DOI: 10.11817/j.ysxb.1004.0609.2020-36341

淬火速率对含Sc(Zr)高强韧Al-Zn-Mg-Cu合金微观组织和力学性能的影响

李芳芳1,徐国富1, 2,李 耀1,黄继武1, 2,邓 英1, 2,尹志民1, 2

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 有色金属材料科学与工程教育部重点实验室,长沙 410083)

摘 要:通过末端淬火实验(JEQ)、X射线衍射仪(XRD)、扫描电镜(SEM)、透射电子显微镜(TEM)研究一种热挤压Al-Zn-Mg-Cu-Sc-Zr棒材的淬火敏感性。结果表明:随着距离淬火端越远,冷却速率从1800 ℃/min下降至111 ℃/min,合金硬度从150 HB下降至133 HB,抗拉强度从430 MPa下降至375 MPa。当冷却速率为131.2 ℃/min时,合金的硬度为135 HB,合金淬透深度约为93mm。随着冷却速率的降低,端淬时远离淬火端位置,平衡η相先后在晶界、晶内处析出、长大、粗化;时效后,析出的η′强化相的数量减小;时效后,合金内出现无沉淀析出带(PFZ),晶界的PFZ变宽,宽化至160 nm。

关键词:Al-Zn-Mg-Cu-Sc-Zr合金;淬火敏感性;力学性能;显微组织

文章编号:1004-0609(2020)-02-0264-09 中图分类号:TG146.2 文献标志码:A

7xxx铝合金因为具有低密度、高强度、好的加工性能等特点被广泛的应用于航空航天和汽车等领域[1-2]。在Al合金所有的微合金化添加元素中,Sc、Zr对于开发具有优良的力学性能、焊接性能、腐蚀性能的新型轻质结构材料有着最显著的潜力[3]。研究表明,微量元素Sc、Zr在Al合金中以Al3(Sc,Zr)弥散粒子存在,对于抑制再结晶长大,促进晶粒细化有着显著效果[4],从而获得更优异的性能。但Sc、Zr元素较为昂贵,工业化生产会增大成产成本。本文所用实验合金为Al-7.01Zn-1.39Mg-2.25Cu-0.07Zr-0.07Sc(质量分数,%),Sc、Zr元素含量仅为0.07%,经(470 ℃,1 h)+淬火+(120 ℃,24 h)处理后,挤压方向抗拉强度可达605 MPa,实际的研究意义和潜在的应用价值。

7xxx铝合金作为一种典型的热处理强化型合金,其强化效果受温度的影响很大。淬火过程中,适当的冷却速率可以保留更多的溶质原子和空位,是时效强化的前提[5]。在缓冷时会析出粗大的平衡相,同时消耗大量溶质原子使得后续时效过程中强化析出相减少[6],减弱时效强化的效果,从而表现出淬火敏感性。随着航空航天工业的迅速发展,单片组件因其可以减轻组件质量和较低的装配成本吸引了越来越多人的关注,因此对大截面的合金厚板和锻件有了迫切的需求[2]。为了防止这种材料中心位置和边缘位置的性能差异较大的现象发生,确保性能的均匀性,提高其使用寿命,对铝合金的淬火敏感性的研究也显得愈发的重要。研究铝合金的淬火敏感性的方法有许多,其中较为常见的有末端淬火实验法、TTT曲线[7]、TTP曲线[8]等。其中末端淬火方法(Jominy end-quench test, JEO)最初是被设计用来测试钢的淬透性[9],这种方法相对于其他几种方法来说更简便明了,大量的实验证明,在确定适当的淬火工艺时,有重要意义,是研究时效强化铝合金厚截面材料淬透性的有效途径[10]。例如刘胜胆等[11]通过JEQ实验研究了不同冷却速率对Al-Zn-Mg-Cu合金强度与腐蚀性能的影响;张新明等[12]通过JEQ实验研究了7085、7050、7055 3种铝合金厚板的淬透性,证明Zn、Mg质量比的提高会降低淬透性等。本文将研究含微量Sc(Zr)的高强韧Al-Zn-Mg-Cu合金的淬火敏感性,在末端淬火实验的基础上,分析淬火速率对其微观结构和力学性能的影响。旨在为高强高淬透性的新型铝合金材料及其制备工艺提供实验依据。

1 实验

1.1 实验材料的制备

实验材料采用高纯铝、纯镁、纯锌、Al-50Cu、Al-4Zr、Al-2Sc、Al-5Cr及Al-5Ti-1B中间合金为原料,经过750~780 ℃熔炼,在铸铁模里进行浇注得到直径为118 mm的圆铸锭;运用SPECTROLAB/MAXx测得合金成分为Al-7.01Zn-1.39Mg-2.25Cu-0.07Zr- 0.07Sc-0.06Cr-0.06Ti-0.08Fe-0.06Si(质量分数,%)。对所得铸锭进行(350 ℃,6 h)+(470 ℃,16 h)均匀化退火;将退火后的铸锭进行挤压变形加工处理,挤压比为20.3:1,得到直径为30 mm的圆棒;然后加工成直径为25 mm,长度为160 mm的棒材作为末端淬火试样,并在端淬试样距离端部5、15、30、50、100、150 mm处埋入K型压簧式热电偶。

1.2 试验方法

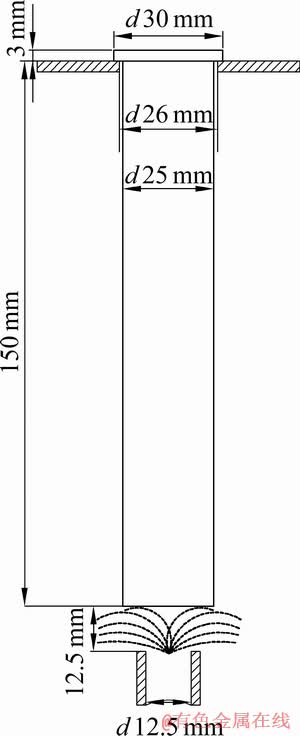

试样进行470 ℃、1 h的固溶处理,立即转移至CK-III-2端淬试验机淬火,示意图如图1所示。经淬火后试样进行(120 ℃、24 h)的时效处理,从近水端5 mm开始每隔8 mm测量其布氏硬度,取其平均值,所用仪器为MHBS-3000数显布氏硬度计,所加载荷为2450 N,加载时间为15 s;从近水端开始,每10 mm取一个圆片,根据GB/T 16865—2013标准,从圆片中切出3个尺寸为15 mm×6 mm×2 mm的工字型拉伸样,再在MTS-810上进行室温拉伸,拉伸速率为1 mm/min。取端淬样距离近水端0、35、95、126 mm位置制样,进行微观组织分析。其中物相分析在D/max 2500上进行,扫描范围为5°~85°,扫描速率1 (°)/min;粗大第二相的分布观察在FEI Sirion-200 扫描电镜背散模式下完成;透射分析在TECNAI G2 F20型透射电镜上进行,透射样品需要先预磨到80 μm左右,以70%CH3OH+30%HNO3(体积分数)为电解液进行双喷减薄,采用液氮冷却,温度控制在-20 ℃左右。

图1 末端淬火试验示意图

Fig. 1 Schematic illustration of Jominy end-quench (JEQ) test

2 结果与分析

2.1 端淬降温曲线

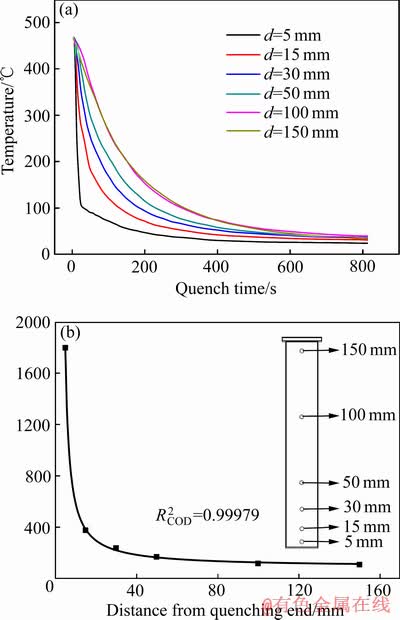

图2 离淬火端不同距离处的冷却曲线和平均冷却速率

Fig. 2 Cooling curves(a) and average cooling rates(b) at different positions from quenching end

端淬试样不同位置的冷却曲线如图2(a)所示。由图2(a)可知,在100 ℃以上温度降低较快,而100 ℃以下降温减缓。且随着与淬火端的距离增加,降温速率逐渐减小。计算合金在敏感温度区(250~370 ℃[13])的平均降温速率如图2(b)所示。在d为5、15、30、50、100、150 mm处,冷却速率分别为v为1800、379、240、172、120、111 ℃/min。由图2(b)可知,冷却速率在20 mm内急速下降,之后下降趋势变缓,到100 mm往后的位置冷却速度几乎不变。将曲线进行拟合,得到冷却速率v与距端部距离d的数学关系式如下所示:

(d≥5) (1)

(d≥5) (1)

2.2 淬透性曲线

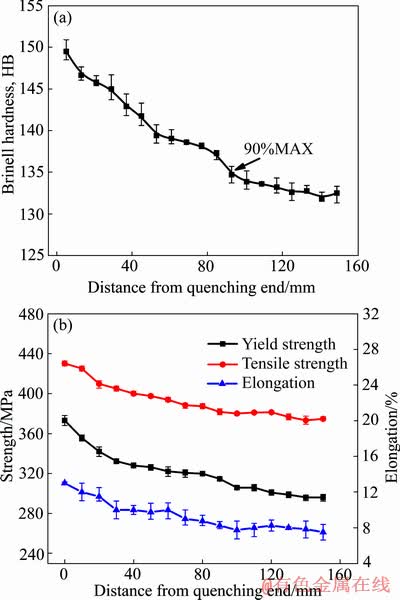

时效态试样不同位置处的硬度分布如图3(a)所示,由图3(a)可知,随着离淬火端的距离增加,冷却速率从大于1800 ℃/min减缓至111 ℃/min,所测得的硬度值呈下降趋势,从150 HB下降至133 HB。一般规定,硬度值下降至90%时的点为合金的淬透层深度[14],由图可得本文实验合金的淬透深度为93 mm,此处的硬度值约为135 HB。将d=93 mm代入式(1),可以得到此时的冷却速率v约为131.2 ℃/min。为了进一步评价冷却速率对机械性能的影响,对时效态试样不同位置处的拉伸力学性能进行了测量,结果如图 3(b)所示,由图3可知随着冷却速率的减小至111 ℃/min,其抗拉强度、屈服强度和伸长率都总体呈现下降趋势,分别从430 MPa、373 MPa和13%,下降至375 MPa、296 MPa和7.5%。

图3 时效态试样离淬火端不同距离处的布氏硬度和强度

Fig. 3 Brinell hardness(a) and strength(b) at different positions from quenching end after aging treatments

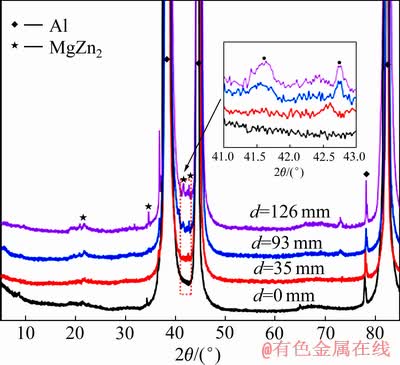

2.3 XRD分析

图4所示为端淬试样进行固溶-端淬-时效处理后取不同位置测得的XRD谱。由图4可知,合金在固溶时效后主要生成的第二相为MgZn2。当距离淬火端0 mm时,MgZn2的衍射峰为一个小鼓包,MgZn2含量较少,查阅文献[15]可知,此时合金中,MgZn2的主要存在形式为η′过渡相。当距离淬火端为35 mm时合金的MgZn2的衍射峰的峰强增强,随着与淬火端距离增长到93 mm和126 mm时,MgZn2的衍射峰更为明显,但二者的变化较小。这说明距离淬火端越远,合金析出的MgZn2平衡相的量会增加,但逐渐会达到最高值。

图4 时效态试样离淬火端不同距离处的XRD谱

Fig. 4 XRD patterns of as-aged samples at d of 0 mm, 35 mm, 75 mm, 126 mm of end-quenched bar

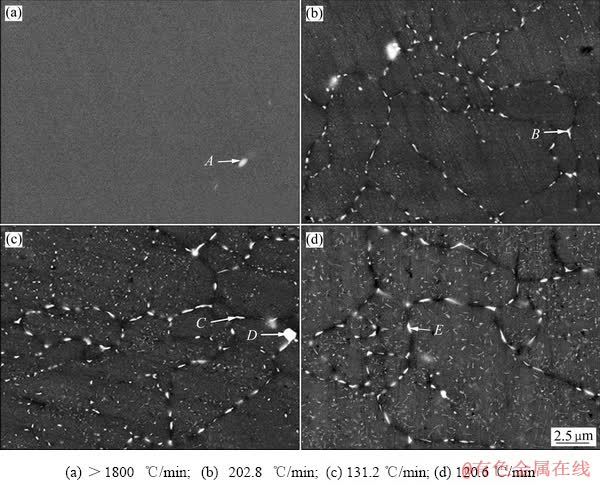

2.4 SEM分析

距端淬态试样端部不同距离位置处不同冷却速度的背散射电子图像如图5所示。并对其中A、B、C、D点进行EDS分析,其分析结果如表1所示。从图5(a)中可以看出,当冷却速率v大于1800 ℃/min时,除了小部分白色初生相外,没有明显粗大的析出相。当d=35 mm,v=202.8 ℃/min时,在晶界处出现与初生相相比较为细小的的第二相,如图5(b)所示。随着离淬火端距离变远冷却速率降低,当d=93 mm,v=131.2 ℃/min时,晶界处析出的第二相变大,同时,在晶内处也析出了尺寸较为细小的第二相,当d=126 mm,v=120.6 ℃/min时,晶粒内部析出的第二相也变得更明显,如图5(c)~(d)所示。由EDS分析可知,初生相主要为铁铜杂质相(A、D点);晶界第二相主要包含Al、Zn、Mg 3种元素(B、C、E点)所示。由此可见,晶界析出的为MgZn2相与XRD结果相对应。

图5 不同冷却速率端淬态样品SEM的背散射电子分析照片

Fig. 5 SEM images of solution specimen subjected to different cooling rates

表1 不同冷却速率样品时效后的EDS分析结果

Table 1 EDS analysis results of solution samples at different cooling rates

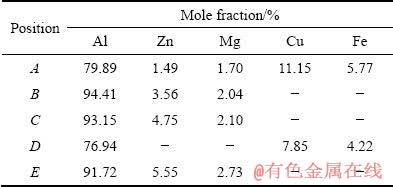

2.5 TEM分析

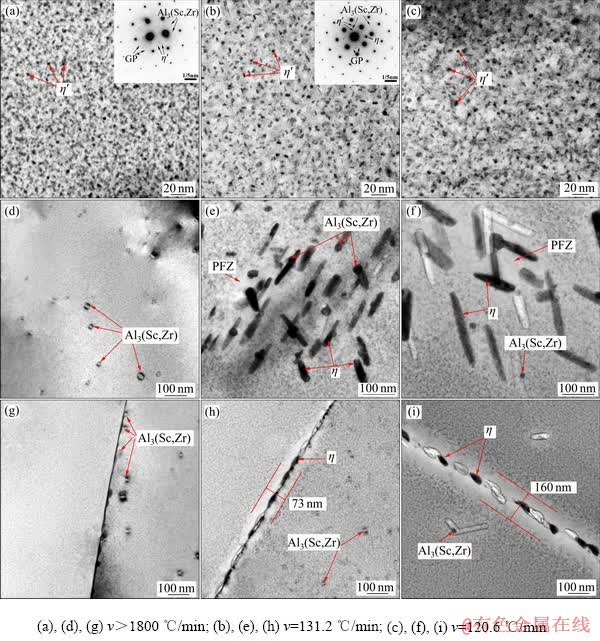

图6(a)~(c)所示为合金在不同冷却速率条件下样品端淬态的析出相图片。由图6(a)可知,当冷却速率高于1800 ℃/min时,除部分马蹄状Al3(Sc,Zr)粒子外,看不到第二相的存在,随着冷却速率降低,当v=131.2 ℃/min时,晶内可以看到明显的长条状平衡相如图6(b)所示,平均长度在98 nm左右。结合文献和图6(b)能谱分析可知,此长条状平衡相为η平衡相。当v下降至120.6 ℃/min时,晶内η相的长度增加,达到134 nm左右,同时二者可以观察到部分粒状的Al3(Sc,Zr)粒子成为了η平衡相的形核核心[4]。

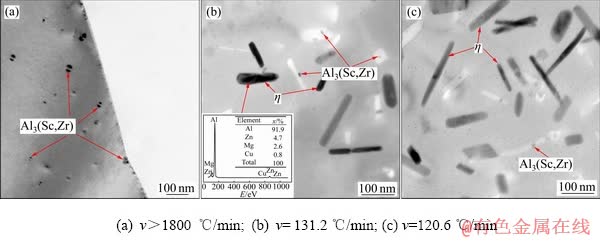

图7(a)~(f)所示为合金在不同冷却速率条件下样品时效后的析出相图片。由图7(a)~(c)可知,在不同冷却速度下,晶内都均匀分布着细小弥散的第二相,从7(a)的电子衍射花样[16]可以看出,7(a)中细小第二相主要是η′强化相,随着冷却速率的降低,晶内分布的η′强化相逐渐减少,GP区仍然存在。当冷却速率高于1800 ℃/min时,η相析出被抑制,几乎观察不到粗大的η相的存在;当v=131.2 ℃/min时,晶内同样可以看到平均长度约为93 nm的长条状平衡相,并从图7(b)中的电子衍射花样可以确认此长条状平衡像为η平衡相。当v下降至120.6 ℃/min时,晶内η平衡相的尺寸明显增加,达到150 nm左右,如图7(e)~(f)所示。

图7(g)~(i)所示为实验合金在不同冷却速率条件下样品时效后的晶界形貌。由图7(g)可知,v>1800 ℃/min时,晶界上的第二相细小且连续,没有明显PFZ的存在,周边存在部分马蹄状Al3(Sc,Zr)粒子,尺寸在30 nm左右。随着冷却速率的下降,晶界上第二相的长度增加,分布逐渐变得不连续,PFZ的宽度变大。当冷却速率下降至131.2 ℃/min时,PFZ宽度约为73 nm;当冷却速率为120.6 ℃/min时,PFZ宽度约为160 nm。

图6 不同冷却速率时样品端淬态的透射电子分析照片和能谱分析照片

Fig. 6 TEM images and EDS analysis of solution specimen subjected to different cooling rates

图7 实验合金不同冷却速率时样品时效后的TEM像

Fig. 7 TEM images of aged specimen subjected to different cooling rates

3 讨论

3.1 冷却速率对微观组织的影响

3.1.1 冷却速率对淬火析出的影响

淬火过程中第二相的析出主要是一个均匀形核和长大的过程[17],根据经典形核理论[18],其形核速率I都可以表示为

(2)

(2)

式中:c为常数; 为形核激活能;Q为溶质原子的扩散激活能;k为玻尔茨曼常数;T为绝对温度。

为形核激活能;Q为溶质原子的扩散激活能;k为玻尔茨曼常数;T为绝对温度。

在这个过程中形核激活能 (J)和临界形核半径Rk可表示[19]为

(J)和临界形核半径Rk可表示[19]为

(3)

(3)

(4)

(4)

式中: 为单位体积两相自由能之差;

为单位体积两相自由能之差; 为单位面积自由能;Tm为理论结晶温度;Hm为单位体积的相变潜热;

为单位面积自由能;Tm为理论结晶温度;Hm为单位体积的相变潜热; 为过冷度。

为过冷度。

由式(2)可知,当温度低于理论结晶温度Tm时,形核速率主要受合金形核功因子 和原子扩散的几率因子

和原子扩散的几率因子 两方面控制。联立式(3)和(4)可得,形核激活能

两方面控制。联立式(3)和(4)可得,形核激活能 和临界形核半径Rk受过冷度

和临界形核半径Rk受过冷度 控制,随着温度的增加,过冷度减小,Rk和

控制,随着温度的增加,过冷度减小,Rk和 的值会增大,

的值会增大, 的值会减少;同时溶质原子的扩散激活能Q随温度改变很小[20],当温度上升时,

的值会减少;同时溶质原子的扩散激活能Q随温度改变很小[20],当温度上升时, 也会变大,可得形核率和温度的关系如图8所示。当温度较小(<250 ℃)时,形核率主要受

也会变大,可得形核率和温度的关系如图8所示。当温度较小(<250 ℃)时,形核率主要受 控制,形核功小但同时原子扩散速率小,形核速率较低;温度较高(>370 ℃)时,形核率受

控制,形核功小但同时原子扩散速率小,形核速率较低;温度较高(>370 ℃)时,形核率受 控制,原子扩散速率大但所需临界形核半径增大,需要的能量起伏也会增加,稳定晶核难以形成,从而形核率随之减少。

控制,原子扩散速率大但所需临界形核半径增大,需要的能量起伏也会增加,稳定晶核难以形成,从而形核率随之减少。

图8 形核率与温度的关系[19]

Fig. 8 Relationship between nucleation rate and temperature[19]

如图6(a)所示,当d=0 mm,v>1800 ℃/min时,合金淬火过程中在中温阶段停留时间很短,难以形成稳定晶核,因此,难以出现粗大η相;当d=93 mm,v=131.2 ℃/min时,样品在中温阶段形成大量晶核,大于临界形核半径的晶核发生长大,得到平均长度约98 nm的粗大η相,如图6(b)。当d=93 mm,v=120.6 ℃/min,冷却速率继续减慢,增加原子扩散的时间,也就是增加了粒子长大和粗化的时间[10],使合金中第二相平均长度明显增加至134 nm,如图6(c)。同时在冷却过程中,过冷度增大,Rk减小,部分晶核开始长大,已经长大的粒子继续长大,导致合金中粒子大小不一。

由于晶界、第二相等非平衡缺陷提高系统的自由能G,使得这部分自由能变化 差变大,增加了MgZn2析出的驱动力,所以,在端淬过程中,会优先形核长大,如图5所示。值得注意的是,有文献[21]指出纳米级Al3(Sc,Zr)粒子和基体共格,不易成为MgZn2析出的核心,但在热处理过程中,位错与Al3(Sc,Zr)粒子发生作用,在粒子周围形成位错环,自由能提高,从而成为核心,如图6(b)~(c)所示。

差变大,增加了MgZn2析出的驱动力,所以,在端淬过程中,会优先形核长大,如图5所示。值得注意的是,有文献[21]指出纳米级Al3(Sc,Zr)粒子和基体共格,不易成为MgZn2析出的核心,但在热处理过程中,位错与Al3(Sc,Zr)粒子发生作用,在粒子周围形成位错环,自由能提高,从而成为核心,如图6(b)~(c)所示。

3.1.2 冷却速率对时效析出的影响

端淬实验后,将样品进行120 ℃、24 h的时效处理,在这过程中会发生脱溶,7xxx铝合金脱溶序列通常为[22]:过饱和固溶体(SSS)→GP区→η′相→η(MgZn2)相。在时效初期合金会析出GP区,GP区是预脱溶时期产生的原子偏聚,与Al基体完全共格,界面能较小容易析出。随着时效时间延长或时效温度的上升,GP区可以作为非均匀形核的位置长大,转化为与基体半共格的η′相,η′相为六方结构,其晶胞参数为a=b= 0.496 nm,c=1.402 nm[23]。时效时间的继续延长或更高的温度,析出了完全不共格的η(MgZn2)相,η相为六方晶格,其晶胞参数为a=b=0.523 nm,c=0.859 nm[24]。在时效过程中,合金脱溶的驱动力 和临界形核半径

和临界形核半径 可表示为[25]

可表示为[25]

(5)

(5)

(6)

(6)

式中:k为玻尔茨曼常数;T为绝对温度;vat为沉淀原子体积,可视为常数;ceq为基体平衡溶质浓度;c为基体当前溶质浓度; 为沉淀与基体间的界面能。所以,在等温时效过程中

为沉淀与基体间的界面能。所以,在等温时效过程中 和

和 的值只与基体当前溶质浓度c有关。瓦格纳和卡普曼提出[26],时效沉淀的析出同样取决于临界形核半径

的值只与基体当前溶质浓度c有关。瓦格纳和卡普曼提出[26],时效沉淀的析出同样取决于临界形核半径 的大小,大于

的大小,大于 的晶胚可以长大,反之将溶解。

的晶胚可以长大,反之将溶解。

当v>1800 ℃/min时,120 ℃、24 h时效处理后合金生成了大量η′相与部分GP区但不能析出η相。如图7(a)所示。随着冷却速率下降,由图4可知,合金析出的MgZn2相的量会增加,基体中的溶质浓度c减小,驱动力 的值减小,临界形核半径

的值减小,临界形核半径 增大,从而导致时效析出η′相逐渐减少,但GP区仍存在,如图7(a)~(c)所示;由图7(a)电子衍射花样可以看出,此时时效态样品中MgZn2的主要存在形式为η′强化相;在端淬过程中析出的粗大MgZn2会在时效过程中作为异质形核核心,吸收周边的溶质,继续长大同时出现PFZ区,如图7(d)~(f)所示,随着冷却速率减小,粒子长大,导致PFZ会变宽,其中晶界上的PFZ从30 nm宽化至160 nm,如图7(g)~(i)所示。

增大,从而导致时效析出η′相逐渐减少,但GP区仍存在,如图7(a)~(c)所示;由图7(a)电子衍射花样可以看出,此时时效态样品中MgZn2的主要存在形式为η′强化相;在端淬过程中析出的粗大MgZn2会在时效过程中作为异质形核核心,吸收周边的溶质,继续长大同时出现PFZ区,如图7(d)~(f)所示,随着冷却速率减小,粒子长大,导致PFZ会变宽,其中晶界上的PFZ从30 nm宽化至160 nm,如图7(g)~(i)所示。

3.2 冷却速率对力学性能的影响

本文实验合金是典型的热处理可强化型合金,经120 ℃、24 h的时效处理后合金发生了脱溶,生成第二相,如图7所示。其中GP区和η′相分别与基体共格和半共格界面,具有强化作用,一般认为后者效果更好[4]。所以,合金的强度和η′相的数量有着很大的关系。当粒子较小时,位错一般以切割粒子的方式移动,其临界切应力可表示为[27]

(7)

(7)

其中: 、m和n为常数;f为粒子的体积分数;r为粒子半径。所以,

、m和n为常数;f为粒子的体积分数;r为粒子半径。所以, 只与f和r有关。

只与f和r有关。

由图7(a)~(c)可知,冷却速率的下降,η′相的半径变化不大,粒子数量明显减少,相应的f减小,导致 减小,位错更易移动,所以合金的硬度和强度减少;

减小,位错更易移动,所以合金的硬度和强度减少;

冷却速率下降会导致η相的长大和粗化,如图7(d)~(f)。对于这些粗大相,当位错与其发生交互作用时,难以直接切过,而是在粒子前受阻弯曲,随着外加剪切力的增加使得位错持续以弯曲的方式运动,直至达成闭环,留下一个位错环,其余位错绕过粒子,恢复原状,继续向前滑移。位错线通过粒子所需的临界切应力 可表示为[25]

可表示为[25]

(8)

(8)

式中: 为常数;f为粒子的体积分数;r为粒子半径。随着半径r增大,所需临界切应力

为常数;f为粒子的体积分数;r为粒子半径。随着半径r增大,所需临界切应力 减小,位错更易移动,强化效应减弱。当粒子尺寸一定时,体积分数f越大,强化效果越好,按

减小,位错更易移动,强化效应减弱。当粒子尺寸一定时,体积分数f越大,强化效果越好,按 变化,但体积分数相对于粒子半径的影响较小[19]。所以这部分第二相粒子的长大和粗化使得合金硬度和强度下降。同时,粗大的第二相会增加与基体之间的界面,使之容易脱开产生裂纹源,从而使伸长率下降[28]。除此之外,在端淬过程中析出的粗大η相时效过程中吸收周围的溶质原子,使PFZ的宽度增加至160 nm,导致强化相分布不均匀,对合金的力学性能和伸长率也存在着负面影响。所以综上所述,随着冷却速率减小,合金的硬度、强度和伸长率减小,如图3所示。

变化,但体积分数相对于粒子半径的影响较小[19]。所以这部分第二相粒子的长大和粗化使得合金硬度和强度下降。同时,粗大的第二相会增加与基体之间的界面,使之容易脱开产生裂纹源,从而使伸长率下降[28]。除此之外,在端淬过程中析出的粗大η相时效过程中吸收周围的溶质原子,使PFZ的宽度增加至160 nm,导致强化相分布不均匀,对合金的力学性能和伸长率也存在着负面影响。所以综上所述,随着冷却速率减小,合金的硬度、强度和伸长率减小,如图3所示。

4 结论

1) 随着冷却速率v从大于1800 ℃/min下降至111 ℃/min,合金硬度从150 HB减小至133 HB,抗拉强度、屈服强度和伸长率分别从430 MPa、373 MPa和13%,下降至375 MPa、296 MPa和7.5%。同时,v大于131.2 ℃/min合金可以被淬透,淬透深度为93 mm。在研究的冷却速率范围内,试样的冷却速率v的离淬火端的距离d之间的关系式为 (d≥5)。

(d≥5)。

2) 随着冷却速率下降,当v>1800 ℃/min时,端淬态样品内无η粗大相的存在,随着冷却速率降低,当v=131.2 ℃/min时,晶内可以看到平均尺寸约为98 nm的长条状η平衡相;当v下降至120.6 ℃/min时,晶内η平衡相的尺寸增加,达到134 nm左右。

3) 随着冷却速率下降,经120 ℃、24 h时效处理后,合金中析出η′强化相减少,PFZ宽化至160 nm。

REFERENCES

[1] EDAGR A S, WILLIAMS J C. Progress in structural materials for aerospace systems1[J]. Acta Materialia, 2003, 51(19): 5775-5799.

[2] FERNANDO C, RUANO O A. Superplasticity of aerospace 7075 (Al-Zn-Mg-Cu) aluminium alloy obtained by severe plastic deformation[J]. Defect and Diffusion Forum, 2018, 385: 39-44.

[3] DENG Ying, YIN Zhi-min, ZHAO Kai, DUAN Jia-qi, HE Zhen-bo. Effects of Sc and Zr microalloying additions on the microstructure and mechanical properties of new Al-Zn-Mg alloys[J]. Journal of Alloys and Compounds, 2012, 530: 71-80.

[4] LIU Jing, YAO Pei, ZHAO Nai-qin, SHI Chun-sheng, LI Hui-jun, LI Xuan, XI De-sheng, YANG Shuo. Effect of minor Sc and Zr on recrystallization behavior and mechanical properties of novel Al-Zn-Mg-Cu alloys[J]. Journal of Alloys & Compounds, 2016, 657: 717-725.

[5] CHEN Jun-zhou, ZHEN Liang, YANG Shou-jie, SHAO Wen-zhu, DAI Sheng-dong. Investigation of precipitation behavior and related hardening in AA 7055 aluminum alloy[J]. Materials Science & Engineering A, 2009, 500(1): 34-42.

[6] ZHANG Xin-ming, LIU Wen-jun, LIU Sheng-dan, ZHOU Ming-zhe. Effect of processing parameters on quench sensitivity of an AA7050 sheet[J]. Materials Science and Engineering A, 2011, 528(3): 795-802.

[7] DONG Fei, YI You-ping, HUANG Shi-quan, ZHANG Yu-xun. TTT curves and quench sensitivity of 2A14 aluminum alloy[J]. Materials Review, 2017, 31(10): 77-81.

[8] 张新明, 刘文军, 刘胜胆, 袁玉宝, 邓运来. 7050铝合金的TTP曲线[J]. 中国有色金属学报, 2009, 19(5): 861-868.

ZHANG Xin-ming, LIU Wen-jun, LIU Sheng-dan, YUAN Yu-bao, DENG Yun-lai. TTP curve of aluminum alloy 7050[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(5): 861-868.

[9] MARROW J. Understanding the jominy end quench test[J]. Industrial Heating, 20001, 68: 57-60.

[10] JIANG Fu-qing, HUANG Ji-wu, TANG Lei, WANG Feng-xiang, XIAO Quan-feng, YIN Zhi-min. Effects of quench rate on mechanical properties and microstructures of high-strength 7046A aluminum alloy[J]. The Journal of metals, 2018, 71(5): 1722-1730.

[11] LI Dong-feng, YIN Bang-wen, LEI Yue, LIU Sheng-dan, DENG Yun-lai, ZHANG Xin-ming. Critical quenching rate for high hardness and good exfoliation corrosion resistance of Al-Zn-Mg-Cu alloy plate[J]. Metals and Materials International, 2016, 22(2): 222-228.

[12] ZHANG Xin-ming, ZHANG Duan-zheng, LIU Sheng-dan, LI Chen-bo, DENG Yun-lai. Hardenability of three 7000 series aluminum alloys based on Jominy end quench test[J]. Journal of Central South University, 2015, 46(2): 421-426.

[13] 肖 靖, 易幼平, 崔金栋, 黄始全. 7085铝合金的淬火敏感性[J]. 材料导报, 2018, 32(12): 1998-2002.

XIAO Jing, YI You-ping, CUI Jin-dong, HUANG Shi-quan. The quench sensitivity of 7085 aluminium alloy[J]. Materials review, 2018, 32(12): 1998-2002.

[14] TZENG Y C, WU C T, LEE S L. The effect of trace Sc on the quench sensitivity of Al-7Si-0.6Mg alloys[J]. Materials Letters, 2015, 161: 340-342.

[15] FAN Xi-gang, JIANG Da-ming, MENG Qing-chang, LAI Zhong-hong, ZHANG Xin-mei. Characterization of precipitation microstructure and properties of 7150 aluminium alloy[J]. Materials Science & Engineering A, 2006, 427(1): 130-135.

[16] BERG L K, GJONNES J, HANSEN V, LI X Z, KNUTSON W M, WATERLOO G, SCHRYVERS D, WALLENBERG L R. GP-zones in Al-Zn-Mg alloys and their role in artificial aging[J]. Acta Materialia, 2001, 49(17): 3443-3451.

[17] DUMONT D, DESCHAMPS A, BRECHET Y, SIGLI C, EHRSTROM J C. Characterisation of precipitation microstructures in aluminium alloys 7040 and 7050 and their relationship to mechanical behaviour[J]. Metal Science Journal, 2013, 20(5): 567-576

[18] BURKE J. The kinetics of phase transformation in metal[M]. London: Pergamon Press, 1965.

[19] 郑子樵. 材料科学基础[M]. 长沙: 中南大学出版社, 2005: 156-161.

ZHENG Zi-qiao. Fundamentals of materials science[M]. Changsha: Central South University Press, 2005: 156-161.

[20] NIE Bao-hua, LIU Pei-ying, ZHOU Tie-tao. Effect of compositions on the quenching sensitivity of 7050 and 7085 alloys[J]. Materials Science & Engineering A, 2016, 667: 106-114.

[21] DORWARD R C, BEERNTSEN D. Grain structure and quench-rate effects on strength and toughness of AA7050 Al-Zn-Mg-Cu-Zr alloy plate[J]. Metallurgical & Materials Transactions A, 1995, 26(9): 2481-2484.

[22] HANSEN V, STILLER K, WATERLOO G, GJONNES J, LI X Z. Structures and transformations during artificial aging of an industrial 7xxx-series Al-Zn-Mg-Zr alloy[J]. Materials Science Forum, 2002, 396/402: 815-820.

[23] KYERNELAND A, HANSEN V, THORKILDSEN G. Transformations and structures in the Al-Zn-Mg alloy system: A diffraction study using synchrotron radiation and electron precession[J]. Materials Science and Engineering A, 2011, 528(3): 880-887.

[24] GJONNES J, SIMENSEN C J. An electron microscope investigation of the microstructure in an aluminium-zinc- magnesium alloy[J]. Acta Metallurgica, 1970, 18(8): 881-890.

[25] DESCHAMPS A, BRECHET Y. Influence of predeformation and ageing of an Al-Zn-Mg alloy—Modeling of precipitation kinetics and yield stress[J]. Acta Materialia, 1998, 47(1): 293-305.

[26] WAGNER R, KAMPMANN R, VOORHEES P W. Homogeneous second-phase precipitation[M]. German: Wiley-VCH Press, 2011.

[27] PENG Xiao-yan, LI Yao, LIANG Xiao-peng, GUO Qi, XU Guo-fu, PENG Yong-yi. Precipitate behavior and mechanical properties of enhanced solution treated Al-Zn-Mg-Cu alloy during non-isothermal ageing[J]. Journal of Alloys & Compounds, 2017, 735: 964-974.

[28] SHI N, ARSENAULT R J. Plastic flow in SiC/A1 composites-strengthening and ductility[J]. Annual Review of Materials Science, 1994, 24(1): 321-357.

Effects of quench rate on mechanical properties and microstructures of high strength and toughness Al-Zn-Mg-Cu alloy with Sc(Zr) addition

LI Fang-fang1, XU Guo-fu1, 2, LI Yao1, HUANG Ji-wu1, 2, DENG Ying1, 2, YIN Zhi-min1, 2

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Metal Materials Science and Engineering, Ministry of Education, Central South University, Changsha 410083, China)

Abstract: The quench sensitivity of the Al-7.01Zn-1.39Mg-2.25Cu-0.07Zr-0.07Sc alloy were investigated by the Jominy end-quench(JEQ) test, X-ray diffraction (XRD), scanning electron microscopy (SEM) and transmission electron microscopy (TEM). The results show that, with the increase of the distance from the quenched end of the bar (d) and the decrease of average cooling rates from 1800 ℃/min to 111 ℃/min, the hardness falls to 133 HB from 150 HB and the tensile strength falls to 375 MPa from 430 MPa. When the critical average cooling rate is about 131.2 ℃/min and the d is 93 mm, 90% of the maximum hardness can be obtained. As the cooling rate reduces, the microstructure change as follows: the η equilibrium phase forms in the grain boundary and grained at different positions from the quenching end in the JEQ process in sequence, the number of η′ strengthening precipitates decreases after aging, the width of precipitate free zone near grain boundaries reaches up to 160 nm.

Key words: Al-Zn-Mg-Cu-Sc-Zr alloy; quench sensitivity; mechanical properties; microstructures

Foundation item: Project(51601229) supported by the National Natural Science Foundation of China; Project (2016B090931004) supported by the Project Science and Research Plan of Guangdong Province, China; Project(CSUZC201812) supported by the Open Sharing Fund of the Large-Scale Instruments and Equipments of Central South University, China

Received date: 2019-02-22; Accepted date: 2019-10-12

Corresponding author: HUANG Ji-wu; Tel: +86-13077388763; E-mail: huangjiwu_CSU@163.com

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51601229);广东省科学研究计划项目(2016B090931004);中南大学贵重精密仪器开放共享基金(CSUZC201812)

收稿日期:2019-02-22;修订日期:2019-10-12

通信作者:黄继武,教授,博士;电话:13077388763;E-mail:huangjiwu_CSU@163.com