Hou-an, LI Yi-min, TANG Si-wen. Phases evolution of molybnenum silicide coating in plasma spraying and heat treatment process[J]. Transactions of the China Welding Institution, 2008, 32(8): 29-33.

[13] HUREVICH V, MINSK B, PAWLOWSKI L. Heating of porous particles in the plasma flame[C]// Proceedings of the 2003 International Thermal Spray Conference. OH, German: ASM International, Materials Park, 2002: 32.

(编辑 李艳红)

基金项目:国防基础研究资助项目(A3720060115);湖南省科技计划项目(2010GK3144)

收稿日期:2010-01-19;修订日期:2010-06-03

通信作者:颜建辉,副教授,博士;电话:0731-58290847;E-mail: yanjianhui88@163.com